ASTM D3764-01

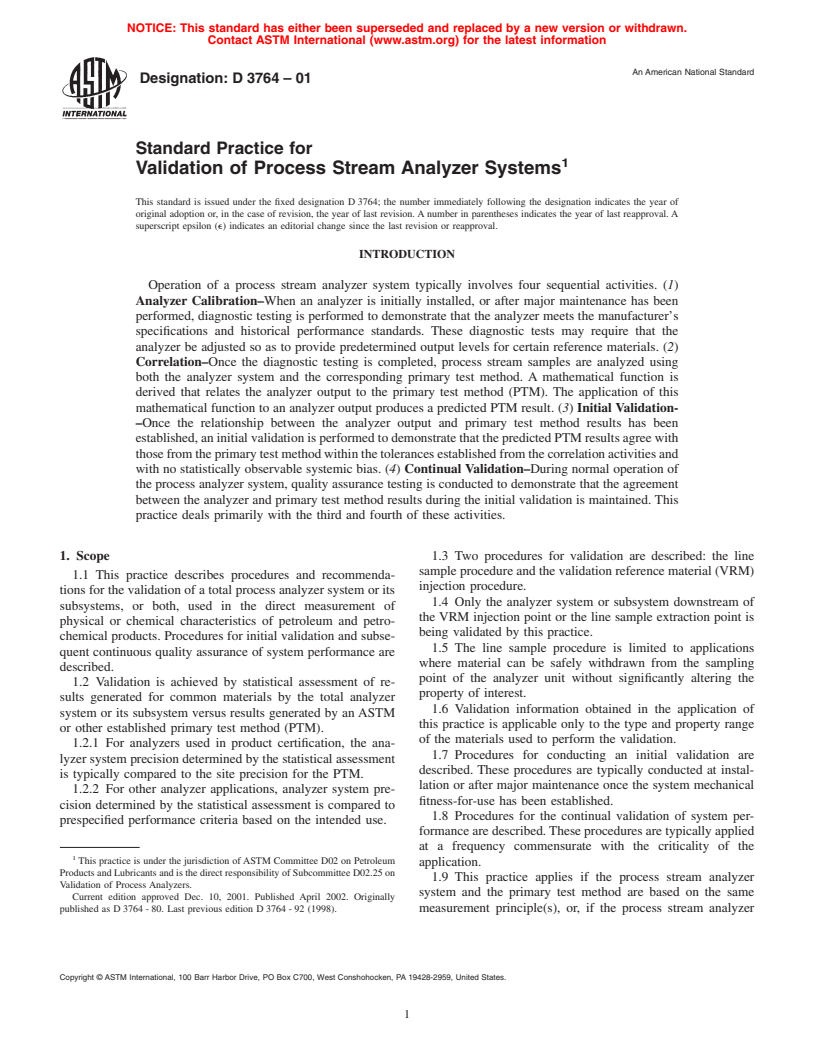

(Practice)Standard Practice for Validation of Process Stream Analyzer Systems

Standard Practice for Validation of Process Stream Analyzer Systems

SCOPE

1.1 This practice describes procedures and recommendations for the validation of a total process analyzer system or its subsystems, or both, used in the direct measurement of physical or chemical characteristics of petroleum and petrochemical products. Procedures for initial validation and subsequent continuous quality assurance of system performance are described.

1.2 Validation is achieved by statistical assessment of results generated for common materials by the total analyzer system or its subsystem versus results generated by an ASTM or other established primary test method (PTM).

1.2.1 For analyzers used in product certification, the analyzer system precision determined by the statistical assessment is typically compared to the site precision for the PTM.

1.2.2 For other analyzer applications, analyzer system precision determined by the statistical assessment is compared to prespecified performance criteria based on the intended use.

1.3 Two procedures for validation are described: the line sample procedure and the validation reference material (VRM) injection procedure.

1.4 Only the analyzer system or subsystem downstream of the VRM injection point or the line sample extraction point is being validated by this practice.

1.5 The line sample procedure is limited to applications where material can be safely withdrawn from the sampling point of the analyzer unit without significantly altering the property of interest.

1.6 Validation information obtained in the application of this practice is applicable only to the type and property range of the materials used to perform the validation.

1.7 Procedures for conducting an initial validation are described. These procedures are typically conducted at installation or after major maintenance once the system mechanical fitness-for-use has been established.

1.8 Procedures for the continual validation of system performance are described. These procedures are typically applied at a frequency commensurate with the criticality of the application.

1.9 This practice applies if the process stream analyzer system and the primary test method are based on the same measurement principle(s), or, if the process stream analyzer system uses a direct and well-understood measurement principle that is similar to the measurement principle of the primary test method it is intended to predict.

1.10 This practice is not intended for use if the process stream analyzer system utilizes an indirect or mathematically modeled measurement principle such as chemometric or multivariate analysis techniques. Users should refer to Practice D 6122 for detailed validation procedures for these types of analyzer systems.

1.11 This practice does not address procedures for diagnosing causes of validation failure.

1.12 This practice does not address the methodology for establishing the correlation equation used to generate predicted PTM results using analyzer outputs, nor the expected prediction error. The former is assumed to have been correctly developed as part of the analyzer application development work.

1.13 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3764–01

Standard Practice for

1

Validation of Process Stream Analyzer Systems

This standard is issued under the fixed designation D3764; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Operation of a process stream analyzer system typically involves four sequential activities. (1)

Analyzer Calibration–When an analyzer is initially installed, or after major maintenance has been

performed, diagnostic testing is performed to demonstrate that the analyzer meets the manufacturer’s

specifications and historical performance standards. These diagnostic tests may require that the

analyzer be adjusted so as to provide predetermined output levels for certain reference materials. (2)

Correlation–Once the diagnostic testing is completed, process stream samples are analyzed using

both the analyzer system and the corresponding primary test method. A mathematical function is

derived that relates the analyzer output to the primary test method (PTM). The application of this

mathematical function to an analyzer output produces a predicted PTM result. (3) Initial Validation-

–Once the relationship between the analyzer output and primary test method results has been

established,aninitialvalidationisperformedtodemonstratethatthepredictedPTMresultsagreewith

thosefromtheprimarytestmethodwithinthetolerancesestablishedfromthecorrelationactivitiesand

with no statistically observable systemic bias. (4) Continual Validation–During normal operation of

the process analyzer system, quality assurance testing is conducted to demonstrate that the agreement

between the analyzer and primary test method results during the initial validation is maintained. This

practice deals primarily with the third and fourth of these activities.

1. Scope 1.3 Two procedures for validation are described: the line

sampleprocedureandthevalidationreferencematerial(VRM)

1.1 This practice describes procedures and recommenda-

injection procedure.

tions for the validation of a total process analyzer system or its

1.4 Only the analyzer system or subsystem downstream of

subsystems, or both, used in the direct measurement of

the VRM injection point or the line sample extraction point is

physical or chemical characteristics of petroleum and petro-

being validated by this practice.

chemical products. Procedures for initial validation and subse-

1.5 The line sample procedure is limited to applications

quent continuous quality assurance of system performance are

where material can be safely withdrawn from the sampling

described.

point of the analyzer unit without significantly altering the

1.2 Validation is achieved by statistical assessment of re-

property of interest.

sults generated for common materials by the total analyzer

1.6 Validation information obtained in the application of

system or its subsystem versus results generated by anASTM

this practice is applicable only to the type and property range

or other established primary test method (PTM).

of the materials used to perform the validation.

1.2.1 For analyzers used in product certification, the ana-

1.7 Procedures for conducting an initial validation are

lyzersystemprecisiondeterminedbythestatisticalassessment

described. These procedures are typically conducted at instal-

is typically compared to the site precision for the PTM.

lation or after major maintenance once the system mechanical

1.2.2 For other analyzer applications, analyzer system pre-

fitness-for-use has been established.

cision determined by the statistical assessment is compared to

1.8 Procedures for the continual validation of system per-

prespecified performance criteria based on the intended use.

formancearedescribed.Theseproceduresaretypicallyapplied

at a frequency commensurate with the criticality of the

1

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

application.

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.25on

1.9 This practice applies if the process stream analyzer

Validation of Process Analyzers.

system and the primary test method are based on the same

Current edition approved Dec. 10, 2001. Published April 2002. Originally

measurement principle(s), or, if the process stream analyzer

published as D3764-80. Last previous edition D3764-92 (1998).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3764–01

system uses a direct and well-understood measurement prin- 3.1.2 precision, n—the closeness of agreement betwee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.