ASTM E539-07

(Test Method)Standard Test Method for X-Ray Fluorescence Spectrometric Analysis of 6Al-4V Titanium Alloy

Standard Test Method for X-Ray Fluorescence Spectrometric Analysis of 6Al-4V Titanium Alloy

SIGNIFICANCE AND USE

This method is suitable for providing data on the chemical composition of 6Al-4V titanium alloys for the scope elements. It is intended to be used for routine production control and for determination of chemical composition for the purpose of certifying material specification compliance. Additionally, the analytical performance data included with this method may be used as a benchmark to determine if similar X-ray spectrometers provide equivalent precision and accuracy.

SCOPE

1.1 This test method covers the X-ray fluorescence analysis of 6Al-4V titanium alloy for the following elements in the ranges indicated:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E539–07

Standard Test Method for

X-Ray Fluorescence Spectrometric Analysis of 6Al-4V

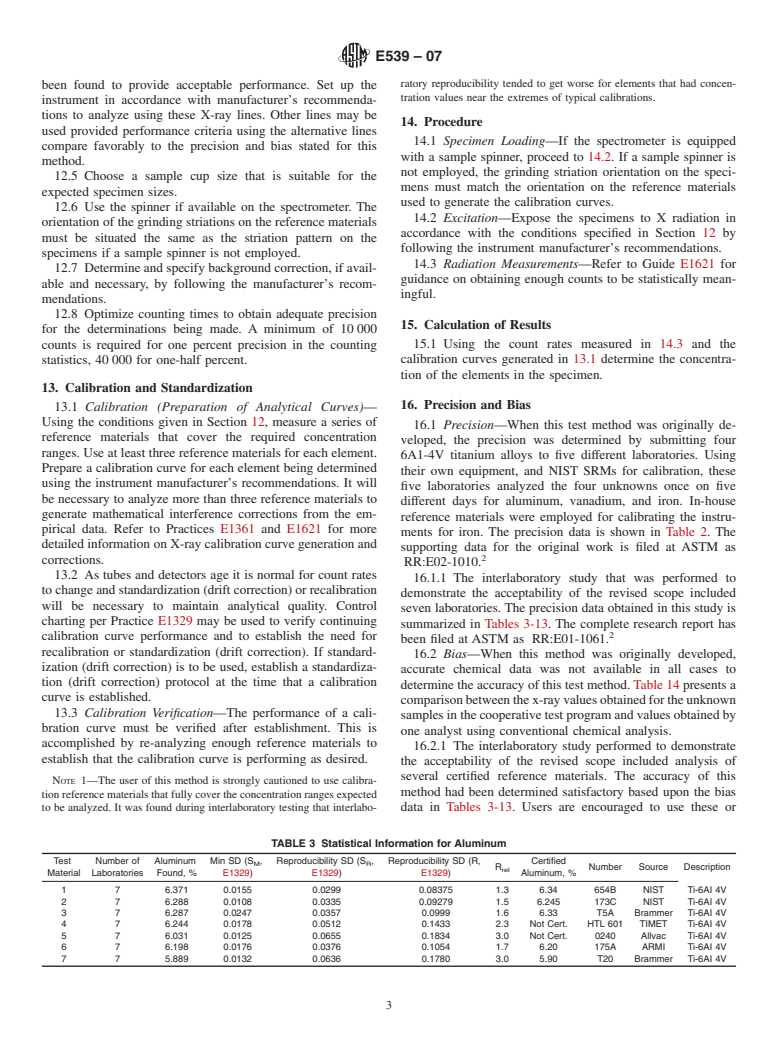

1

Titanium Alloy

This standard is issued under the fixed designation E539; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1361 Guide for Correction of Interelement Effects in

2 X-Ray Spectrometric Analysis

1.1 Thistestmethod coverstheX-rayfluorescenceanalysis

E1621 Guide for X-Ray Emission Spectrometric Analysis

of 6Al-4V titanium alloy for the following elements in the

ranges indicated:

3. Terminology

Element Concentration Range, %

3.1 Definitions:

Aluminum 4.6 to 7.2

Chromium 0.023 to 0.071

3.1.1 For definitions of terms used in this test method, refer

Copper 0.015 to 0.066

to Terminology E135.

Iron 0.1 to 0.3

Manganese 0.009 to 0.068

4. Summary of Test Method

Molybdenum 0.018 to 0.072

Nickel 0.026 to 0.073

4.1 The specimen is finished to a clean, uniform surface and

Silicon 0.03 to 0.06

then irradiated by high energy X-ray photons. Secondary X-

Tin 0.016 to 0.076

Vanadium 2.6 to 5.4

rays are produced and emitted from the sample. This radiation

Zirconium 0.009 to 0.064

is diffracted by means of analyzing crystals and focused on a

1.2 This standard does not purport to address all of the detector which measures the count rates at specified wave-

safety concerns, if any, associated with its use. It is the lengths. The outputs of the detectors in voltage pulses are

responsibility of the user of this standard to establish appro- integrated or counted. Radiation measurements are made based

priate safety and health practices and determine the applica- on the time required to reach a fixed number of counts, or on

bility of regulatory limitations prior to use. Specific precau- the total counts obtained for a fixed time (generally expressed

tionary statements are given in Section 10. in counts per unit time). Concentrations of the elements are

determined by relating the measured radiation of unknown

2. Referenced Documents

samples to calibration curves prepared using reference materi-

3

2.1 ASTM Standards: als of known compositions.

E135 Terminology Relating to Analytical Chemistry for

5. Significance and Use

Metals, Ores, and Related Materials

5.1 This method is suitable for providing data on the

E1172 Practice for Describing and Specifying a

chemical composition of 6Al-4V titanium alloys for the scope

Wavelength-Dispersive X-Ray Spectrometer

elements. It is intended to be used for routine production

E1329 PracticeforVerificationandUseofControlChartsin

control and for determination of chemical composition for the

Spectrochemical Analysis

purpose of certifying material specification compliance. Addi-

tionally, the analytical performance data included with this

method may be used as a benchmark to determine if similar

1

This test method is under the jurisdiction of ASTM Committee E01 on

X-ray spectrometers provide equivalent precision and accu-

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

racy.

responsibility of Subcommittee E01.06 on Ti, Zr, W, Mo, Ta, Nb, Hf, Re.

Current edition approved June 1, 2007. Published June 2007. Originally

approved in 1975. Last previous edition approved in 2006 as E539 – 06. DOI: 6. Interferences

10.1520/E0539-07.

2 6.1 Line overlaps, interelement effects and matrix effects

Supporting data for this test method as determined by cooperative testing have

may exist for some of the scope elements. A list of potential

been filed at ASTM International Headquarters and may be obtained by requesting

Research Report RR:E2-1010 and Research Report RR:E01-1061.

line overlaps is provided in section 6.2. Modern X-ray spec-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

trometers provide software for generation of mathematical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

corrections to model the effects of line overlaps, interelement

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and matrix interferences. The user of this method may choose

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E539–07

to use these mathematical corrections for analysis. Guide as well as state and local regulations relating to radiation

E1621 provide a more extensive overview of mathematical hygiene must be followed. Additionally, the safety guidelines

interference correction methods. established by the instrument manufacturer should be fol-

6.2 Potential lin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.