ASTM F1269-06

(Test Method)Test Methods for Destructive Shear Testing of Ball Bonds

Test Methods for Destructive Shear Testing of Ball Bonds

SIGNIFICANCE AND USE

Failure of microelectronic devices is often due to the failure of an interconnection bond. A common type of interconnection bond is the thermo compression or thermosonic gold wire bond. A very important element of this interconnection is the first bond or ball bond. These test methods can assist in maintaining control of the process for making ball bonds. They can be used to distinguish between weak and nonadherent ball bonds, of both, and bonds that are acceptably strong.

These test methods are appropriate for on-line use in process control, for process development, for purchase specifications, and for research in support of improved yield and reliability. Since the ball shearing method tests only the first bond in a microelectronic wire bond interconnection system, it must be used in a complementary fashion6 ,7 with the wire bond pull test.3

SCOPE

1.1 These test methods cover tests to determine the shear strength of a series of ball bonds made by either thermal compression or thermosonic techniques. Note 1Common usage at the present time considers the term "ball bond'' to include the enlarged spheriodal or nailhead portion of the wire, (produced by the flameoff and first bonding operation in the thermal compression and thermosonic process, or both,) the underlying bonding pad, and the ball bond-bonding pad interfacial-attachment area or weld interface.

1.2 These test methods cover ball bonds made with small diameter (from 18 to 76-µm (0.0007 to 0.003-in.)) wire of the type used in integrated circuits and hybrid microelectronic assemblies.

1.3 These test methods can be used only when the ball height and diameter are large enough and adjacent interfering structures are far enough away to allow suitable placement and clearance (above the bonding pad and between adjacent bonds) of the shear test ram.

1.4 These test methods are destructive. They are appropriate for use in process development or, with a proper sampling plan, for process control or quality assurance.

1.5 A nondestructive procedure is possible; although it may be contra indicated due to the possible interference with adjacent wire bonds and microcircuit components.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1269 − 06

StandardTest Methods for

1

Destructive Shear Testing of Ball Bonds

This standard is issued under the fixed designation F1269; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 These test methods cover tests to determine the shear 2.1 ASTM Standards:

strength of a series of ball bonds made by either thermal F458PracticeforNondestructivePullTestingofWireBonds

compression or thermosonic techniques. F459Test Methods for Measuring Pull Strength of Micro-

electronic Wire Bonds

NOTE 1—Common usage at the present time considers the term “ball

4

2.2 NIST Documents:

bond’’ to include the enlarged spheriodal or nailhead portion of the wire,

(produced by the flameoff and first bonding operation in the thermal NBS Handbook 105-1Specification andTolerances for Ref-

compression and thermosonic process, or both,) the underlying bonding

erence Standards and Field Standards, Weights and Mea-

pad, and the ball bond-bonding pad interfacial-attachment area or weld

sures

interface.

IOLM Class M2-Circular 547-1 Precision Laboratory Stan-

1.2 These test methods cover ball bonds made with small

dards of Mass and Laboratory Weights

diameter (from 18 to 76-µm (0.0007 to 0.003-in.)) wire of the

5

2.3 Military Standard:

type used in integrated circuits and hybrid microelectronic

MIL-STD 883C,Method2010

assemblies.

3. Terminology

1.3 These test methods can be used only when the ball

height and diameter are large enough and adjacent interfering

3.1 Definitions of Terms Specific to This Standard:

structuresarefarenoughawaytoallowsuitableplacementand

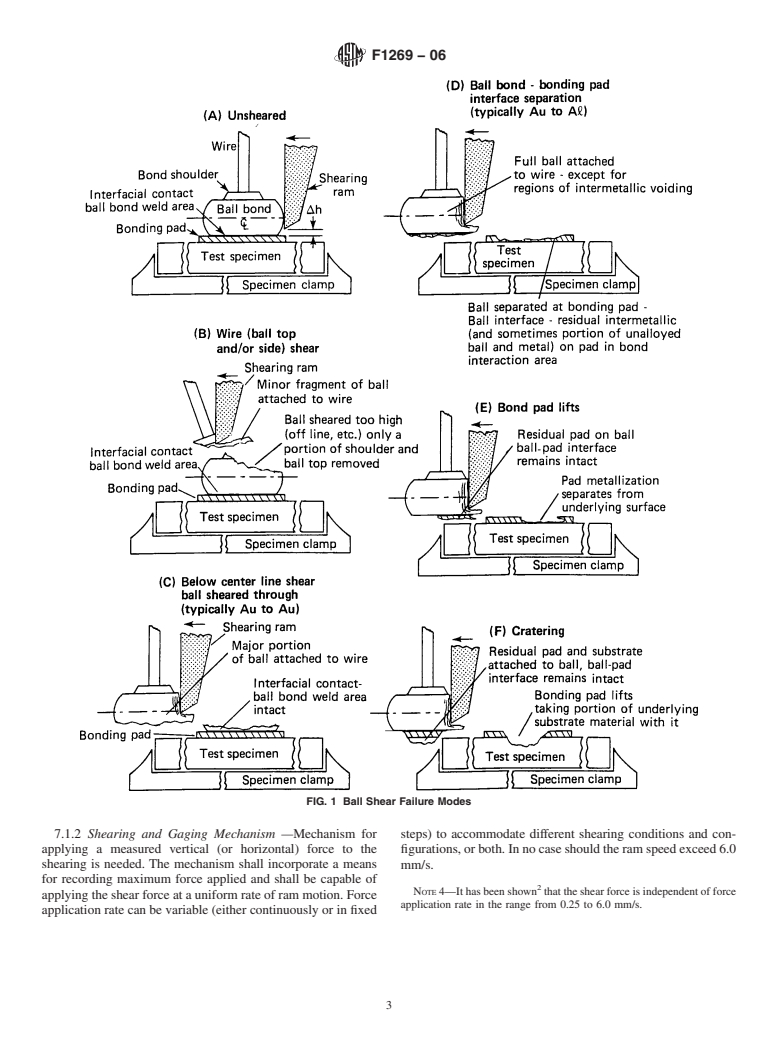

3.1.1 ball lift—a separation of the ball bond at the bonding

clearance(abovethebondingpadandbetweenadjacentbonds)

pad interface with little or no residual (less than 25% of the

of the shear test ram.

bond deformation area) ball metallization remaining on the

bonding pad (that remains essentially intact). In the case of

1.4 Thesetestmethodsaredestructive.Theyareappropriate

gold ball bonds on aluminum pad metallization, a ball lift is

foruseinprocessdevelopmentor,withapropersamplingplan,

defined as a separation of the ball bond at the bonding pad

for process control or quality assurance.

2 interface with little or no intermetallic formation either present

1.5 Anondestructiveprocedureispossible; althoughitmay

or remaining (area of intermetallic less than 25% of the bond

be contra indicated due to the possible interference with

deformation area).

adjacent wire bonds and microcircuit components.

3.1.1.1 Discussion—ntermetallic refers to the aluminum

1.6 The values stated in SI units are to be regarded as the

gold alloy formed at the ball bond pad metallization interfacial

standard. The values given in parentheses are for information

area where a gold ball bond is attached to an aluminum pad

only.

metallization.

1.7 This standard does not purport to address all of the

3.1.2 ball shear (weld interface separation)— an appre-

safety concerns, if any, associated with its use. It is the

ciable intermetallic (in the case of the aluminum-gold system)

responsibility of the user of this standard to establish appro-

and ball metallization, or both, (in the case of the gold-to-gold

priate safety and health practices and determine the applica-

system) remains on the bonding pad (area of remaining metal

bility of regulatory limitations prior to use.

or intermetallic greater than 25% of the bond deformation

area).

1

These test methods are under the jurisdiction of ASTM Committee F01 on

3

Electronics and is the direct responsibility of Subcommittee F01.07 on Wire For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Bonding, Flip Chip, and Tape Automated Bonding. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Jan. 1, 2006. Published February 2006. Originally Standards volume information, refer to the standard’s Document Summary page on

approvedin1989.Lastpreviouseditionapprovedin2001asF1269–89(2001).DOI: the ASTM website.

4

10.1520/F1269-06. Available from the National Technical Information Service, 5285 Port Royal

2

Panousis, N. T., and Fischer, M. W., “Nondestructive Shear Testing of Ball Rd., Springfield, VA 22161.

5

Bonds’’, International Journal of Hybrid Microelectronics , Vol 6, No. 1, 1983, p. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

142. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.