ASTM E840-95(2000)

(Practice)Standard Practice for Using Flame Photometric Detectors in Gas Chromatography

Standard Practice for Using Flame Photometric Detectors in Gas Chromatography

SCOPE

1.1 This practice is intended as a guide for the use of a flame photometric detector (FPD) as the detection component of a gas chromatographic system.

1.2 This practice is directly applicable to an FPD that employs a hydrogen-air flame burner, an optical filter for selective spectral viewing of light emitted by the flame, and a photomultiplier tube for measuring the intensity of light emitted.

1.3 This practice describes the most frequent use of the FPD which is as an element-specific detector for compounds containing sulfur (S) or phosphorus (P) atoms. However, nomenclature described in this practice are also applicable to uses of the FPD other than sulfur or phosphorus specific detection.

1.4 This practice is intended to describe the operation and performance of the FPD itself independently of the chromatographic column. However, the performance of the detector is described in terms which the analyst can use to predict overall system performance when the detector is coupled to the column and other chromatographic system components.

1.5 For general gas chromatographic procedures, Practice E260 should be followed except where specific changes are recommended herein for use of an FPD.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see Section 4, Hazards.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E840–95 (Reapproved 2000)

Standard Practice for

Using Flame Photometric Detectors in Gas

Chromatography

This standard is issued under the fixed designation E840; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope CGAP-1 Safe Handling of Compressed Gases in Contain-

ers

1.1 Thispracticeisintendedasaguidefortheuseofaflame

CGAG-5.4 Standard for Hydrogen Piping Systems at

photometric detector (FPD) as the detection component of a

Consumer Locations

gas chromatographic system.

CGAP-9 The Inert Gases: Argon, Nitrogen and Helium

1.2 This practice is directly applicable to an FPD that

CGAV-7 Standard Method of Determining CylinderValve

employs a hydrogen-air flame burner, an optical filter for

Outlet Connections for Industrial Gas Mixtures

selective spectral viewing of light emitted by the flame, and a

CGAP-12 Safe Handling of Cryogenic Liquids

photomultiplier tube for measuring the intensity of light

HB-3 Handbook of Compressed Gases

emitted.

1.3 ThispracticedescribesthemostfrequentuseoftheFPD

3. Terminology

which is as an element-specific detector for compounds con-

3.1 Definitions—For definitions relating to gas chromatog-

taining sulfur (S) or phosphorus (P) atoms. However, nomen-

raphy, refer to Practice E355.

clature described in this practice are also applicable to uses of

3.2 Descriptions of Terms—Descriptions of terms used in

the FPD other than sulfur or phosphorus specific detection.

this practice are included in Sections 7-17.

1.4 This practice is intended to describe the operation and

3.3 Symbols:Symbols—A list of symbols and associated

performance of the FPD itself independently of the chromato-

units of measurement is included in Annex A1.

graphic column. However, the performance of the detector is

described in terms which the analyst can use to predict overall

4. Hazards

system performance when the detector is coupled to the

4.1 Gas Handling Safety—The safe handling of com-

column and other chromatographic system components.

pressed gases and cryogenic liquids for use in chromatography

1.5 For general gas chromatographic procedures, Practice

is the responsibility of every laboratory. The Compressed Gas

E260 should be followed except where specific changes are

Association,(CGA),amembergroupofspecialtyandbulkgas

recommended herein for use of an FPD.

suppliers, publishes the following guidelines to assist the

1.6 This standard does not purport to address all of the

laboratory chemist to establish a safe work environment.

safety concerns, if any, associated with its use. It is the

Applicable CG publications include CGAP-1, CGAG-5.4,

responsibility of the user of this standard to establish appro-

CGAP-9, CGAV-7, CGAP-12, and HB-3.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific safety

5. Principles of Flame Photometric Detectors

information, see Section 4, Hazards.

5.1 The FPD detects compounds by burning those com-

pounds in a flame and sensing the increase of light emission

2. Referenced Documents

from the flame during that combustion process. Therefore, the

2.1 ASTM Standards:

2 FPD is a flame optical emission detector comprised of a

E260 Practice for Packed Column Gas Chromatography

hydrogen-air flame, an optical window for viewing emissions

E355 Practice for Gas Chromatography Terms and Rela-

2 generated in the flame, an optical filter for spectrally selecting

tionships

the wavelengths of light detected, a photomultiplier tube for

2.2 CGA Standards:

measuring the intensity of light emitted, and an electrometer

for measuring the current output of the photomultiplier.

5.2 The intensity and wavelength of light emitted from the

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

FPDflamedependsonthegeometricconfigurationoftheflame

Spectroscopy and is the direct responsibility of Subcommittee E13.19 on Chroma-

tography.

Current edition approved May 15, 1995. Published July 1995. Originally

published as E840–81. Last previous edition E840–91. Available from Compressed Gas Association, Inc., 1725 Jefferson Davis

Annual Book of ASTM Standards, Vol 14.02. Highway, Arlington, VA 22202-4100.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E840–95 (2000)

burner and on the absolute and relative flow rates of gases the approximate square of the S-atom flow. Since the FPD

supplied to the detector. By judicious selection of burner response depends on the P-atom or S-atom mass flow per unit

geometryandgasflowrates,theFPDflameisusuallydesigned time into the detector, the FPD is a mass flow rate type of

to selectively enhance optical emissions from certain types of detector. The upper limit to the intensity of light emitted from

molecules while suppressing emissions from other molecules. boththeHPOandS moleculesisgenerallydeterminedbythe

5.3 Typical FPD flames are normally not hot enough to onset of self-absorption effects in the emitting flame. At high

promoteabundantopticalemissionsfromatomicspeciesinthe concentrations of S and P atoms in the flame, the concentra-

flame. Instead, the optical emissions from an FPD flame tionsofgroundstateS andHPOmoleculesbecomessufficient

usually are due to molecular band emissions or continuum to reabsorb light emitted from the radiating states of HPO and

emissionsresultingfromrecombinationofatomicormolecular S .

speciesintheflame.Forsulfurdetection,lightemanatingfrom

5.6 InthepresenceofahydrocarbonbackgroundintheFPD

the S molecule is generally detected. For phosphorus detec-

flame, the light emissions from the phosphorus and sulfur

tion, light emanating from the HPO molecule is generally

compounds can be severely quenched (2). Such quenching can

detected. Interfering light emissions from general hydrocarbon

occur in the gas chromatographic analysis of samples so

compounds are mainly comprised of CH and C molecular

complex that the GC column does not completely separate the

band emissions, and CO+O→ CO +hg continuum radia-

phosphorus or sulfur compounds from overlapping hydrocar-

tion.

bon compounds. Quenching can also occur as the result of an

5.4 Hydrogen – air or hydrogen – oxygen diffusion flames

underlying tail of a hydrocarbon solvent peak preceding

are normally employed for the FPD. In such diffusion flames,

phosphorus or sulfur compounds in a chromatographic sepa-

the hydrogen and oxygen do not mix instantaneously, so that

ration. The fact that the phosphorus or sulfur response is

these flames are characterized by significant spatial variations

reducedbyquenchingisnotalwaysapparentfromachromato-

in both temperature and chemical species. The important

gram since the FPD generally gives little response to the

chemical species in a hydrogen – air flame are the H, O, and

hydrocarbon.Theexistenceofquenchingcanoftenberevealed

OH flame radicals. These highly reactive species play a major

by a systematic investigation of the variation of the FPD

role in decomposing incoming samples and in the subsequent

responseasafunctionofvariationsinsamplevolumewhilethe

production of the desired optical emissions. Optical emissions

analyte is held at a constant amount.

from the HPO and S molecular systems are highly favored in

5.7 The chromatographic detection of trace level phospho-

those regions of an FPD flame which are locally rich in

rus or sulfur compounds can be complicated by the fact that

H-atoms, while CH and C light emissions from hydrocarbons

such compounds often tend to be highly reactive and adsorp-

originate mainly from those flame regions which are locally

tive. Therefore, care must be taken to ensure that the entire

rich in O-atoms. The highest sensitivity and specificity for

chromatographic system is properly free of active sites for

sulfur and phosphorus detection are achieved only when the

adsorption of phosphorus or sulfur compounds. The use of

FPD flame is operated with hydrogen in excess of that

silanized glass tubing as GC injector liners and GC column

stoichiometricamountrequiredforcompletecombustionofthe

materials is a good general practice.At near ambient tempera-

oxygen supplied to the flame. This assures a large flame

tures, GC packed columns made of FEP TFE-fluorocarbon,

volume that is locally abundant in H-atoms, and a minimal

specially coated silica gel, or treated graphitized carbon are

flame volume that is locally abundant in O-atoms. The sensi-

often used for the analysis of sulfur gases.

tivity and specificity of the FPD are strongly dependent on the

absolute and relative flow rates of hydrogen and air. The

6. Detector Construction

optimum hydrogen and air flow rates depend on the detailed

6.1 Burner Design:

configuration of the flame burner. For some FPD designs, the

6.1.1 Single Flame Burner (2,3)—The most popular FPD

flows which are optimum for phosphorus detection are not the

burner uses a single flame to decompose sample compounds

same as the flows which are optimum for sulfur detection.

and generate the optical emissions. In this burner, carrier gas

Also, the flows which are optimum for one sample compound

and sample compounds in the effluent of a GC column are

may not necessarily be optimum for another sample com-

mixed with air and conveyed to an orifice in the center of a

pound.

flame tip. Excess hydrogen is introduced from the outer

5.5 Although the detailed chemistry occurring in the FPD

perimeter of this flame tip so as to produce a relatively large,

flame has not been firmly established, it is known that the

diffuse hydrogen-rich flame. With this burner and flow con-

intenseemissionsfromtheHPOandS moleculesaretheresult

figuration,lightemissionsfromhydrocarboncompoundsoccur

of chemiluminescent reactions in the flame rather than thermal

primarily in the locally oxygen-rich core of the flame in close

excitation of these molecules (1). The intensity of light

proximity to the flame tip orifice, while HPO and S emissions

radiated from the HPO molecule generally varies as a linear 2

occur primarily in the upper hydrogen-rich portions of the

function of P-atom flow into the flame. In the case of the S

flame. Improved specificity is therefore obtained by the use of

emission,thelightintensityisgenerallyanonlinearfunctionof

an optical shield at the base of the flame to prevent hydrocar-

S-atom flow into the flame, and most often is found to vary as

bon emissions from being in the direct field of view. The light

emissions generated in this flame are generally viewed from

the side of the flame. Some of the known limitations of this

The boldface numerals in parentheses refer to the list of references at the end

of this practice. burner are as follows:

E840–95 (2000)

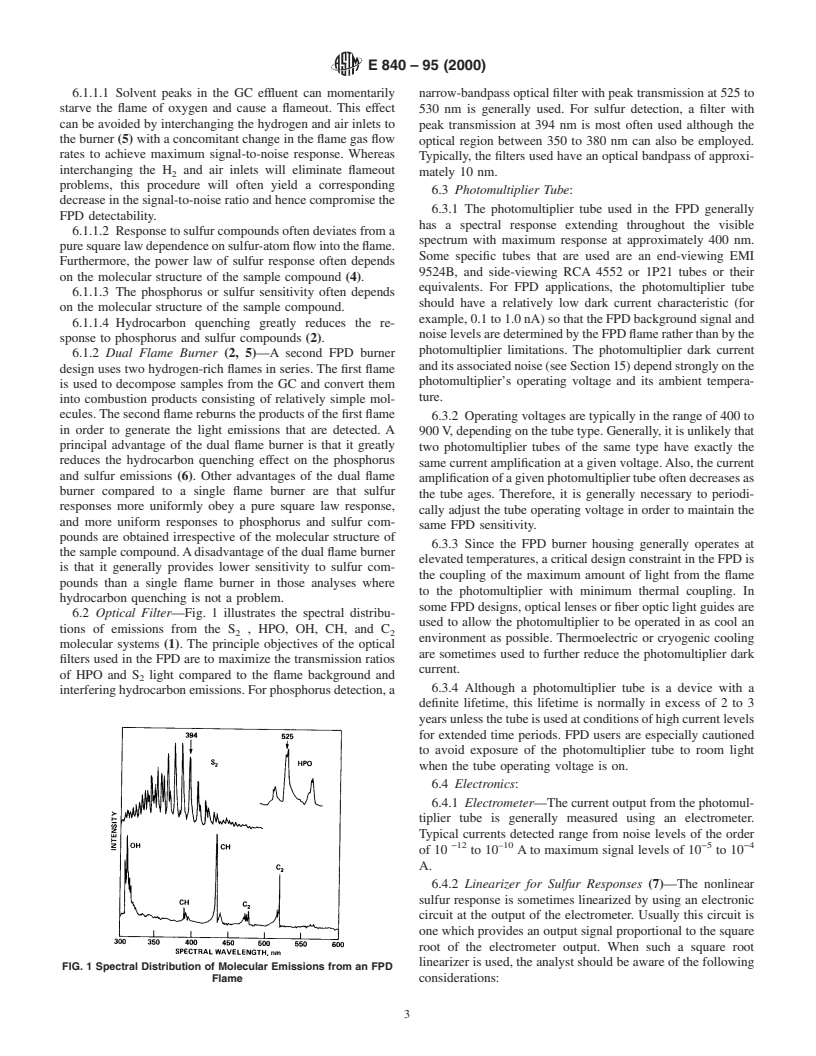

6.1.1.1 Solvent peaks in the GC effluent can momentarily narrow-bandpassopticalfilterwithpeaktransmissionat525to

starve the flame of oxygen and cause a flameout. This effect 530 nm is generally used. For sulfur detection, a filter with

can be avoided by interchanging the hydrogen and air inlets to

peak transmission at 394 nm is most often used although the

the burner (5) with a concomitant change in the flame gas flow

optical region between 350 to 380 nm can also be employed.

rates to achieve maximum signal-to-noise response. Whereas

Typically, the filters used have an optical bandpass of approxi-

interchanging the H and air inlets will eliminate flameout

2 mately 10 nm.

problems, this procedure will often yield a corresponding

6.3 Photomultiplier Tube:

decreaseinthesignal-to-noiseratioandhencecompromisethe

6.3.1 The photomultiplier tube used in the FPD generally

FPD detectability.

has a spectral response extending throughout the visible

6.1.1.2 Responsetosulfurcompoundsoftendeviatesfroma

spectrum with maximum response at approximately 400 nm.

puresquarelawdependenceonsulfur-atomflowintotheflame.

Some specific tubes that are used are an end-viewing EMI

Furthermore, the power law of sulfur response often depends

9524B, and side-viewing RCA 4552 or 1P21 tubes or their

on the molecular structure of the sample compound (4).

equivalents. For FPD applications, the photomultiplier tube

6.1.1.3 The phosphorus or sulfur sensitivity often depends

should have a relatively low dark current characteristic (for

on the molecular structure of the sample compound.

example,0.1to1.0nA)sothattheFPDbackgroundsignaland

6.1.1.4 Hydrocarbon quenching greatly reduces the re-

noiselevelsaredeterminedbytheFPDflameratherthanbythe

sponse to phosphorus and sulfur compounds (2).

photomultiplier limitations. The photomultiplier dark current

6.1.2 Dual Flame Burner (2, 5)—A second FPD burner

anditsassociatednoise(seeSection15)dependstronglyonthe

design uses two hydrogen-rich flames in series.The first flame

photomultiplier’s operating voltage and its ambient tempera-

is used to decompose samples from the GC and convert them

ture.

into combustion products consisting of relatively simple mol-

ecules.Thesecondflamereburnstheproductsofthefirstflame

6.3.2 Operating voltages are typically in the range of 400 to

in order to generate the light emissions that are detected. A

900V,dependingonthetubetype.Generally,itisunlikelythat

principal advantage of the dual flame burner is that it greatly

two photomultiplier tubes of the same type have exactly the

reduces the hydrocarbon quenching effect on the phosphorus

samecurrentamplificationatagivenvoltage.Also,thecurrent

and sulfur emissions (6). Other advantages of the dual flame

amplificationofagivenphotomultipliertubeoftendecreasesas

burner compared to a single flame burner are that sulfur

the tube ages. Therefore, it is generally necessary to periodi-

responses more uniformly obey a pure square law response,

cally adjust the tube operating voltage in order to maintain the

and more uniform responses to phosphorus and sulfur com-

same FPD sensitivity.

pounds are obtained irrespective of the molecular structure of

6.3.3 Since the FPD burner housing generally operates at

thesamplecompound.Adisadvantageofthedualflameburner

elevatedtemperatures,acriticaldesignconstraintintheFPDis

is that it generally provides lower sensitivity to sulfur com-

the coupling of the maximum amount of light from the flame

pounds than a single flame burner in those analyses where

to the photomultiplier with minimum thermal coupling. In

hydrocarbon quenching is not a problem.

someFPDdesigns,opticallensesorfiberopticlightguidesare

6.2 Optical Filter—Fig. 1 illustrates the spectral distribu-

used to allow the photomultiplier to be operated in as cool an

tions of emissions from the S , HPO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.