ASTM G74-82(1996)e1

(Test Method)Standard Test Method for Ignition Sensitivity of Materials to Gaseous Fluid Impact

Standard Test Method for Ignition Sensitivity of Materials to Gaseous Fluid Impact

SCOPE

1.1 This method describes a technique to determine the relative sensitivity of materials to dynamic pressure impacts by gases such as oxygen, air, or blends of gases containing oxygen.

1.2 This method describes the test apparatus and test procedures that may be employed in the evaluation of materials for use in gases under dynamic pressure operating conditions up to gage pressures of 10 000 psi (69 MPa) at ambient temperature.

1.3 This method is primarily a test for ranking of materials. This method is not necessarily valid for determination of the sensitivity of the materials in an "as-used" configuration since the material sensitivity may be altered because of changes in material configuration, usage, and environment. This method can be employed to provide batch-to-batch acceptance data. Acceptability of any material may be based on its performance at a particular test pressure, or test pressure may be varied to determine the reaction threshold of a material, as specified by the user.

1.4 The criteria used for the acceptance, retest, and rejection of materials for any given application shall be determined by the user and are not fixed by this method.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: G 74 – 82 (Reapproved 1996)

Standard Test Method for

Ignition Sensitivity of Materials to Gaseous Fluid Impact

This standard is issued under the fixed designation G 74; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in March 1996.

1. Scope MIL-D-16791-E Detergent, General Purpose (Liquid, Non-

ionic)

1.1 This method describes a technique to determine the

MIL-0-27210E, Amendment 1-Oxygen, Aviator’s Breath-

relative sensitivity of materials to dynamic pressure impacts by

ing, Liquid and Gas

gases such as oxygen, air, or blends of gases containing

MIL-C-81302C Cleaning Compound, Solvent, Trichlorotri-

oxygen.

fluoroethane

1.2 This method describes the test apparatus and test pro-

cedures that may be employed in the evaluation of materials for

3. Summary of Method

use in gases under dynamic pressure operating conditions up to

3.1 The gaseous impact test system is designed to expose

gage pressures of 10 000 psi (69 MPa) at ambient temperature.

material specimens or small components/elements to high-

1.3 This method is primarily a test for ranking of materials.

velocity (dynamic) gaseous impact environments. The basic

This method is not necessarily valid for determination of the

configuration consists of a high-pressure accumulator, a high-

sensitivity of the materials in an “as-used” configuration since

speed pressurization (impact) valve, test system pressurization

the material sensitivity may be altered because of changes in

lines, test chamber/fixture, test chamber purge and vent sys-

material configuration, usage, and environment. This method

tems, and a valve sequencer/control device. Fig. 1 is a

can be employed to provide batch-to-batch acceptance data.

schematic of a typical test system.

Acceptability of any material may be based on its performance

3.2 The general procedure is to prepare the test specimen,

at a particular test pressure, or test pressure may be varied to

record significant pretest data, and place the test specimen in

determine the reaction threshold of a material, as specified by

the test chamber. The test specimen is then subjected to

the user.

sequential gaseous impacts by alternately opening and closing

1.4 The criteria used for the acceptance, retest, and rejection

the test chamber pressurization (impact) and vent valves. The

of materials for any given application shall be determined by

test data obtained may include test chamber pressures and

the user and are not fixed by this method.

temperatures, test chamber pressure rise times, pressurization

1.5 This standard does not purport to address all of the

and vent valve actuation times, and sequence times. The test

safety concerns, if any, associated with its use. It is the

specimen is then removed and examined for any significant

responsibility of the user of this standard to establish appro-

changes and evidence of reactions. Pertinent data are recorded.

priate safety and health practices and determine the applica-

The test is repeated using a fresh specimen for each impact test

bility of regulatory limitations prior to use. For specific

cycle until the desired user-selected criteria are met.

precautions see Section 7.

4. Significance and Use

2. Referenced Documents

4.1 This test evaluates the relative sensitivity of materials to

2.1 ASTM Standards:

2 dynamic pressure impacts by various gaseous fluid media (may

D 1193 Specification for Reagent Water

include mixtures of gases).

G 63 Guide for Evaluating Non-Metallic Materials for Oxy-

3 4.2 Any change or variations in test specimen configura-

gen Service

4 tions, thickness, preparation, and cleanliness may cause a

2.2 Military Standards:

significant change in impact sensitivity/reaction.

4.3 A reaction is indicated by an abrupt increase in test

This method is under the jurisdiction of ASTM Committee G-4 on Compat-

specimen temperature or by obvious changes in odor, color, or

ibility and Sensitivity of Materials in Oxygen Enriched Atmospheres and is the

material appearance, or a combination thereof, as observed

direct responsibility of Subcommittee G04.01 on Test Methods.

during post test examinations. Odor alone is not considered

Current edition approved Oct. 29, 1982. Published February 1983.

positive evidence that a reaction has occurred.

Annual Book of ASTM Standards, Vol 11.01.

Annual Book of ASTM Standards, Vol 14.02.

4.4 Suggested criteria for test completion at a given pressure

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

are:

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

G74

Equipment List:

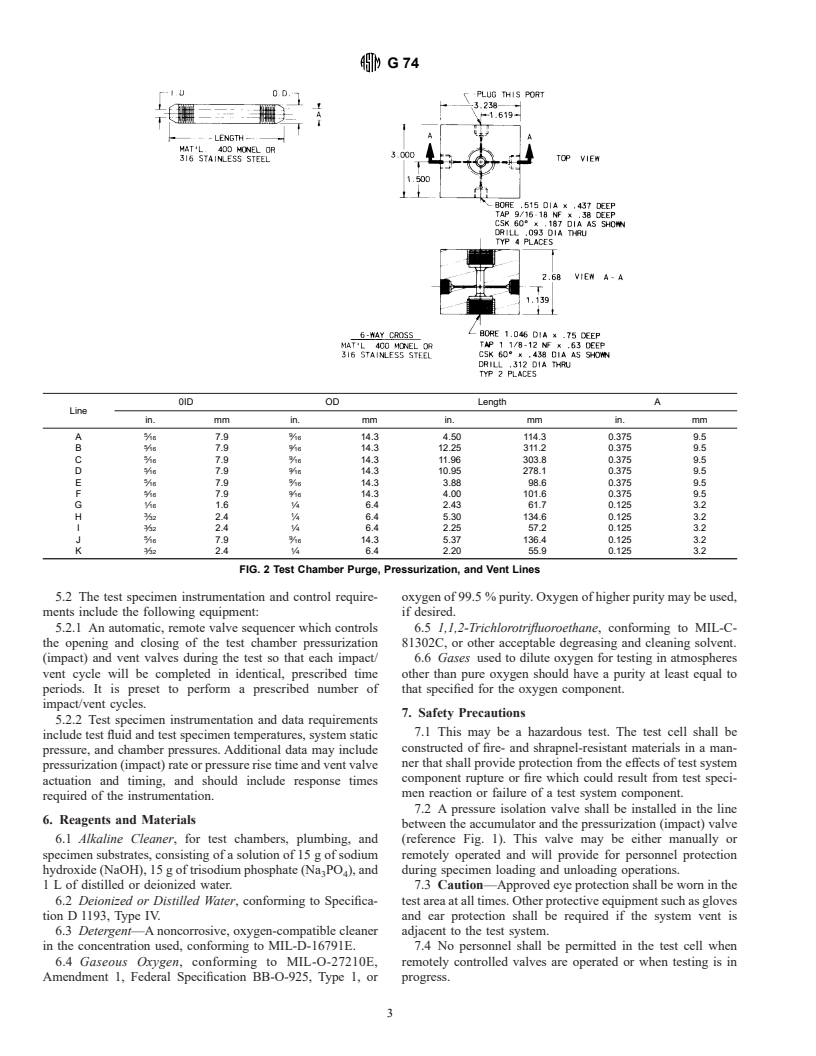

A-K See Fig. Fig. 2

L High-pressure Dwg 4-2219 (or equal)

M High-pressure Catalog 60-22HF9 (or equal); orient as indicated

N Flodyne P/N 5A170 (or equal)

P Teledyne Taber Model 2101 (or equal)

Q Circle Seal P/N VC1009A (or equal)

R Flodyne P/N 2A170 (or equal)

FIG. 1 Gaseous Impact Test System Schematic

4.4.1 Each specimen is subjected to five impacts. pressurization of test chamber in accordance with 5.1.2. These

4.4.2 A material passes if no reactions occur in 20 succes- lines shall contain an isolation valve to provide a safety factor

sive samples. for system operation. The isolation valve shall have a flow

4.4.3 A material fails if one reaction occurs in a maximum factor at least equal to the pressurization (impact) valve.

of 20 or fewer successive samples. 5.1.4 The test chamber vent valve shall be sized to allow the

4.5 Materials may be ranked by the maximum pressure test chamber pressure to decay to atmospheric pressure be-

(pressure threshold) at which they pass the test. tween impacts.

4.6 Material acceptance may be on the basis of passing at a

NOTE 1—The ability of a given gaseous impact test system to rank

selected pressure.

materials is based on two basic parameters: the test chamber pressuriza-

tion rate and the accumulator pressure. There may be variations in the test

5. Apparatus

chamber pressurization rate of different test systems at a given test

(accumulator) pressure; however, the test chamber pressurization rate of a

5.1 A typical gaseous impact test system used for determin-

given test system shall be maintained within the limits specified in

ing the sensitivity of materials to gaseous impact (adiabatic

5.1.2-5.1.4. If these limits are maintained, a test system should be able to

compression) is schematically depicted in Fig. 1. Details of this

rank materials. For example, a properly functioning test system should

typical test system are depicted in Figs. 2-5. The major test

rank most batches of chloroprene rubbers below most batches of vi-

system components are described as follows:

nylidene fluoride hexafluoropropylene rubbers, which should rank below

5.1.1 The accumulator provides gaseous test fluid storage most batches of polytetrafluoroethylene polymers. This ranking cannot,

however, be considered absolute due to material batch differences im-

and is precharged to the desired test pressure (potential energy

posed by contamination, differences in types and amounts of mold release

head). The capacity requirement is dependent on the test

agents, differences in cures, etc.

chamber and line size and the number of impacts required per

test sequence. It is sized to limit static head loss to less than 5.1.5 The inside diameter and the length of the pressuriza-

4 % of initial pressure during any test sequence. tion line to the test chamber are critical. This section also

5.1.2 The test chamber shall be pressurized from the base contains a six-way cross for purge, vent, and instrumentation

line pressure value (normally atmospheric ambient pressure) to line connections. All line sections between the accumulator and

95 % of test pressure in not less than 10 nor more than 50 ms. the test chamber shall be straight and smooth to minimize flow

This range is not to be construed to be an acceptable variation losses. Dimensions of the lines and six-way cross for a typical

in any one system, but is the pressure rise time range permitted test system are shown in Fig. 2.

among different systems. The average pressure rise time of a 5.1.6 The gaseous impact test chamber subassembly is

given system shall vary not more than 620 % at a given test configured to hold and position the test specimen. It also

pressure during the operational life of the system nor vary more contains a thermocouple to monitor the test specimen tempera-

than 63 ms for a given test set of 20 impacts. ture. Other requisites include the ability to readily install and

5.1.3 The fluid lines between the accumulator and pressur- remove the test specimen. Details of a typical test chamber are

ization valve shall be sized to minimize flow losses and enable depicted in Figs. 3-5.

G74

0ID OD Length A

Line

in. mm in. mm in. mm in. mm

5 9

A ⁄16 7.9 ⁄16 14.3 4.50 114.3 0.375 9.5

5 9

B ⁄16 7.9 ⁄16 14.3 12.25 311.2 0.375 9.5

5 9

C ⁄16 7.9 ⁄16 14.3 11.96 303.8 0.375 9.5

5 9

D ⁄16 7.9 ⁄16 14.3 10.95 278.1 0.375 9.5

5 9

E ⁄16 7.9 ⁄16 14.3 3.88 98.6 0.375 9.5

5 9

F ⁄16 7.9 ⁄16 14.3 4.00 101.6 0.375 9.5

1 1

G ⁄16 1.6 ⁄4 6.4 2.43 61.7 0.125 3.2

3 1

H ⁄32 2.4 ⁄4 6.4 5.30 134.6 0.125 3.2

3 1

I ⁄32 2.4 ⁄4 6.4 2.25 57.2 0.125 3.2

5 9

J ⁄16 7.9 ⁄16 14.3 5.37 136.4 0.125 3.2

3 1

K ⁄32 2.4 ⁄4 6.4 2.20 55.9 0.125 3.2

FIG. 2 Test Chamber Purge, Pressurization, and Vent Lines

5.2 The test specimen instrumentation and control require- oxygen of 99.5 % purity. Oxygen of higher purity may be used,

ments include the following equipment: if desired.

5.2.1 An automatic, remote valve sequencer which controls 6.5 1,1,2-Trichlorotrifluoroethane, conforming to MIL-C-

the opening and closing of the test chamber pressurization 81302C, or other acceptable degreasing and cleaning solvent.

(impact) and vent valves during the test so that each impact/ 6.6 Gases used to dilute oxygen for testing in atmospheres

vent cycle will be completed in identical, prescribed time other than pure oxygen should have a purity at least equal to

periods. It is preset to perform a prescribed number of that specified for the oxygen component.

impact/vent cycles.

7. Safety Precautions

5.2.2 Test specimen instrumentation and data requirements

7.1 This may be a hazardous test. The test cell shall be

include test fluid and test specimen temperatures, system static

constructed of fire- and shrapnel-resistant materials in a man-

pressure, and chamber pressures. Additional data may include

ner that shall provide protection from the effects of test system

pressurization (impact) rate or pressure rise time and vent valve

component rupture or fire which could result from test speci-

actuation and timing, and should include response times

men reaction or failure of a test system component.

required of the instrumentation.

7.2 A pressure isolation valve shall be installed in the line

6. Reagents and Materials

between the accumulator and the pressurization (impact) valve

6.1 Alkaline Cleaner, for test chambers, plumbing, and (reference Fig. 1). This valve may be either manually or

specimen substrates, consisting of a solution of 15 g of sodium remotely operated and will provide for personnel protection

hydroxide (NaOH), 15 g of trisodium phosphate (Na PO ), and during specimen loading and unloading operations.

3 4

1 L of distilled or deionized water. 7.3 Caution—Approved eye protection shall be worn in the

6.2 Deionized or Distilled Water, conforming to Specifica- test area at all times. Other protective equipment such as gloves

tion D 1193, Type IV. and ear protection shall be required if the system vent is

6.3 Detergent—A noncorrosive, oxygen-compatible cleaner adjacent to the test system.

in the concentration used, conforming to MIL-D-16791E. 7.4 No personnel shall be permitted in the test cell when

6.4 Gaseous Oxygen, conforming to MIL-O-27210E, remotely controlled valves are operated or when testing is in

Amendment 1, Federal Specification BB-O-925, Type 1, or progress.

G74

All equipment and containers used must be suitable and

recommended for oxygen service.

Never attempt to transfer oxygen from cylinder in which it is

received to any other cylinder. Do not mix gases in cylinders.

Do not drop cylinder. Make sure cylinder is secured at all

times.

Keep cylinder valve closed when not in use.

Stand away from outlet when opening cylinder valve.

For technical use only. Do not use for inhalation purposes.

Keep cylinder out of sun and away from heat.

Keep cylinder from corrosive environment.

Do not use cylinder without label.

Do not use dented or damaged cylinders.

7.7.1 See Compressed Gas ASSOCIATION BOOKLETS G-4

and G-4.1 for details of safe practice in the use of oxygen.

8. Test Specimens

8.1 Test the specimens in a thickness of 0.060 6 0.005 in.

(1.52 6 0.13 mm) (standard thickness), or in the end-use

thickness if less than 0.055 in. (1.40 mm). If specimens are

tested in a thickness other than 0.060 6 0.005 in., note the

deviation. The specimens shall be representative of the as-used

condition. The as-used condition may be either the new

installed condition, or where preferable, the condition that

exists at any time in the service life.

8.2 Maintain specimens clean at all times. Prepare and

handle the specimens with new, visibly clean, vinyl surgical

gloves or equivalent. Do not touch the materials or specimens

FIG. 3 Test Chamber Subassembly

with bare hands during or after the cleaning process.

7.5 The housekeeping and maintenance characteristics of 8.3 Typical preparation procedures for various materials are

the test area shall be considered for both safety and cleanliness as follows:

aspects. 8.3.1 Sheet stock materials shall be in 0.060 6 0.005-in.

7.6 1,2,2-Trichlorotrifluoroethane: (1.52 6 0.13-mm) thickness and prepared as ⁄16-in. (4.76-

Warning! Harmful if inhaled. mm)-diameter disks.

High concentrations may cause unconsciousness or death. 8.3.2 Apply coatings and paint in end-use thickness onto

Contact may cause skin irritation and dermatitis. clean 0.060 6 0.005-in.-thick by ⁄16-in.-diameter (1.52 6 0.13

Avoid prolonged or repeated breathing of vapor or spray by 4.76-mm), Type 316 stainless steel substrates. Cure applied

mist. material in accordance with the manufacturer’s recommenda-

Use only with adequate ventilation. tions. Record cured coating thickness and application and cure

Eye irritation and dizziness are indications of overex

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.