ASTM C1524-02a(2010)

(Test Method)Standard Test Method for Water-Extractable Chloride in Aggregate (Soxhlet Method) (Withdrawn 2019)

Standard Test Method for Water-Extractable Chloride in Aggregate (Soxhlet Method) (Withdrawn 2019)

SIGNIFICANCE AND USE

Water-extractable chloride, when present in sufficient amount, has a potential to initiate or accelerate corrosion of metals, such as steel, embedded in or contacting a cementitious system, such as mortar, grout, or concrete. This test method is applicable when aggregates contain a high background of naturally occurring chloride (see ACI 222.1–96 ). Test Method C1152/C1152M determines acid-soluble chloride and Test Method C1218/C1218M determines water-soluble chloride. Both Test Methods C1152/C1152M and C1218/C1218M pulverize the sample to a fine powder or fine granular material. The Soxhlet method is intended to use nonpulverized material. Results with some aggregates have shown that the Soxhlet procedure extracts an extremely low amount of chloride, with most of it remaining in the rock, and therefore, it is not available for corrosion.

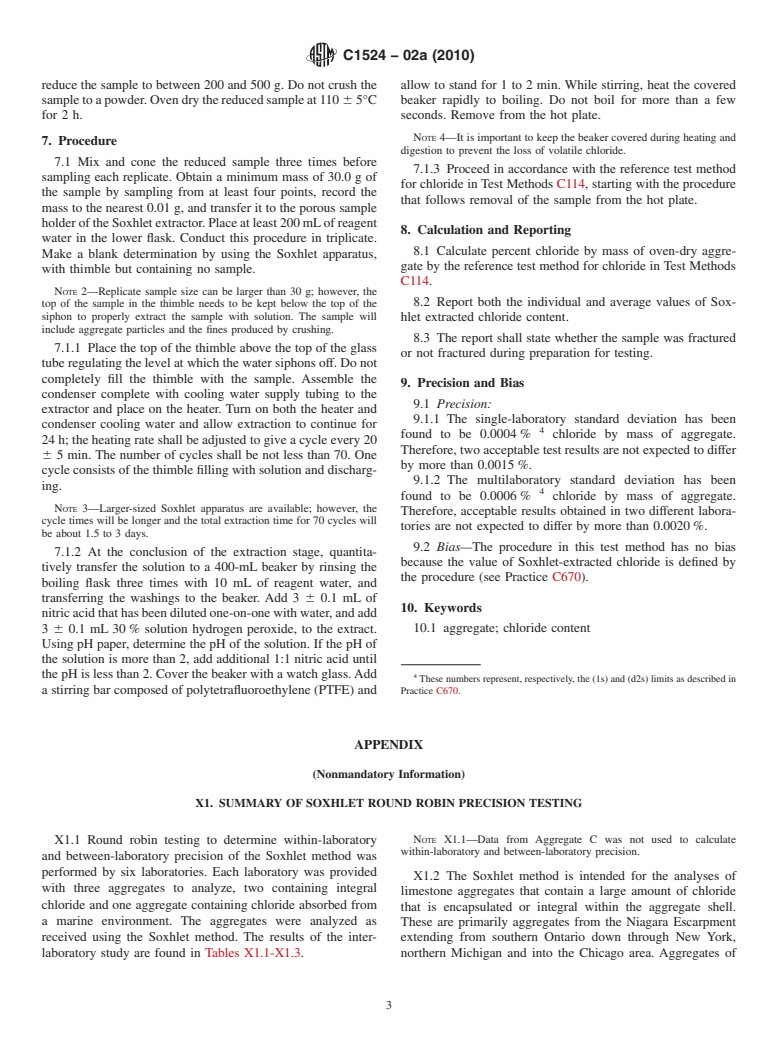

The Soxhlet extraction apparatus consists of three sections: the boiling flask, which contains reagent water at the beginning of the test; the extractor, which contains the sample inside a thimble; and, the condenser. The extractor functions by boiling the water, which condenses and drips on to the sample. When the water attains a fixed height above the sample, the extractor siphons the water from the thimble back to the boiling flask. The process repeats itself until the test is terminated. (Refer to Fig. 1.)

SCOPE

1.1 This test method provides procedures for sampling and analysis of aggregate for water-extractable chloride using a Soxhlet extractor.

Note 1—This test method is to be used when significantly high chloride content has been found in aggregates, concretes, or mortars.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provided procedures for sampling and analysis of aggregate for water-extractable chloride using a Soxhlet extractor.

Formerly under the jurisdiction of Committee C09 on Concrete and Concrete Aggregates, this test method was withdrawn in January 2019 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1524 − 02a (Reapproved 2010)

Standard Test Method for

Water-Extractable Chloride in Aggregate (Soxhlet Method)

This standard is issued under the fixed designation C1524; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Steel in Mortar and Concrete Using the Soxhlet Extractor

1.1 This test method provides procedures for sampling and

3. Significance and Use

analysis of aggregate for water-extractable chloride using a

3.1 Water-extractable chloride, when present in sufficient

Soxhlet extractor.

amount, has a potential to initiate or accelerate corrosion of

NOTE1—Thistestmethodistobeusedwhensignificantlyhighchloride

metals, such as steel, embedded in or contacting a cementitious

content has been found in aggregates, concretes, or mortars.

system, such as mortar, grout, or concrete. This test method is

1.2 The values stated in SI units are to be regarded as

applicable when aggregates contain a high background of

standard. No other units of measurement are included in this

naturally occurring chloride (seeACI 222.1–96 ). Test Method

standard.

C1152/C1152M determines acid-soluble chloride and Test

1.3 This standard does not purport to address all of the

Method C1218/C1218M determines water-soluble chloride.

safety concerns, if any, associated with its use. It is the

Both Test Methods C1152/C1152M and C1218/C1218M pul-

responsibility of the user of this standard to establish appro-

verize the sample to a fine powder or fine granular material.

priate safety and health practices and determine the applica-

The Soxhlet method is intended to use nonpulverized material.

bility of regulatory limitations prior to use.

Results with some aggregates have shown that the Soxhlet

procedure extracts an extremely low amount of chloride, with

2. Referenced Documents

most of it remaining in the rock, and therefore, it is not

available for corrosion.

2.1 ASTM Standards:

C114 Test Methods for Chemical Analysis of Hydraulic 3.2 The Soxhlet extraction apparatus consists of three sec-

Cement

tions: the boiling flask, which contains reagent water at the

C670 Practice for Preparing Precision and Bias Statements beginning of the test; the extractor, which contains the sample

for Test Methods for Construction Materials

insideathimble;and,thecondenser.Theextractorfunctionsby

C1152/C1152M Test Method for Acid-Soluble Chloride in boiling the water, which condenses and drips on to the sample.

Mortar and Concrete

When the water attains a fixed height above the sample, the

C1218/C1218M Test Method for Water-Soluble Chloride in extractorsiphonsthewaterfromthethimblebacktotheboiling

Mortar and Concrete

flask. The process repeats itself until the test is terminated.

D75 Practice for Sampling Aggregates (Refer to Fig. 1.)

D1193 Specification for Reagent Water

4. Apparatus

E11 Specification for Woven Wire Test Sieve Cloth and Test

Sieves

4.1 Sampling Equipment:

4.1.1 The apparatus required for obtaining aggregate

2.2 American Concrete Institute Standard:

ACI 222.1–96 Provisional Standard Test Method for Water- samples is described in Practice D75.

Soluble Chloride Available for Corrosion of Embedded

4.2 Sampling Processing Apparatus, the same as in Test

Method C1218/C1218M without pulverization.

4.3 Soxhlet Extractor Apparatus, shall have the following

This test method is under the jurisdiction of ASTM Committee C09 on

minimum size and consist of the following (see Fig. 1).

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

4.3.1 Reflux-Type Condenser, with a 34/45-mm ground-

C09.69 on Miscellaneous Tests.

glass fitting to the extractor, and having a 27-mm inside

Current edition approved Dec. 1, 2010. Published March 2011. Originally

approved in 2002. Last previous edition approved in 2002 as C1524 – 02a. DOI:

diameter by a 192-mm body length.

10.1520/C1524-02AR10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094, http://www.concrete.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1524 − 02a (2010)

FIG. 1 Soxhlet Extraction Apparatus

4.3.2 Soxhlet Extraction Tube, with a 34/45-mm ground- 5. Reagents

glass fitting to the condenser and a 24/40-mm ground-glass

5.1 The reagents required for the chloride determination are

fitting to the boiling flask, for holding sample thimbles 25 mm

given in the test method for chloride of Test Methods C114,

by 80 mm (diameter by height).

and the Procedure section of Test Method C1218/C1218M.

4.3.3 A250-mLboilingflaskwitha24/40-mmground-glass

5.2 Reagent water is either deionized or distilled, conform-

fitting.

ing to the requirements of Specification D1193 for Type III

4.3.4 A heating mantel, burner, or hot plate configured for

reagent water.

the flask capable of attaining 200°C.

4.3.5 Suitable Sample Holder, such as a porous extraction

6. Sample Preparation

thimble having a 25-mm inside diameter and 80-mm external

6.1 Preparation:

length.

6.1.1 For Nominal Maximum Aggregate Sizes 25.0 mm or

4.4 The apparatus required for the chloride determination

Greater: Use a jaw crusher or hammer, and reduce the sample

step is given in the test method for chloride in Test Methods so that the particles pass a 25.0-mm sieve and are representa-

C114.

tive of the sample. Use a sample splitter or use coning and

quartering to reduce the sample to between 200 and 500 g. Do

4.5 pH Paper, short-range 0.0-3.0.

notcrushthesampletoapowder.Ovendrythereducedsample

4.6 Drying Oven, of sufficient size, capable of continuously

at 110 6 5°C for 2 h.

heating at 110 6 5°C.

6.1.2 For Nominal Maximum Aggregate Sizes Less Than

4.7 Sieve, 25.0 mm, complying with Specification E11. 25.0 mm: Use a sample splitter or use coning and quartering to

C1524 − 02a (2010)

reduce the sample to between 200 and 500 g. Do not crush the allow to stand for 1 to 2 min. While stirring, heat the covered

sampletoapowder.Ovendrythereducedsampleat110 65°C beaker rapidly to boiling. Do not boil for more than a few

for2h. seconds. Remove from the hot plate.

NOTE 4—It is important to keep the beaker covered during heating and

7. Procedure

digestion to prevent the loss of volatile chloride.

7.1 Mix and cone the reduced sample three times before

7.1.3 Proceed in accordance with the reference test method

sampling each replicate. Obtain a minimum mass of 30.0 g of

for chloride in Test Methods C114, starting with the procedure

the sample by sampling from at least four points, record the

that follows removal of the sample from the hot pla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.