ASTM E148-66 (1981)

(Specification)Specification for Apparatus for Microdetermination of Nitrogen by the Dumas Method (Withdrawn 1987)

Specification for Apparatus for Microdetermination of Nitrogen by the Dumas Method (Withdrawn 1987)

General Information

Standards Content (Sample)

Designation: E 148 - 66 (Reapproved 1981)

Standard Specification for

APPARATUS FOR MICRODETERMINATION OF

NITROGEN BY DUMAS METHOD’

This standard is issued under the fixed designation E 148; the number immediately foliowing the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval A superscript epsilon (E) indicates an editorial change since the last revision or reapproval.

1. Scope nection tube.

4.1.1 Long Furnace:

1.1 This specification covers apparatus

4.1.1.1 The long furnace shall have a maxi-

used for the microdetermination of nitrogen

mum over-all length of 8 in. (203 mm) with

by the Dumas method, including carbon-diox-

the wall thickness at the ends not to exceed

ide supply, gas-control unit, combustion unit,

’/* in. (6 mm). The heating well in the fur-

and measuring apparatus.

nace shall accommodate combustion tubes up

NOTE 1-Many of these specifications were

to 13-mm outside diameter. Electric heating

originally developed by the Committee on Micro-

chemical Apparatus, Division of Analytical Chem- elements shall be easily replaceable. The fur-

istry, American Chemical Society.’

nace shall be mounted firmly on a substantial

NOTE 2-The values stated in U.S. cuctomacy

support.

unifs are to be regarded as the standard. The met-

ric equivalents of US. customary units may be 4.1.1.2 The furnace shall be capable of

approximate.

continuous operation at temperatures up to

800 C: as measured inside the combustion

2. Carbon-Dioxide Supply

tube in the middle of the furnace. The tem-

2.1 Apparatus for the supply of carbon di-

perature drop from the center to points 1 in.

oxide may be one of two types, as follows:

(25 mm) and l’/d in. (45 mm) from either

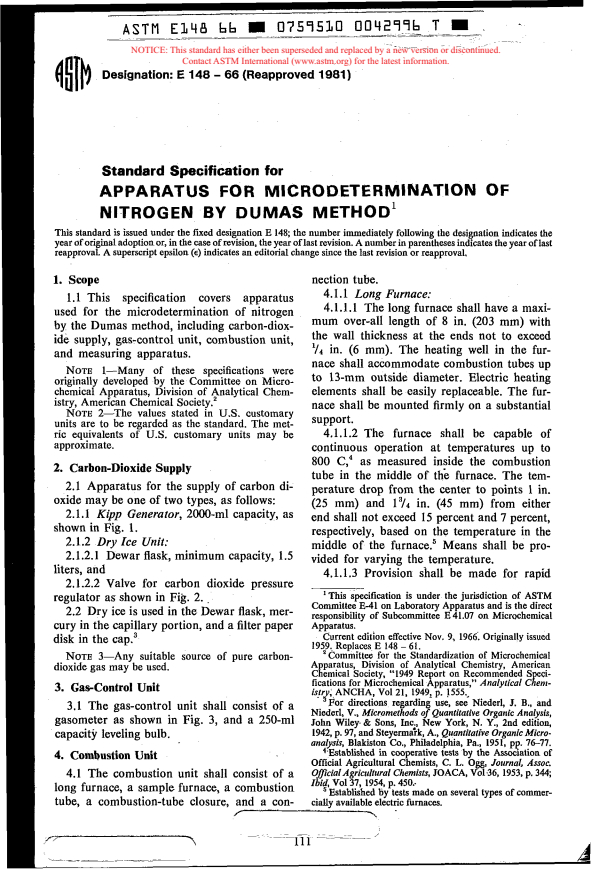

2.1.1 Kipp Generator, 2000-ml capacity, as

end shall not exceed 15 percent and 7 percent,

shown in Fig. 1.

respectively, based on the temperature in the

2.1.2 Dry Ice Unit

middle of the f~rnace.~ Means shall be pro-

2.1.2.1 Dewar flask, minimum capacity, 1.5

vided for varying the temperature.

liters, and

4.1.1.3 Provision shall be made for rapid

2.1.2.2 Valve for carbon dioxide pressure

‘This specification is under the jurisdiction of ASTM

regulator as shown in Fig. 2.

Committee E41 on Laboratory Apparatus and is the direct

2.2 Dry ice is used in the Dewar flask, mer-

responsibility of Subcommittee E41.W on Microchemical

Apparatus.

cury in the capillary portion, and a filter paper

Current edition effective Nov. 9, 1966. Originally issued

disk in the cap.3

19519. Replaces E 148 - 61.

NOTE 3-Any suitable source of pure carbon- Committee for the Standardization of Microchemical

of Analytical Chemistry, American

Apparatus, Division

dioxide gas may be used.

Chemical Society, “1949 Report on Recommended S ci

fications for Microchemical Apparatus,” Analytical CgmI

3. Gascontrol Unit

ismy. ANCHA, Vol 21, 1949, p. 1555,

’For directions regarding use, see Niederl, I. B., and

3.1 The gas-control unit shall consist of a

Niederl, V., Micromethods of Quantitative Organic Analysis,

gasometer as shown in Fig. 3, and a 250-ml

John Wiley-& Sons, inc., New York, N. Y., 2nd edition,

1942, p. 97, and SteyennaTk, A., Quantitative Organic Micro-

capacity leveling bulb.

ana!ysis, Blakiston Co., Philadelphia, Pa., 1951, pp 76-77.

?.Established in cooperative tesis by the Association of

4. Combustion Unit

Oficial Agricultural Chemists, C. L. Os, Journal, Ascoc.

Oficial Agricultural Chemists, JOACA, Vol-36, 1953, p. 344;

4.1 The combustion unit shall consist of a

Ibìd, Vol 37, 1954, p. 450.

long furnace, a sample furnace, a combustion

‘Established by tests made on several types of commer-

tube, a combustion-tube closure. and a con- ciallv available electric furnaces.

---------------------- Page: 1 ----------------------

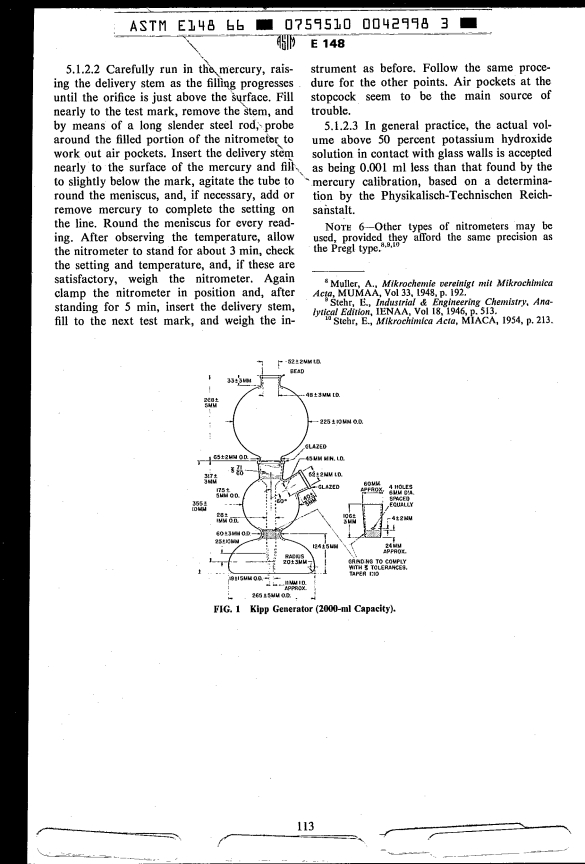

some device for continuous or provisional in-

dication of the temperature at the middle of

the furnace.

4.1.2 Sample Furnace:

5. Measuring Unit

4.1.2.1 The sample furnace shall have an

5.1 The measuring unit shall consist of a

overall length not less than 2'/2 in. (65 mm)

flow-control device and a nitrometer.

nor more than 4 in. (102 mm) with wall thick-

5.1.1 Flow Control Device-Either of the

ness at the ends not to exceed '/4 in. (6 mm).

following items may be used:

The heating well in the furnace shall accom-

5.1.1.1 Precision stopcock as shown in Fig.

modate combustion tubes up to 13-mm out-

9, or

side diameter. Electric heating elements shall

5.1.1.2 All-metal needle valve as shown in

be easily replaceable. The furnace shall be

Fig. 10.

mounted firmly on a 'substantial support.

NOTE- 5-An interchangeable ground joint may

4.1.2.2 The furnace shall be capable of

be attached to the constricted end of the precision

continuous operation at temperatures up to stopcock or to each end of the needle valve.

800 CS4 as measured inside the combustion

.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.