ASTM E1237-93(2014)

(Guide)Standard Guide for Installing Bonded Resistance Strain Gages

Standard Guide for Installing Bonded Resistance Strain Gages

SIGNIFICANCE AND USE

4.1 Methods and procedures used in installing bonded resistance strain gages can have significant effects upon the performance of those sensors. Optimum and reproducible detection of surface deformation requires appropriate and consistent surface preparation, mounting procedures, and verification techniques.

SCOPE

1.1 This guide provides guidelines for installing bonded resistance strain gages. It is not intended to be used for bulk or diffused semiconductor gages. This document pertains only to adhesively bonded strain gages.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1237 −93 (Reapproved 2014)

Standard Guide for

Installing Bonded Resistance Strain Gages

This standard is issued under the fixed designation E1237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope measurement of small changes of resistance produced by a

strain gage, where the gages may be wired in the following

1.1 This guide provides guidelines for installing bonded

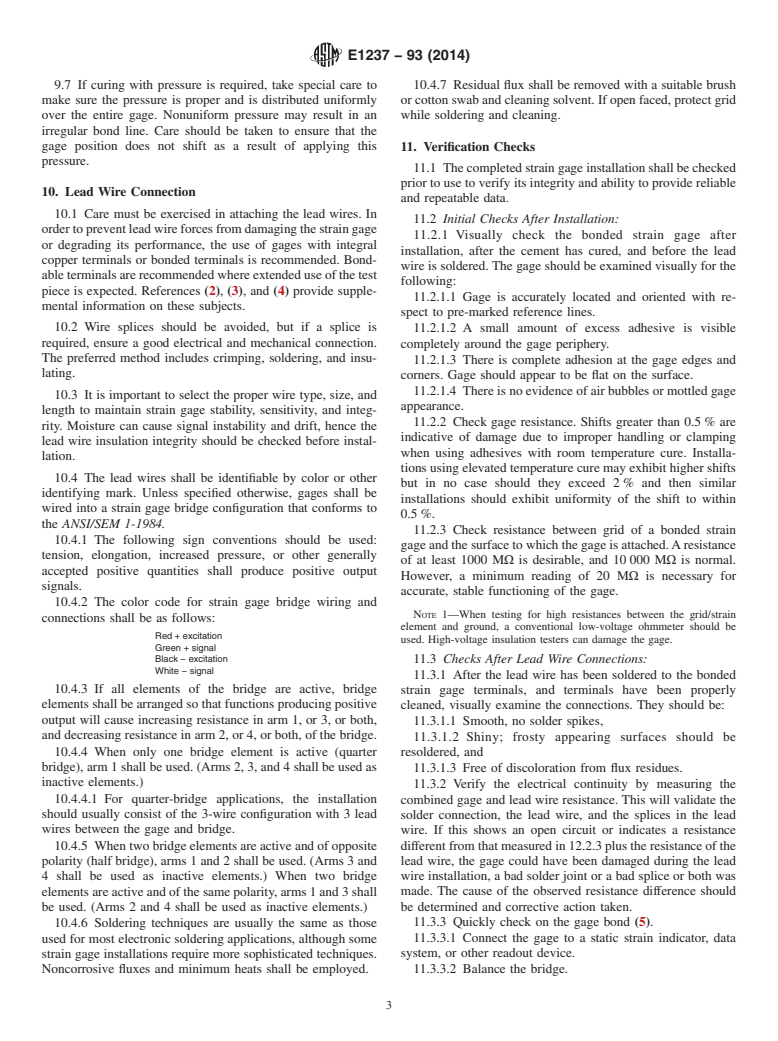

configuration (see also Fig. 1 and Fig. 2):

resistance strain gages. It is not intended to be used for bulk or

Arm 1 between + excitation and − signal

diffused semiconductor gages. This document pertains only to

Arm 2 between − excitation and − signal

adhesively bonded strain gages.

Arm 3 between + signal and − excitation

Arm 4 between + signal and + excitation

1.2 The values stated in inch-pound units are to be regarded

3.2 Definitions of Terms Specific to This Standard:

as standard. The values given in parentheses are mathematical

3.2.1 bonded resistance strain gage—a resistive element

conversions to SI units that are provided for information only

with a carrier that is attached by bonding to the base material

and are not considered standard.

so that the resistance of the element will vary as the surface of

1.3 This standard does not purport to address all of the

the base material to which it is attached is deformed.

safety concerns, if any, associated with its use. It is the

3.2.1.1 Discussion—For a complete explanation of this term

responsibility of the user of this standard to establish appro-

see Test Methods E251.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

2. Referenced Documents

4.1 Methods and procedures used in installing bonded

resistance strain gages can have significant effects upon the

2.1 ASTM Standards:

performance of those sensors. Optimum and reproducible

E251 Test Methods for Performance Characteristics of Me-

detection of surface deformation requires appropriate and

tallic Bonded Resistance Strain Gages

consistent surface preparation, mounting procedures, and veri-

2.2 Other Standards:

fication techniques.

ANSI/SEM 1-1984; Standard for Portable Strain-Indicating

Instruments—Designation of Strain Gage Bridge and

5. Gage Selection

Color Code of Terminal Connections; August 16, 1984.

5.1 Careful consideration must be given to the intended use

3. Terminology

when selecting an appropriate gage. Installation and operating

characteristics of a gage are affected by many factors such as

3.1 Definitions:

resistive element alloy, carrier material, gage length, gage and

3.1.1 lead wire—an electrical conductor used to connect a

resistive element pattern, solder tab type and configuration,

sensor to its instrumentation.

temperature compensation characteristics, resistance of active

3.1.2 resistance strain gage bridge—a common

elements, gage factor, and options desired.

Wheatsone bridge made up of strain gages used for the

5.2 Factors that should also be considered include type of

test or application, operating temperature range, environmental

This guide is under the jurisdiction of ASTM Committee E28 on Mechanical

conditions, accuracy requirements, stability, maximum

Testing and is the direct responsibility of Subcommittee E28.01 on Calibration of

elongation, test conditions (static or dynamic) and duration,

Mechanical Testing Machines and Apparatus.

and simplicity and ease of installation. Dissipation of self-

Current edition approved April 15, 2014. Published August 2014. Originally

approved in 1993. Last previous edition approved in 2009 as E1237 – 93 (2009).

generated heat to the carrier should be considered in selecting

DOI: 10.1520/E1237-93R14.

gage resistance and size of grid.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.3 To minimize errors due to strain gradients over the gage

Standards volume information, refer to the standard’s Document Summary page on

area, gage size should normally be small with respect to the

the ASTM website.

dimensions of an immediately adjacent geometric irregularity

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. (hole, fillet, etc.). However, the gage size should generally be

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1237−93 (2014)

6.3 Strain gages from different manufacturers may differ.

Generally, each manufacturer will supply instructions and

recommendations for bonding. These instructions should be

considered when making a selection.

7. Surface Preparation

7.1 The surface must be properly prepared to ensure good

bonding. Surface preparation includes solvent degreasing,

cleaning, mechanical preparation, and chemical preparation.

FIG. 1 Designation of Strain Gage Bridge and Color Code of

The surface should be smooth, but not highly polished.

Lead Wires (Full Bridge)

Preparation of this surface must be compatible with the gage,

bonding method, and base material.

7.2 Erroneous gage readings may be caused by poor bond-

ing of strain gages, which could be due to unremoved coatings

suchaspaint,scale,rust,andoils.Poorbondingmayalsoresult

from applying gages to improperly prepared surfaces, such as

mirror smooth finishes or surfaces containing deep pits and

gouges.

7.3 Strain gage manufacturers supply surface preparation

suggestions and recommendations. This information should be

reviewed and considered when preparing base material sur-

FIG. 2 Designations of Strain Gage Bridge and Color Code of

faces for the particular gages selected.

Lead Wires ( ⁄4 Bridge)

8. Gage Installation—General

8.1 All work must be performed with clean hands and tools.

large relative to the underlying material structure (grain size,

Allmaterialsneededshouldbeassembledandreadilyavailable

fabric-reinforced composite weave pattern, etc.).

at the gage installation location.

5.4 A two- or three-element rosette gage should be used

8.2 Thespecificsurfacepreparationproceduresshouldbein

unless the strain state is unquestionably uniaxial. A single-

accordancewiththeinstructionssuppliedforthebondingagent

element gage may be selected to measure the strain due to a

selected. Bonding agent handling and safety precautions

uniaxial strain state if the principal directions are known.

should be reviewed and carefully followed.

5.5 Temperature compensation of the gage should be se-

8.3 The detailed gage installation procedures available from

lected to match the thermal coefficient of expansion of the base

the strain gage manufacturer for the particular gage/bonding

material, where possible. As a note of caution, for extreme

technique system selected should be carefully reviewed and

temperature changes, nominal or handbook data on the thermal

rigorously followed. Deviations from these procedures, if any,

expansion characteristics of the base material may not be

should be documented and verified to ensure that the installa-

sufficiently accurate, and actual calibration may be required.

tion will yield suitably accurate results.

5.6 Strain gage manufacturers provide detailed critiques of

4 8.4 Gage handling and alignment procedures should be

the various factors that affect gage selection (1).

rigorously followed. Deviations, if any, should be documented.

5.7 For nonroutine applications, the advice of experienced

users and of strain gage manufacturers should be sought. 9. Gage Installation—Adhesive

Specific verification tests may be required to ensure accurate

9.1 Ensure that the proper adhesive is selected for a given

results.

gage type. Follow gage manufacturer’s recommendations for

selecting an adhesive.

6. Bonding Technique Selection

9.2 The environment to which a gage is to be subjected and

6.1 Selection of the proper bonding technique and agent is

test duration should be considered when selecting an adhesive.

important. Because the bonding agent becomes part of the

9.3 Ensure that the adhesive to be used is not out-of-date

strain gage system, many of the gage selection factors should

with regard to storage and shelf life requirements.

be considered in bonding technique or agent selection.

9.4 Ensure that test material temperature range and gage/

6.2 Additional selection factors include compatibility of the

bonding system temperature range are compatible.

bonding materials used in the selected gage construction with

thematerialundertest,environmentalconditions,andavailable

9.5 Temperatures and times should be monitored to ensure

installation time.

that the adhesive temperature and pot life requirements, if

applicable, are not exceeded.

9.6 Adhesive curing methods and schedules should be

The boldface numbers in parentheses refer to the list of references at the end of

this standard. rigorously followed. Deviations, if any, should be documented.

E1237−93 (2014)

9.7 If curing with pressure is required, take special care to 10.4.7 Residual flux shall be removed with a suitable brush

make sure the pressure is proper and is distributed uniformly or cotton sw

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1237 − 93 (Reapproved 2009) E1237 − 93 (Reapproved 2014)

Standard Guide for

Installing Bonded Resistance Strain Gages

This standard is issued under the fixed designation E1237; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This guide provides guidelines for installing bonded resistance strain gages. It is not intended to be used for bulk or diffused

semiconductor gages. This document pertains only to adhesively bonded strain gages.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E251 Test Methods for Performance Characteristics of Metallic Bonded Resistance Strain Gages

2.2 Other Standards:

ANSI/SEM 1-1984; Standard for Portable Strain-Indicating Instruments—Designation of Strain Gage Bridge and Color Code

of Terminal Connections; August 16, 1984.

3. Terminology

3.1 Definitions:

3.1.1 lead wire—an electrical conductor used to connect a sensor to its instrumentation.

3.1.2 resistance strain gage bridge—a common

Wheatsone bridge made up of strain gages used for the measurement of small changes of resistance produced by a strain gage,

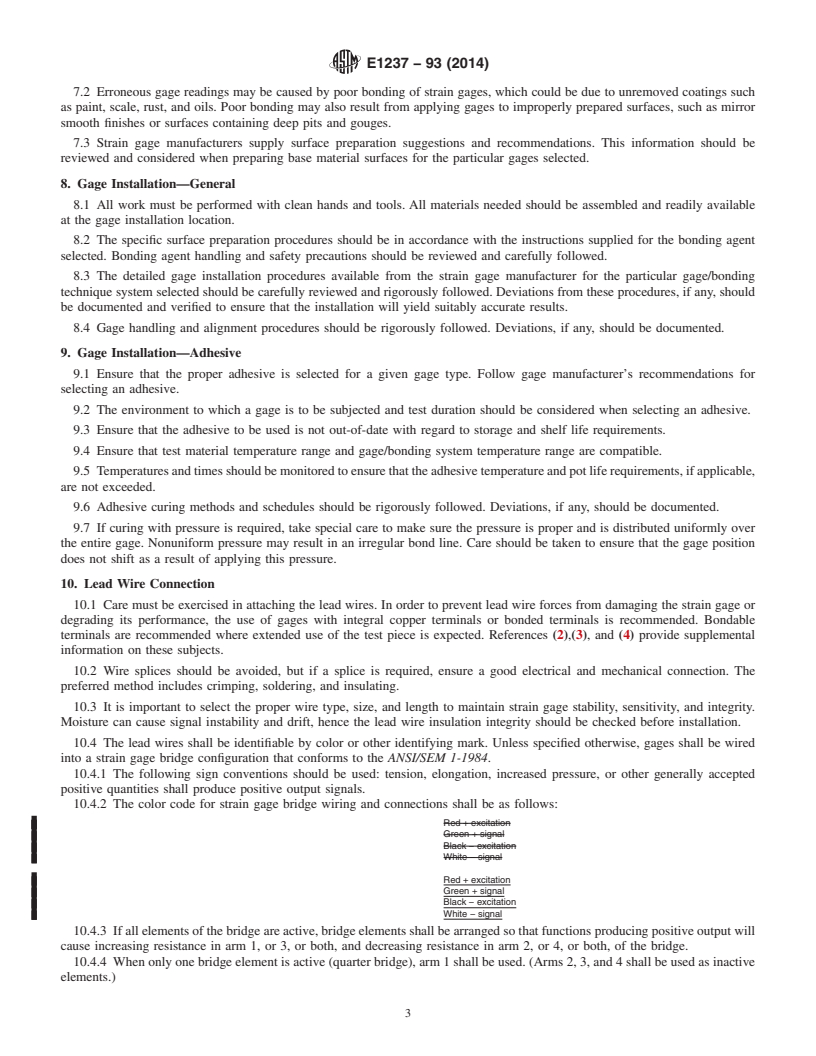

where the gages may be wired in the following configuration (see also Fig. 1 and Fig. 2):

Arm 1 between + excitation and − signal

Arm 2 between − excitation and − signal

Arm 3 between + signal and − excitation

Arm 4 between + signal and + excitation

Arm 1 between + excitation and − signal

Arm 2 between − excitation and − signal

Arm 3 between + signal and − excitation

Arm 4 between + signal and + excitation

3.2 Definitions of Terms Specific to This Standard:

3.2.1 bonded resistance strain gage—a resistive element with a carrier that is attached by bonding to the base material so that

the resistance of the element will vary as the surface of the base material to which it is attached is deformed. (For a complete

definition of this term see Test Methods E251.)

This guide is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.01 on Calibration of Mechanical

Testing Machines and Apparatus.

Current edition approved April 1, 2009April 15, 2014. Published September 2009August 2014. Originally approved in 1993. Last previous edition approved in 20032009

as E1237 – 93 (2003).(2009). DOI: 10.1520/E1237-93R09.10.1520/E1237-93R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute, 11 W. 42nd St., 13th floor,Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.10036,

http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1237 − 93 (2014)

FIG. 1 Designation of Strain Gage Bridge and Color Code of

FIG. 2 Designations of Strain Gage Bridge and Color Code of

Lead Wires (Full Bridge)

Lead Wires ( ⁄4 Bridge)

3.2.1.1 Discussion—

For a complete explanation of this term see Test Methods E251.

4. Significance and Use

4.1 Methods and procedures used in installing bonded resistance strain gages can have significant effects upon the performance

of those sensors. Optimum and reproducible detection of surface deformation requires appropriate and consistent surface

preparation, mounting procedures, and verification techniques.

5. Gage Selection

5.1 Careful consideration must be given to the intended use when selecting an appropriate gage. Installation and operating

characteristics of a gage are affected by many factors such as resistive element alloy, carrier material, gage length, gage and

resistive element pattern, solder tab type and configuration, temperature compensation characteristics, resistance of active

elements, gage factor, and options desired.

5.2 Factors that should also be considered include type of test or application, operating temperature range, environmental

conditions, accuracy requirements, stability, maximum elongation, test conditions (static or dynamic) and duration, and simplicity

and ease of installation. Dissipation of self-generated heat to the carrier should be considered in selecting gage resistance and size

of grid.

5.3 To minimize errors due to strain gradients over the gage area, gage size should normally be small with respect to the

dimensions of an immediately adjacent geometric irregularity (hole, fillet, etc.). However, the gage size should generally be large

relative to the underlying material structure (grain size, fabric-reinforced composite weave pattern, etc.).

5.4 A two- or three-element rosette gage should be used unless the strain state is unquestionably uniaxial. A single element

single-element gage may be selected to measure the strain due to a uniaxial strain state if the principal directions are known.

5.5 Temperature compensation of the gage should be selected to match the thermal coefficient of expansion of the base material,

where possible. As a note of caution, for extreme temperature changes, nominal or handbook data on the thermal expansion

characteristics of the base material may not be sufficiently accurate, and actual calibration may be required.

5.6 Strain gage manufacturers provide detailed critiques of the various factors whichthat affect gage selection (1).

5.7 For nonroutine applications, the advice of experienced users and of strain gage manufacturers should be sought. Specific

verification tests may be required to ensure accurate results.

6. Bonding Technique Selection

6.1 Selection of the proper bonding technique and agent is important. Because the bonding agent becomes part of the strain gage

system, many of the gage selection factors should be considered in bonding technique or agent selection.

6.2 Additional selection factors include compatibility of the bonding materials used in the selected gage construction with the

material under test, environmental conditions, and available installation time.

6.3 Strain gages from different manufacturers may differ. Generally, each manufacturer will supply instructions and

recommendations for bonding. These instructions should be considered when making a selection.

7. Surface Preparation

7.1 The surface must be properly prepared to ensure good bonding. Surface preparation includes solvent degreasing, cleaning,

mechanical preparation, and chemical preparation. The surface should be smooth, but not highly polished. Preparation of this

surface must be compatible with the gage, bonding method, and base material.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

E1237 − 93 (2014)

7.2 Erroneous gage readings may be caused by poor bonding of strain gages, which could be due to unremoved coatings such

as paint, scale, rust, and oils. Poor bonding may also result from applying gages to improperly prepared surfaces, such as mirror

smooth finishes or surfaces containing deep pits and gouges.

7.3 Strain gage manufacturers supply surface preparation suggestions and recommendations. This information should be

reviewed and considered when preparing base material surfaces for the particular gages selected.

8. Gage Installation—General

8.1 All work must be performed with clean hands and tools. All materials needed should be assembled and readily available

at the gage installation location.

8.2 The specific surface preparation procedures should be in accordance with the instructions supplied for the bonding agent

selected. Bonding agent handling and safety precautions should be reviewed and carefully followed.

8.3 The detailed gage installation procedures available from the strain gage manufacturer for the particular gage/bonding

technique system selected should be carefully reviewed and rigorously followed. Deviations from these procedures, if any, should

be documented and verified to ensure that the installation will yield suitably accurate results.

8.4 Gage handling and alignment procedures should be rigorously followed. Deviations, if any, should be documented.

9. Gage Installation—Adhesive

9.1 Ensure that the proper adhesive is selected for a given gage type. Follow gage manufacturer’s recommendations for

selecting an adhesive.

9.2 The environment to which a gage is to be subjected and test duration should be considered when selecting an adhesive.

9.3 Ensure that the adhesive to be used is not out-of-date with regard to storage and shelf life requirements.

9.4 Ensure that test material temperature range and gage/bonding system temperature range are compatible.

9.5 Temperatures and times should be monitored to ensure that the adhesive temperature and pot life requirements, if applicable,

are not exceeded.

9.6 Adhesive curing methods and schedules should be rigorously followed. Deviation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.