ASTM D3612-02(2009)

(Test Method)Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography

Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography

SIGNIFICANCE AND USE

Oil and oil-immersed electrical insulation materials may decompose under the influence of thermal and electrical stresses, and in doing so, generate gaseous decomposition products of varying composition which dissolve in the oil. The nature and amount of the individual component gases that may be recovered and analyzed may be indicative of the type and degree of the abnormality responsible for the gas generation. The rate of gas generation and changes in concentration of specific gases over time are also used to evaluate the condition of the electric apparatus.

Note 1—Guidelines for the interpretation of gas-in-oil data are given in IEEE C57.104.

SCOPE

1.1 This test method covers three procedures for extraction and measurement of gases dissolved in electrical insulating oil having a viscosity of 20 cSt (100 SUS) or less at 40°C (104°F), and the identification and determination of the individual component gases extracted. Other methods have been used to perform this analysis.

1.2 The individual component gases that may be identified and determined include:

Hydrogen—H2 Oxygen—O2 Nitrogen—N2 Carbon monoxide—CO Carbon dioxide—CO2 Methane—CH4 Ethane—C2H6 Ethylene—C2H4 Acetylene—C2H2 Propane—C3H8 Propylene—C3H6

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements see 6.1.8, 30.2.2 and 30.3.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3612 − 02 (Reapproved 2009)

Standard Test Method for

Analysis of Gases Dissolved in Electrical Insulating Oil by

Gas Chromatography

This standard is issued under the fixed designation D3612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2779Test Method for Estimation of Solubility of Gases in

Petroleum Liquids

1.1 This test method covers three procedures for extraction

D2780TestMethodforSolubilityofFixedGasesinLiquids

and measurement of gases dissolved in electrical insulating oil

(Withdrawn 2010)

havingaviscosityof20cSt(100SUS)orlessat40°C(104°F),

D3613Practice for Sampling Insulating Liquids for Gas

and the identification and determination of the individual

AnalysisandDeterminationofWaterContent(Withdrawn

component gases extracted. Other methods have been used to

2007)

perform this analysis.

D4051PracticeforPreparationofLow-PressureGasBlends

1.2 The individual component gases that may be identified

E260Practice for Packed Column Gas Chromatography

and determined include:

2.2 IEEE Standard:

Hydrogen—H

2 C57.104 GuidefortheInterpretationofGasesGeneratedin

Oxygen—O 4

Oil-Immersed Transformers

Nitrogen—N

2.3 IEC Standard:

Carbon monoxide—CO

Carbon dioxide—CO

2 PublicationNo.567GuidefortheSamplingofGasesandof

Methane—CH

Oil from Oil-Filled Electrical Equipment and for the

Ethane—C H

2 6

Analysis of Free and Dissolved Gases

Ethylene—C H

2 4

Acetylene—C H

2 2

Propane—C H

3. Terminology

3 8

Propylene—C H

3 6

3.1 Definitions of Terms Specific to This Standard:

1.3 This standard does not purport to address all of the

3.1.1 gas content of oil by volume—in Method A, the total

safety concerns, if any, associated with its use. It is the

volume of gases, corrected to 760 torr (101.325 kPa) and 0°C,

responsibility of the user of this standard to establish appro-

contained in a given volume of oil, expressed as a percentage.

priate safety and health practices and determine the applica-

In Methods B and C, the sum of the individual gas concentra-

bility of regulatory limitations prior to use. For specific

tionscorrectedto760torr(101.325kPa)and0°C,expressedin

warning statements see 6.1.8, 30.2.2 and 30.3.1.

percent or parts per million.

3.1.2 headspace—a volume of gas phase in contact with a

2. Referenced Documents

volumeofoilinaclosedvessel.Thevesselisaheadspacevial

2.1 ASTM Standards:

of 20-mL nominal capacity.

D2140Practice for Calculating Carbon-Type Composition

3.1.2.1 Discussion—Other vessel volumes may also be

of Insulating Oils of Petroleum Origin

used, but the analytical performance may be somewhat differ-

D2300Test Method for Gassing of Electrical Insulating

ent than that specified in Method C.

Liquids Under Electrical Stress and Ionization (Modified

3.1.3 parts per million (ppm) by volume of (specific gas) in

Pirelli Method)

oil—thevolumeofthatgascorrectedto760torr(101.325kPa)

and 0°C, contained in 10 volume of oil.

3.1.4 sparging, v—agitatingtheliquidsampleusingagasto

This test method is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gasesand is the direct responsibility of Subcom-

strip other gases free.

mittee D27.03 on Analytical Tests.

Current edition approved May 15, 2009. Published June 2009. Originally

approved in 1977. Last previous edition approved in 2002 as D3612–02 (2009). The last approved version of this historical standard is referenced on

DOI: 10.1520/D3612-02R09. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from IEEE, 345 E. 47th St., New York, NY 10017.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Electrotechnical Commission (IEC), 3 rue de

Standards volume information, refer to the standard’s Document Summary page on Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3612 − 02 (2009)

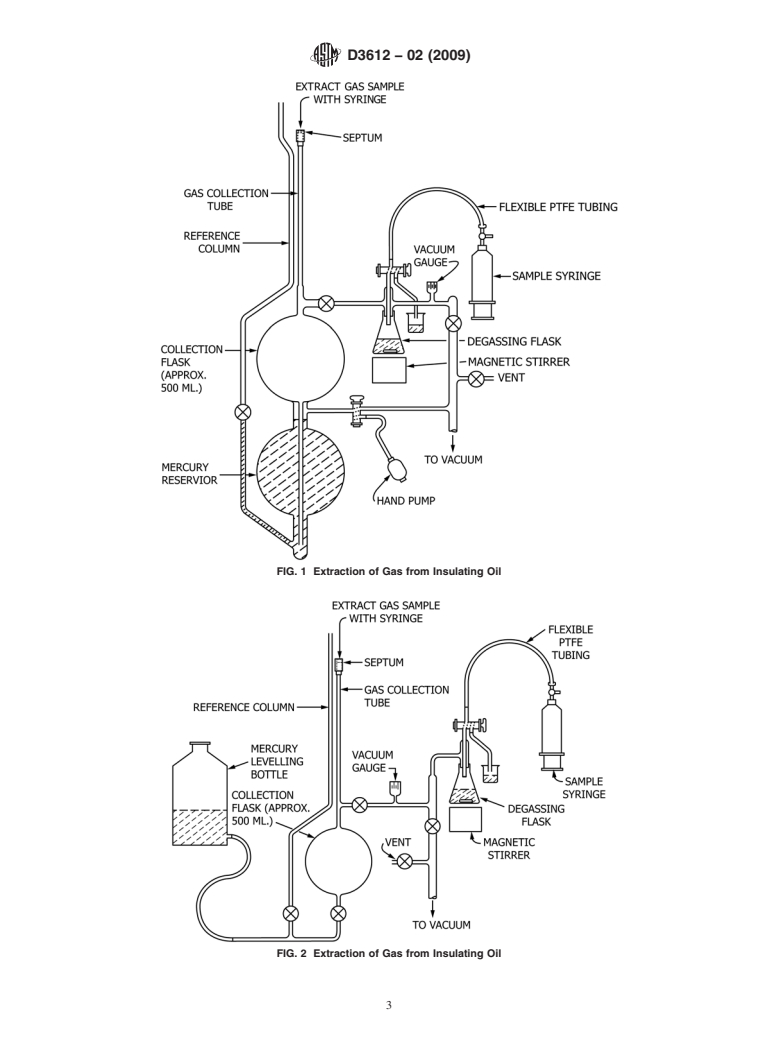

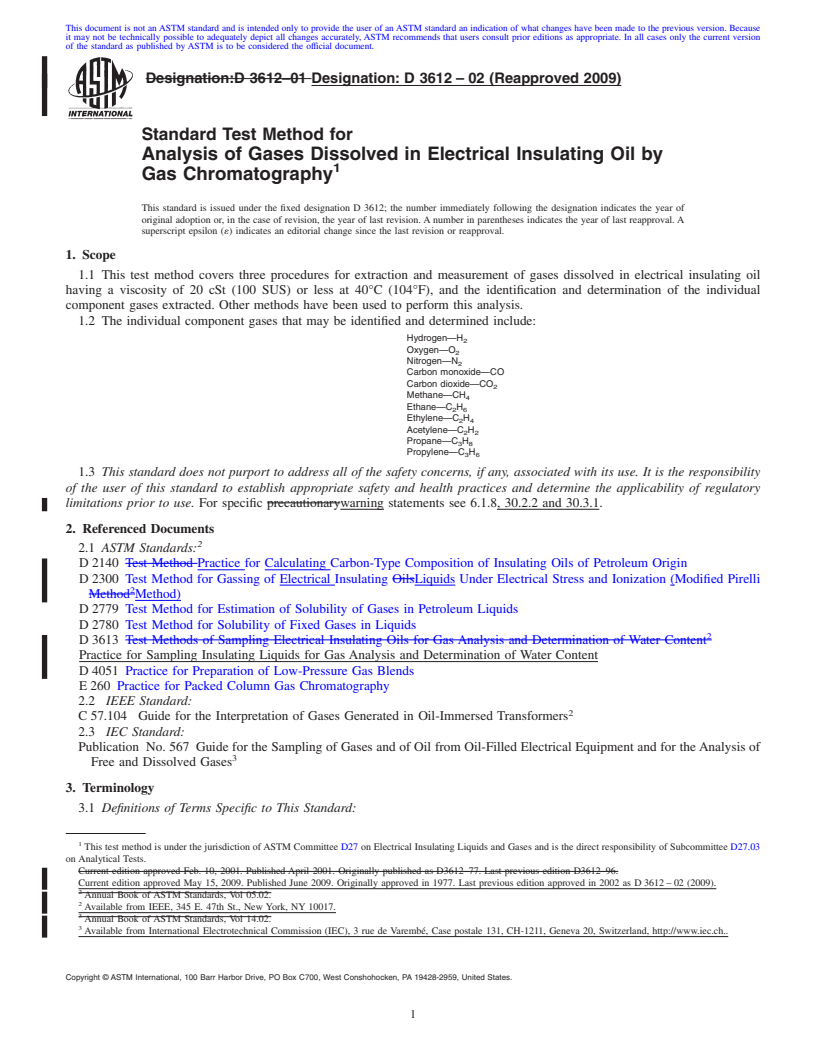

3.1.5 volume concentration of (specific gas) in the gas 6. Apparatus

sample—the volume of the specific gas contained in a given 6

6.1 Apparatus of the type shown in Fig. 1 or Fig. 2 is

volumeofthegassampleatthesametemperatureandpressure

suitable for use with up to 50-mL samples of oil and consists

(as the measured total volume), expressed either as a percent-

of the following components:

age or in parts per million.

NOTE2—Thissamplesizehasbeenfoundtobesufficientformostoils.

However, oil that has had only limited exposure to air may contain much

4. Summary of Test Method

smalleramountsofnitrogenandoxygen.Fortheseoilsitmaybedesirable

to increase the size of the sample and the extraction apparatus.

4.1 MethodA—Dissolvedgasesareextractedfromasample

NOTE 3—Alternative apparatus designs including the use of a Toepler

of oil by introduction of the oil sample into a pre-evacuated

pump have also been found successful.

known volume. The evolved gases are compressed to atmo-

6.1.1 Polytetrafluoroethylene (PTFE) Tubing, narrow-bore,

spheric pressure and the total volume measured.

terminatedwithaLuer-Lockfittedglasssyringe,andleadingto

a solid plug, three-way, high-vacuum stopcock.

4.2 Method B—Dissolvedgasesareextractedfromasample

6.1.2 Degassing Flask, with a glass inlet tube, of sufficient

of oil by sparging the oil with the carrier gas on a stripper

volume to contain up to 50 mL of oil below the inlet tube,

column containing a high surface area bead.

capable of being evacuated through a vacuum pump, contain-

4.3 Method C—MethodCconsistsofbringinganoilsample

ing a PTFE-coated magnetic spin bar, and mounted on a

in contact with a gas phase (headspace) in a closed vessel

magnetic stirrer.

purgedwithargon.Thedissolvedgasescontainedintheoilare

6.1.3 Means of Measuring Absolute Pressure within the

then equilibrated in the two phases in contact under controlled

apparatus.

conditions (in accordance with Henry’s law). At equilibrium,

6.1.4 Vacuum Pumping System, capable of evacuating the

−3

the headspace is overpressurized with argon and then the

glasswaretoanabsolutepressureof1×10 torr(130mPa)or

content of a loop is filled by the depressurization of the

lower.

headspaceagainsttheambientatmosphericpressure.Thegases

6.1.5 Vacuum Glassware, sufficiently large compared to the

contained in the loop are then introduced into a gas chromato-

volume of the oil sample, so that virtually complete degassing

graph.

isobtainedandthatthevolumetriccollectionratioisaslargeas

possible. A 500-mL gas collecting flask has been found

4.4 Theremaybesomedifferencesinthelimitsofdetection

suitable.

and precision and bias between Methods A, B, and C for

6.1.6 High-Vacuum Valves or Stopcocks, employing the

various gases.

minimum necessary amounts of high-vacuum stopcock grease

4.5 Aportionoftheextractedgases(MethodA)orallofthe

are used throughout the apparatus.

extractedgases(MethodB)oraportionoftheheadspacegases

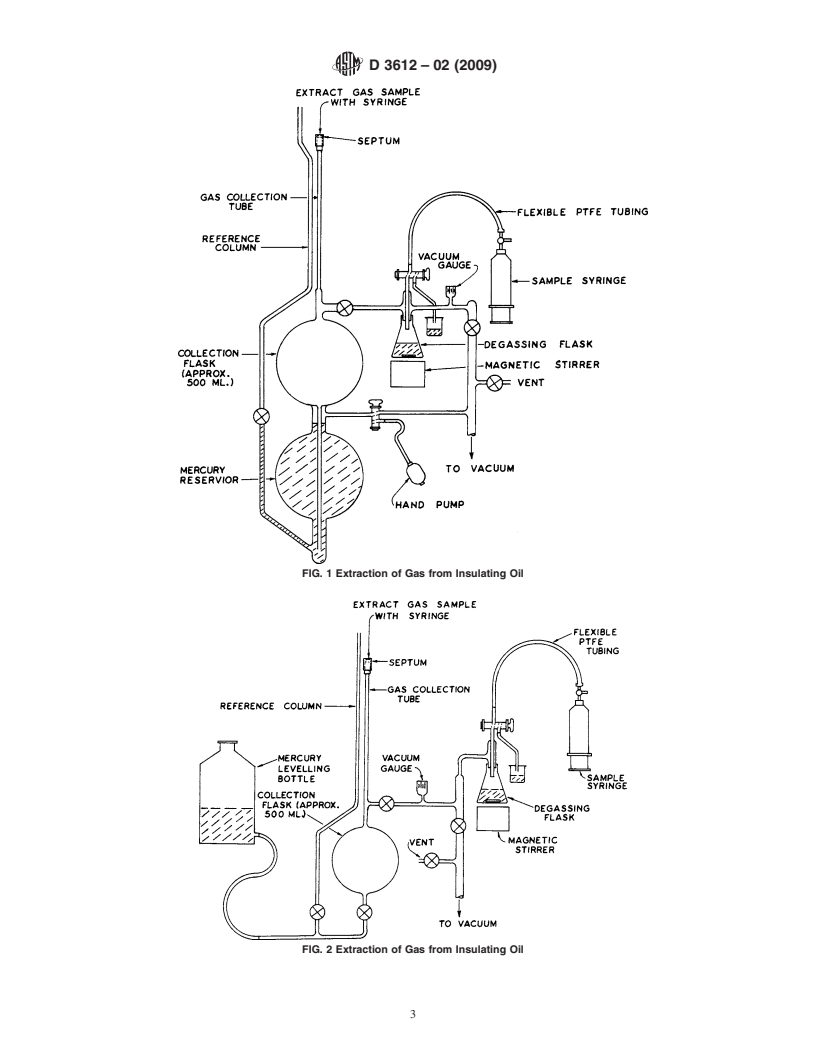

6.1.7 Gas Collection Tube, calibrated in 0.01-mLdivisions,

(Method C) is introduced into a gas chromatograph. Calibra-

capable of containing up to 5 mL of gas, terminated with a

tioncurvesareusedinMethodCtoestablishtheconcentration

silicone rubber retaining septum. A suitable arrangement is

of each species. The composition of the sample is calculated shown in Fig. 3.

from its chromatogram by comparing the area of the peak of

6.1.8 Reservoir of Mercury, sufficient to fill the collection

each component with the area of the peak of the same flask and collection tube. (Warning—Mercury vapor is ex-

component on a reference chromatogram made on a standard

tremely toxic. Appropriate precautions should be taken.)

mixture of known composition.

7. Sampling

5. Significance and Use 7.1 Obtain samples in accordance with the procedure de-

scribed in Test Methods D3613 for sampling with syringetype

5.1 Oilandoil-immersedelectricalinsulationmaterialsmay

devices or rigid metal cylinders. The use of rigid metal

decompose under the influence of thermal and electrical

cylinders is not recommended for use with Method B.

stresses, and in doing so, generate gaseous decomposition

7.2 The procurement of representative samples without loss

products of varying composition which dissolve in the oil.The

ofdissolvedgasesorexposuretoairisveryimportant.Itisalso

natureandamountoftheindividualcomponentgasesthatmay

important that the quantity and composition of dissolved gases

be recovered and analyzed may be indicative of the type and

remain unchanged during transport to the laboratory. Avoid

degree of the abnormality responsible for the gas generation.

prolonged exposure to light by immediately placing drawn

The rate of gas generation and changes in concentration of

specific gases over time are also used to evaluate the condition

of the electric apparatus.

Ace Glass and Lurex Glass manufacture glass extractors. For Ace Glass, the

glass apparatus conforming to Fig. 1 is Part E-13099-99-99 and Fig. 2 is Part

NOTE1—Guidelinesfortheinterpretationofgas-in-oildataaregivenin

E-1400-99. Available from P.O. Box 688, 1430 Northwest Blvd., Vineland, NJ

IEEE C57.104. 08360 or Lurex Glass, 1298 Northwest Blvd., Vineland, NJ 08360.

D3612 − 02 (2009)

FIG. 1 Extraction of Gas from Insulating Oil

FIG. 2 Extraction of Gas from Insulating Oil

D3612 − 02 (2009)

V = totalinternalvolumeofextractionapparatusbeforeoil

T

sample is introduced, and

K = Ostwald solubility coefficient of component i.

i

9.4 Determine the Ostwald solubility coefficients of fixed

gases in accordance with Test Method D2780.

9.5 Ostwald solubility coefficients that have been deter-

mined for a number of gases in one specific electrical insulat-

ing oil at 25°C are shown as follows.Values for gases in other

oils may be estimated by reference to Test Method D2779.

Ostwald Solubility (Note 5)

Component Gas

Coefficient, K , 25°C, 760 mm Hg

i

Hydrogen 0.0558

Nitrogen 0.0968

Carbon monoxide 0.133

Oxygen 0.179

Methane 0.438

Carbon dioxide 1.17

Acetylene 1.22

Ethylene 1.76

FIG. 3 Retaining Rubber Septum for Gas Collection Tube

Ethane 2.59

Propane 11.0

NOTE 5—The Ostwald coefficient values shown in this table are correct

onlyforthespecificmineraloilhavingadensityat15.5°Cof0.855g/cm

samples into light-proof containers and retaining them there

usedintheoriginaldetermination.Ostwaldcoefficientsformineraloilsof

until the start of testing.

different density may be calculated as follows:

7.2.1 To maintain the integrity of the sample, keep the time

0.980 2density

between sampling and testing as short as possible. Evaluate

K ~corrected! 5 K (3)

i i

0.130

containers for maximum storage time. Samples have been

where, density =density of the oil of interest, g/cm at 15.5°C (60°F).

stored in syringes and metal cylinders for four weeks with no

This equation is derived from the equation in Test Method D2779. Note

appreciable change in gas content.

especially that all of the Ostwald coefficients are changed by the same

factor, meaning that though the absolute solubilities of each of the gases

NOTE 4—Additional sampling procedures using flexible metal cans are

will change if a different oil is used, the ratio of the solubility of one gas

currently being studied for use with Method A.

to another gas will remain constant.

METHOD A—VACUUM EXTRACTION

9.6 A procedure to check the extraction efficiency requires

the use of prepared gas-in-oil standards of known concentra-

8. Method A—Vacuum Extraction

tion.ThemethodsofpreparationareoutlinedinAnnexA1and

Annex A2.

8.1 Method A employs vacuum extraction to separate the

gases from the oil. The evolved gases are compressed to

10. Procedure

atmospheric pressure and the total volume measured. The

10.1 Lower the mercury level from the collection flask.

gases are then analyzed by gas chromatography.

10.2 Evacuate the system of collection flask and degassing

9. Preparation of Apparatus −3

flasktoanabsolutepressureof1×10 torr(130mPa)orless.

(In Fig. 1, the space above the mercury in the reservoir must

9.1 Check the apparatus carefully for vacuum tightness of

all joints and stopcocks. also be evacuated.)

10.3 Connect the oil sample syringe by the PTFE tubing to

9.2 Measure the total volume of the extraction apparatus,

V , and the volume of the collection space, V , and calculate the three-way stopcock leading to the degassing flask.

T c

the ratio as the volumetric collection ratio:

10.4 Flush a small quantity of oil from the syringe through

V thetubingandstopcocktowaste,makingsurethatalltheairin

c

(1)

V 2 V the connecting tubing is displaced by oil.

T o

10.4.1 Any gas bubbles present in the syringe should be

where V =the volume of oil to be added.

o

retained during this flushing operation. This may be accom-

9.3 Calculate the degassing efficiencies for each individual

plished by inverting the syringe so that the bubble remains at

component gas as follows: the plunger end of the syringe during the flushing operation.

10.5 Close the stopcocks to the vacuum pumps and then

E 5 (2)

i

K V

slowly open the three-way stopcock to allow oil and any gas

i o

V 2 V

bubbles that may be present from the sample syringe to enter

T o

the degassing flask.

where:

E = degassing efficiency of component i,

i

Daoust, R., Dind, J. E., Morgan, J., and Regis, J, “Analysis of Gas Dissolved

V = volume of oil sample,

o

in Transformer Oils,” Doble Conference, 1971, Sections 6–110.

D3612 − 02 (2009)

10.6 Allow the desired amount of oil to enter the degassing 11.4 The apparatus shall provide sufficient repeatability so

flask and operate the magnetic stirrer vigorously for approxi- thatsuccessiverunsofareferencestandardagreewithin 61%

mately 10 min. This is the volume, V used in the calculation with respect to area under the peaks for hydrocarbon and

o

in 15.4. carbon oxide components.

10.6.1 If a gas bubble is present in the syringe, either

11.5 Awiderangeofchromatographicconditionshavebeen

analyze the total content of the syringe including the bubble;

successfullyemployed.Bothargonandheliumhavebeenused

or, if the gas bubble is large, and it is suspected that the

as carrier gases (see Note 7). In some cases, a separate GC or

concentration of dissolved gases is high, measure and analyze

other device is used for the detection and quantification of

the gas bubble separately, extract an aliquot of the oil sample,

hydrogen when helium is used as a carrier gas.

and correct as applicable.

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 3612–01 Designation:D 3612–02 (Reapproved 2009)

Standard Test Method for

Analysis of Gases Dissolved in Electrical Insulating Oil by

Gas Chromatography

This standard is issued under the fixed designation D 3612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers three procedures for extraction and measurement of gases dissolved in electrical insulating oil

having a viscosity of 20 cSt (100 SUS) or less at 40°C (104°F), and the identification and determination of the individual

component gases extracted. Other methods have been used to perform this analysis.

1.2 The individual component gases that may be identified and determined include:

Hydrogen—H

Oxygen—O

Nitrogen—N

Carbon monoxide—CO

Carbon dioxide—CO

Methane—CH

Ethane—C H

2 6

Ethylene—C H

2 4

Acetylene—C H

2 2

Propane—C H

3 8

Propylene—C H

3 6

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionarywarning statements see 6.1.8, 30.2.2 and 30.3.1.

2. Referenced Documents

2.1 ASTM Standards:

D2140 Test Method Practice for Calculating Carbon-Type Composition of Insulating Oils of Petroleum Origin

D2300 Test Method for Gassing of Electrical Insulating OilsLiquids Under Electrical Stress and Ionization (Modified Pirelli

Method Method)

D2779 Test Method for Estimation of Solubility of Gases in Petroleum Liquids

D2780 Test Method for Solubility of Fixed Gases in Liquids

D3613 Test Methods of Sampling Electrical Insulating Oils for Gas Analysis and Determination of Water Content

Practice for Sampling Insulating Liquids for Gas Analysis and Determination of Water Content

D4051 Practice for Preparation of Low-Pressure Gas Blends

E260 Practice for Packed Column Gas Chromatography

2.2 IEEE Standard:

C57.104 Guide for the Interpretation of Gases Generated in Oil-Immersed Transformers

2.3 IEC Standard:

Publication No. 567 Guide for the Sampling of Gases and of Oil from Oil-Filled Electrical Equipment and for theAnalysis of

Free and Dissolved Gases

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This test method is under the jurisdiction ofASTM Committee D27 on Electrical Insulating Liquids and Gases and is the direct responsibility of Subcommittee D27.03

on Analytical Tests.

Current edition approved Feb. 10, 2001. Published April 2001. Originally published as D3612–77. Last previous edition D3612–96.

Current edition approved May 15, 2009. Published June 2009. Originally approved in 1977. Last previous edition approved in 2002 as D3612–02 (2009).

Annual Book of ASTM Standards, Vol 05.02.

Available from IEEE, 345 E. 47th St., New York, NY 10017.

Annual Book of ASTM Standards, Vol 14.02.

Available from International Electrotechnical Commission (IEC), 3 rue de Varembé, Case postale 131, CH-1211, Geneva 20, Switzerland, http://www.iec.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3612–02 (2009)

3.1.1 gas content of oil by volume— in Method A, the total volume of gases, corrected to 760 torr (101.325 kPa) and 0°C,

containedinagivenvolumeofoil,expressedasapercentage.InMethodsBandC,C,thesumoftheindividualgasconcentrations

corrected to 760 torr (101.325 kPa) and 0°C, expressed in percent or parts per million.

3.1.2 headspace—a volume of gas phase in contact with a volume of oil in a closed vessel. The vessel is a headspace vial of

20-mL nominal capacity.

3.1.2.1 Discussion—Other vessel volumes may also be used, but the analytical performance may be somewhat different than

that specified in Method C.

3.1.3 parts per million (ppm) by volume of (specific gas) in oil—the volume of that gas corrected to 760 torr (101.325 kPa) and

0°C, contained in 10 volume of oil.

3.1.4 sparging, v—agitating the liquid sample using a gas to strip other gases free.

3.1.5 volume concentration of (specific gas) in the gas sample—the volume of the specific gas contained in a given volume of

the gas sample at the same temperature and pressure (as the measured total volume), expressed either as a percentage or in parts

per million.

4. Summary of Test Method

4.1 MethodA—Dissolvedgasesareextractedfromasampleofoilbyintroductionoftheoilsampleintoapre-evacuatedknown

volume. The evolved gases are compressed to atmospheric pressure and the total volume measured.

4.2 Method B—Dissolved gases are extracted from a sample of oil by sparging the oil with the carrier gas on a stripper column

containing a high surface area bead.

4.3 Method C—Method C consists of bringing an oil sample in contact with a gas phase (headspace) in a closed vessel purged

with argon.The dissolved gases contained in the oil are then equilibrated in the two phases in contact under controlled conditions

(in accordance with Henry’s law).At equilibrium, the headspace is overpressurized with argon and then the content of a loop is

filled by the depressurization of the headspace against the ambient atmospheric pressure.The gases contained in the loop are then

introduced into a gas chromatograph.

4.4 There may be some differences in the limits of detection and precision and bias between MethodsA, B, and C for various

gases.

4.5 A portion of the extracted gases (Method A) or all of the extracted gases (Method B) or a portion of the headspace gases

(MethodC)isintroducedintoagaschromatograph.CalibrationcurvesareusedinMethodCtoestablishtheconcentrationofeach

species.Thecompositionofthesampleiscalculatedfromitschromatogrambycomparingtheareaofthepeakofeachcomponent

withtheareaofthepeakofthesamecomponentonareferencechromatogrammadeonastandardmixtureofknowncomposition.

5. Significance and Use

5.1 Oil and oil-immersed electrical insulation materials may decompose under the influence of thermal and electrical stresses,

andindoingso,generategaseousdecompositionproductsofvaryingcompositionwhichdissolveintheoil.Thenatureandamount

oftheindividualcomponentgasesthatmayberecoveredandanalyzedmaybeindicativeofthetypeanddegreeoftheabnormality

responsibleforthegasgeneration.Therateofgasgenerationandchangesinconcentrationofspecificgasesovertimearealsoused

to evaluate the condition of the electric apparatus.

NOTE 1—Guidelines for the interpretation of gas-in-oil data are given in IEEE C57.104.

6. Apparatus

6.1Apparatus

6.1 Apparatus of the type shown in Fig. 1 or Fig. 2 is suitable for use with up to 50-mL samples of oil and consists of the

following components:

NOTE 2—This sample size has been found to be sufficient for most oils. However, oil that has had only limited exposure to air may contain much

smaller amounts of nitrogen and oxygen. For these oils it may be desirable to increase the size of the sample and the extraction apparatus.

NOTE 3—Alternative apparatus designs including the use of a Toepler pump have also been found successful.

6.1.1 Polytetrafluoroethylene (PTFE) Tubing, narrow-bore, terminated with a Luer-Lock fitted glass syringe, and leading to a

a solid plug, three-way, high-vacuum stopcock.

6.1.2 Degassing Flask, with a glass inlet tube, of sufficient volume to contain up to 50 mLof oil below the inlet tube, capable

of being evacuated through a vacuum pump, containing a PTFE-coated magnetic spin bar, and mounted on a magnetic stirrer.

6.1.3 Means of Measuring Absolute Pressure within the apparatus.

−3

6.1.4 Vacuum Pumping System, capable of evacuating the glassware to an absolute pressure of 1 310 torr (130 mPa) or

lower.

Available from IEEE, 345 E. 47th St., New York, NY 10017.

Ace Glass and Lurex Glass manufacture glass extractors. ForAce Glass, the glass apparatus conforming to Fig. 1 is Part E-13099-99-99 and Fig. 2 is Part E-1400-99.

Available from P.O. Box 688, 1430 Northwest Blvd., Vineland, NJ 08360 or Lurex Glass, 1298 Northwest Blvd., Vineland, NJ 08360.

D 3612–02 (2009)

FIG. 1 Extraction of Gas from Insulating Oil

FIG. 2 Extraction of Gas from Insulating Oil

D 3612–02 (2009)

6.1.5 Vacuum Glassware, sufficiently large compared to the volume of the oil sample, so that virtually complete degassing is

obtained and that the volumetric collection ratio is as large as possible. A 500-mL gas collecting flask has been found suitable.

6.1.6 High-Vacuum Valves or Stopcocks,employingtheminimumnecessaryamountsofhigh-vacuumstopcockgreaseareused

throughout the apparatus.

6.1.7 Gas Collection Tube, calibrated in 0.01-mLdivisions, capable of containing up to 5 mLof gas, terminated with a silicone

rubber retaining septum. A suitable arrangement is shown in Fig. 3.

6.1.8 Reservoir of Mercury, sufficient to fill the collection flask and collection tube. Note4—(Caution:Mercury Warning

—Mercury vapor is extremely toxic. Appropriate precautions should be taken.)

7. Sampling

7.1 Obtain samples in accordance with the procedure described in Test Methods D3613for sampling with syringetype devices

or rigid metal cylinders. The use of rigid metal cylinders is not recommended for use with Method B.

7.2 The procurement of representative samples without loss of dissolved gases or exposure to air is very important. It is also

important that the quantity and composition of dissolved gases remain unchanged during transport to the laboratory. Avoid

prolonged exposure to light by immediately placing drawn samples into light-proof containers and retaining them there until the

start of testing.

7.2.1 To maintain the integrity of the sample, keep the time between sampling and testing as short as possible. Evaluate

containersformaximumstoragetime.Sampleshavebeenstoredinsyringesandmetalcylindersforfourweekswithnoappreciable

change in gas content.

NOTE 54—Additional sampling procedures using flexible metal cans are currently being studied for use with Method A.

METHOD A—VACUUM EXTRACTION

8. Method A—Vacuum Extraction

8.1 MethodAemploys vacuum extraction to separate the gases from the oil.The evolved gases are compressed to atmospheric

pressure and the total volume measured. The gases are then analyzed by gas chromatography.

9. Preparation of Apparatus

9.1 Check the apparatus carefully for vacuum tightness of all joints and stopcocks.

9.2 Measure the total volume of the extraction apparatus, V , and the volume of the collection space, V , and calculate the ratio

T c

as the volumetric collection ratio:

V

c

(1)

V 2 V

T o

where V =the volume of oil to be added.

o

9.3 Calculate the degassing efficiencies for each individual component gas as follows:

E 5 (2)

i

KV

i o

1 1

V 2 V

T o

FIG. 3 Retaining Rubber Septum for Gas Collection Tube

D 3612–02 (2009)

where:

E = degassing efficiency of component i,

i

V = volume of oil sample,

o

V = total internal volume of extraction apparatus before oil sample is introduced, and

T

K = Ostwald solubility coefficient of component i.

i

9.4 Determine the Ostwald solubility coefficients of fixed gases in accordance with Test Method D2780.

9.5 Ostwald solubility coefficients that have been determined for a number of gases in one specific electrical insulating oil at

25°C are shown as follows. Values for gases in other oils may be estimated by reference to Test Method D2779.

Ostwald Solubility (Note 6)

Component Gas

Coefficient, K , 25°C, 760 mm Hg

i

Ostwald Solubility (Note 5)

Component Gas

Coefficient, K , 25°C, 760 mm Hg

i

Hydrogen 0.0558

Nitrogen 0.0968

Carbon monoxide 0.133

Oxygen 0.179

Methane 0.438

Carbon dioxide 1.17

Acetylene 1.22

Ethylene 1.76

Ethane 2.59

Propane 11.0

NOTE6—The 5—The Ostwald coefficient values shown in this table are correct only for the specific mineral oil having a density at 15.5°C of 0.855

g/cm used in the original determination. Ostwald coefficients for mineral oils of different density may be calculated as follows:

0.980 2density

K ~corrected!5 K (3)

i i

0.130

where, density =density of the oil of interest, g/cm at 15.5°C (60°F). This equation is derived from the equation in Test Method D2779. Note

especiallythatalloftheOstwaldcoefficientsarechangedbythesamefactor,meaningthatthoughtheabsolutesolubilitiesofeachofthegaseswillchange

if a different oil is used, the ratio of the solubility of one gas to another gas will remain constant.

9.6 Aproceduretochecktheextractionefficiencyrequirestheuseofpreparedgas-in-oilstandardsofknownconcentration.The

methods of preparation are outlined in Annex A1 and Annex A2.

10. Procedure

10.1 Lower the mercury level from the collection flask.

−3

10.2 Evacuate the system of collection flask and degassing flask to an absolute pressure of 1 310 torr (130 mPa) or less. (In

Fig. 1, the space above the mercury in the reservoir must also be evacuated.)

10.3 Connect the oil sample syringe by the PTFE tubing to the three-way stopcock leading to the degassing flask.

10.4 Flush a small quantity of oil from the syringe through the tubing and stopcock to waste, making sure that all the air in the

connecting tubing is displaced by oil.

10.4.1 Any gas bubbles present in the syringe should be retained during this flushing operation. This may be accomplished by

inverting the syringe so that the bubble remains at the plunger end of the syringe during the flushing operation.

10.5 Close the stopcocks to the vacuum pumps and then slowly open the three-way stopcock to allow oil and any gas bubbles

that may be present from the sample syringe to enter the degassing flask.

10.6 Allow the desired amount of oil to enter the degassing flask and operate the magnetic stirrer vigorously for approximately

10 min. This is the volume, V used in the calculation in 15.4.

o

10.6.1 If a gas bubble is present in the syringe, either analyze the total content of the syringe including the bubble; or, if the

gas bubble is large, and it is suspected that the concentration of dissolved gases is high, measure and analyze the gas bubble

separately, extract an aliquot of the oil sample, and correct as applicable.

10.7 Close the stopcock isolating the collection flask, and allow mercury to flow into the collection flask.

10.8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.