ASTM F31-05

(Specification)Standard Specification for 42% Nickel-6% Chromium-Iron Sealing Alloy

Standard Specification for 42% Nickel-6% Chromium-Iron Sealing Alloy

ABSTRACT

This specification covers iron-nickel-chromium alloy (UNS K94760) used primarily for glass-sealing applications in electronic devices. The chemical composition of the material shall conform to the requirements prescribed. Chemical analysis shall be made, when desired, in accordance with the prescribed requirements. The average linear coefficient of thermal expansion shall be within limits of the requirements specified. The material shall be commercially smooth, uniform in cross section, in composition, and in temper; it shall be free of scale, corrosion, cracks, seams, scratches, slivers, and other defects.

SCOPE

1.1 This specification covers an iron-nickel-chromium alloy (UNS K94760) used primarily for glass-sealing applications in electronic devices.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

The following safety hazards caveat applies only to Section 13. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F31 – 05

Standard Specification for

1

42 % Nickel-6 % Chromium-Iron Sealing Alloy

ThisstandardisissuedunderthefixeddesignationF31;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Ordering Information

1.1 Thisspecificationcoversaniron-nickel-chromiumalloy 3.1 Ordersformaterialunderthisspecificationshallinclude

(UNSK94760)usedprimarilyforglass-sealingapplicationsin the following information:

electronic devices. 3.1.1 Size,

1.2 Thevaluesstatedininch-poundunitsaretoberegarded 3.1.2 Temper (Section 6),

as the standard. The values given in parentheses are for 3.1.3 Surface finish (Section 8),

information only. 3.1.4 Marking and packaging (Section 13), and

1.3 The following safety hazards caveat applies only to 3.1.5 Certification if required.

Section13.Thisstandarddoesnotpurporttoaddressallofthe

4. Chemical Composition

safety concerns, if any, associated with its use. It is the

4.1 The material shall conform to the requirements ofTable

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 1 as to chemical composition.

bility of regulatory limitations prior to use.

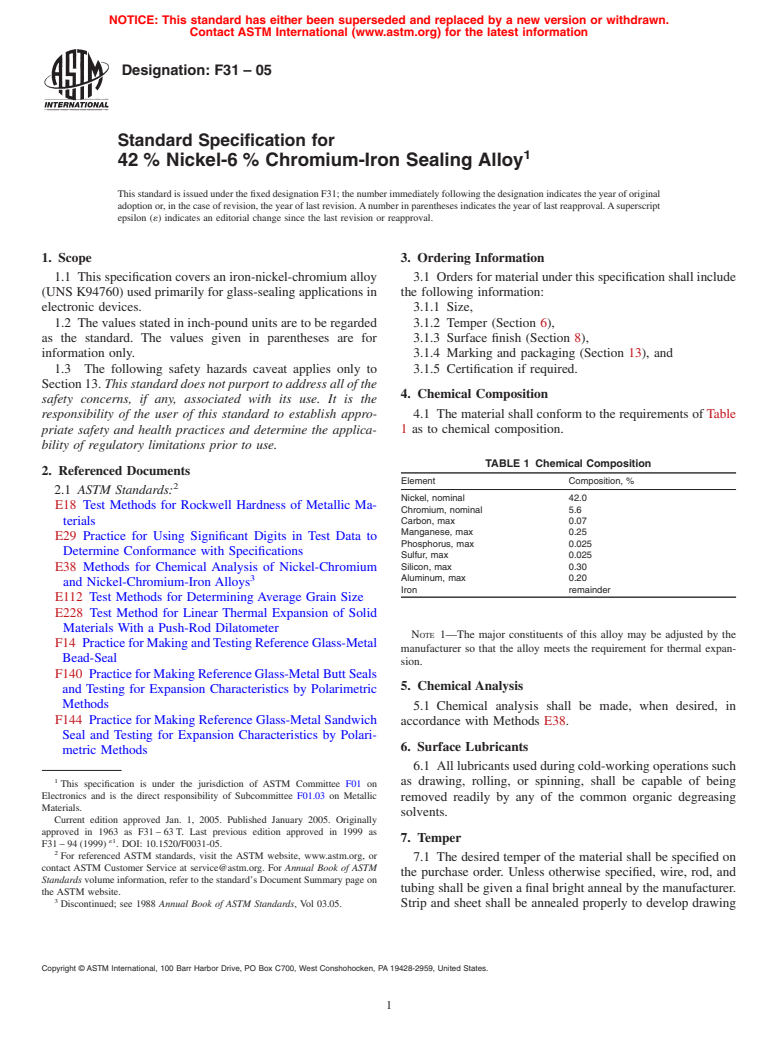

TABLE 1 Chemical Composition

2. Referenced Documents

Element Composition, %

2

2.1 ASTM Standards:

Nickel, nominal 42.0

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Chromium, nominal 5.6

Carbon, max 0.07

terials

Manganese, max 0.25

E29 Practice for Using Significant Digits in Test Data to

Phosphorus, max 0.025

Determine Conformance with Specifications

Sulfur, max 0.025

Silicon, max 0.30

E38 Methods for Chemical Analysis of Nickel-Chromium

3 Aluminum, max 0.20

and Nickel-Chromium-Iron Alloys

Iron remainder

E112 Test Methods for Determining Average Grain Size

E228 Test Method for Linear Thermal Expansion of Solid

Materials With a Push-Rod Dilatometer

NOTE 1—The major constituents of this alloy may be adjusted by the

F14 PracticeforMakingandTestingReferenceGlass-Metal

manufacturer so that the alloy meets the requirement for thermal expan-

Bead-Seal

sion.

F140 PracticeforMakingReferenceGlass-MetalButtSeals

5. Chemical Analysis

and Testing for Expansion Characteristics by Polarimetric

Methods

5.1 Chemical analysis shall be made, when desired, in

F144 PracticeforMakingReferenceGlass-MetalSandwich

accordance with Methods E38.

Seal and Testing for Expansion Characteristics by Polari-

6. Surface Lubricants

metric Methods

6.1 Alllubricantsusedduringcold-workingoperationssuch

1

as drawing, rolling, or spinning, shall be capable of being

This specification is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

removed readily by any of the common organic degreasing

Materials.

solvents.

Current edition approved Jan. 1, 2005. Published January 2005. Originally

approved in 1963 as F31–63T. Last previous edition approved in 1999 as

7. Temper

´1

F31–94(1999) . DOI: 10.1520/F0031-05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 The desired temper of the material shall be specified on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the purchase order. Unless otherwise specified, wire, rod, and

Standards volume information, refer to the standard’s Document Summary page on

tubing shall be given a final bright anneal by the manufacturer.

the ASTM website.

3

Discontinued; see 1988 Annual Book of ASTM Standards, Vol 03.05. Strip and sheet shall be annealed properly to develop drawing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

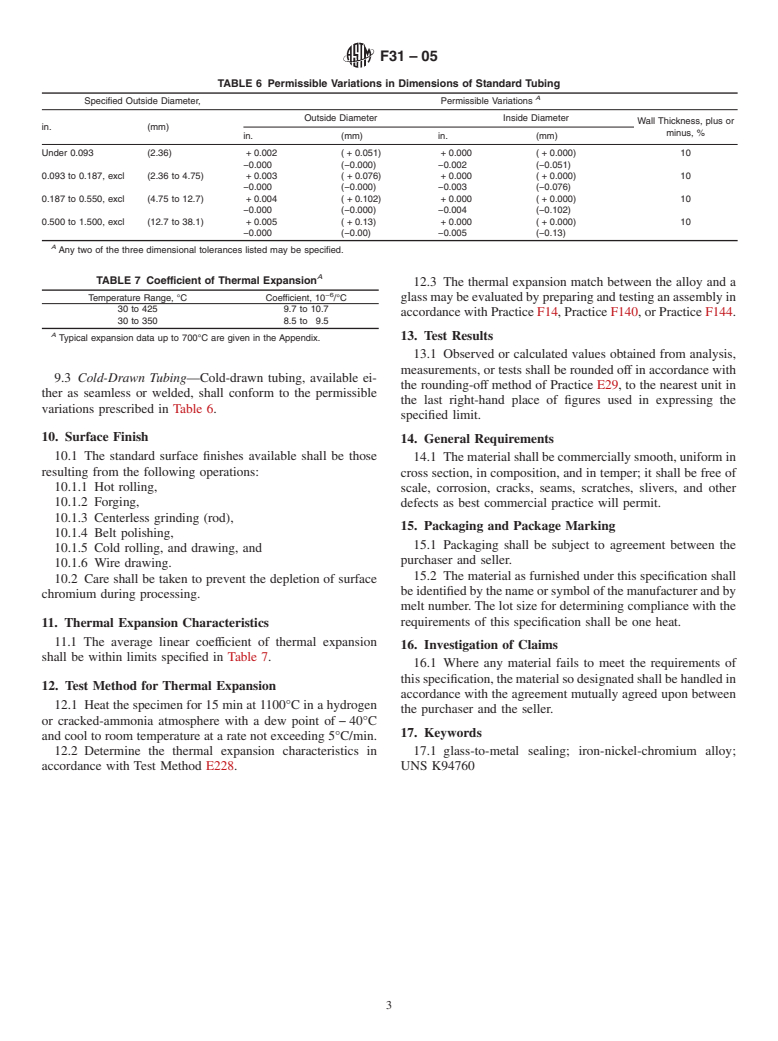

F31–05

TABLE 2 Permissible Variations in Thickness of Cold-Rolled Strip

3

NOTE 1— Measurement shall be made at least ⁄8 in. (9.5 mm) from the edge of strip over 1-in. (25.4 mm) wide.

Specified Thickness Permissible Variations in Thickness for Width Given, 6

(Under 76 Over 3 to 6 (76to150 Over 6 to 12 (150 to 300 Over 12 to 16 (300 to 400

in. (mm) Under 3 in.

mm) in. mm) in. mm) in. mm)

0.160 to 0.100, incl (4.06 to 2.54) 0.002 (0.05) 0.003 (0.076) 0.004 (0.10) 0.004 (0.10)

0.099 to 0.069, incl (2.51 to 1.75) 0.002 (0.05) 0.003 (0.076) 0.003 (0.076) 0.004 (0.10)

0.068 to 0.050, incl (1.73 to 1.27) 0.002 (0.05) 0.003 (0.076) 0.003 (0.076) 0.003 (0.076)

0.049 to 0.035, incl (1.24 to 0.89) 0.002 (0.05) 0.0025 (0.064) 0.003 (0.076) 0.003 (0.076)

0.034 to 0.029, incl (0.86 to 0.74) 0.0015 (0.038) 0.002 (0.05) 0.0025 (0.064) 0.0025 (0.064)

0.028 to 0.026, incl (0.71 to 0.66) 0.0015 (0.038) 0.0015 (0.038) 0.002 (0.05) 0.002 (0.05)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.