ASTM E209-00

(Practice)Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates

Standard Practice for Compression Tests of Metallic Materials at Elevated Temperatures with Conventional or Rapid Heating Rates and Strain Rates

SCOPE

1.1 This practice covers procedures, equipment, and specimens for compression tests on metallic materials under conditions of (1) conventional rates of heating and straining, (2) rapid rates of heating and straining, and (3) combinations of rapid rates of heating and conventional rates of straining or of conventional rates of heating and rapid rates of straining.

1.2 This practice covers compression tests in which the specimen is heated to a constant and uniform temperature and held at that temperature while it is loaded at a controlled rate of strain. Because of their ductility, metals rarely rupture in compression tests; therefore, the end point of these tests is defined as the point at which 1.5 percent total strain under load is reached in the gage length of the specimen unless rupture occurs before that point. Note 1-In metals with extremely high elastic limit or low modulus of elasticity it is conceivable that 1.5 percent total strain under load could be reached before the 0.2 percent-offset yield strength is reached. In this event the 0.2 percent-offset yield strength will be the end point of the test unless rupture occurs before that point. Note 2-For acceptable compression tests it is imperative that the specimens not buckle before the end point is reached. For this reason the equipment and procedures, as discussed in this recommended practice, must be designed to maintain uniform loading and axial alignment. For sheet-type compression specimens a test jig providing lateral support to the faces of the specimen is generally necessary to prevent buckling.

1.3 Preferred conditions of testing are recommended so that data from different sources conducting the tests will be comparable.

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E209–00

Standard Practice for

Compression Tests of Metallic Materials at Elevated

Temperatures with Conventional or Rapid Heating Rates

and Strain Rates

This standard is issued under the fixed designation E209; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of Metallic Materials

E83 Practice for Verification and Classification of Exten-

1.1 this practice covers compression test in which the

someters

specimenisheatedtoacaonstantanduniformtemperatureand

held at temperature while an axial force is applied at a

3. Apparatus

controlled rate of strain.

3.1 TestingMachines—Machinesusedforcompressiontest-

1.2 This practice covers compression tests in which the

ing shall conform to the requirements of Practices E4.

specimen is heated to a constant and uniform temperature and

3.2 Bearing Blocks and LoadingAdapters—Loadbothends

held at that temperature while it is loaded at a controlled rate

of the compression specimens through bearing blocks or

of strain.

through pin-type adapters that are part of the compression-

NOTE 1—In metals with extremely high elastic limit or low modulus of

testing assembly. Bearing blocks may be designed with flat

elasticity it is conceivable that 1.5 percent total strain under load could be

bearing faces for sheet- or bar-type specimens. Sheet speci-

reached before the 0.2 percent-offset yield strength is reached. In this

mens may also be loaded through pin-type adapters that are

event the 0.2 percent-offset yield strength will be the end point of the test

clamped rigidly to the grip sections of specimens designed for

unless rupture occurs before that point.

theseadapters (1). Themainrequirementisthatthemethodof

NOTE 2—For acceptable compression tests it is imperative that the

specimens not buckle before the end point is reached. For this reason the

applying the force be consistent with maintaining axial align-

equipment and procedures, as discussed in this recommended practice,

mentanduniformloadingonthespecimenthroughoutthetest.

must be designed to maintain uniform loading and axial alignment.

When bearing blocks with flat faces are used, the load-bearing

1.3 Preferred conditions of testing are recommended so that surfacesshouldbesmoothandparallelwithinverycloselimits.

data from different sources conducting the tests will be Thetoleranceforparallelismforthesesurfacesshouldbeequal

comparable. to or closer than that specified for the loaded ends of the

1.4 The values stated in inch-pound units are to be regarded specimens. The design of the equipment should provide

as the standard. adequate rigidity so that parallelism is maintained during

1.5 This standard does not purport to address all of the heating and loading. The bearing blocks or pin-type adapters

safety concerns, if any, associated with its use. It is the should be made of a material that is sufficiently hard at the

responsibility of the user of this standard to establish appro- testing temperature to resist plastic indentation at maximum

priate safety and health practices and determine the applica- force. They should also be of a material or coated with a

bility of regulatory limitations prior to use. material that is sufficiently oxidation resistant at the maximum

testing temperature to prevent the formation of an oxide

2. Referenced Documents

coating that would cause misalignment. In any compression

2.1 ASTM Standards:

testitisimportantthatthespecimenbecarefullycenteredwith

E4 Practices for Force Verification of Testing Machines respect to the bearing blocks, which in turn should be centered

E9 Test Methods of Compression Testing of Metallic Ma-

with respect to the testing machine heads.

terials at Room Temperature

NOTE 3—Bearing blocks with straight cylindrical or threaded holes

E21 Test Methods for Elevated Temperature Tension Tests

depending on specimen design may be used for bar-type specimens

providing the apparatus qualifies in accordance with Section 9.

NOTE 4—Bearing blocks of an adjustable type to provide parallel

loading surfaces are discussed in Test Methods E9. Bearing blocks with

ThispracticeisunderthejurisdictionofASTMCommitteeE-28onMechanical

a spherical seat for the upper block are also shown.

Testing and is the direct responsibility of Subcommittee E28.10 on Effect of

Elevated Temperature on Properties.

Current edition approved May 10, 2000. Originally published as E 209–1963.

Last previous edtion, E209–65(93).

2 3

Annual Book of ASTM Standards, Vol 03.01. Boldface numbers in parentheses refer to references at the end of this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E209

3.3 Subpresses—A subpress or other alignment device is

necessary in order to maintain suitable alignment when testing

specimens that are not laterally supported, unless the testing

machinehasbeendesignedspecificallyforaxialalignmentand

uniform application of force in elevated-temperature compres-

sion testing.Asubpress for room-temperature testing is shown

in Test Methods E9. For elevated-temperature compression

testing, the subpress must accommodate the heating and

loading devices and the temperature-sensing elements. The

design of the subpress is largely dependent on the size and

strength of the specimens, the temperatures to be used, the

environment, and other factors. It must be designed so the ram

does not jam or tilt the frame as a result of heating or

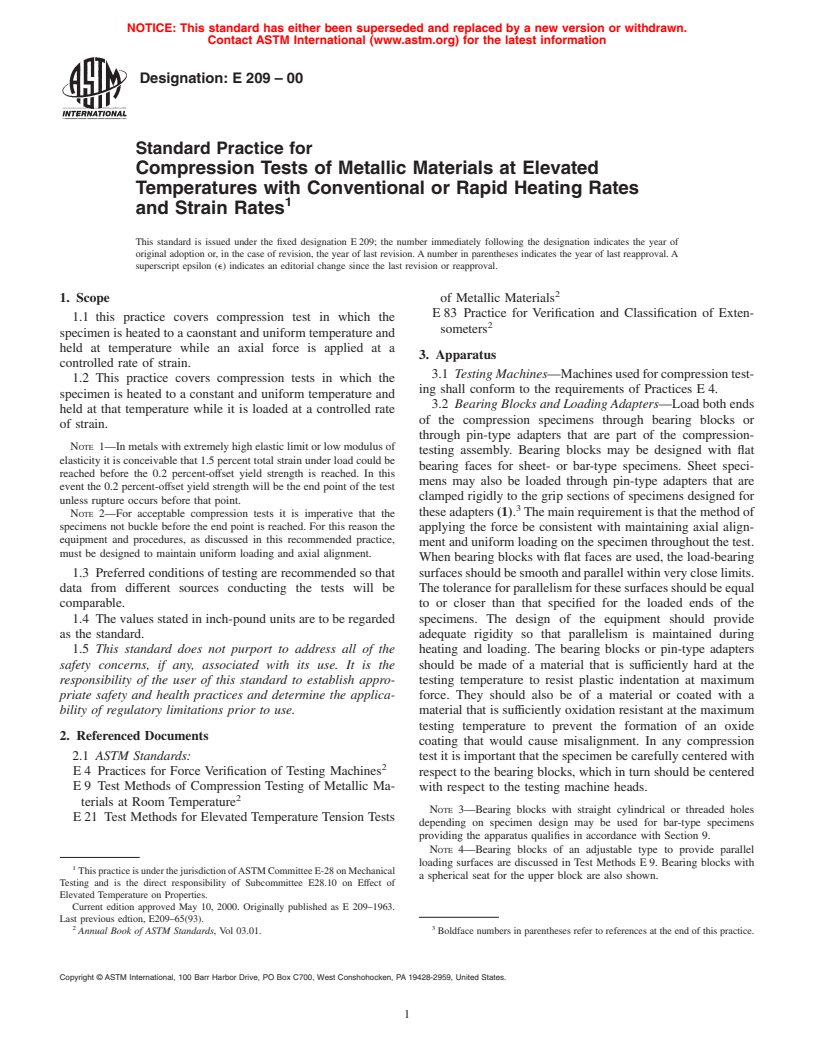

FIG. 1 Specimen Side Support Plates (Ref 4)

application of force. If the bearing faces of the subpress, the

opposite faces of both bearing blocks, and the ends of the

specimen are respectively plane and parallel within very close

limits, it is unnecessary to use adjustable or spherical seats. In side-support plate that has been used in compression jigs to

any case, the specimen should be properly centered in the 1800°F (982°C) is shown in Fig. 1(b) (4). This is an assembly

subpress. ofsmalltitaniumcarbideballsbackedupbyatitaniumcarbide

plate. The balls protrude through holes in the front retaining

3.4 CompressionTestingJigs—Whentestingsheetmaterial,

plate.Theholesfortheballsarelargeenoughtoallowrotation

buckling of the specimen during application of compessive

andtranslationofeachballwhileatthesametimeretainingthe

forces must be prevented. This may be accomplished by using

balls in the plate assembly. The spacing of the balls, which is

a jig containing side-support plates that bear against the faces

normally about ⁄8 in. (3.2 mm), determines the minimum

of the specimen. The jig must afford a suitable combination of

specimen thickness that can be tested without buckling be-

lateral-support pressure and spring constant to prevent buck-

tween the balls. Rational values of the ball spacing can be

lingwithoutinterferingwithaxialdeformationofthespecimen

obtained from calculations based upon the plastic buckling of

(1). Although suitable combinations vary somewhat with

simply supported plates where the plate width can be taken as

variationsinspecimenmaterialandthickness,testingtempera-

the ball spacing. Another type of jig has a number of leaf-

ture, and accuracy of alignment, acceptable results can be

springsupportsoneachsideofthespecimen(3, 5).Thisdesign

obtained with rather wide ranges of lateral-support pressure

islimitedtoatemperaturerangeinwhichthemetalleaf-spring

and spring constant for any given test conditions. Generally,

elements can support the specimen satisfactorily. Jigs for use

the higher the spring constant of the jig, the lower the

with specimens that are heated by self resistance are discussed

lateral-support pressure that is required. Proper adjustment of

in Ref 1, 6 and 7, which also provide quantitative information

these test variables may be established in preliminary verifi-

on the effects of lubrication, lateral-support pressure, spring

cation tests for the equipment (Section 9).

constant, and misalignment.

3.4.1 This practice does not intend to designate specific

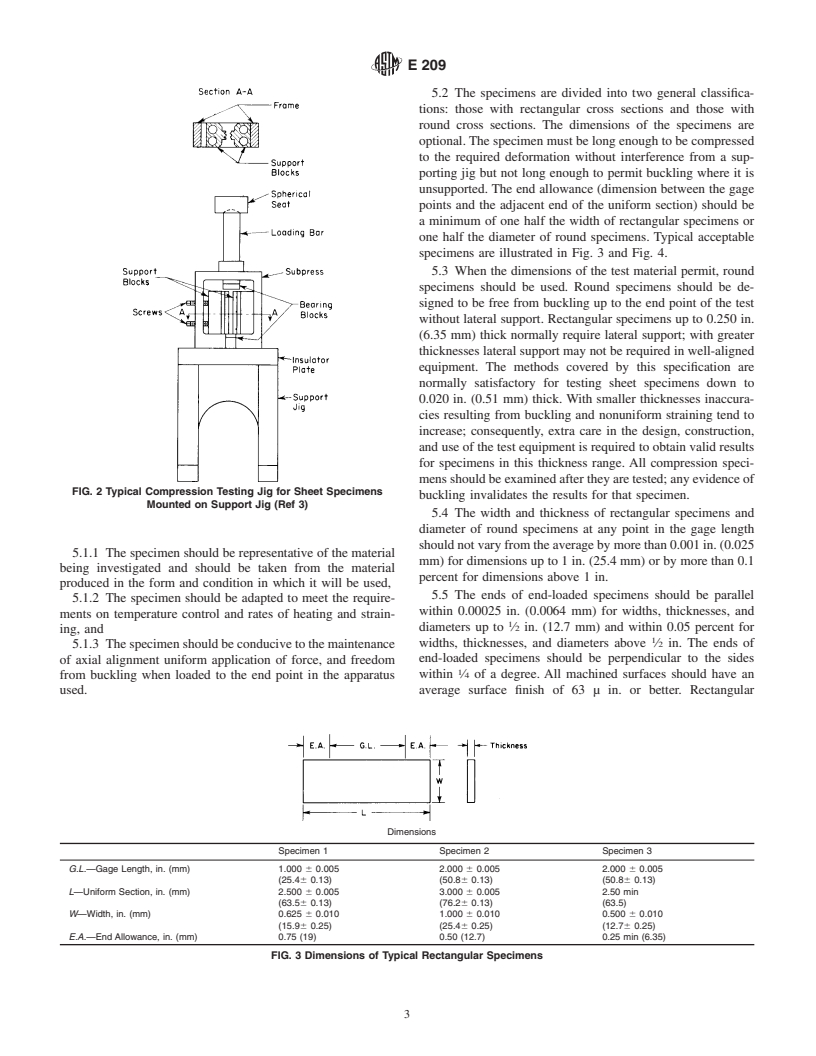

3.4.2 The side-support plates are assembled in a frame that

compressionjigsfortestingsheetmetals,butmerelytoprovide

is part of the jig.Atypical frame and jig assembly is shown in

a few illustrations and references to jigs that have been used

Fig.2.Afurnaceisplacedaroundthejigafterthespecimenand

successfully. Many other jigs are acceptable provided they

extensometerareassembledinthejig.Theholesinthesupport

prevent buckling and pass the qualification tests set forth in

blocks are for auxiliary cartridge-type heaters.

Section 9. Satisfactory results have been obtained in room-

temperature testing using the jigs illustrated in Test Methods

4. Heating Apparatus

E9. These jigs usually require that the specimen be lubricated

4.1 Theapparatusandmethodforheatingthespecimensare

to permit normal compression on loading. For elevated-

not specified, but in present practice the following are mainly

temperature testing, modified jigs that accommodate the heat-

used.

ingandstrain-measuringequipmentaswellasthetemperature-

4.1.1 The resistance of the specimen gage length to the

sensing elements must be used. A number of compression-

passage of an electric current,

testingjigshavebeenevaluatedspecificallyforperformancein

4.1.2 Resistance heating supplemented by radiant heating,

elevated-temperature tests (2, 3). The preferred type depends

4.1.3 Radiant heating,

on the material, its thickness, and the temperatures involved.

4.1.4 Induction heating, or

For moderately elevated temperatures, one of the room-

4.1.5 Convection heating with circulating-air furnace.

temperaturedesignsmaybeusedinanoveninwhichtheairis

4.2 Theapparatusmustbesuitableforheatingthespecimen

circulated to provide uniform heating. One design for side-

under the conditions specified in Section 5.

support plates that has been found satisfactory for use at

temperatures up to 1000°F (538°C) when lubricated with

5. Test Specimen

graphiteisshowninFig.1(a)(4).Longitudinalgroovesarecut

ineachplatewiththegroovesoffsetacrossthethicknessofthe 5.1 Thesizeandshapeofthetestspecimenshouldbebased

specimen.Theseplatesaremadeoftitaniumcarbide.Atypeof on three requirements as follows:

E209

5.2 The specimens are divided into two general classifica-

tions: those with rectangular cross sections and those with

round cross sections. The dimensions of the specimens are

optional.Thespecimenmustbelongenoughtobecompressed

to the required deformation without interference from a sup-

porting jig but not long enough to permit buckling where it is

unsupported. The end allowance (dimension between the gage

points and the adjacent end of the uniform section) should be

a minimum of one half the width of rectangular specimens or

one half the diameter of round specimens. Typical acceptable

specimens are illustrated in Fig. 3 and Fig. 4.

5.3 When the dimensions of the test material permit, round

specimens should be used. Round specimens should be de-

signed to be free from buckling up to the end point of the test

without lateral support. Rectangular specimens up to 0.250 in.

(6.35 mm) thick normally require lateral support; with greater

thicknesses lateral support may not be required in well-aligned

equipment. The methods covered by this specification are

normally satisfactory for testing sheet specimens down to

0.020 in. (0.51 mm) thick. With smaller thicknesses inaccura-

cies resulting from buckling and nonuniform straining tend to

increase; consequently, extra care in the design, construction,

and use of the test equipment is required to obtain valid results

for specimens in this thickness range. All compression speci-

mensshouldbeexaminedaftertheyaretested;anyevidenceof

FIG. 2 Typical Compression Testing Jig for Sheet Specimens

buckling invalidates the results for that specimen.

Mounted on Support Jig (Ref 3)

5.4 The width and thickness of rectangular specimens and

diameter of round specimens at any point in the gage length

shouldnotvaryfromtheaveragebymorethan0.001in.(0.025

5.1.1 The specimen should be representative of the material

mm) for dimensions up to 1 in. (25.4 mm) or by more than 0.1

being investigated and should be taken from the material

percent for dimensions above 1 in.

produced in the form and condition in which it will be used,

5.5 The ends of end-loaded specimens should be parallel

5.1.2 The specimen should be adapted to meet the require-

within 0.00025 in. (0.0064 mm) for widths, thicknesses, and

ments on temperature control and rates of heating and strain-

diameters up to ⁄2 in. (12.7 mm) and within 0.05 percent for

ing, and

widths, thicknesses, and diameters above ⁄2 in. The ends of

5.1.3 Thespecimenshouldbeconducivetothemaintenance

end-loaded specimens should be perpendicular to the sides

of axial alignment uniform application of force, and freedom

within ⁄4 of a degree. All machined surfaces should have an

from buckling when loaded to the end point in the apparatus

used. average surface finish of 63 µ in. or better. Rectangular

Dimensions

Specimen 1 Specimen 2 Specimen 3

G.L.—Gage Length, in. (mm) 1.000 6 0.005 2.000 6 0.005 2.000 6 0.005

(25.46 0.13) (50.86 0.13) (50.86 0.13)

L—Uniform Section, in. (mm) 2.500 6 0.005 3.000 6 0.005 2.50 min

(63.56 0.13) (76.26 0.13) (63.5)

W—Width, in. (mm) 0.625 6 0.010 1.000 6 0.010 0.500 6 0.010

(15.96 0.25) (25.46 0.25) (12.76 0.25)

E.A.—End Allowance, in. (mm) 0.75 (19) 0.50 (12.7) 0.25 min (6.35)

FIG. 3 Dimensions of Typical Rectangular Specimens

E209

Dimensions

Specimen 1 Specimen 2 Specimen 3

G.L.—Gage Length, in. 1.000 6 0.005 2.000 6 0.005 1.000 6 0.005

(25.46 0.13) (50.86 0.13) (25.46 0.13)

L—Uniform Section, in. 1.500 6 0.005 3.375 6 0.05 1.500 6 0.005

(38.16 0.13) (85.86 1.27) (38.16 0.13)

D—Diameter, in. 0.500 6 0.010 1.125 6 0.010 0.375 6 0.010

(12.76 0.25) (28.66 0.25) (9.56 0.25)

E.A.—End Allowance, in. 0.25 (6.35) 0.69 (17.5) 0.25 (6.35)

NOTE 1—Specimen 3, because of its smaller diameter, is especially suitable for tests in which rapid heating is desired.

FIG. 4 Dimensions of Typical Round Specimens

specimensshouldhaveawidthofmaterial,equaltoatleastthe bothtypesoftestsshouldbethesame.Theheatingandholding

thickness of the specimen, machined from all sheared or time actually used should be reported.

stamped edges. 6.2 Rapid Heating—When a rapid heating rate is desired,

5.6 Shoulderedspecimensmaybeusedinlieuofspecimens the preferred conditions for heating the gage length of the

with uniform width or diameter, provided the method of specimen a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.