ASTM A627-03

(Test Method)Standard Test Methods for Tool-Resisting Steel Bars, Flats, and Shapes for Detention and Correctional Facilities

Standard Test Methods for Tool-Resisting Steel Bars, Flats, and Shapes for Detention and Correctional Facilities

SCOPE

1.1 These test methods cover requirements for simulated service tests and testing equipment for determining the performance characteristics of various types and shapes of steels designated for use in detention and correctional facilities as fixed barriers to prevent egress and to control passage.

1.2 It is the intent of these test methods to help ensure that opening assemblies such as detention security windows, grilles, bar grating, and other physical barriers incorporating steel bars perform at or above minimum acceptable levels for control of passage to unauthorized or secure areas, for confinement of inmates and to delay or frustrate escape attempts. To meet the intent of these test methods, opening assembles must perform to grade requirements shown in Tables X1.1 and X1.2 in Appendix X1.

1.3 These test methods apply primarily to the steels used as essential components of detention security windows, grilles, bar grating, and so forth, in opening assemblies enclosing or separating secure areas of detention/correctional facilities.

1.4 The values stated in inch-pound units are to be regarded as standard. The SI values given in parentheses are for information only.

1.5 This standard updates and combines two previous standards, ASTM Specifications A 627-95 and A 629-94, establishing new security grades and time durations.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A627 – 03

Standard Test Methods for

Tool-Resisting Steel Bars, Flats, and Shapes for Detention

1

and Correctional Facilities

This standard is issued under the fixed designation A627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover requirements for simulated 2.1 ASTM Standards:

service tests and testing equipment for determining the perfor- C39/C39M Test Method for Compressive Strength of Cy-

mance characteristics of various types and shapes of steels lindrical Concrete Specimens

designated for use in detention and correctional facilities as E4 Practices for Force Verification of Testing Machines

fixed barriers to prevent egress and to control passage. E18 Test Methods for Rockwell Hardness of Metallic Ma-

1.2 It is the intent of these test methods to help ensure that terials

opening assemblies such as detention security windows, E329 Specification for Agencies Engaged in Construction

grilles, bar grating, and other physical barriers incorporating Inspection and/or Testing

steel bars perform at or above minimum acceptable levels for

3. Terminology

control of passage to unauthorized or secure areas, for confine-

ment of inmates and to delay or frustrate escape attempts. To 3.1 Definitions:

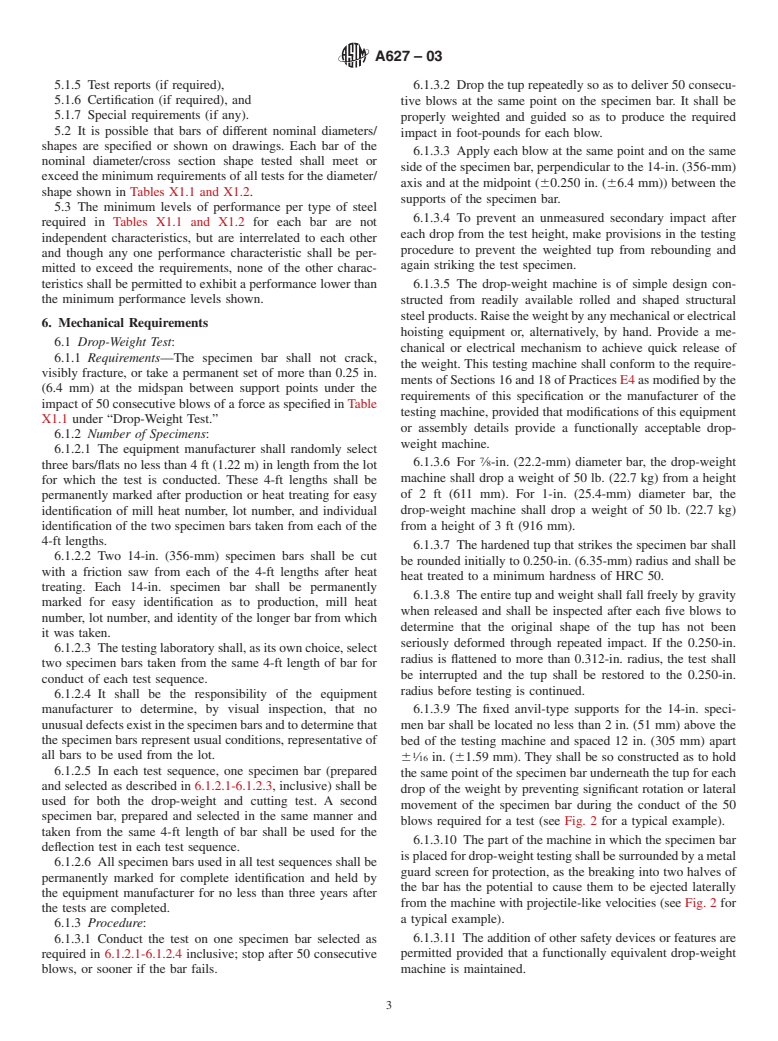

3.1.1 bars, n—round, ribbed, hexagonal, or other shaped

meet the intent of these test methods, opening assembles must

perform to grade requirements shown in Tables X1.1 and X1.2 bars that can be readily reduced to a round cross-sectional

7

shape, ⁄8-in. (22.2-mm) or 1-in. (25.4-mm) diameter (see Fig.

in Appendix X1.

1 5 1

1.3 These test methods apply primarily to the steels used as 1). Also flat bars: ⁄4 by 2 in. (6.4 by 50.8 mm); ⁄16 by 2 ⁄4 in.

3 1

(7.9 by 57.2 mm) or ⁄8 by 2 ⁄2 in. (9.6 by 63.5 mm).

essential components of detention security windows, grilles,

bar grating, and so forth, in opening assemblies enclosing or 3.1.2 composite tool-resisting steel bar/flat, n—a bar/flat

separating secure areas of detention/correctional facilities. that is a composite of a tungsten carbide or other hard material,

for cutting resistance and of a high strength, low alloy steel,

1.4 The values stated in inch-pound units are to be regarded

as standard. The SI values given in parentheses are for heat treated up to HRC 45 max. hardness for impact and

deflection resistance.

information only.

1.5 This standard updates and combines two previous stan- 3.1.3 cutting test, n—a simulated service test in which the

rating is based on the number of a specific type of tungsten

dards, ASTM Specifications A627-95 and A629-94, establish-

ing new security grades and time durations. carbide rod saws required to cut through the bar.

3.1.4 effective tool-resisting (ETR) area, n—the cross-

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the sectional area of the portion of the bar that is tool resistant.

3.1.5 equipment manufacturer, n—a manufacturer who fab-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- ricates and assembles security products, including tool-

resisting steel bars, for installation in areas requiring security

bility of regulatory limitations prior to use.

against ingress and egress. This manufacturer processes the

semi-finished bar and fabricates finished products suitable for

use in opening assemblies requiring these specified perfor-

mance characteristics. This manufacturer is also responsible

1

This specification is under the jurisdiction of ASTM Committee F33 on

Detention and Correctional Facilities and is the direct responsibility of Subcommit-

2

tee F33.02 on Physical Barriers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 10, 2003. Published July 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1968. Last previous edition approved in 1995 as A627 – 95. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0627-03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A627 – 03

FIG. 1 Shaped Bars

forheattreating,fabricating,andassemblingallancillaryitems openings such as fixed and operable exterior and interior

so as not to impair the performance character

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.