ASTM G105-02

(Test Method)Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests

Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests

SCOPE

1.1 This test method covers laboratory procedures for determining the resistance of metallic materials to scratching abrasion by means of the wet sand/rubber wheel test. It is the intent of this procedure to provide data that will reproducibly rank materials in their resistance to scratching abrasion under a specified set of conditions.

1.2 Abrasion test results are reported as volume loss in cubic millimeters. Materials of higher abrasion resistance will have a lower volume loss.

1.3 Values stated in SI units are to be regarded as the standard. Inch-pound units are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 105 – 02

Standard Test Method for

1

Conducting Wet Sand/Rubber Wheel Abrasion Tests

This standard is issued under the fixed designation G105; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers laboratory procedures for de- 3.1 abrasive wear—wear due to hard particles or hard

termining the resistance of metallic materials to scratching protuberances forced against and moving along a solid surface

abrasion by means of the wet sand/rubber wheel test. It is the (TerminologyG40).

intent of this procedure to provide data that will reproducibly 3.1.1 Discussion—This definition covers several different

rank materials in their resistance to scratching abrasion under wear modes or mechanisms that fall under the abrasive wear

a specified set of conditions. category. These modes may degrade a surface by scratching,

,

78

1.2 Abrasion test results are reported as volume loss in cutting, deformation, or gouging (1 and 2).

cubic millimeters. Materials of higher abrasion resistance will

4. Summary of Test Method

have a lower volume loss.

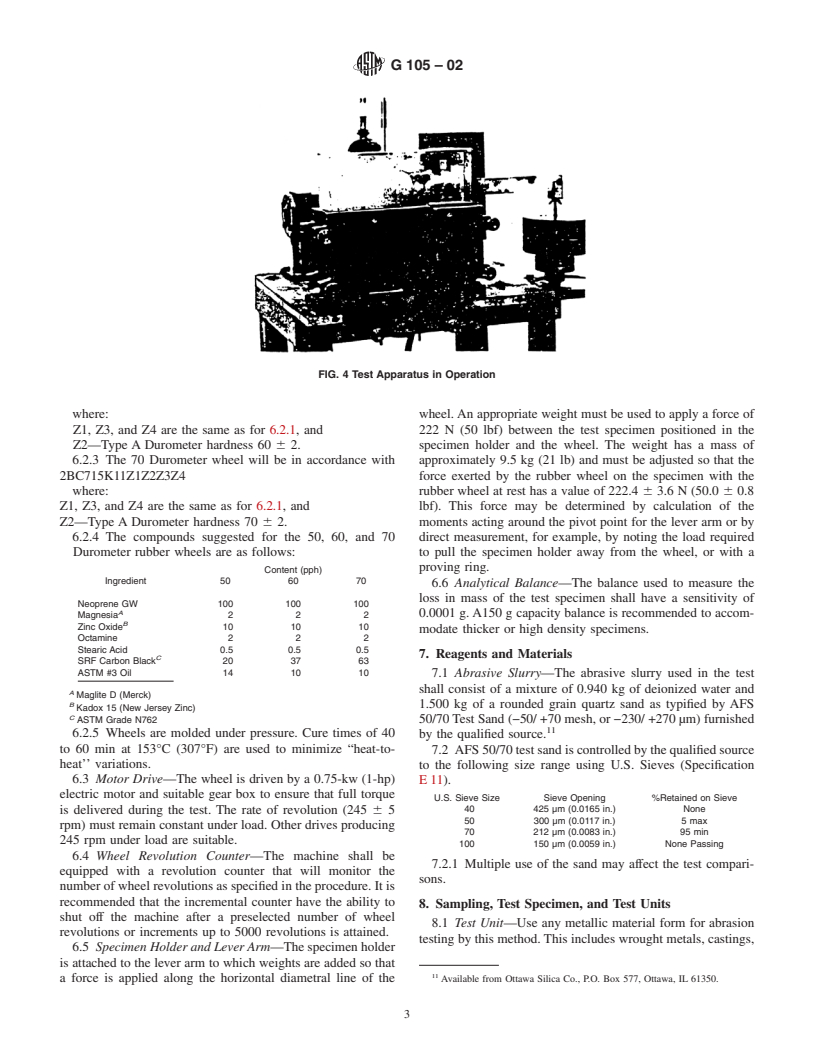

4.1 The wet sand/rubber wheel abrasion test (Fig. 1) in-

1.3 Values stated in SI units are to be regarded as the

standard. Inch-pound units are provided for information only. volves the abrading of a standard test specimen with a slurry

containing grit of controlled size and composition. The abra-

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the sive is introduced between the test specimen and a rotating

wheel with a neoprene rubber tire or rim of a specified

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- hardness. The test specimen is pressed against the rotating

wheel at a specified force by means of a lever arm while the

bility of regulatory limitations prior to use.

grit abrades the test surface. The rotation of the wheel is such

2. Referenced Documents

that stirring paddles on both sides agitate the abrasive slurry

2.1 ASTM Standards: through which it passes to provide grit particles to be carried

D2000 Classification System for Rubber Products inAuto- across the contact face in the direction of wheel rotation.

2

motive Applications 4.2 Three wheels are required with nominal Shore A

D 2240 Test Method for Rubber Property—Durometer Durometer hardnesses of 50, 60, and 70, with a hardness

3

Hardness toleranceof 62.0.Arun-inisconductedwiththe50Durometer

E11 Specification for Wire-Cloth and Sieves for Testing wheel, followed by the test with 50, 60, and 70 Durometer

4

Purposes wheelsinorderofincreasinghardness.Specimensareweighed

E122 Practice for Calculating Sample Size to Estimate, before and after each run and the loss in mass recorded. The

With a Specified Tolerable Error, the Average for a logarithms of mass loss are plotted as a function of measured

4

Characteristic of a Lot or Process rubber wheel hardness and a test value is determined from a

E177 Practice for Use of the Terms Precision and Bias in least square line as the mass loss at 60.0 Durometer. It is

4

ASTM Test Methods necessary to convert the mass loss to volume loss, due to wide

5

G40 Terminology Relating to Wear and Erosion differences in density of materials, in order to obtain a ranking

2.2 Other Standard: of materials.Abrasion is then reported as volume loss in cubic

6

SAE J200 millimetres.

5. Significance and Use (1-7)

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

5.1 Theseverityofabrasivewearinanysystemwilldepend

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive

upon the abrasive particle size, shape and hardness, the

Wear.

magnitude of the stress imposed by the particle, and the

Current edition approved Nov. 10, 2002. Published January 2003. Originally

e1

approved in 1989. Last previous edition approved in 1997 as G105–89 (1997) .

2

Annual Book of ASTM Standards, Vols 09.02.

3

Annual Book of ASTM Standards, Vol 09.01.

4 7

Annual Book of ASTM Standards, Vol 14.02. Available from Society of Automotive Engineers, 400 Commonwealth Dr.,

5

Annual Book of ASTM Standards, Vol 03.02. Warrendale, PA 15096.

6 8

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

Dr., Warrendale, PA 15096-0001. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 --------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.