ASTM C1270-97(2021)

(Practice)Standard Practice for Detection Sensitivity Mapping of In-Plant Walk-Through Metal Detectors

Standard Practice for Detection Sensitivity Mapping of In-Plant Walk-Through<brk /> Metal Detectors

SIGNIFICANCE AND USE

5.1 A complex set of variables affect metal detection and detection sensitivity. Some physical characteristics of metal objects that influence detection are material composition, shape, surface area, surface and internal electrical and magnetic properties, and finish. The orientation of a test object can greatly influence detection as can the direction and speed or changes in speed while passing through the detection zone. Nearby large metal objects and metal moving in near proximity to a metal detector also affect operation, as do temperature and humidity, and can be a cause for nuisance alarms. Additionally, most currently manufactured walk-through metal detectors have some means for programming the operation of the detector for special conditions or requirements; these variables and the effect they have on the operation of in-plant detectors must be considered if a test program is to be effective. This practice is intended to minimize the impact of these variables on the operation of in-plant detectors by systematically testing the installed detectors in the operating environment with the test object(s) specified by the regulatory authority requirements.

5.2 This practice may be used to determine the critical test object from a group of test objects, its critical orientation, and the critical test path through the detection zone. This information may allow the use of a single test object for setting the operational sensitivity of the detector and performing periodic performance evaluations necessary to ensure a high probability that all test objects in the group are detectible within the capabilities of the detector.

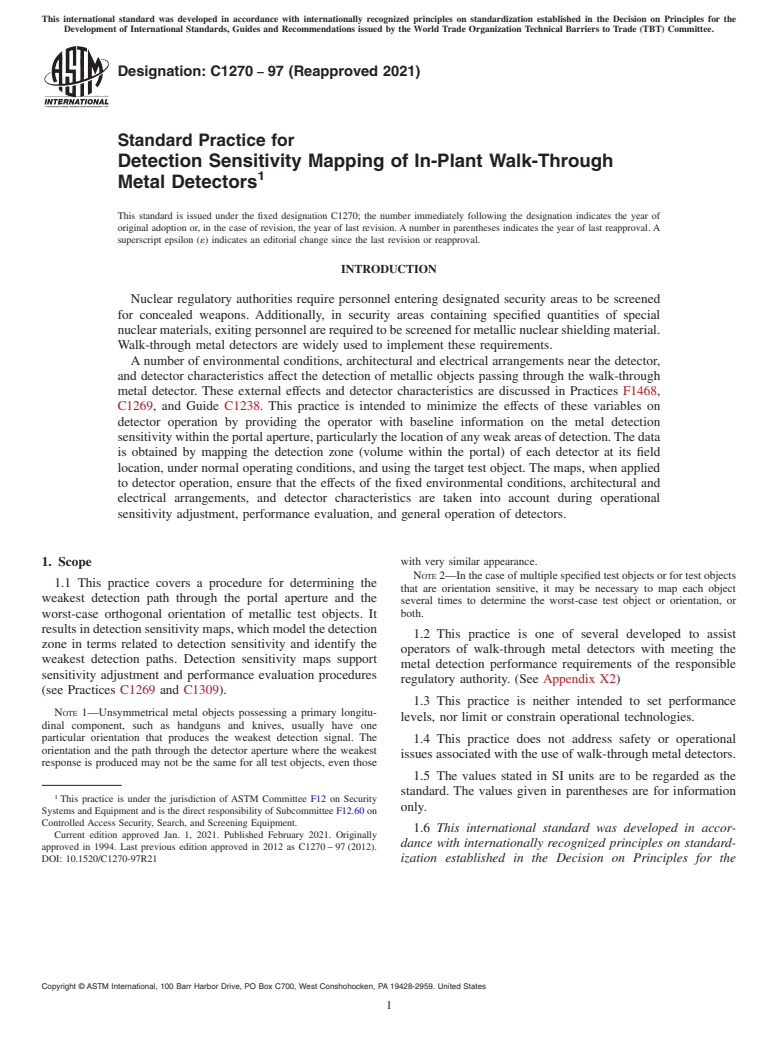

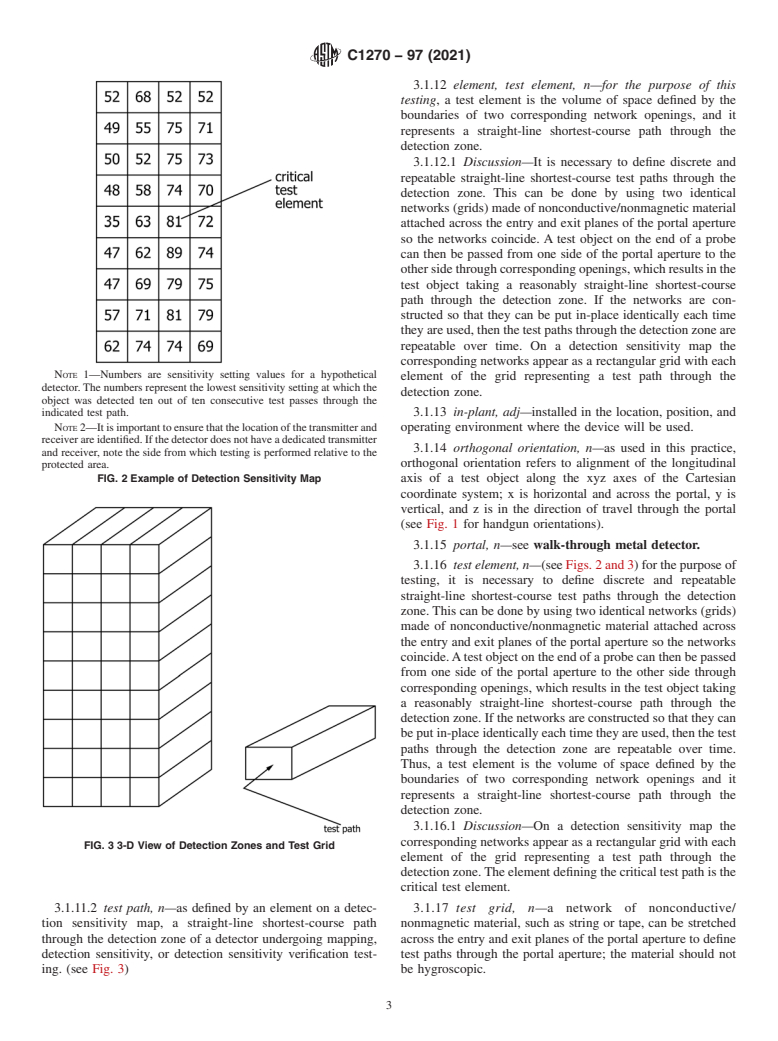

5.3 The detection sensitivity map(s) generated by this practice provides baseline metal detection data for the specified test objects and can serve as a foundation for in-plant walk-through metal detector set-up and performance evaluation testing. The detection sensitivity map(s) may be incorporated into a detector performance test log in suppo...

SCOPE

1.1 This practice covers a procedure for determining the weakest detection path through the portal aperture and the worst-case orthogonal orientation of metallic test objects. It results in detection sensitivity maps, which model the detection zone in terms related to detection sensitivity and identify the weakest detection paths. Detection sensitivity maps support sensitivity adjustment and performance evaluation procedures (see Practices C1269 and C1309).

Note 1: Unsymmetrical metal objects possessing a primary longitudinal component, such as handguns and knives, usually have one particular orientation that produces the weakest detection signal. The orientation and the path through the detector aperture where the weakest response is produced may not be the same for all test objects, even those with very similar appearance.

Note 2: In the case of multiple specified test objects or for test objects that are orientation sensitive, it may be necessary to map each object several times to determine the worst-case test object or orientation, or both.

1.2 This practice is one of several developed to assist operators of walk-through metal detectors with meeting the metal detection performance requirements of the responsible regulatory authority. (See Appendix X2)

1.3 This practice is neither intended to set performance levels, nor limit or constrain operational technologies.

1.4 This practice does not address safety or operational issues associated with the use of walk-through metal detectors.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barrie...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1270 − 97 (Reapproved 2021)

Standard Practice for

Detection Sensitivity Mapping of In-Plant Walk-Through

1

Metal Detectors

This standard is issued under the fixed designation C1270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Nuclear regulatory authorities require personnel entering designated security areas to be screened

for concealed weapons. Additionally, in security areas containing specified quantities of special

nuclearmaterials,exitingpersonnelarerequiredtobescreenedformetallicnuclearshieldingmaterial.

Walk-through metal detectors are widely used to implement these requirements.

Anumber of environmental conditions, architectural and electrical arrangements near the detector,

and detector characteristics affect the detection of metallic objects passing through the walk-through

metal detector. These external effects and detector characteristics are discussed in Practices F1468,

C1269, and Guide C1238. This practice is intended to minimize the effects of these variables on

detector operation by providing the operator with baseline information on the metal detection

sensitivity within the portal aperture, particularly the location of any weak areas of detection.The data

is obtained by mapping the detection zone (volume within the portal) of each detector at its field

location, under normal operating conditions, and using the target test object. The maps, when applied

to detector operation, ensure that the effects of the fixed environmental conditions, architectural and

electrical arrangements, and detector characteristics are taken into account during operational

sensitivity adjustment, performance evaluation, and general operation of detectors.

with very similar appearance.

1. Scope

NOTE 2—In the case of multiple specified test objects or for test objects

1.1 This practice covers a procedure for determining the

that are orientation sensitive, it may be necessary to map each object

weakest detection path through the portal aperture and the

several times to determine the worst-case test object or orientation, or

worst-case orthogonal orientation of metallic test objects. It both.

resultsindetectionsensitivitymaps,whichmodelthedetection

1.2 This practice is one of several developed to assist

zone in terms related to detection sensitivity and identify the

operators of walk-through metal detectors with meeting the

weakest detection paths. Detection sensitivity maps support

metal detection performance requirements of the responsible

sensitivity adjustment and performance evaluation procedures

regulatory authority. (See Appendix X2)

(see Practices C1269 and C1309).

1.3 This practice is neither intended to set performance

NOTE 1—Unsymmetrical metal objects possessing a primary longitu-

levels, nor limit or constrain operational technologies.

dinal component, such as handguns and knives, usually have one

particular orientation that produces the weakest detection signal. The

1.4 This practice does not address safety or operational

orientation and the path through the detector aperture where the weakest

issues associated with the use of walk-through metal detectors.

response is produced may not be the same for all test objects, even those

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1

This practice is under the jurisdiction of ASTM Committee F12 on Security

only.

Systems and Equipment and is the direct responsibility of Subcommittee F12.60 on

Controlled Access Security, Search, and Screening Equipment.

1.6 This international standard was developed in accor-

Current edition approved Jan. 1, 2021. Published February 2021. Originally

dance with internationally recognized principles on standard-

approved in 1994. Last previous edition approved in 2012 as C1270 – 97 (2012).

DOI: 10.1520/C1270-97R21 ization established in the Decision on Principles for the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1270 − 97 (2021)

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C1238 Guide for Installation of Walk-Through Metal Detec-

tors

C1269 Practice forAdjusting Operational Sensitivity

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.