ASTM D1929-96

(Test Method)Standard Test Method for Determining Ignition Temperature of Plastics

Standard Test Method for Determining Ignition Temperature of Plastics

SCOPE

1.1 This fire test response test method² covers a laboratory determination of the flash ignition temperature and spontaneous ignition temperature of plastics using a hot-air furnace.

1.2 Caution-During the course of combustion, gases or vapors, or both, are evolved that may be hazardous to personnel. Adequate precautions should be taken to protect the operator.

1.3 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazards or fire risk assessment of materials, products, or assemblies under actual fire conditions.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 1.2 and 1.4.

Note 1- This test method and ISO 871-1996 are identical in all technical details.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1929 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining Ignition Temperature of Plastics

This standard is issued under the fixed designation D 1929; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 176 Terminology of Fire Standards

2.2 International Standards:

1.1 This fire test response test method covers a laboratory

ISO 871-1996 Plastics—Determination of Ignition Tem-

determination of the flash ignition temperature and spontane-

perature Using a Hot-Air Furnace

ous ignition temperature of plastics using a hot-air furnace.

ISO 5725 Precision of Test Methods—Determination of

1.2 Caution—During the course of combustion, gases or

Repeatability and Reproducibility for Standard Test Meth-

vapors, or both, are evolved that may be hazardous to person-

ods by Interlaboratory Tests

nel. Adequate precautions should be taken to protect the

IEC 584-2 Thermocouples—Part 2: Tolerances

operator.

1.3 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

3.1 Definitions: For definitions of terms relating to fire, see

only.

Terminology E 176.

1.4 This standard should be used to measure and describe

3.2 Definitions of Terms Specific to This Standard:

the properties of materials, products, or assemblies in response

3.2.1 flash ignition temperature (FIT)—the minimum tem-

to heat and flame under controlled laboratory conditions and

perature at which, under specified test conditions, sufficient

should not be used to describe or appraise the fire hazard or

flammable gases are emitted to ignite momentarily upon

fire risk of materials, products, or assemblies under actual fire

application of a small external pilot flame.

conditions. However, results of this test may be used as

3.2.2 glowing combustion—combustion of a material in the

elements of a fire risk assessment which takes into account all

solid phase without flame but with emission of light from the

of the factors which are pertinent to an assessment of the fire

combustion zone, caused by slow decomposition and carbon-

hazard of a particular end use.

ization at various points in the specimen, without general

1.5 This standard does not purport to address all of the

ignition occurring.

safety concerns, if any, associated with its use. It is the

3.2.3 spontaneous ignition temperature or self-ignition tem-

responsibility of the user of this standard to establish appro-

perature (SIT)—the minimum temperature at which the self-

priate safety and health practices and determine the applica-

heating properties of the specimen lead to ignition or ignition

bility of regulatory limitations prior to use. Specific precau-

occurs of itself, under specified test conditions, in the absence

tionary statements are given in 1.2 and 1.4.

of any additional flame ignition source.

NOTE 1—This test method and ISO 871-1996 are identical in all

technical details.

4. Significance and Use

4.1 Tests made under conditions herein prescribed can be of

2. Referenced Documents

considerable value in comparing the relative ignition charac-

2.1 ASTM Standards:

teristics of different materials. Values obtained represent the

D 618 Practice for Conditioning Plastics for Testing

lowest ambient air temperature that will cause ignition of the

material under the conditions of this test. Test values are

expected to rank materials according to ignition susceptibility

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

under actual use conditions.

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

(Section D20.30.03).

4.2 This test is not intended to be the sole criterion for fire

Current edition approved July 10, 1996. Published September 1996. Originally

hazard. In addition to ignition temperatures, fire hazards

published as D 1929 – 62 T. Last previous edition D 1929 – 91a.

include other factors such as burning rate or flame spread,

In 1996, this test method was totally revised to be technically equal to ISO

871-1996, and a specific air velocity is specified, which eliminates the need for

intensity of burning, fuel contribution, products of combustion,

approximations.

and others.

The following reference may be of interest in connection with this test method:

Stetchkin, N. P., “A Method and Apparatus for Determining the Ignition Charac-

teristics of Plastics,” Journal of Research, National Institute of Standards and Annual Book of ASTM Standards, Vol 04.07.

Technology, Vol 43, No. 6, December 1949 (RP 2052), p. 591. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 08.01. Floor, New York, NY 10036.

D 1929

5. Apparatus stand at least 750°C, with an inside diameter of 75 6 5 mm,

length of 2306 20 mm, and thickness of approximately 3 mm,

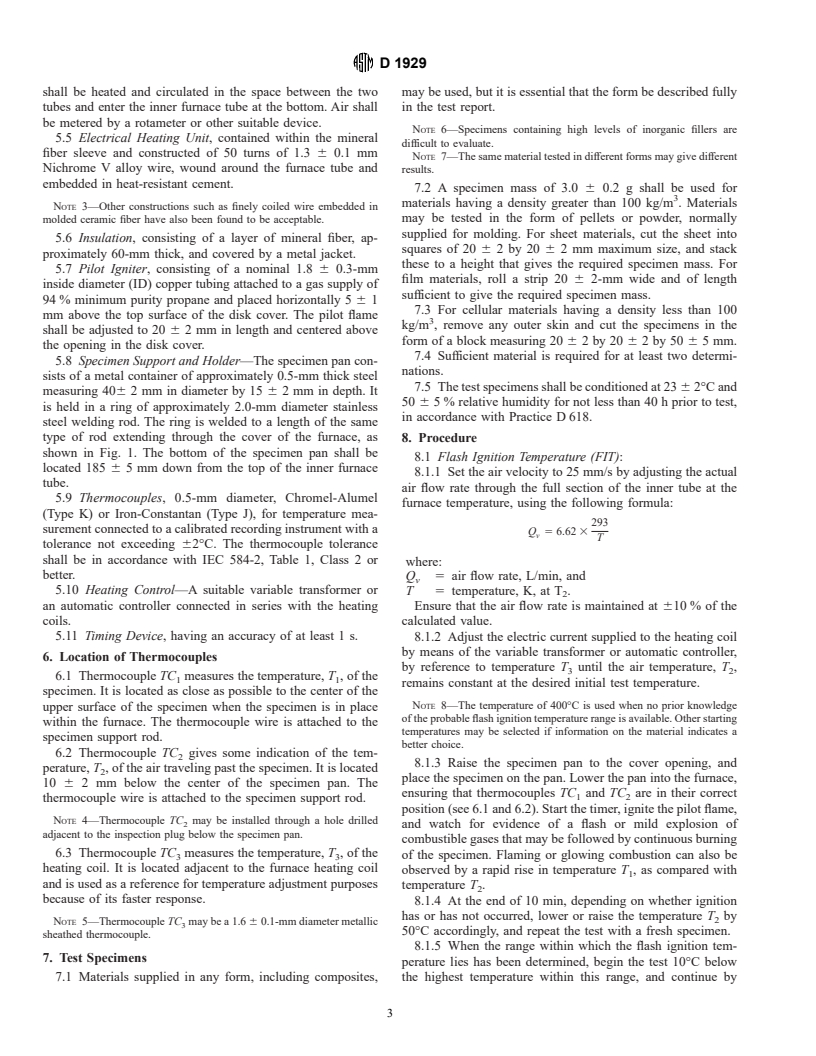

5.1 Hot-Air Ignition Furnace —A furnace similar to that

placed inside the furnace tube and positioned 20 6 2mm

shown in Fig. 1, consisting primarily of an electrical heating

FIG. 1 Cross Section of Hot-Air Ignition Furnace

unit and specimen holder. above the furnace floor on three small spacer blocks. The top

5.2 Furnace Tube—A vertical tube with an inside diameter is covered by a disk of heat-resistant material with a 25 6

of 100 6 5 mm and a length of 230 6 20 mm, made of a 2-mm diameter opening in the center that is used for observa-

ceramic that will withstand at least 750°C. The vertical tube tion and passage of smoke and gases. The pilot flame is located

stands on the furnace floor, fitted with a plug for the removal of immediately above the opening.

accumulated residue.

NOTE 2—Fire resistant materials such as silica glass and stainless steel

5.3 Inner Ceramic Tube—A ceramic tube that will with-

have also been found suitable for this application.

5.4 Air Source—An outside air source to supply clean air

near the top of the annular space between the ceramic tubes,

Model SS1, a furnace available from Atlas Electric Devices Co., 4114 North

Ravenswood Ave., Chicago, IL 60613, has been found suitable for this purpose. through a copper tube at a steady and controllable rate. Air

D 1929

shall be heated and circulated in the space between the two may be used, but it is essential that the form be described fully

tubes and enter the inner furnace tube at the bottom. Air shall in the test report.

be metered by a rotameter or other suitable device.

NOTE 6—Specimens containing high levels of inorganic fillers are

5.5 Electrical Heating Unit, contained within the mineral

difficult to evaluate.

fiber sleeve and constructed of 50 turns of 1.3 6 0.1 mm

NOTE 7—The same material tested in different forms may give different

Nichrome V alloy wire, wound around the furnace tube and results.

embedded in heat-resistant cement.

7.2 A specimen mass of 3.0 6 0.2 g shall be used for

materials having a density greater than 100 kg/m . Materials

NOTE 3—Other constructions such as finely coiled wire embedded in

may be tested in the form of pellets or powder, normally

molded ceramic fiber have also been found to be acceptable.

supplied for molding. For sheet materials, cut the sheet into

5.6 Insulation, consisting of a layer of mineral fiber, ap-

squares of 20 6 2by20 6 2 mm maximum size, and stack

proximately 60-mm thick, and covered by a metal jacket.

these to a height that gives the required specimen mass. For

5.7 Pilot Igniter, consisting of a nominal 1.8 6 0.3-mm

film materials, roll a strip 20 6 2-mm wide and of length

inside diameter (ID) copper tubing attached to a gas supply of

sufficient to give the required specimen mass.

94 % minimum purity propane and placed horizontally 5 6 1

7.3 For cellular materials having a density less than 100

mm above the top surface of the disk cover. The pilot flame

kg/m , remove any outer skin and cut the specimens in the

shall be adjusted to 20 6 2 mm in length and centered above

form of a block measuring 20 6 2by20 6 2by50 6 5 mm.

the opening in the disk cover.

7.4 Sufficient material is required for at least two determi-

5.8 Specimen Support and Holder—The specimen pan con-

nations.

sists of a metal container of approximately 0.5-mm thick steel

7.5 The test specimens shall be conditioned at 23 6 2°C and

measuring 406 2 mm in diameter by 15 6 2 mm in depth. It

50 6 5 % relative humidity for not less than 40 h prior to test,

is held in a ring of approximately 2.0-mm diameter stainless

in accordance with Practice D 618.

steel welding rod. The ring

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.