ASTM F2280-08e1

(Specification)Standard Specification for “Twist Off” Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 150 ksi Minimum Tensile Strength

Standard Specification for <span class='unicode'>“</span>Twist Off<span class='unicode'>”</span> Type Tension Control Structural Bolt/Nut/Washer Assemblies, Steel, Heat Treated, 150 ksi Minimum Tensile Strength

ABSTRACT

This specification covers two types of heat treated, steel, tension control bolt-nut-washer assemblies, also referred to as "sets," having a tensile strength of 150 to 173 ksi. These assemblies are capable of developing a minimum predetermined tension when installed by applying torque to the nut, while at the same time applying a counter torque to separate the spline end from the body of the bolt using an appropriate spline drive installation tool. The tension control bolts are designated by type denoting chemical composition as follows: type 1 - alloy steel, and type 3 - weathering steel. The chemical composition of the tension control bolts, nuts, and washers shall conform to the requirements specified. The assembly lot tension test shall be performed on fastener assemblies to determine the ability of the assembly to provide the required minimum tension. Tensile strength, proof load, hardness, and carburization/decarburization shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers two types of heat treated, steel, tension control bolt-nut-washer assemblies, also referred to as “sets,” having a tensile strength of 150 to 173 ksi. These assemblies are capable of developing a minimum predetermined tension when installed by applying torque to the nut, while at the same time applying a counter torque to separate the spline end from the body of the bolt using an appropriate spline drive installation tool.

1.2 An assembly consists of a tension control bolt with spline end (covered by this specification) and a suitable nut and washer covered by reference to applicable ASTM specifications.

1.3 The fastener assemblies are intended for use in structural connections. These connections, installation procedures, and the use of alternate design structural bolts are covered under the requirements of the “Specification for Structural Joints Using ASTM or A490 Bolts”, approved by the Research Council on Structural Connections.

1.4 The assemblies are available with either round (button or dome) heads, heavy hex structural heads, or alternate design heads described in Section 11 , in sizes ½ to 1 1/8 in. inclusive, in two types specified in Section 4.

1.5 Tension control bolts manufactured and marked in accordance with the requirements of Specification A490, and conforming to the dimensional and other requirements of this specification, will be considered an acceptable alternate under this specification for two years following initial publication.

1.6 The following precautionary statement pertains only to the test method portions, Sections 15 and 16, of this Specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2280 – 08

Standard Specification for

“Twist Off” Type Tension Control Structural Bolt/Nut/Washer

Assemblies, Steel, Heat Treated, 150 ksi Minimum Tensile

1

Strength

This standard is issued under the fixed designation F2280; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

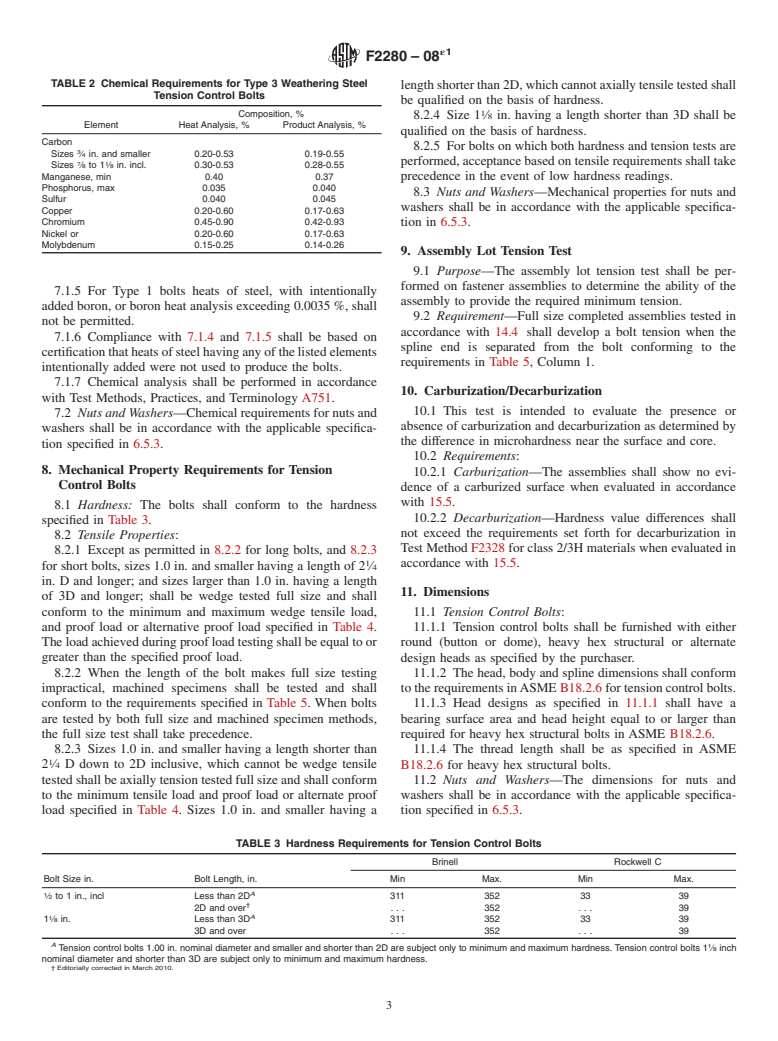

´ NOTE—Table 3 was editorially corrected in March 2010.

1. Scope* priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This specification covers two types of heat treated,

steel, tension control bolt-nut-washer assemblies, also referred

2. Referenced Documents

to as “sets,” having a tensile strength of 150 to 173 ksi. These

2

2.1 ASTM Standards:

assemblies are capable of developing a minimum predeter-

A490 Specification for Structural Bolts, Alloy Steel, Heat

mined tension when installed by applying torque to the nut,

Treated, 150 ksi Minimum Tensile Strength

whileatthesametimeapplyingacountertorquetoseparatethe

A563 Specification for Carbon and Alloy Steel Nuts

splineendfromthebodyoftheboltusinganappropriatespline

A751 Test Methods, Practices, andTerminology for Chemi-

drive installation tool.

cal Analysis of Steel Products

1.2 An assembly consists of a tension control bolt with

E709 Guide for Magnetic Particle Testing

splineend(coveredbythisspecification)andasuitablenutand

E1444 Practice for Magnetic Particle Testing

washer covered by reference to applicable ASTM specifica-

F436 Specification for Hardened Steel Washers

tions.

F606 Test Methods for Determining the Mechanical Prop-

1.3 The fastener assemblies are intended for use in struc-

erties of Externally and Internally Threaded Fasteners,

tural connections. These connections, installation procedures,

Washers, Direct Tension Indicators, and Rivets

and the use of alternate design structural bolts are covered

F788/F788M Specification for Surface Discontinuities of

under the requirements of the “Specification for Structural

Bolts, Screws, and Studs, Inch and Metric Series

Joints UsingASTM orA490 Bolts”, approved by the Research

F1470 Practice for Fastener Sampling for Specified Me-

Council on Structural Connections.

chanical Properties and Performance Inspection

1.4 The assemblies are available with either round (button

F1789 Terminology for F16 Mechanical Fasteners

or dome) heads, heavy hex structural heads, or alternate design

F2328 Test Method for Determining Decarburization and

1 1

heads described in Section 11 , in sizes ⁄2 to 1 ⁄8 in. inclusive,

Carburization in Hardened and Tempered Threaded Steel

in two types specified in Section 4.

Bolts, Screws and Studs

1.5 Tension control bolts manufactured and marked in

G101 Guide for Estimating the Atmospheric Corrosion

accordance with the requirements of Specification A490, and

Resistance of Low-Alloy Steels

conforming to the dimensional and other requirements of this

3

2.2 ASME Standards:

specification, will be considered an acceptable alternate under

B1.1 Unified Inch Screw Threads

this specification for two years following initial publication.

B1.3M Screw Threads Gaging Systems for Dimensional

1.6 The following precautionary statement pertains only to

Acceptability—Inch and Metric Screw Threads

the test method portions, Sections 15 and 16, of this Specifi-

B18.2.6 Fasteners for Use in Structural Applications

cation: This standard does not purport to address all of the

4

2.3 Research Council on Structural Connections:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction of ASTM Committee F16 on Standards volume information, refer to the standard’s Document Summary page on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, the ASTM website.

3

Nuts, Rivets and Washers. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved Jan. 1, 2008. Published January 2008. Originally International Headquarters, Three Park Ave., New York, NY 10016-5990.

4

approved in 2006. Last previous edition approved in 2006 as F2280–06. DOI: Available from American Institute of Steel Construction (AISC), One E.

10.1520/F2280-08. Wacker Dr., Suite 3100, Chicago, IL 60601-2001.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.