ASTM E925-02

(Practice)Standard Practice for Monitoring the Calibration of Ultraviolet-Visible Spectrophotometers whose Spectral Slit Width does not Exceed 2 nm

Standard Practice for Monitoring the Calibration of Ultraviolet-Visible Spectrophotometers whose Spectral Slit Width does not Exceed 2 nm

SIGNIFICANCE AND USE

This practice permits an analyst to compare the performance of an instrument to the manufacturer’supplied performance specifications and to verify its suitability for continued routine use. It also provides generation of calibration monitoring data on a periodic basis, forming a base from which any changes in the performance of the instrument will be evident.

SCOPE

1.1 This practice covers the parameters of spectrophotometric performance that are critical for testing the adequacy of instrumentation for most routine tests and methods within the wavelength range of 200 to 700 nm and the absorbance range of 0 to 2. The recommended tests provide a measurement of the important parameters controlling results in spectrophotometric methods, but it is specifically not to be inferred that all factors in instrument performance are measured.

1.2 This practice may be used as a significant test of the performance of instruments for which the spectral slit width does not exceed 2 nm and for which the manufacturer's specifications for wavelength and absorbance accuracy do not exceed the performance tolerances employed here. This practice employs an illustrative tolerance of ± 1 % relative for the error of the absorbance scale over the range of 0.2 to 2.0, and of 1.0 nm for the error of the wavelength scale. A suggested maximum stray radiant power ratio of 4 x 10-4 yields

1.3 This practice should be performed on a periodic basis, the frequency of which depends on the physical environment within which the instrumentation is used. Thus, units handled roughly or used under adverse conditions (exposed to dust, chemical vapors, vibrations, or combinations thereof) should be tested more frequently than those not exposed to such conditions. This practice should also be performed after any significant repairs are made on a unit, such as those involving the optics, detector, or radiant energy source.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E925–02

Standard Practice for

Monitoring the Calibration of Ultraviolet-Visible

Spectrophotometers whose Spectral Slit Width does not

1

Exceed 2 nm

This standard is issued under the fixed designation E925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

In the application of spectrophotometric methods of analysis it is the responsibility of the analyst

to verify and validate that the instrument is functioning properly and is capable of providing

acceptable analytical results. It is preferable that the verification of instrument performance be

accomplished through the use of reference materials whose properties have been accurately

determined.Suchmaterialsarereadilyavailable,andtheiruseinthetestsandmeasurementsdescribed

inthispracticeissatisfactoryforevaluatingtheperformanceofspectrophotometerswhosespectralslit

width does not exceed the value for which the intrinsic or certified properties are valid.Acompromise

maximumpermissiblespectralslitwidthof2nmisrecommendedforthereferencematerialsanderror

tolerances recommended here.

This practice covers some of the essential instrumental parameters that should be evaluated to

ensure the acceptability of the analytical data routinely obtained on the instrument. These parameters

include the accuracy of the wavelength and absorbance scales and stray radiant power levels.

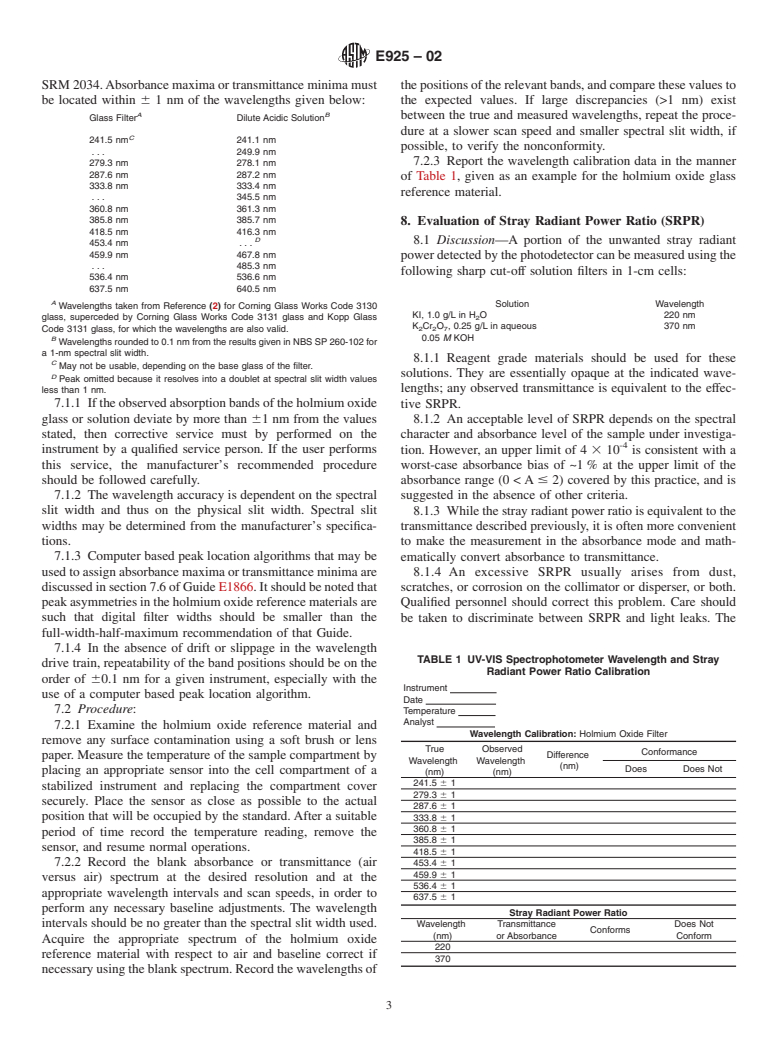

The accuracy of the wavelength scale in both the UV and visible regions is determined using the

sharp absorption bands of a holmium oxide glass or solution filter. The absorbance scale accuracy in

the UV region (235–350 nm) is determined using acidic solutions of potassium dichromate. In the

visibleregion(440–635nm)theabsorbanceaccuracyisdeterminedusingindividuallycertifiedneutral

density glass filters. The use of these reference materials provides a valid and relatively simple means

to test the errors in the wavelength and absorbance scales of small spectral slit width spectrophotom-

eters in the spectral ranges indicated. A simplified version of the opaque filter method is provided as

a test for excessive stray radiant energy.

1. Scope 1.2 This practice may be used as a significant test of the

performance of instruments for which the spectral slit width

1.1 This practice covers the parameters of spectrophotomet-

does not exceed 2 nm and for which the manufacturer’s

ric performance that are critical for testing the adequacy of

2

specifications for wavelength and absorbance accuracy do not

instrumentation for most routine tests and methods within the

exceed the performance tolerances employed here. This prac-

wavelength range of 200 to 700 nm and the absorbance range

tice employs an illustrative tolerance of 61 % relative for the

of0to2.Therecommendedtestsprovideameasurementofthe

error of the absorbance scale over the range of 0.2 to 2.0, and

important parameters controlling results in spectrophotometric

of 61.0 nm for the error of the wavelength scale.Asuggested

methods, but it is specifically not to be inferred that all factors

-4

maximum stray radiant power ratio of 4 3 10 yields <1 %

in instrument performance are measured.

absorbance bias at an absorbance of 2. These tolerances are

chosen to be compatible with many chemical applications

while comfortably exceeding the uncertainty of the certified

1

This practice is under the jurisdiction of ASTM Committee E13 on Molecular

values for the reference materials and typical manufacturer’s

SpectroscopyandisthedirectresponsibilityofSubcommitteeE13.01onUltraviolet

specifications for error in the wavelength and absorbance

and Visible Spectroscopy.

Current edition approved March 10, 2002. Published May 2002. Originally

scales of the instrument under test. The user is encouraged to

´1

published as E925 – 83. Last previous edition D925 – 83 (1994) . DOI: 10.1520/

develop and use tolerance values more appropriate to the

E0925-02.

2

requirements of the end use application. This procedure is

Routine tests are defined as those in which absorbance data obtained on a

sample are compared to those of a standard sample preparation. designed to verify quantitative performance on an ongoing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E925–02

basis and to compare one instrument’s performance with that 4. Significance and Use

of other similar units. Refer to Practice E275 to extensively

4.1 This practice permits an analyst to compare the perfor-

evaluate the performance of an instrument.

mance of an instrument to the manufac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.