ASTM D4092-96

(Terminology)Standard Terminology: Plastics: Dynamic Mechanical Properties

Standard Terminology: Plastics: Dynamic Mechanical Properties

SCOPE

1.1 This terminology is a compilation of definitions and descriptions of technical terms used in dynamic mechanical property measurements on polymeric materials, including solutions, melts, and solids. Terms that are generally understood or defined adequately in other readily available sources are either not included or sources identified.

1.2 A definition is a single sentence with additional information included in notes. It is reviewed every five years and the year of the last review or revision is appended.

1.3 Definitions identical to those published by another standards organization or ASTM committee are identified with the abbreviation of the name of the organization or the ASTM committee; for example, ICTA is the International Conference on Thermal Analysis and- ISO is the International Standards Organization, Specifically ISO 472: 1988 (E/F) document.

1.4 Descriptions of terms specific to dynamic mechanical measurements are identified with an italicized introductory phrase.

Note 1—This terminology is similar to ISO 6721-1 1994 in title only. The ISO document cites only 13 terms and this terminology defines 49 relevant terms.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4092 – 96 An American National Standard

Standard Terminology Relating to

Dynamic Mechanical Measurements on Plastics

This standard is issued under the fixed designation D 4092; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Mechanical Properties, Part 1, General Principles

1.1 This terminology is a compilation of definitions and

3. Terminology Definitions and Descriptions

descriptions of technical terms used in dynamic mechanical

alpha (a) loss peak (in dynamic mechanical measurement)—

property measurements on polymeric materials, including so-

lutions, melts, and solids. Terms that are generally understood the first peak in the damping curve below the melt, in order

of decreasing temperature or increasing frequency. (1981)

or defined adequately in other readily available sources are

either not included or sources identified. beta (b) loss peak (in dynamic mechanical measurement)—

the second peak in the damping curve below the melt, in

1.2 A definition is a single sentence with additional infor-

order of decreasing temperature or increasing frequency.

mation included in notes. It is reviewed every five years and

the year of the last review or revision is appended. (1981)

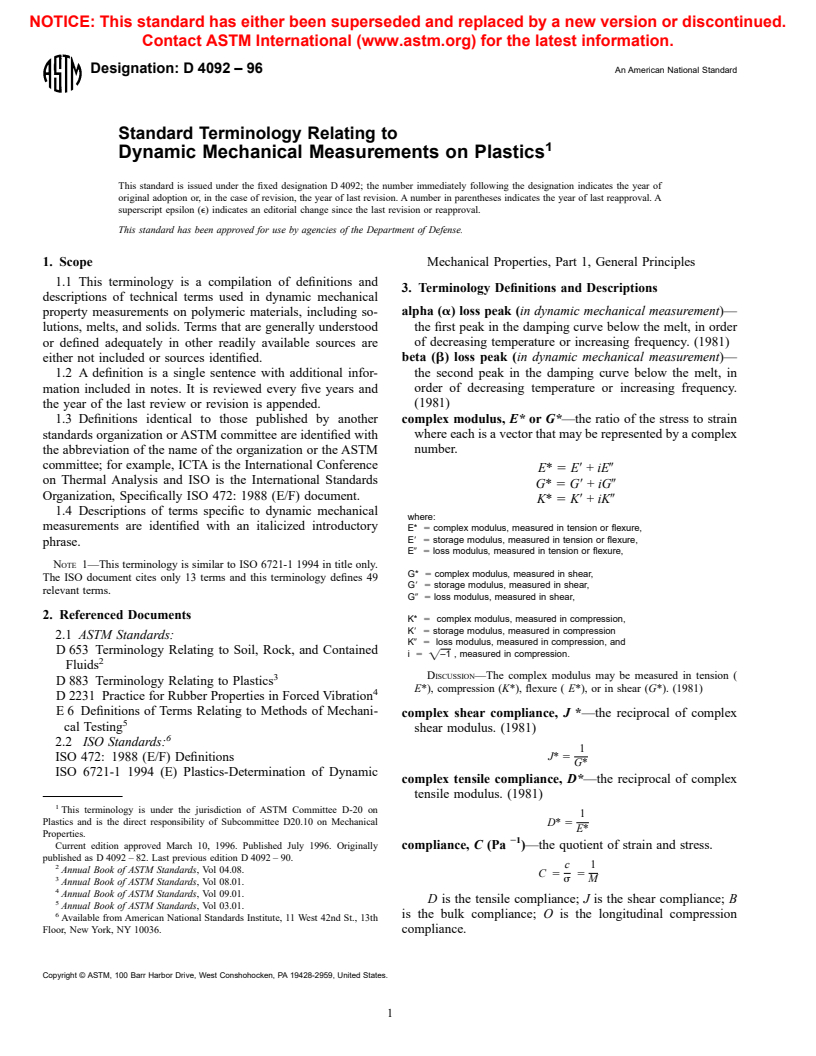

complex modulus, E* or G*—the ratio of the stress to strain

1.3 Definitions identical to those published by another

standards organization or ASTM committee are identified with where each is a vector that may be represented by a complex

number.

the abbreviation of the name of the organization or the ASTM

committee; for example, ICTA is the International Conference

E* 5 E8 + iE9

on Thermal Analysis and ISO is the International Standards

G* 5 G8 + iG9

Organization, Specifically ISO 472: 1988 (E/F) document.

K* 5 K8 + iK9

1.4 Descriptions of terms specific to dynamic mechanical

where:

measurements are identified with an italicized introductory

E* 5 complex modulus, measured in tension or flexure,

E8 5 storage modulus, measured in tension or flexure,

phrase.

E9 5 loss modulus, measured in tension or flexure,

NOTE 1—This terminology is similar to ISO 6721-1 1994 in title only.

G* 5 complex modulus, measured in shear,

The ISO document cites only 13 terms and this terminology defines 49

G8 5 storage modulus, measured in shear,

relevant terms.

G9 5 loss modulus, measured in shear,

2. Referenced Documents

K* 5 complex modulus, measured in compression,

K8 5 storage modulus, measured in compression

2.1 ASTM Standards:

K9 5 loss modulus, measured in compression, and

D 653 Terminology Relating to Soil, Rock, and Contained

i 5 –1 , measured in compression.

=

Fluids

DISCUSSION—The complex modulus may be measured in tension (

D 883 Terminology Relating to Plastics

E*), compression (K*), flexure ( E*), or in shear (G*). (1981)

D 2231 Practice for Rubber Properties in Forced Vibration

E 6 Definitions of Terms Relating to Methods of Mechani-

complex shear compliance, J *—the reciprocal of complex

cal Testing

shear modulus. (1981)

2.2 ISO Standards:

ISO 472: 1988 (E/F) Definitions J* 5

G*

ISO 6721-1 1994 (E) Plastics-Determination of Dynamic

complex tensile compliance, D*—the reciprocal of complex

tensile modulus. (1981)

This terminology is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical D* 5

E*

Properties.

−1

compliance, C (Pa )—the quotient of strain and stress.

Current edition approved March 10, 1996. Published July 1996. Originally

published as D 4092 – 82. Last previous edition D 4092 – 90.

c 1

Annual Book of ASTM Standards, Vol 04.08.

C 5 5

s M

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 09.01.

D is the tensile compliance; J is the shear compliance; B

Annual Book of ASTM Standards, Vol 03.01.

is the bulk compliance; O is the longitudinal compression

Available from American National Standards Institute, 11 West 42nd St., 13th

Floor, New York, NY 10036. compliance.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4092

transition. (D-20) (1981)

critical damping (in dynamic mechanical measurement)—that

damping required for the borderline condition between

glass transition temperature, T —the approximate midpoint

g

oscillatory and nonoscillatory behavior. (1983).

of the temperature range over which the glass transition

damping—the loss in energy, dissipated as heat, that results

takes place.

when a material or material system is subjected to an

DISCUSSION—The glass transition temperature can be determined

oscillatory load or displacement. (1981)

readily only by observing the temperature at which a significant change

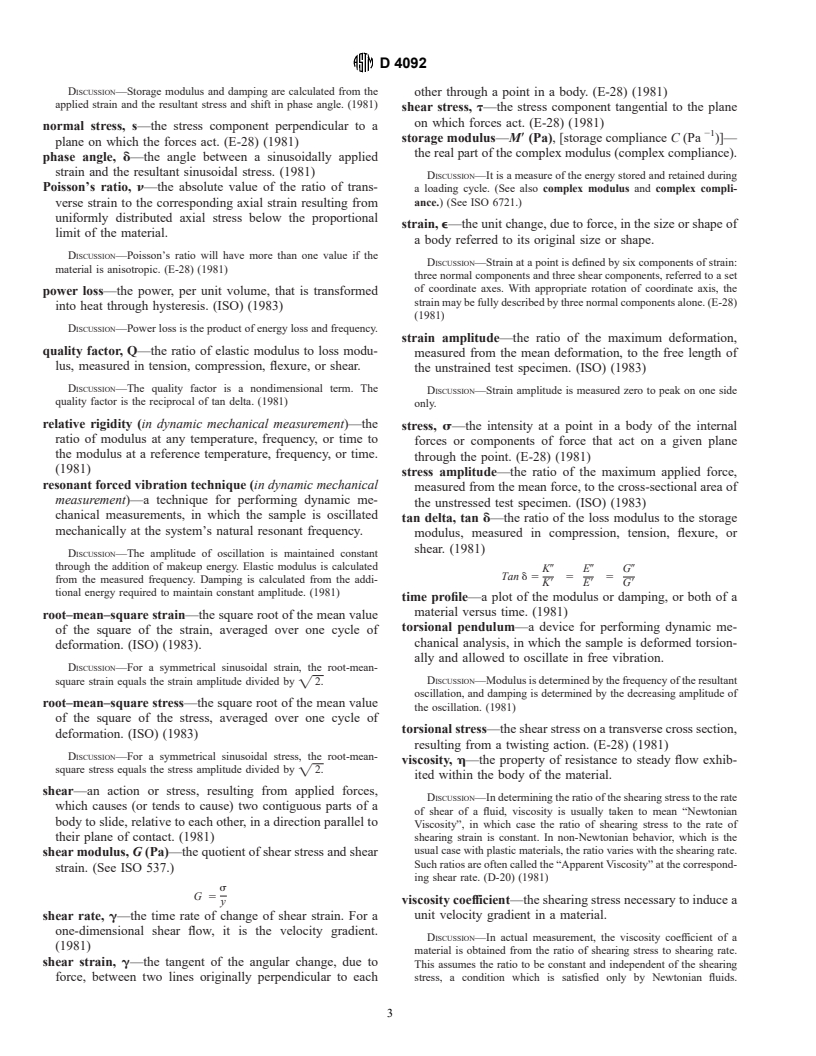

damping ratio, μ —the ratio of actual damping to critical

takes place in a specific electrical, mechanical, or other physical

damping. (1983).

property. Moreover, the observed temperature can vary significantly,

depending on the specific property chosen for observation and on

DISCUSSION—Damping ratio is a function of the logarithmic decre-

details of the experimental technique (for example, rate of heating,

ment (D):

frequency). Therefore, the observed T should be considered only an

g

D/2p

estimate. The most reliable estimates are normally obtained from the

μ 5 5 sin arctan ~D/2p!

1 1 ~D/2p!

= loss peak observed in dynamic mechanical tests or from dilatometric

For small values of D, it is: μ5D/2p

data. (D-20) (1981)

dissipation factor— see tan delta.

hysteresis loop (in dynamic mechanical measurement)—the

dynamic mechanical measurement—a technique in which closed curve representing successive stress-strain status of

either the modulus or damping, or both, of a substance under

the material during a cyclic deformation. (ISO) (1983)

oscillatory load or displacement is measured as a function of

DISCUSSION—Hysteresis loops may be centered around the origin of

temperature, frequency, or time, or combination thereof.

coordinates or, more frequently, displaced to various levels of strain or

(1981)

stress; in this case, the shape of the loop becomes variously asymmetri-

dynamic modulus—see complex modulus.

cal, but this fact is frequently disregarded.

elasticity—that property of materials that causes them to return

logarithmic decrement, D (in dynamic mechanical

to their original form or condition after the applied force is

measurement)—the natural logarithm of the ratio of any two

removed. (1981)

(or more) successive amplitudes of like sign, in the decay of

elastic modulus—see complex modulus and storage modu-

single frequency oscillation:

lus.

1 A

energy loss—the energy per unit volume that is lost in each n

D5 ln

k A

deformation cycle. (ISO) (1983) n 1 k

where A and A are amplitudes (in radians of rotation) of

n n+k

DISCUSSION—Energy loss is the hysteresis loop area, calculated with

two oscillations, and k is the number of oscillations separating

reference to coordinate scales.

the two amplitude measurements. (1981)

free vibration (in dynamic mechanical measurement)—a tech-

loss angle, d— see phase angle.

nique for performing dynamic mechanical measurements in

loss factor—see tan d.

which the sample is deformed, released, and allowed to

−1

loss modulus—M9(Pa)—[loss compliance O9 (Pa )]: the

oscillate freely at the system’s natural resonant frequency.

imaginary part of the complex modulus (compliance).

DISCUSSION—Elastic modulus is calculated from the measured reso-

DISCUSSION—It is a measure of the energy lost (dissipated during a

nant frequency, and damping is calculated from the rate at which the

loading cycle). (See also complex modulus and complex compliance.)

amplitude of the oscillation decays. (1981)

(See ISO 6721.)

frequency profile , n—a plot of the dynamic properties of a

loss tangent—see tan delta.

material, at a constant temperature, as a function of test

mean modulus—the ratio of mean stress to mean strain. (ISO)

frequency. (1981)

(1983)

gamma (g) loss peak , n—the third peak in the damping curve

mean strain—the average value of strain during a single

below the melt, in the order of decreasing temperature or

complete hysteresis loop of cyclic deformation. (IS

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.