ASTM D6196-03(2009)

(Practice)Standard Practice for Selection of Sorbents, Sampling, and Thermal Desorption Analysis Procedures for Volatile Organic Compounds in Air

Standard Practice for Selection of Sorbents, Sampling, and Thermal Desorption Analysis Procedures for Volatile Organic Compounds in Air

SIGNIFICANCE AND USE

This practice is recommended for use in measuring the concentration of VOCs in ambient, indoor, and workplace atmospheres. It may also be used for measuring emissions from materials in small or full scale environmental chambers for material emission testing or human exposure assessment.

Such measurements in ambient air are of importance because of the known role of VOCs as ozone precursors, and in some cases (for example, benzene), as toxic pollutants in their own right.

Such measurements in indoor air are of importance because of the association of VOCs with air quality problems in indoor environments, particularly in relation to sick building syndrome and emissions from building materials. Many volatile organic compounds have the potential to contribute to air quality problems in indoor environments and in some cases toxic VOCs may be present at such elevated concentrations in home or workplace atmospheres as to prompt serious concerns over human exposure and adverse health effects (6).

Such measurements in workplace air are of importance because of the known toxic effects of many such compounds.

In all three environments, in order to protect the environment as a whole and human health in particular, it is necessary to take measurements of air quality as part of an overall assessment in relation to mandatory requirements.

The choices of sorbents, sampling method, and analytical methodology affect the efficiency of sorption, recovery, and quantification of individual VOCs. This practice is potentially effective for a wide range of volatile organic compounds found in air, over a wide range of volatilities and concentration levels. However, it is the responsibility of the user to ensure that the sampling, recovery, analysis, and quality control for the measurement of a specific VOC of interest are within acceptable limits. Guidance for this evaluation is part of the scope of this practice.

SCOPE

1.1 This practice is intended to assist in the selection of sorbents and procedures for the sampling and analysis of ambient (1) , indoor (2) and workplace (3, 4) atmospheres for a variety of common volatile organic compounds (VOCs). It may also be used for measuring emissions from materials in small or full scale environmental chambers or for human exposure assessment.

1.2 A complete listing of VOCs for which this practice has been tested, at least over part of the measurement range (1.6), is shown in Tables 1-9. For other compounds this practice shall be tested according to EN 1076 (pumped); Practice D 6246, ISO 16107, ANSI/ISEA 104, EN 838 or EN 13528-1/EN 13528-2 (diffusive); or other appropriate validation protocols (Sections 13 and 14). (5,1)

1.3 This practice is based on the sorption of VOCs from air onto selected sorbents or combinations of sorbents. Sampled air is either drawn through a tube containing one or a series of sorbents (pumped sampling) or allowed to diffuse, under controlled conditions, onto the sorbent tube or tubes (diffusive or passive sampling). The sorbed VOCs are subsequently recovered by thermal desorption and analyzed by capillary gas chromatography.

1.4 This practice applies to three basic types of samplers that are compatible with thermal desorption: (1) pumped sorbent tubes containing one or more sorbents; (2) axial diffusive samplers (typically of the same physical dimensions as standard pumped sorbent tubes and containing only one sorbent); and (3) radial diffusive samplers.

1.5 This practice recommends a number of sorbents that can be packed in sorbent tubes, for use in the sampling of a wide range of different volatile organic compounds boiling in the range 0 to 400°C (v.p. 15 to 0.01 kPa at 25°C).

1.5.1 For pumped sampling, sorbent selection is based on breakthrough capacity. Single-bed tubes containing for example sorbent Type A , are appropriate for normal alkanes from n-C6 (hexane) to n-C10 (decane) and substances with similar volatility (v...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6196 − 03(Reapproved 2009)

Standard Practice for

Selection of Sorbents, Sampling, and Thermal Desorption

Analysis Procedures for Volatile Organic Compounds in Air

This standard is issued under the fixed designation D6196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5.1 For pumped sampling, sorbent selection is based on

breakthrough capacity. Single-bed tubes containing for ex-

1.1 This practice is intended to assist in the selection of

3,4

ample sorbent Type A are appropriate for normal alkanes

sorbents and procedures for the sampling and analysis of

2 from n-C (hexane) to n-C (decane) and substances with

6 10

ambient (1) , indoor (2) and workplace (3, 4) atmospheres for

similar volatility (v.p. 15 to 0.3 kPa at 25°C). More volatile

a variety of common volatile organic compounds (VOCs). It

materials should be sampled on stronger sorbents, such as

may also be used for measuring emissions from materials in

3,5

sorbentTypeB .Othersorbenttypesthanthosespecifiedmay

small or full scale environmental chambers or for human

be used, if their breakthrough capacities are adequate and their

exposure assessment.

thermal desorption blanks are sufficiently small. Examples are

1.2 Acomplete listing of VOCs for which this practice has

given in Appendix X2. A broader range of VOCs may be

been tested, at least over part of the measurement range (1.6),

sampled using multi-bed tubes.

isshowninTables1-9.Forothercompoundsthispracticeshall

1.5.2 Guidance given for the selection of sorbents for

be tested according to EN 1076 (pumped); Practice D6246,

pumped monitoring tubes can be applied equally well to axial

ISO 16107, ANSI/ISEA 104, EN 838 or EN 13528-

diffusive sampling tubes. The restriction to a single sampling

1⁄EN13528-2 (diffusive); or other appropriate validation pro-

surface (hence single sorbent), limits the target analyte range

tocols (Sections 13 and 14). (5,1)

that can be monitored by a single tube. However, the unobtru-

sive nature and low cost of diffusive samplers usually means

1.3 This practice is based on the sorption of VOCs from air

that two or more samplers containing different sorbents can be

onto selected sorbents or combinations of sorbents. Sampled

used in parallel without impacting study objectives.

air is either drawn through a tube containing one or a series of

1.5.3 The high sampling rate and associated risk of back

sorbents (pumped sampling) or allowed to diffuse, under

diffusion associated with radial diffusive samplers typically

controlled conditions, onto the sorbent tube or tubes (diffusive

restricts the use of these samplers to compounds of equal or

or passive sampling). The sorbed VOCs are subsequently

lower volatility than benzene. It also means that stronger

recovered by thermal desorption and analyzed by capillary gas

sorbents are generally required for these samplers when

chromatography.

compared with either axial diffusive or pumped sorbent tubes.

1.4 This practice applies to three basic types of samplers

1.6 This practice can be used for the measurement of

that are compatible with thermal desorption: (1) pumped

airborne vapors of these volatile organic compounds over a

sorbent tubes containing one or more sorbents; (2) axial

wide concentration range.

diffusive samplers (typically of the same physical dimensions

1.6.1 With pumped sampling, this practice can be used for

as standard pumped sorbent tubes and containing only one

the measurement of airborne vapors of VOCs in a concentra-

sorbent); and (3) radial diffusive samplers.

3 3

tionrangeofapproximately0.1µg/m to1g/m ,forindividual

1.5 Thispracticerecommendsanumberofsorbentsthatcan

organic compounds in 1–10 Lair samples. The method is also

be packed in sorbent tubes, for use in the sampling of a wide

suitable for the measurement of the airborne concentrations of

range of different volatile organic compounds boiling in the

individual components of volatile organic mixtures, provided

range 0 to 400°C (v.p. 15 to 0.01 kPa at 25°C).

Ifyouareawareofalternativesorbenttypes,pleaseprovidethisinformationto

ThispracticeisunderthejurisdictionofASTMCommitteeD22onAirQuality ASTM Headquarters. Your comments will be carefully considered at a meeting of

and is the direct responsibility of Subcommittee D22.05 on Indoor Air. the responsible technical committee, which you may attend.

Current edition approved March 1, 2009. Published March 2009. Originally An example of sorbent Type A known to perform as specified in this practice

approved in 1997. Last previous edition approved in 2003 as D6196-03. DOI: is Chromosorb 106 manufactured by Manville Corp., USA and available from

10.1520/D6196-03R09. several commercial sources.

2 5

The bold face numbers in parentheses refer to the list of references at the end An example of sorbent Type B known to perform as specified in this practice

of this practice. is Carboxen 569 manufactured by Supelco, Inc., USA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6196 − 03 (2009)

that the total loading of the mixture does not exceed the 1.9 This standard does not purport to address all of the

capacity of the tube. Quantitative measurements are possible safety concerns, if any, associated with its use. It is the

when using validated procedures with appropriate quality responsibility of the user of this standard to establish appro-

assurance measures. priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.6.2 Withaxialdiffusivesampling,thispracticeisvalidfor

the measurement of airborne vapors of volatile organic com-

2. Referenced Documents

pounds in a concentration range of approximately 2 mg/m to

10 mg/m for individual organic compounds for an exposure

2.1 ASTM Standards:

3 3

time of8hor0.3 mg/m to 300 mg/m for individual organic D1356Terminology Relating to Sampling and Analysis of

compounds for an exposure time of four weeks.The method is

Atmospheres

also suitable for the measurement of the airborne concentra-

D3686Practice for Sampling Atmospheres to Collect Or-

tions of individual components of volatile organic mixtures

ganic Compound Vapors (Activated Charcoal Tube Ad-

provided that the total loading of the mixture does not exceed

sorption Method)

the capacity of the tube.

D6246Practice for Evaluating the Performance of Diffusive

Samplers

1.6.3 With radial diffusive sampling, this practice is valid

for the measurement of airborne vapors of volatile organic D6306GuideforPlacementandUseofDiffusionControlled

Passive Monitors for Gaseous Pollutants in Indoor Air

compounds in a concentration range of approximately 0.3

3 3

mg/m to 300 mg/m for individual organic compounds for E355PracticeforGasChromatographyTermsandRelation-

ships

exposuretimesofonetosixhours.Themethodisalsosuitable

for the measurement of the airborne concentrations of indi-

2.2 ISO Standards:

vidual components of volatile organic mixtures provided that

ISO5725Precision of Test Methods

thetotalloadingofthemixturedoesnotexceedthecapacityof

ISO6349GasAnalysis.PreparationofCalibrationGasMix-

the tube.

tures. Permeation Method

1.6.4 The upper limit of the useful range is set by the ISO6879Air Quality. Performance Characteristics and Re-

sorptive capacity of the sorbent used, and by the linear lated Concepts for Air Quality Measuring Methods 1983

dynamicrangeofthegaschromatograph,columnanddetector, ISO16107Workplace Atmospheres—Protocol for Evaluat-

or by the sample splitting capability of the analytical instru- ing the Performance of Diffusive Samplers

mentation used. The sorptive capacity is measured as a

2.3 CEN Standards:

breakthrough volume of air, which determines the maximum

EN482WorkplaceAtmospheres: General Requirements for

air volume that must not be exceeded when sampling with a

the Performance of Procedures for the Measurement of

pump.

Chemical Agents

1.6.5 The lower limit of the useful range depends on the EN838Workplace Atmospheres: Requirements and Test

noise level of the detector and on blank levels of analyte or

Methods for Diffusive Samplers for the Determination of

interfering artifacts, or both, on the sorbent tubes. Gases and Vapours

1.6.6 Artifactsaretypically<1ngfortypicalsamplingtubes EN1076Workplace Atmospheres: Pumped Sorbent Tubes

3,6

for the Determination of Gases and Vapours. Require-

(7.2) containing well-conditioned sorbent Type C and car-

ments and Test Methods

bonaceous sorbents such as graphitized carbon, carbon mo-

EN1232WorkplaceAtmospheres:PumpsforPersonalSam-

lecularsievesandpurecharcoals;at1to5nglevelsforsorbent

3,7

pling of Chemical Agents. Requirements and Test Meth-

Type D and at 5 to 50 ng levels for other porous polymers

3,8

ods

such as sorbent Type A and sorbent Type E . Method

ENISO-16017 (parts 1 and 2)Air Quality—Sampling and

sensitivityistypicallylimitedto0.5µg/m for10Lairsamples

analysis of volatile organic compounds in ambient air,

with this latter group of sorbent types because of their inherent

indoor air and workplace air by sorbent tube/thermal

high background.

desorption/capillary gas chromatography

1.7 This procedure can be used for personal and fixed

EN13528-1Ambient Air Quality—Diffusive samplers for

location sampling. It cannot be used to measure instantaneous

the determination of concentrations of gases and vapours

or short-term fluctuations in concentration. Alternatives for

- Requirements and test methods. Part 1: General require-

on-site measurement include, but are not limited to gas

ments

chromatography and infrared spectrometry.

EN13528-2Ambient Air Quality—Diffusive samplers for

1.8 The sampling method gives a time-weighted average the determination of concentrations of gases and vapours

result.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

An example of sorbent Type C known to perform as specified in this practice Standards volume information, refer to the standard’s Document Summary page on

is Tenax GR manufactured by Enka Research Institute NV, NL. the ASTM website.

7 10

An example of sorbent Type D known to perform as specified in this practice AvailablefromAmericanNationalStandardsInstitute(ANSI),25W.43rdSt.,

is Tenax TA manufactured by Enka Research Institute NV, NL. 4th Floor, New York, NY 10036, http://www.ansi.org.

8 11

An example of sorbent Type E known to perform as specified in this practice Available from European Committee for Standardization (CEN), 36 rue de

is Porapak Q manufactured by Waters Associates Inc., USA. Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

D6196 − 03 (2009)

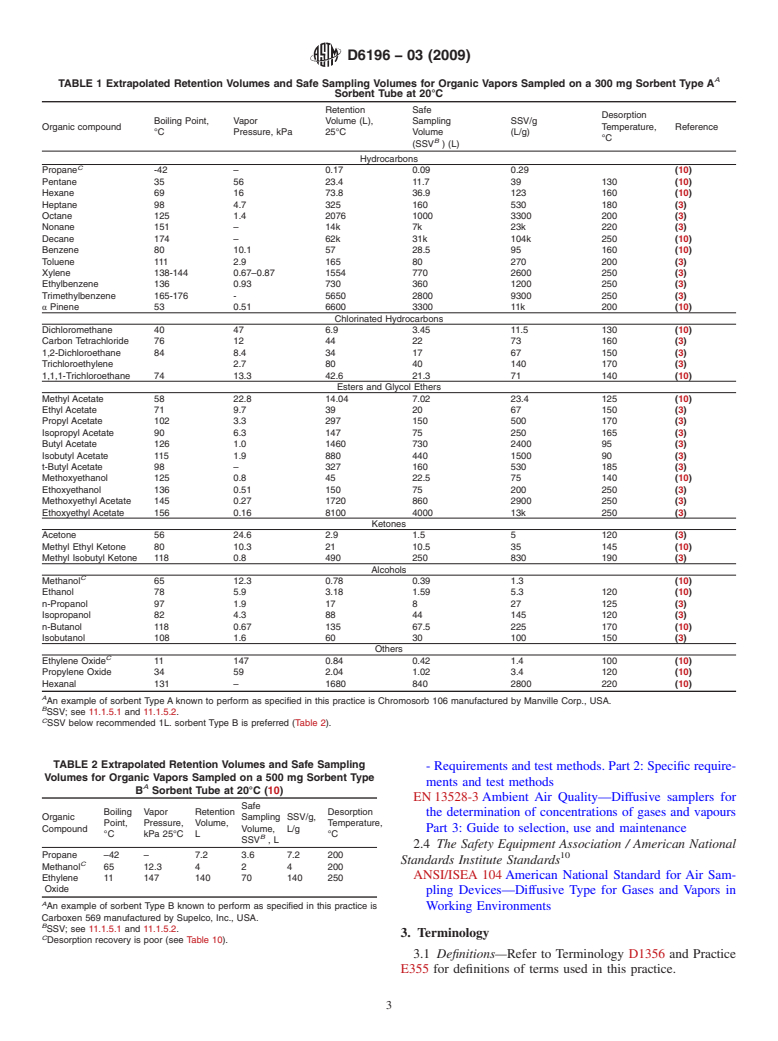

A

TABLE 1 Extrapolated Retention Volumes and Safe Sampling Volumes for Organic Vapors Sampled on a 300 mg Sorbent Type A

Sorbent Tube at 20°C

Retention Safe

Desorption

Boiling Point, Vapor Volume (L), Sampling SSV/g

Organic compound Temperature, Reference

°C Pressure, kPa 25°C Volume (L/g)

°C

B

(SSV )(L)

Hydrocarbons

C

Propane -42 – 0.17 0.09 0.29 (10)

Pentane 35 56 23.4 11.7 39 130 (10)

Hexane 69 16 73.8 36.9 123 160 (10)

Heptane 98 4.7 325 160 530 180 (3)

Octane 125 1.4 2076 1000 3300 200 (3)

Nonane 151 – 14k 7k 23k 220 (3)

Decane 174 – 62k 31k 104k 250 (10)

Benzene 80 10.1 57 28.5 95 160 (10)

Toluene 111 2.9 165 80 270 200 (3)

Xylene 138-144 0.67–0.87 1554 770 2600 250 (3)

Ethylbenzene 136 0.93 730 360 1200 250 (3)

Trimethylbenzene 165-176 - 5650 2800 9300 250 (3)

α Pinene 53 0.51 6600 3300 11k 200 (10)

Chlorinated Hydrocarbons

Dichloromethane 40 47 6.9 3.45 11.5 130 (10)

Carbon Tetrachloride 76 12 44 22 73 160 (3)

1,2-Dichloroethane 84 8.4 34 17 67 150 (3)

Trichloroethylene 2.7 80 40 140 170 (3)

1,1,1-Trichloroethane 74 13.3 42.6 21.3 71 140 (10)

Esters and Glycol Ethers

Methyl Acetate 58 22.8 14.04 7.02 23.4 125 (10)

Ethyl Acetate 71 9.7 39 20 67 150 (3)

Propyl Acetate 102 3.3 297 150 500 170 (3)

Isopropyl Acetate 90 6.3 147 75 250 165 (3)

Butyl Acetate 126 1.0 1460 730 2400 95 (3)

Isobutyl Acetate 115 1.9 880 440 1500 90 (3)

t-Butyl Acetate 98 – 327 160 530 185 (3)

Methoxyethanol 125 0.8 45 22.5 75 140 (10)

Ethoxyethanol 136 0.51 150 75 200 250 (3)

Methoxyethyl Acetate 145 0.27 1720 860 2900 250 (3)

Ethoxyethyl Acetate 156 0.16 8100 4000 13k 250 (3)

Ketones

Acetone 56 24.6 2.9 1.5 5 120 (3)

Methyl Ethyl Ketone 80 10.3 21 10.5 35 145 (10)

Methyl Isobutyl Ketone 118 0.8 490 250 830 190 (3)

Alcohols

C

Methanol 65 12.3 0.78 0.39 1.3 (10)

Ethanol 78 5.9 3.18 1.59 5.3 120 (10)

n-Propanol 97 1.9 17 8 27 125 (3)

Isopropanol 82 4.3 88 44 145 120 (3)

n-Butanol 118 0.67 135 67.5 225 170 (10)

Isobutanol 108 1.6 60 30 100 150 (3)

Others

C

Ethylene Oxide 11 147 0.84 0.42 1.4 100 (10)

Propylene Oxide 34 59 2.04 1.02 3.4 120 (10)

Hexanal 131 – 1680 840 2800 220 (10)

A

An example of sorbent Type A known to perform as specified in this practice is Chromosorb 106 manufactured by Manville Corp., USA.

B

SSV; see 11.1.5.1 and 11.1.5.2.

C

SSV below recommended 1L. sorbent Type B is preferred (Table 2).

TABLE 2 Extrapolated Retention Volumes and Safe Sampling

- Requirements and test methods. Part 2: Specific require-

Volumes for Organic Vapors Sampled on a 500 mg Sorbent Type

ments and test methods

A

B Sorbent Tube at 20°C (10)

EN13528-3Ambient Air Quality—Diffusive samplers for

Safe

Boiling Vapor Retention Desorption

the determination of concentrations of gases and vapours

Organic Sampling SSV/g,

Point, Pressure, Volume, Temperature,

Compound Volume, L/g Part 3: Guide to selection, use and maintenance

°C kPa 25°C L °C

B

SSV ,L

2.4 The Safety Equipment Association / American National

Propane –42 – 7.2 3.6 7.2 200 10

Standards Institute Standards

C

Methanol 65 12.3 4 2 4 200

ANSI/ISEA 104American National Standard for Air Sam-

Ethylene 11 147 140 70 140 250

Oxide

pling Devices—Diffusive Type for Gases and Vapors in

A

An example of sorbent Type B known to perform as specified in this practice is Working Environments

Carboxen 569 manufactured by Supelco, Inc., USA.

B

SSV; see 11.1.5.1 and 11.1.5.2.

3. Terminology

C

Desorption recovery is poor (see Table 10).

3.1 Definitions—Refer to Terminology D1356 and Practice

E355 for definitions of terms used in this practice.

D6196 − 03 (2009)

A

TABLE 3 Extrapolated Retention Volumes and Safe Sampling Volumes for Organic Vapors Sampled on a 200 mg Sorbent Type D

Sorbent Tube at 20°C (3)

Safe

Vapor Desorption

Boiling Point, Retention Sa

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6196–97 Designation: D 6196 – 03 (Reapproved 2009)

Standard Practice for

Selection of Sorbents, Sampling, and Pumped Sampling/

ThermalThermal Desorption Analysis Procedures for Volatile

Organic Compounds in Air

This standard is issued under the fixed designation D 6196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice is intended to assist in the selection of sorbents and procedures for the sampling and analysis of ambient (Ref

1) , indoor (2) and workplace (33, 4) atmospheres for a variety of common volatile organic compounds (VOCs). It may also be

used for measuring emissions from materials in small or full scale environmental chambers or for human exposure assessment.

1.2 A complete listing of VOCs for which this practice has been tested, at least over part of the measurement range (1.51.6),

is shown in Tables 1-6.1-9. For other compounds this practice shall be tested according to EN 1076 (pumped); Practice D 6246,

ISO 16107, ANSI/ISEA 104, EN 838 or EN 13528-1/EN 13528-2 (diffusive); or other appropriate validation protocols (Sections

13 and 14). (45,1)

1.3This practice is based on the sorption of VOCs from air onto selected sorbents or combinations of sorbents. Sampled air is

pulled through a tube containing these sorbents.The sorbedVOCs are subsequently recovered by thermal desorption and analyzed

by capillary gas chromatography.

1.4This practice recommends a number of sorbents that can be packed in sorbent tubes, for use in the sampling of a wide range

of different volatile organic compounds, in the range 0 to 400°C (v.p. 15 to 0.01 kPa at 25°C). Single-bed tubes containing for

example sorbent Type A

1.3 This practice is based on the sorption of VOCs from air onto selected sorbents or combinations of sorbents. Sampled air

is either drawn through a tube containing one or a series of sorbents (pumped sampling) or allowed to diffuse, under controlled

conditions,ontothesorbenttubeortubes(diffusiveorpassivesampling).ThesorbedVOCsaresubsequentlyrecoveredbythermal

desorption and analyzed by capillary gas chromatography.

1.4 This practice applies to three basic types of samplers that are compatible with thermal desorption: (1) pumped sorbent tubes

containing one or more sorbents; ( 2) axial diffusive samplers (typically of the same physical dimensions as standard pumped

sorbent tubes and containing only one sorbent); and (3) radial diffusive samplers.

1.5 This practice recommends a number of sorbents that can be packed in sorbent tubes, for use in the sampling of a wide range

of different volatile organic compounds boiling in the range 0 to 400°C (v.p. 15 to 0.01 kPa at 25°C).

1.5.1 For pumped sampling, sorbent selection is based on breakthrough capacity. Single-bed tubes containing for example

,

3 4

sorbent Type A are appropriate for normal alkanes from n-C (hexane) to n-C (decane) and substances with similar volatility

6 10

3,5

(v.p. 15 to 0.3 kPa at 25°C). More volatile materials should be sampled on stronger sorbents, such as sorbent Type B . Other

sorbent types than those specified may be used, if their breakthrough capacities are adequate and their thermal desorption blanks

are sufficiently small. Examples are given in Appendix X2. A broader range of VOCs may be sampled using multi-bed tubes.

1.5This practice can be used for the measurement of airborne vapors of these volatile organic compounds in a concentration

range of approximately 0.1 µg/m

1.5.2 Guidance given for the selection of sorbents for pumped monitoring tubes can be applied equally well to axial diffusive

sampling tubes. The restriction to a single sampling surface (hence single sorbent), limits the target analyte range that can be

monitored by a single tube. However, the unobtrusive nature and low cost of diffusive samplers usually means that two or more

This practice is under the jurisdiction of ASTM Committee D-22 on Sampling and Analysis of Atmospheres and is the direct responsibility of Subcommittee D22.05

on Indoor Air.

Current edition approved Nov. 10, 1997. Published January 1998.

This practice is under the jurisdiction of ASTM Committee D22 on Air Quality and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

Current edition approved March 1, 2009. Published March 2009. Originally approved in 1997. Last previous edition approved in 2003 as D 6196 - 03.

The bold face numbers in parentheses refer to the list of references at the end of this practice.

If you are aware of alternative sorbent types, please provide this information to ASTM Headquarters. Your comments will be carefully considered at a meeting of the

responsible technical committee, which you may attend.

An example of sorbent Type A known to perform as specified in this practice is Chromosorb 106 manufactured by Manville Corp., USA and available from several

commercial sources.

An example of sorbent Type B known to perform as specified in this practice is Carboxen 569 manufactured by Supelco, Inc., USA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6196 – 03 (2009)

samplers containing different sorbents can be used in parallel without impacting study objectives.

1.5.3 The high sampling rate and associated risk of back diffusion associated with radial diffusive samplers typically restricts

theuseofthesesamplerstocompoundsofequalorlowervolatilitythanbenzene.Italsomeansthatstrongersorbentsaregenerally

required for these samplers when compared with either axial diffusive or pumped sorbent tubes.

1.6 This practice can be used for the measurement of airborne vapors of these volatile organic compounds over a wide

concentration range.

1.6.1 With pumped sampling, this practice can be used for the measurement of airborne vapors of VOCs in a concentration

3 3

range of approximately 0.1 µg/m to 1 g/m , for individual organic compounds in 1–10 Lair samples. The method is also suitable

for the measurement of the airborne concentrations of individual components of volatile organic mixtures, provided that the total

loading of the mixture does not exceed the capacity of the tube. Quantitative measurements are possible when using validated

procedures with appropriate quality assurance measures.

1.5.1The upper limit of the useful range is set by the sorptive capacity of the sorbent used, and by the linear dynamic range of

the gas chromatograph, column and detector, or by the sample splitting capability of the analytical instrumentation used. The

sorptive capacity is measured as a breakthrough volume of air, which determines the maximum air volume that must not be

exceeded when sampling.

1.5.2The lower limit of the useful range depends on the noise level of the detector and on blank levels of analyte or interfering

artifacts, or both, on the sorbent tubes.

1.5.3Artifacts are typically <1ng for well conditioned sorbent Type C

1.6.2 With axial diffusive sampling, this practice is valid for the measurement of airborne vapors of volatile organic compounds

in a concentration range of approximately 2 mg/m to 10 mg/m for individual organic compounds for an exposure time of 8 h

3 3

or 0.3 mg/m to 300 mg/m for individual organic compounds for an exposure time of four weeks. The method is also suitable

for the measurement of the airborne concentrations of individual components of volatile organic mixtures provided that the total

loading of the mixture does not exceed the capacity of the tube.

1.6.3 Withradialdiffusivesampling,thispracticeisvalidforthemeasurementofairbornevaporsofvolatileorganiccompounds

3 3

in a concentration range of approximately 0.3 mg/m to 300 mg/m for individual organic compounds for exposure times of one

to six hours. The method is also suitable for the measurement of the airborne concentrations of individual components of volatile

organic mixtures provided that the total loading of the mixture does not exceed the capacity of the tube.

1.6.4 The upper limit of the useful range is set by the sorptive capacity of the sorbent used, and by the linear dynamic range

of the gas chromatograph, column and detector, or by the sample splitting capability of the analytical instrumentation used. The

sorptive capacity is measured as a breakthrough volume of air, which determines the maximum air volume that must not be

exceeded when sampling with a pump.

1.6.5 The lower limit of the useful range depends on the noise level of the detector and on blank levels of analyte or interfering

artifacts, or both, on the sorbent tubes.

3,6

1.6.6 Artifacts are typically <1ng for typical sampling tubes (7.2) containing well-conditioned sorbent Type C and

carbonaceous sorbents such as graphitized carbon, carbon molecular sieves and pure charcoals; at 1 to 5 ng levels for sorbentType

3,7 3,8

D andat5to50nglevelsforotherporouspolymerssuchassorbentTypeAandsorbentTypeE .Methodsensitivityistypically

limited to 0.5 µg/m for 10 L air samples with this latter group of sorbent types because of their inherent high background.

1.6This1.7 This procedure is compatible with low flow rate personal sampling pumps and can be used for personal and fixed

location sampling. It cannot be used to measure instantaneous or short-term fluctuations in concentration.Alternatives for on-site

measurement include, but are not limited to gas chromatography and infrared spectrometry.

1.7The1.8 The sampling method gives a time-weighted average result.

1.81.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 1356 Terminology Relating to Atmospheric Sampling and Analysis of Atmospheres

D 3686 Practice for Sampling Atmospheres to Collect Organic Compound Vapors (Activated Charcoal Tube Adsorption

Method) Practice for Sampling Atmospheres to Collect Organic Compound Vapors (Activated Charcoal Tube Adsorption

Method)

D 6246 Practice for Evaluating the Performance of Diffusive Samplers

An example of sorbent Type C known to perform as specified in this practice is Tenax GR manufactured by Enka Research Institute NV, NL.

An example of sorbent Type D known to perform as specified in this practice is “Tenax TA”Tenax TA manufactured by Enka Research Institute NV, NL.

An example of sorbent Type E known to perform as specified in this practice is Porapak Q manufactured by Waters Associates Inc., USA.

Annual Book of ASTM Standards, Vol 11.03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D 6196 – 03 (2009)

A

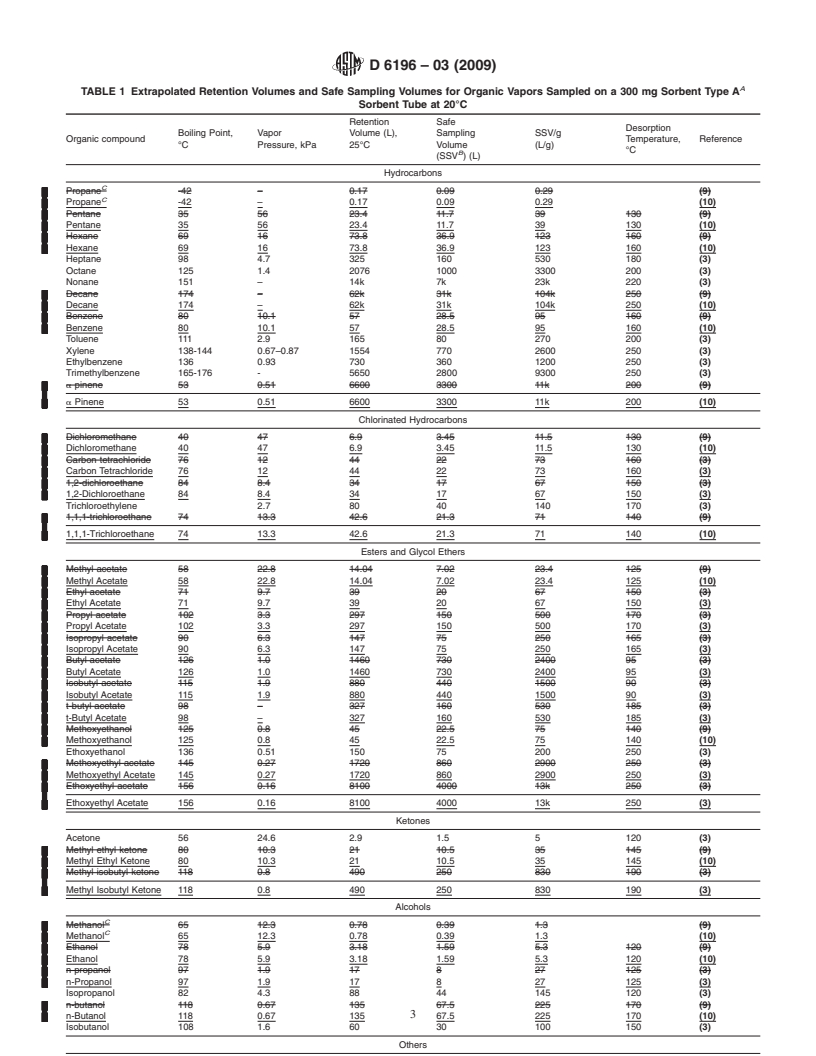

TABLE 1 Extrapolated Retention Volumes and Safe Sampling Volumes for Organic Vapors Sampled on a 300 mg Sorbent Type A

Sorbent Tube at 20°C

Retention Safe

Desorption

Boiling Point, Vapor Volume (L), Sampling SSV/g

Organic compound Temperature, Reference

°C Pressure, kPa 25°C Volume (L/g)

°C

B

(SSV )(L)

Hydrocarbons

C

Propane -42 – 0.17 0.09 0.29 (9)

C

Propane -42 – 0.17 0.09 0.29 (10)

Pentane 35 56 23.4 11.7 39 130 (9)

Pentane 35 56 23.4 11.7 39 130 (10)

Hexane 69 16 73.8 36.9 123 160 (9)

Hexane 69 16 73.8 36.9 123 160 (10)

Heptane 98 4.7 325 160 530 180 (3)

Octane 125 1.4 2076 1000 3300 200 (3)

Nonane 151 – 14k 7k 23k 220 (3)

Decane 174 – 62k 31k 104k 250 (9)

Decane 174 – 62k 31k 104k 250 (10)

Benzene 80 10.1 57 28.5 95 160 (9)

Benzene 80 10.1 57 28.5 95 160 (10)

Toluene 111 2.9 165 80 270 200 (3)

Xylene 138-144 0.67–0.87 1554 770 2600 250 (3)

Ethylbenzene 136 0.93 730 360 1200 250 (3)

Trimethylbenzene 165-176 - 5650 2800 9300 250 (3)

a pinene 53 0.51 6600 3300 11k 200 (9)

a Pinene 53 0.51 6600 3300 11k 200 (10)

Chlorinated Hydrocarbons

Dichloromethane 40 47 6.9 3.45 11.5 130 (9)

Dichloromethane 40 47 6.9 3.45 11.5 130 (10)

Carbon tetrachloride 76 12 44 22 73 160 (3)

Carbon Tetrachloride 76 12 44 22 73 160 (3)

1,2-dichloroethane 84 8.4 34 17 67 150 (3)

1,2-Dichloroethane 84 8.4 34 17 67 150 (3)

Trichloroethylene 2.7 80 40 140 170 (3)

1,1,1-trichloroethane 74 13.3 42.6 21.3 71 140 (9)

1,1,1-Trichloroethane 74 13.3 42.6 21.3 71 140 (10)

Esters and Glycol Ethers

Methyl acetate 58 22.8 14.04 7.02 23.4 125 (9)

Methyl Acetate 58 22.8 14.04 7.02 23.4 125 (10)

Ethyl acetate 71 9.7 39 20 67 150 (3)

Ethyl Acetate 71 9.7 39 20 67 150 (3)

Propyl acetate 102 3.3 297 150 500 170 (3)

Propyl Acetate 102 3.3 297 150 500 170 (3)

Isopropyl acetate 90 6.3 147 75 250 165 (3)

Isopropyl Acetate 90 6.3 147 75 250 165 (3)

Butyl acetate 126 1.0 1460 730 2400 95 (3)

Butyl Acetate 126 1.0 1460 730 2400 95 (3)

Isobutyl acetate 115 1.9 880 440 1500 90 (3)

Isobutyl Acetate 115 1.9 880 440 1500 90 (3)

t-butyl acetate 98 – 327 160 530 185 (3)

t-Butyl Acetate 98 – 327 160 530 185 (3)

Methoxyethanol 125 0.8 45 22.5 75 140 (9)

Methoxyethanol 125 0.8 45 22.5 75 140 (10)

Ethoxyethanol 136 0.51 150 75 200 250 (3)

Methoxyethyl acetate 145 0.27 1720 860 2900 250 (3)

Methoxyethyl Acetate 145 0.27 1720 860 2900 250 (3)

Ethoxyethyl acetate 156 0.16 8100 4000 13k 250 (3)

Ethoxyethyl Acetate 156 0.16 8100 4000 13k 250 (3)

Ketones

Acetone 56 24.6 2.9 1.5 5 120 (3)

Methyl ethyl ketone 80 10.3 21 10.5 35 145 (9)

Methyl Ethyl Ketone 80 10.3 21 10.5 35 145 (10)

Methyl isobutyl ketone 118 0.8 490 250 830 190 (3)

Methyl Isobutyl Ketone 118 0.8 490 250 830 190 (3)

Alcohols

C

Methanol 65 12.3 0.78 0.39 1.3 (9)

C

Methanol 65 12.3 0.78 0.39 1.3 (10)

Ethanol 78 5.9 3.18 1.59 5.3 120 (9)

Ethanol 78 5.9 3.18 1.59 5.3 120 (10)

n-propanol 97 1.9 17 8 27 125 (3)

n-Propanol 97 1.9 17 8 27 125 (3)

Isopropanol 82 4.3 88 44 145 120 (3)

n-butanol 118 0.67 135 67.5 225 170 (9)

n-Butanol 118 0.67 135 67.5 225 170 (10)

Isobutanol 108 1.6 60 30 100 150 (3)

Others

D 6196 – 03 (2009)

TABLE 2 Extrapolated Retention Volumes and Safe Sampling

Volumes for Organic Vapors Sampled on a 500 mg Sorbent Type

A

B Sorbent Tube at 20°C ((910))

Safe

Boiling Vapor R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.