ASTM A159-83(1993)

(Specification)Standard Specification for Automotive Gray Iron Castings

Standard Specification for Automotive Gray Iron Castings

SCOPE

1.1 This specification applies to gray iron castings, cast in sand molds, used in the products of the automobile, truck, tractor, and allied industries.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 159 – 83 (Reapproved 1993)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Automotive Gray Iron Castings

This standard is issued under the fixed designation A 159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. Consult the DoD Index of Specifications and

Standards for the specific year of issue which has been adopted by the Department of Defense. This specification replaces Federal

specification AA-I-653A.

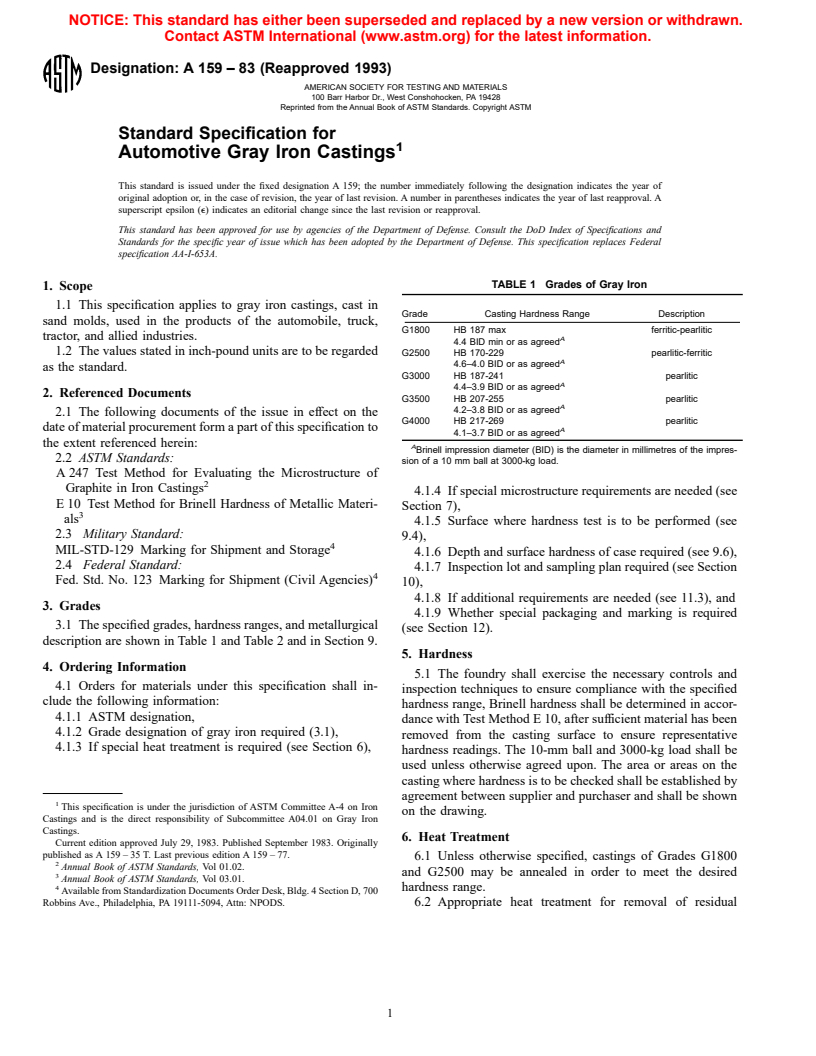

TABLE 1 Grades of Gray Iron

1. Scope

1.1 This specification applies to gray iron castings, cast in

Grade Casting Hardness Range Description

sand molds, used in the products of the automobile, truck,

G1800 HB 187 max ferritic-pearlitic

tractor, and allied industries. A

4.4 BID min or as agreed

1.2 The values stated in inch-pound units are to be regarded

G2500 HB 170-229 pearlitic-ferritic

A

4.6–4.0 BID or as agreed

as the standard.

G3000 HB 187-241 pearlitic

A

4.4–3.9 BID or as agreed

2. Referenced Documents

G3500 HB 207-255 pearlitic

A

4.2–3.8 BID or as agreed

2.1 The following documents of the issue in effect on the

G4000 HB 217-269 pearlitic

date of material procurement form a part of this specification to A

4.1–3.7 BID or as agreed

the extent referenced herein:

A

Brinell impression diameter (BID) is the diameter in millimetres of the impres-

2.2 ASTM Standards:

sion of a 10 mm ball at 3000-kg load.

A 247 Test Method for Evaluating the Microstructure of

2

Graphite in Iron Castings

4.1.4 If special microstructure requirements are needed (see

E 10 Test Method for Brinell Hardness of Metallic Materi-

Section 7),

3

als

4.1.5 Surface where hardness test is to be performed (see

2.3 Military Standard:

9.4),

4

MIL-STD-129 Marking for Shipment and Storage

4.1.6 Depth and surface hardness of case required (see 9.6),

2.4 Federal Standard:

4.1.7 Inspection lot and sampling plan required (see Section

4

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

10),

4.1.8 If additional requirements are needed (see 11.3), and

3. Grades

4.1.9 Whether special packaging and marking is required

3.1 The specified grades, hardness ranges, and metallurgical

(see Section 12).

description are shown in Table 1 and Table 2 and in Section 9.

5. Hardness

4. Ordering Information

5.1 The foundry shall exercise the necessary controls and

4.1 Orders for materials under this specification shall in-

inspection techniques to ensure compliance with the specified

clude the following information:

hardness range, Brinell hardness shall be determined in accor-

4.1.1 ASTM designation,

dance with Test Method E 10, after sufficient material has been

4.1.2 Grade designation of gray iron required (3.1),

removed from the casting surface to ensure representative

4.1.3 If special heat treatment is required (see Section 6),

hardness readings. The 10-mm ball and 3000-kg load shall be

used unless otherwise agreed upon. The area or areas on the

casting where hardness is to be checked shall be established by

agreement between supplier and purchaser and shall be shown

1

This specification is under the jurisdiction of ASTM Committee A-4 on Iron

on the drawing.

Castings and is the direct responsibility of Subcommittee A04.01 on Gray Iron

Castings.

6. Heat Treatment

Current edition approved July 29, 1983. Published September 1983. Originally

published as A 159 – 35 T. Last previous edition A 159 – 77.

6.1 Unless otherwise specified, castings of Grades G1800

2

Annual Book of ASTM Standards, Vol 01.02.

and G2500 may be annealed in order to meet the desired

3

Annual Book of ASTM Standards, Vol 03.01.

4

hardness range.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. 6.2 Appropriate heat treatment for removal of residual

1

---------------------- Page: 1 ----------------------

A 159

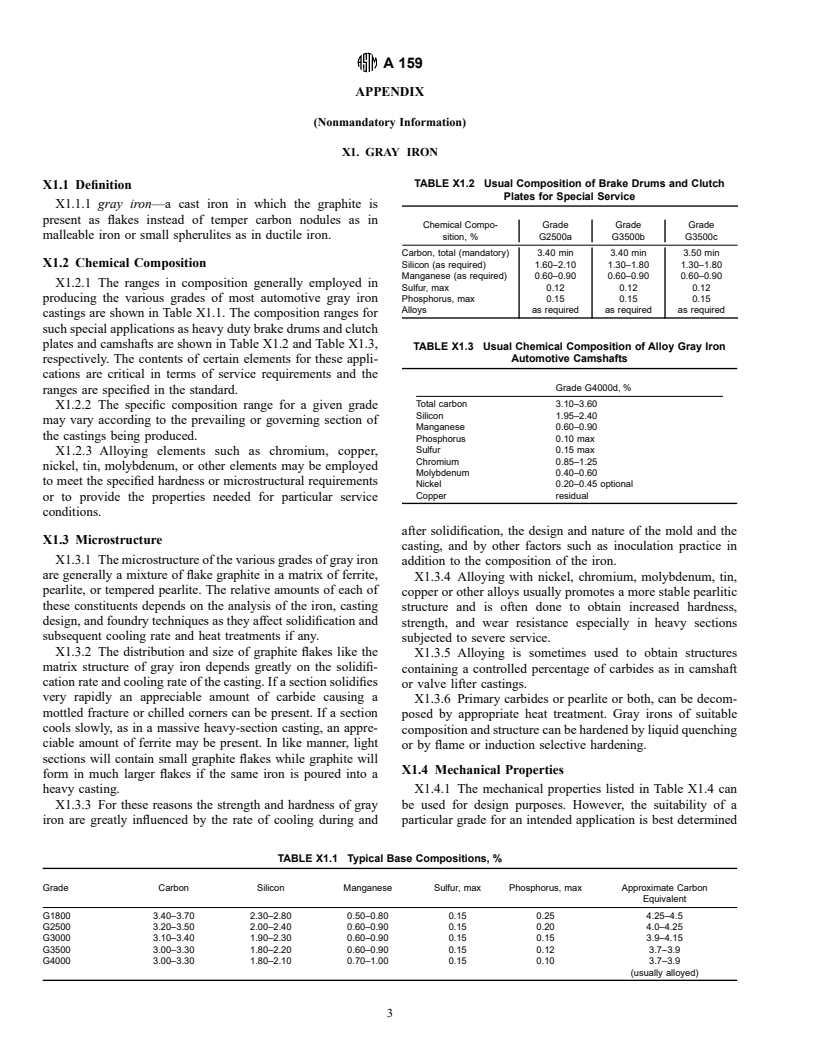

TABLE 2 Brake Drums and Clutch Plates for Special Service

A

Grade Carbon min, % Casting Hardness Microstructure

Graphite Matrix

B

G2500a 3.40 HB 170-229 Type VII, size 2–4 lamellar pearlite

4.6–4.0 BID or as agreed A distribution ferrite if present not to exceed 15%

C B

G3500b 3.40 HB 207-255 Type VII, size 3–5 lamellar pearlite

4.2–3.8 BID or as agreed A distribution ferrite or carbide if present not to exceed 5%

C B

G3500c 3.50 HB 207-255 Type VII, size 3–5 lamellar pearlite

4.2–3.8 BID or as agreed A distribution ferrite or carbide, if present not to exceed 5%

A

The che

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.