ASTM F648-07e1

(Specification)Standard Specification for Ultra-High-Molecular-Weight Polyethylene Powder and Fabricated Form for Surgical Implants

Standard Specification for Ultra-High-Molecular-Weight Polyethylene Powder and Fabricated Form for Surgical Implants

ABSTRACT

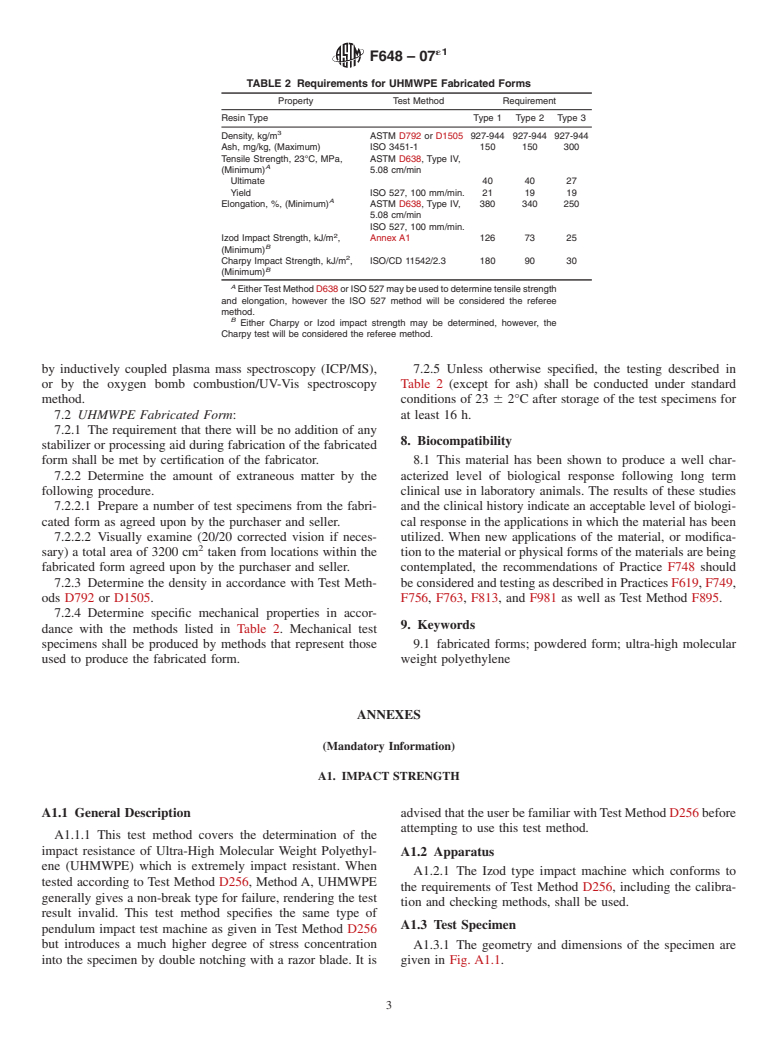

This specification covers ultra-high-molecular-weight polyethylene (UHMWPE) powder and fabricated forms for use in surgical implants. UHMWPE powder shall be of virgin polymer manufactured from a homopolymer of ethylene, while the fabricated forms shall be manufactured from the same UHMWPE powder without any stabilizers or processing aids. Tests for viscosity number, elongation stress, ash content, extraneous matter, and trace elements shall be performed for UHMWPE powders, while tests for density, ash content, tensile strength, yield strength, elongation, and impact strength shall be performed for fabricated forms. All tests shall conform to the requirements specified.

SCOPE

1.1 This specification covers ultra-high molecular weight polyethylene powder (UHMWPE) and fabricated forms intended for use in surgical implants.

1.2 The requirements of this specification apply to UHMWPE in two forms. One is virgin polymer powder (Section 4). The second is any form fabricated from this powder from which a finished product is subsequently produced (Section 5). This specification addresses material characteristics and does not apply to the packaged and sterilized finished implant.

1.3 The provisions of Specification D 4020 apply. Special requirements detailed in this specification are added to describe material which will be used in surgical implants.

1.4 The biological response to polyethylene in soft tissue and bone has been well characterized by a history of clinical use (1, 2, 3) and by laboratory studies (4, 5, 6).

The following precautionary caveat pertains only to the test method portion, Section , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F648 – 07

Standard Specification for

Ultra-High-Molecular-Weight Polyethylene Powder and

1

Fabricated Form for Surgical Implants

ThisstandardisissuedunderthefixeddesignationF648;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Table 1 was editorially corrected in June 2007.

1. Scope Under Flexural Load in the Edgewise Position

D790 Test Methods for Flexural Properties of Unreinforced

1.1 This specification covers ultra-high molecular weight

and Reinforced Plastics and Electrical Insulating Materials

polyethylene powder (UHMWPE) and fabricated forms in-

D792 Test Methods for Density and Specific Gravity (Rela-

tended for use in surgical implants.

tive Density) of Plastics by Displacement

1.2 The requirements of this specification apply to UHM-

D1505 Test Method for Density of Plastics by the Density-

WPE in two forms. One is virgin polymer powder (Section 4).

Gradient Technique

The second is any form fabricated from this powder from

4

D1898 Practice for Sampling of Plastics

which a finished product is subsequently produced (Section 5).

D4020 Specification for Ultra-High-Molecular-Weight

This specification addresses material characteristics and does

Polyethylene Molding and Extrusion Materials

not apply to the packaged and sterilized finished implant.

F619 Practice for Extraction of Medical Plastics

1.3 The provisions of Specification D4020 apply. Special

F748 Practice for Selecting Generic Biological Test Meth-

requirementsdetailedinthisspecificationareaddedtodescribe

ods for Materials and Devices

material which will be used in surgical implants.

F749 Practice for Evaluating Material Extracts by Intracu-

1.4 The biological response to polyethylene in soft tissue

taneous Injection in the Rabbit

and bone has been well characterized by a history of clinical

2

F756 Practice for Assessment of Hemolytic Properties of

use (1, 2, 3) and by laboratory studies (4, 5, 6).

Materials

1.5 The following precautionary caveat pertains only to the

F763 Practice for Short-Term Screening of Implant Materi-

test method portion, Section 7, of this specification: This

als

standard does not purport to address all of the safety concerns,

F813 Practice for Direct Contact Cell Culture Evaluation of

if any, associated with its use. It is the responsibility of the user

Materials for Medical Devices

of this standard to establish appropriate safety and health

F895 Test Method for Agar Diffusion Cell Culture Screen-

practices and determine the applicability of regulatory limita-

ing for Cytotoxicity

tions prior to use.

F981 Practice forAssessment of Compatibility of Biomate-

2. Referenced Documents rials for Surgical Implants with Respect to Effect of

3

Materials on Muscle and Bone

2.1 ASTM Standards:

2.2 ISO Standards

D256 Test Methods for Determining the Izod Pendulum

5

ISO 527 Plastics: Determination of Tensile Properties

Impact Resistance of Plastics

ISO 3451-1 Plastics—Determination of Ash, Part 1: Gen-

D638 Test Method for Tensile Properties of Plastics

5

eral Methods

D648 Test Method for Deflection Temperature of Plastics

ISO 11542/2, Plastics—Ultra-High Molecular Weight Poly-

ethylene (UHMWPE) Moulding and Extrusion

1

Materials—Part 2: Preparation of Test Specimens and

This specification is under the jurisdiction of ASTM Committee F04 on

5

Medical and Surgical Materials and Devices and is the direct responsibility of

Determination

Subcommittee F04.11 on Polymeric Materials.

Current edition approved Feb. 1, 2007. Published February 2007. Originally

3. Terminology

approved in 1980. Last previous edition approved in 2004 as F648 – 04. DOI:

3.1 Definitions of Terms Specific to This Standard:

10.1520/F0648-07E01.

2

The boldface numbers in parentheses refer to the list of references at the end of

this specification.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

F648 – 07

3.1.1 fabricated form, n—any bulk shape of UHMWPE, 4.2.3 When determined as described in ISO 3451-1, the

fabricated from the virgin polymer powder and used during the mean ash of duplicate samples shall not exceed the limits

process of fabricating surgica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.