ASTM F78-97(2002)

(Test Method)Standard Test Method for Calibration of Helium Leak Detectors by Use of Secondary Standards (Withdrawn 2008)

Standard Test Method for Calibration of Helium Leak Detectors by Use of Secondary Standards (Withdrawn 2008)

SCOPE

1.1 This test method covers a procedure for calibrating a mass spectrometer-type helium leak detector with a series of commercially available calibrated leaks without need for recourse to a primary standard.

1.2 Leak detector parameters determined by this test method include:

1.2.1 Minimum detectable signal, drift noise (8.5, with recorder; 8.6, without recorder),

1.2.2 Response time,

1.2.3 Minimum detectable leak rate, and

1.2.4 Sensitivity.

1.3 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

Formerly under the jurisdiction of Committee F01 on Electronics, this test method was withdrawn in June 2008 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F 78–97 (Reapproved 2002)

Standard Test Method for

Calibration of Helium Leak Detectors by Use of Secondary

Standards

ThisstandardisissuedunderthefixeddesignationF78;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.3 standard leak rate—in leak detection, the rate of flow

of atmospheric air of dewpoint less than−25°C through a leak

1.1 This test method covers a procedure for calibrating a

under standard conditions specified as follows: (1) the inlet

mass spectrometer-type helium leak detector with a series of

pressure shall be 1 standard atmosphere 65% (1016 5 kPa),

commercially available calibrated leaks without need for

(2) the outlet pressure shall be less than 1 kPa (0.01 atm), and

recourse to a primary standard.

(3) the temperature shall be 23 6 3°C.

1.2 Leakdetectorparametersdeterminedbythistestmethod

3.2 Definitions of Terms Specific to This Standard:

include:

3.2.1 response time—of a leak detector, for the purposes of

1.2.1 Minimum detectable signal, drift noise (8.5, with

this test method, a measure of the speed of response of the

recorder; 8.6, without recorder),

detector to an incoming helium sample.

1.2.2 Response time,

3.2.1.1 Discussion—In this test method the cleanup time

1.2.3 Minimum detectable leak rate, and

and response time are assumed to be equal.

1.2.4 Sensitivity.

3.2.2 sensitivity—of a leak detector, for the purposes of this

1.3 This standard does not purport to address the safety

test method, the ratio of the change in the output signal to the

concerns, if any, associated with its use. It is the responsibility

applied helium leak rate.

of the user of this standard to establish appropriate safety and

3.3 Other terms used in this test method are defined in

health practices and determine the applicability of regulatory

Definitions E425.

limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 Atleastthreecalibratedleaksaretestedonaheliumleak

2.1 ASTM Standards:

detector, and a correlation is obtained between the output

E1 Specification for ASTM Thermometers

indicationoftheleakdetectorandtheleakrateofthecalibrated

E425 Definitions of Terms Relating to Leak Testing

leaks. These readings are used to plot a calibration line from

3. Terminology which intermediate values, within specified limits, may be

read.

3.1 Definitions:

3.1.1 calibrated leak—in leak detection, a device that per-

5. Interferences

mits leakage through it at a specified rate, of a specific gas,

5.1 Certain materials, particularly organic compounds, will

under specific conditions, with the downstream side of the

entrap or hold helium tracer gas. Use of such materials in

deviceexposedtoapressuresufficientlylowtohavenegligible

connections between the calibrated leak and the leak should be

effect on the leak rate.

minimized to avoid erroneous results. (If the net output

3.1.2 minimum detectable signal—in leak detection, the

readings from any calibrated leak consistently lie outside the

smallest unambiguous output signal that can be derived from a

established limits, the leak should be returned to the supplier

given particular leak detector. Units are detector scale divi-

for a recalibration check.)

sions.

5.2 The background reading, B, should be at most one

3.1.2.1 Discussion—The minimum detectable signal is de-

quarter of the output reading, A. If the value of B approaches

terminedbythenoisepresentin,anddriftof,theoutputsignal.

thatofA,theaccuracyofthedeterminationofNwillsuffer(see

9.3.1).

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

6. Apparatus

Materials.

Current edition approved Dec. 10, 2002. Published May 2003. Originally

6.1 Calibrated Leaks—At least three commercial devices

approved in 1967. Last previous edition approved in 1997 as F78 – 97.

incorporating leaks, one having a leak rate of approximately

Annual Book of ASTM Standards, Vol 14.03.

−9 3 −1 −10 3 −1

3 10 atm·cm ·s (10 Pa·m ·s ), a second having a leak

Discontinued. See 1991 Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 78–97 (2002)

−8 −7 3 −1 −9

value in the nominal range from 10 to 10 atm·cm ·s (10

−8 3 −1

to 10 Pa·m ·s ), and the third having a leak rate of

−6 3 −1 −7 3 −1

approximately 10 atm·cm ·s (10 Pa·m ·s ).

6.1.1 The calibrated leaks shall be obtained from at least

two independent suppliers.

6.1.2 The calibrated leaks shall have been calibrated with

helium gas at a pressure of approximately 1 standard atmo-

sphere 65% (101 6 5 kPa).

6.1.3 Thefollowinginformationshallbeprovidedwitheach

calibrated leak:

3 −1 3 −1

6.1.3.1 Calibrated leak rate, atm·cm ·s (or Pa·m ·s ),

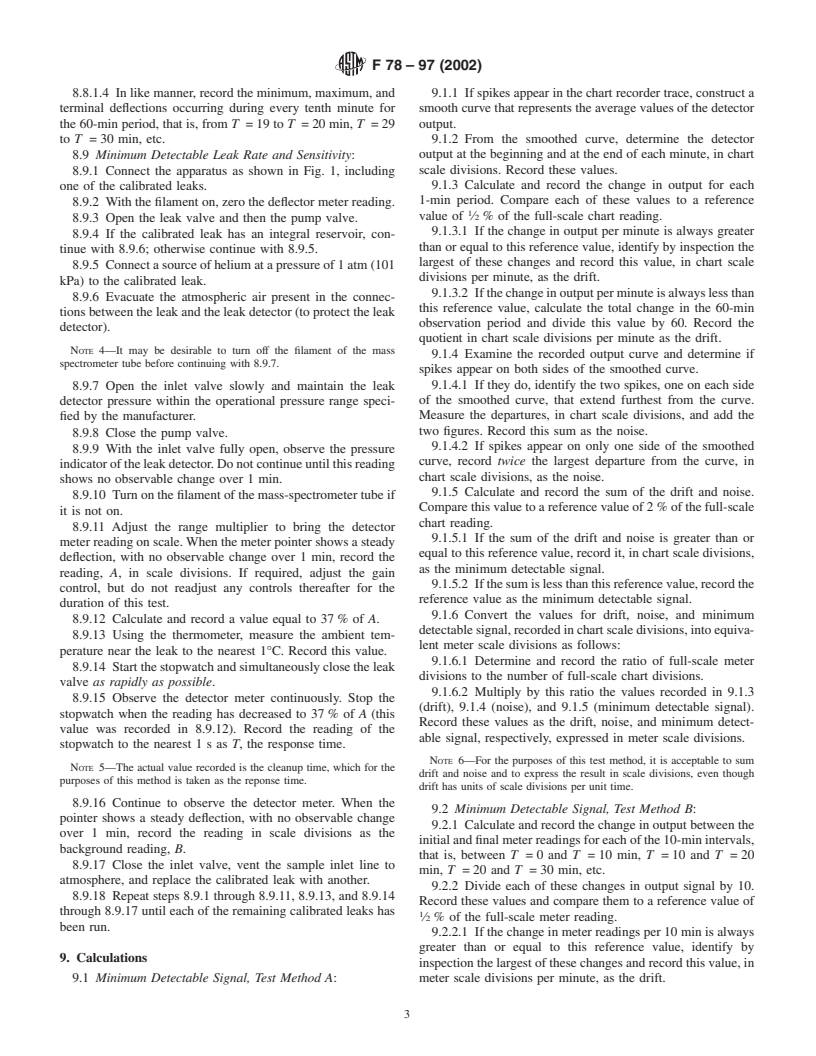

FIG. 1 Schematic Diagram of Apparatus for the Calibration of the

Helium Mass Spectrometer Leak Detector

6.1.3.2 Date of calibration,

6.1.3.3 Temperature of calibration, °C,

3 −1 −1

6.1.3.4 Temperature coefficient, atm·cm ·s ·°C (or

7. Material

3 −1 −1

Pa·m ·s ·°C ), and

7.1 Helium Gas— for use with calibrated leaks not having

6.1.3.5 Ifareservoirisanintegralpartofthecalibratedleak,

an integral reservoir. The helium gas shall have a purity of at

the internal pressure in the reservoir, atm (or Pa) and an aging

least 99.9% and a supply pressure of nominally 1 atm (101

correction.

kPa).

NOTE 1—It is preferable that five, rather than three, calibrated leaks be

used for initial calibrations of helium leak detectors by this method. At

8. Procedure

least two leaks shall be obtained from each of two independent suppliers

8.1 Connecttheheliumleakdetectortobetestedtoasource

when more than three leaks are used.

ofelectricpowerconforminginvoltage,frequency,anddegree

NOTE 2—Although the data on which this specification has been based

of regulation to the manufacturer’s specifications.

were obtained largely from permeation-type leaks, the calibrated leaks

may be of various types such as capillary, pinched tubing, tapered plug, 8.2 Turnonthedetectorforthewarm-upperiodspecifiedby

etc. However, it is recommended that, with all types of leaks, the

the manufacturer.

manufacturer’s recommendations be followed to avoid erroneous test

8.3 Adjust the detector in accordance with the manufactur-

results.

er’s instructions for maximum sensitivity and for maximum

output for a given helium input.

6.2 Thermometer, accurate to 61°C or better in the range

8.4 Close the inlet valve of the detector.

from 18 to 28°C inclusive. A thermometer conforming to

8.5 If the electron-producing filament is not on, turn it on

Thermometer 63C as prescribed in Specification E1 is suit-

andadjustthedetectorzeropositioncontroltoobtainanoutput

able.

signal of at least 10% of the most sensitive scale.

6.3 Chart Recorder, for determining Minimum Detectable

8.6 If the detector has no recorder output or if a suitable

Leak, Method A; an instrument suitable for recording the

chart recorder is not available, continue with 8.8; otherwise,

output of the leak detector under test as a function of time.

continue with 8.7.

6.3.1 The chart recorder shall incorporate a gain control to

8.7 Minimum Detectable Signal, Test Method A, with Re-

permitthedeflectionoftherecorderstylustobeadjustedtofull

corder:

scalewhentheleakdetectormeterisreadingfullscalewiththe

8.7.1 Connect the detector output to the recorder.

leak detector at its most sensitive detection setting.

8.7.2 Record the detector output for 60 min or until the

6.3.2 The time constant of the chart recorder shall not be

output indication has reached full scale. Do not readjust any

greater than that of the leak-detector output meter.

controls during the recording period.

6.3.3 The chart recorder shall be capable of continuous

8.8 Minimum Detectable Signal, Test Method B, without

recording for at least 1 h.

Recorder:

6.4 Stopwatch, calibrated to read in tenths of a second to 60

8.8.1 Observe the detector meter and record its indications

min over an interval of at least 1 h.

as follows. Do not readjust the controls for the 60-min period

6.5 Leak Auxiliary Manifold—If not incorporated in the

of this test.

leak detector, evacuable means for connecting the calibrated

8.8.1.1 Record the pointer deflection, in scale divisions, at

leak to the leak detector, incorporating a roughing pump, leak

time T =0 min.

valve, and pump valve (see Fig. 1).

8.8.1.2 Record the minimum and maximum pointer deflec-

6.5.1 The roughing pump shall have sufficient pumping

tions occurring in the interval from time T =0to T =1 min.

capacity to evacuate the leak auxiliary manifold to an absolute

8.8.1.3 Record the minimum and maximum pointer deflec-

pressure of less than 50 millitorr (or 7 Pa).

tions occurring in the interval from time T =9to T =10 min;

6.5.2 The leak valve shall not act as a source of helium.

record the deflection occurring at T =10 min.

6.5.3 Valves and connections shall contain a minimum of

rubber or other polymeric surfaces that can serve as virtual

leaks.

Commercially available compressed helium of the specified minimum purity,

NOTE 3—It is preferable that the only exposed polymeric surfaces be

supplied in suitable cylinders with appropriate regulators, has been found suitable

those of O-rings. for this test method.

F 78–97 (2002)

8.8.1.4 In like manner, record the minimum, maximum, and 9.1.1 If spikes appear in the chart recorder trace, construct a

terminal deflections occurring during every tenth minute for smooth curve that represents the average values of the detector

the 60-min period, that is, from T =19to T =20 min, T =29 output.

to T =30 min, etc. 9.1.2 From the smoothed curve, determine the detector

output at the beginning and at the end of each minute, in chart

8.9 Minimum Detectable Leak Rate and Sensitivity:

scale divisions. Record these values.

8.9.1 Connect the apparatus as shown in Fig. 1, including

9.1.3 Calculate and record the change in output for each

one of the calibrated leaks.

1-min period. Compare each of these values to a reference

8.9.2 With the filament on, zero the deflector meter reading.

value of ⁄2% of the full-scale chart reading.

8.9.3 Open the leak valve and then the pump valve.

9.1.3.1 If the change in output per minute is always greater

8.9.4 If the calibrated leak has an integral reservoir, con-

than or equal to this reference value, identify by inspection the

tinue with 8.9.6; otherwise continue with 8.9.5.

largest of these changes and record this value, in chart scale

8.9.5 Connectasourceofheliumatapressureof1atm(101

divisions per minute, as the drift.

kPa) to the calibrated leak.

9.1.3.2 Ifthechangeinoutputperminuteisalwayslessthan

8.9.6 Evacuate the atmospheric air present in the connec-

this reference value, calculate the total change in the 60-min

tionsbetweentheleakandtheleakdetector(toprotecttheleak

observation period and divide this value by 60. Record the

detector).

quotient in chart scale divisions per minute as the drift.

NOTE 4—It may be desirable to turn off the filament of the mass

9.1.4 Examine the recorded output curve and determine if

spectrometer tube before continuing with 8.9.7.

spikes appear on both sides of the smoothed curve.

9.1.4.1 If they do, identify the two spikes, one on each side

8.9.7 Open the inlet valve slowly and maintain the leak

of the smoothed curve, that extend furthest from the curve.

detector pressure within the operational pressure range speci-

Measure the departures, in chart scale divisions, and add the

fied by the manufacturer.

two figures. Record this sum as the noise.

8.9.8 Close the pump valve.

9.1.4.2 If spikes appear on only one side of the smoothed

8.9.9 With the inlet valve fully open, observe the pressure

curve, record twice the largest departure from the curve, in

indicatoroftheleakdetector.Donotcontinueuntilthisreading

chart scale divisions, as the noise.

shows no observable change over 1 min.

9.1.5 Calculate and record the sum of the drift and noise.

8.9.10 Turnonthefilamentofthemass-spectrometertubeif

Comparethisvaluetoareferencevalueof2%ofthefull-scale

it is not on.

chart reading.

8.9.11 Adjust the range multiplier to bring the detector

9.1.5.1 If the sum of the drift and noise is greater than or

meterreadingonscale.Whenthemeterpointershowsasteady

equal to this reference value, record it, in chart scale divisions,

deflection, with no observable change over 1 min, record the

as the minimum detectable signal.

reading, A, in scale divisions. If required, adjust the gain

9.1.5.2 Ifthesumislessthanthisreferencevalue,recordthe

control, but do not readjust any controls thereafter for the

reference value as the minimum detectable signal.

duration of this test.

9.1.6 Convert the values for drift, noise, and minimum

8.9.12 Calculate and record a value equal to 37% of A.

detectablesignal,recordedinchartscaledivisions,intoequiva-

8.9.13 Using the thermometer, measure the ambient tem-

lent meter scale divisions as follows:

perature near the leak to the nearest 1°C. Record this value.

9.1.6.1 Determine and record the ratio of full-scale meter

8.9.14 Startthestopwatchandsimultaneouslyclosetheleak

divisions to the number of full-scale chart divisions.

valve as rapidly as possible.

9.1.6.2 Multiply by this ratio the values recorded in 9.1.3

8.9.15 Observe the detector meter continuously. Stop the

(drift), 9.1.4 (noise), and 9.1.5 (minimum detectable signal).

stopwatch when the reading has decreased to 37% of A (this

Record these values as the drift, noise, and minimum detect-

value was recorded in 8.9.12). Record the reading of the

able signal, respectively, expressed in meter scale divisions.

stopwatch to the nearest1sas T, the response time.

NOTE 6—For the purposes of this test method, it is acceptable to sum

NOTE 5—The actual value recorded is the cleanup time, which for the

drift and noise and to express the result in scale divisions, even though

purposes of this method is taken as the reponse time.

drift has units of scale divisions per unit time.

8.9.16 Continue to observe the detector meter. When the

9.2 Minimum Detectable Signal, Test Method B:

pointer shows a steady deflection, with no observable change

9.2.1 Calculate and record the change in output between the

over 1 min, record the reading in scale divisions as the

initialandfinalmeterreadingsforeachofthe10-minintervals,

background reading, B.

that is, between T =0 and T =10 min, T =10 and T =20

8.9.17 Close the inlet valve, vent the sample inlet line to

min, T =20 and T =30 min, etc.

atmosphere, and replace the calibrated le

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.