ASTM B666/B666M-01

(Practice)Standard Practice for Identification Marking of Aluminum and Magnesium Products

Standard Practice for Identification Marking of Aluminum and Magnesium Products

SCOPE

1.1 This practice establishes the physical item marking requirements for identification purposes for aluminum and magnesium products. Package marking for shipment and inspection acceptance is not within the scope of this standard.

1.2 The values stated in either inch-pound units or SI are to be regarded separately as standard. The SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems will result in nonconformance with the practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 666/B 666M – 01

Standard Practice for

Identification Marking of Aluminum and Magnesium

1

Products

This standard is issued under the fixed designation B 666/B 666M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* H35.1 Alloy and Temper Designation Systems for Alumi-

2

num

1.1 This practice establishes the physical item marking

H35.1(M) Alloy and Temper Designation Systems for Alu-

requirements for identification purposes for aluminum and

2

minum

magnesium products. Package marking for shipment and

2.4 Military Standards:

inspection acceptance is not within the scope of this standard.

MIL-STD-409 Alloy Nomenclature and Temper Designa-

1.2 The values stated in either inch-pound units or SI are to

3

tion System for Magnesium Base Alloys

be regarded separately as standard. The SI units are shown in

brackets. The values stated in each system are not exact

3. Terminology

equivalents; therefore, each system must be used indepen-

3.1 Definitions:

dently of the other. Combining values from the two systems

3.1.1 sheet—a rolled wrought product rectangular in cross

will result in nonconformance with the practice.

section and form 0.006 through 0.249 in. [over 0.15 through

1.3 This standard does not purport to address all of the

6.30 mm] thick with sheared, slit, or sawed edges.

safety concerns, if any, associated with its use. It is the

3.1.2 coiled sheet—sheet in coils with slit edges.

responsibility of the user of this standard to establish appro-

3.1.3 flat sheet—sheet with sheared, slit, or sawed edges,

priate safety and health practices and determine the applica-

which has been flattened or leveled.

bility of regulatory limitations prior to use.

3.1.4 plate—a rolled wrought product rectangular in cross

2. Referenced Documents section and form 0.250 in. or thicker [over 6.30 mm in

thickness], with either sheared or sawed edges.

2.1 The following documents of the issue in effect on the

3.1.5 circles—circles cut from coiled sheet, flat sheet or

date of material purchase form a part of this specification to the

plate.

extent referenced herein:

3.1.6 tread plate—sheet or plate having a raised, figured

2.2 ASTM Standards:

pattern on one surface to provide improved traction.

B 361 Specification for Factory-Made Wrought Aluminum

2 3.1.7 foil—a rolled wrought product rectangular in cross

and Aluminum-Alloy Welding Fittings

section of thickness less than 0.006 in. [up through 0.15 mm].

B 404 Specification for Aluminum and Aluminum-Alloy

3.1.8 rod—a solid cylindrical wrought product that is long

Seamless Condenser and Heat-Exchanger Tubes with In-

2

in relation to cross section, which is 0.375 in. or greater [over

tegral Fins

10.00 mm] in diameter.

B 404M Specification for Aluminum and Aluminum-Alloy

3.1.9 bar—asolidwroughtproductthatislonginrelationto

Seamless Condenser and Heat-Exchanger Tubes with In-

2 cross section, which is square or rectangular (excluding plate

tegral Fins

and flattened wire) with sharp or rounded corners or edges, or

B 547 Specification for Aluminum and Aluminum-Alloy

2

is a regular hexagon or octagon, and in which at least one

Formed and Arc-Welded Round Tube

perpendicular distance between parallel faces is 0.375 in. or

B 881 Terminology Relating to Aluminum- and

2

greater [over 10.00 mm].

Magnesium-Alloy Products

3.1.10 profile—a wrought product that is long in relation to

2.3 ANSI Standards:

its cross-sectional dimensions and has a cross section other

than that of sheet, plate, rod, bar, tube, or wire.

3.1.11 structural profile—a profile, rolled or extruded, in

1

This practice is under the jurisdiction of ASTM Committee B07 on Light

certain standard alloys, tempers, sizes, and sections, such as

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on

Aluminum Alloy Wrought Products.

Current edition approved Apr. 10, 2001. Published May 2001. Originally

e1 3

published as B 666 – 80. Last previous edition B 666/B 666M – 96 . Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

2

Annual Book of ASTM Standards, Vol 02.02. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

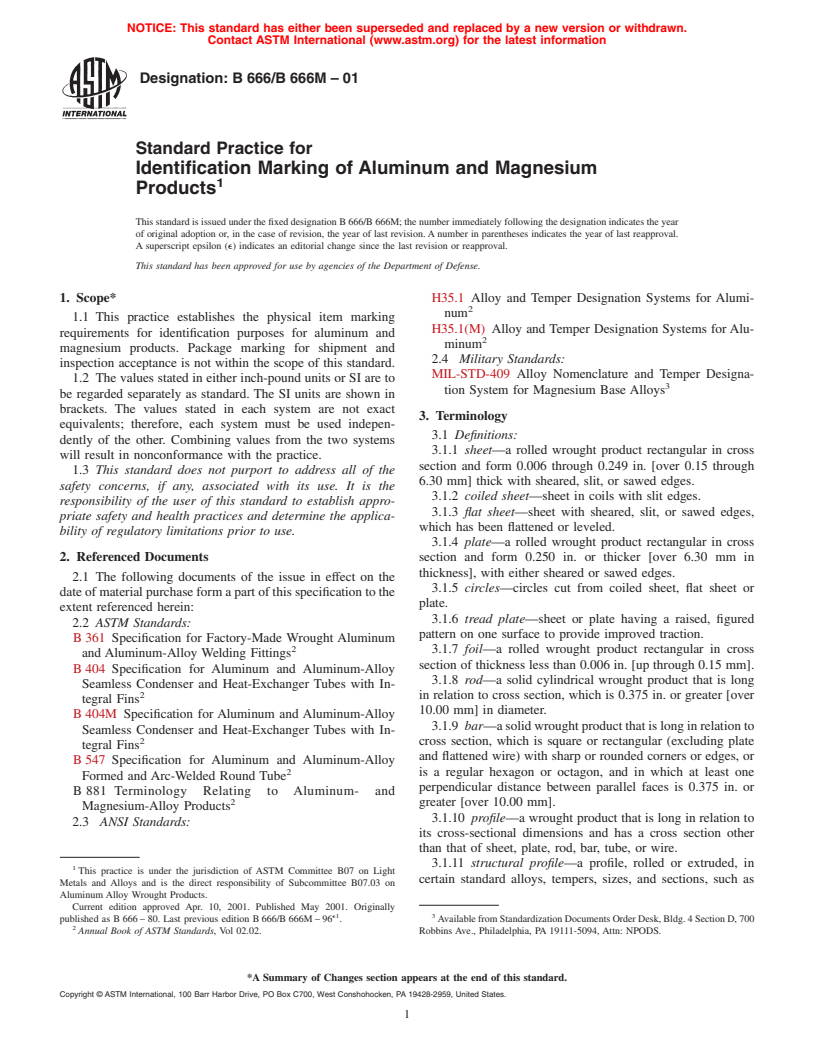

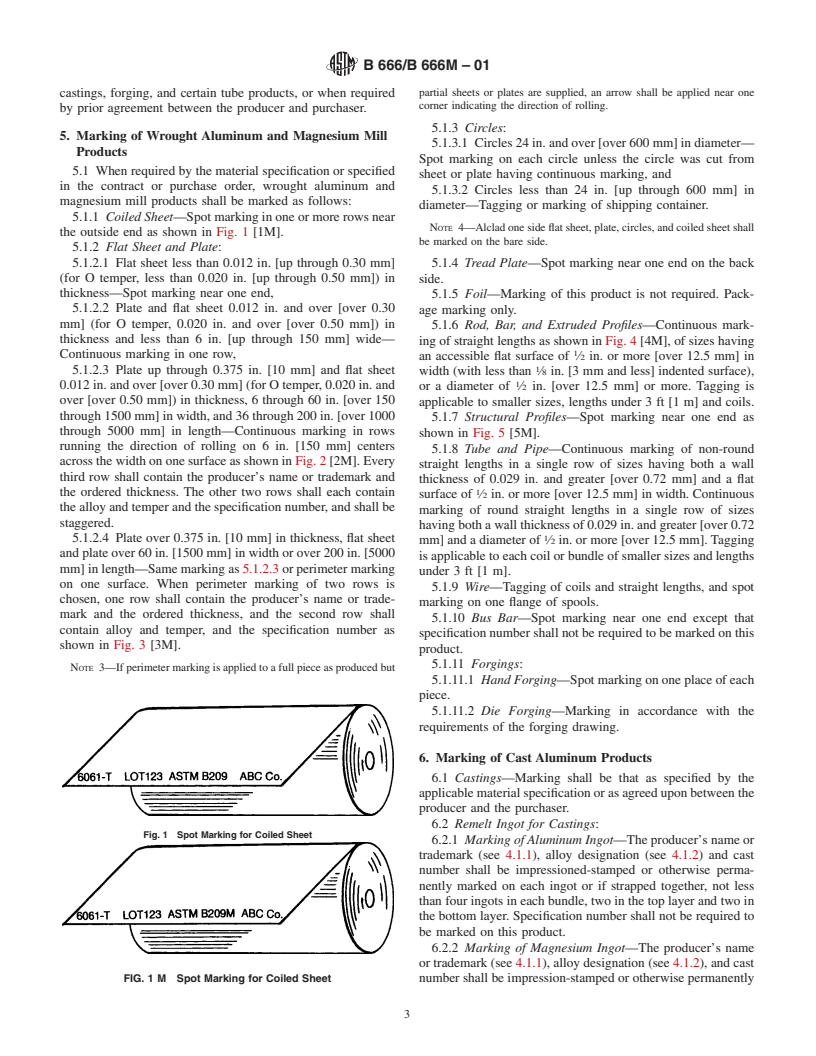

B 666/B 666M – 01

NOTE 1—The company that performs nothing more than a simple

angles, channels, tees, zees, I-beams, and H-sections; com-

shearing or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.