ASTM B788/B788M-09

(Practice)Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

SIGNIFICANCE AND USE

Corrugated aluminum pipe functions structurally as a flexible ring which is supported by and interacts with the compacted surrounding soil. The soil constructed around the pipe is thus an integral part of the structural system. It is therefore important to ensure that the soil structure or backfill is made up of acceptable material and is well-constructed. Field verification of soil structure acceptability using Test Methods D1556, D2167, D2937, or D6938 as applicable, and comparing the results with Test Method D698 in accordance with the specifications for each project, is the most reliable basis for installation of an acceptable structure. The required density and method of measurement are not specified by this practice, but they must be established in the specifications for each project.

SCOPE

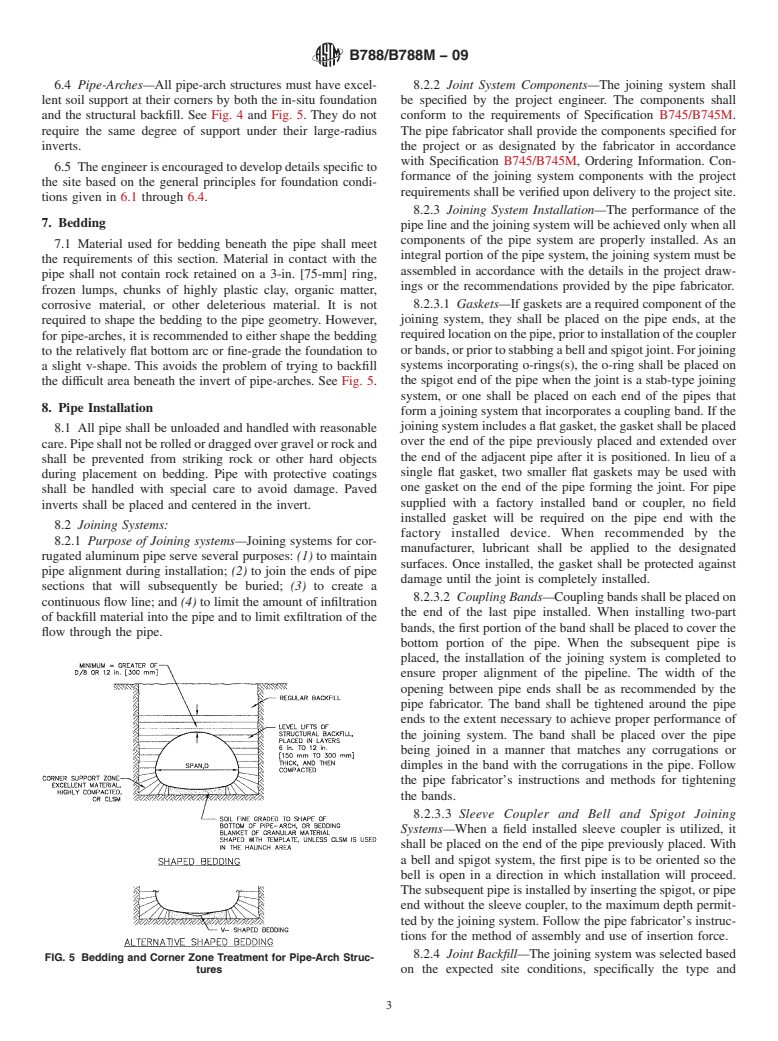

1.1 This practice describes procedures, soils, and soil placement for the proper installation of corrugated aluminum culverts and storm sewers in either trench or projection installations. A typical trench installation is shown in Fig. 1, and a typical embankment (projection) installation is shown in Fig. 2. The pipes described in this practice are manufactured in a factory and furnished to the job in lengths ordinarily from 10 to 30 ft [3 to 9 m], with 20 ft [6 m] being common, for field joining. This practice applies to structures designed in accordance with Practice B790/B790M.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 SI Units—SI units are shown in the text in brackets, and they are the applicable values for metric installation.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

FIG. 1 Typical Trench Installation

FIG. 2 Typical Embankment (Projection) Installation

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B788/B788M − 09

StandardPractice for

Installing Factory-Made Corrugated Aluminum Culverts and

1

Storm Sewer Pipe

This standard is issued under the fixed designation B788/B788M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* Storm Sewers, and Other Buried Conduits

D698 Test Methods for Laboratory Compaction Character-

1.1 This practice describes procedures, soils, and soil place-

3

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

ment for the proper installation of corrugated aluminum

3

kN-m/m ))

culverts and storm sewers in either trench or projection

D1556 Test Method for Density and Unit Weight of Soil in

installations. A typical trench installation is shown in Fig. 1,

Place by Sand-Cone Method

and a typical embankment (projection) installation is shown in

D2167 Test Method for Density and Unit Weight of Soil in

Fig. 2.The pipes described in this practice are manufactured in

Place by the Rubber Balloon Method

a factory and furnished to the job in lengths ordinarily from 10

D2487 Practice for Classification of Soils for Engineering

to 30 ft [3 to 9 m], with 20 ft [6 m] being common, for field

Purposes (Unified Soil Classification System)

joining. This practice applies to structures designed in accor-

D2937 Test Method for Density of Soil in Place by the

dance with Practice B790/B790M.

Drive-Cylinder Method

1.2 The values stated in either SI units or inch-pound units

D6938 Test Method for In-Place Density and Water Content

are to be regarded separately as standard. The values stated in

of Soil and Soil-Aggregate by Nuclear Methods (Shallow

each system may not be exact equivalents; therefore, each

Depth)

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3. Terminology

with the standard.

3.1 Definitions of Terms Specific to This Standard:

1.2.1 SI Units—SI units are shown in the text in brackets,

3.1.1 bedding, n—the earth or other material on which a

and they are the applicable values for metric installation.

pipe is supported.

1.3 This standard does not purport to address all of the

3.1.2 haunch, n—the portion of the pipe cross section

safety concerns, if any, associated with its use. It is the

between the maximum horizontal dimension and the top of the

responsibility of the user of this standard to establish appro-

bedding.

priate safety and health practices and determine the applica-

3.1.3 invert, n—the lowest point on the pipe cross section;

bility of regulatory limitations prior to use.

also, the bottom portion of a pipe.

2. Referenced Documents

3.1.4 pipe, n—a conduit having full circular shape; also, in

2

2.1 ASTM Standards:

a general context, all structure shapes covered by this practice.

B745/B745M Specification for Corrugated Aluminum Pipe

3.1.5 pipe–arch, n—a pipe with an approximate semicircu-

for Sewers and Drains

lar crown, small-radius corners, and large-radius invert.

B790/B790M Practice for Structural Design of Corrugated

Aluminum Pipe, Pipe-Arches, and Arches for Culverts,

4. Significance and Use

4.1 Corrugated aluminum pipe functions structurally as a

1

This practice is under the jurisdiction of ASTM Committee B07 on Light

flexible ring which is supported by and interacts with the

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on

compacted surrounding soil. The soil constructed around the

Aluminum Culvert.

pipe is thus an integral part of the structural system. It is

Current edition approved Nov. 1, 2009. Published December 2009. Originally

therefore important to ensure that the soil structure or backfill

approved in 1988. Last previous edition approved in 2004 as B788/B788M – 04.

DOI: 10.1520/B0788_B0788M-09.

is made up of acceptable material and is well-constructed.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Field verification of soil structure acceptability using Test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods D1556, D2167, D2937,or D6938 as applicable, and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. comparing the results with Test Method D698 in accordance

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B788/B788M − 09

FIG. 1 Typical Trench Installation

1

d = ⁄2 in./ft

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.