ASTM E1515-00

(Test Method)Standard Test Method for Minimum Explosible Concentration of Combustible Dusts

Standard Test Method for Minimum Explosible Concentration of Combustible Dusts

SCOPE

1.1 This test method covers the determination of the minimum concentration of a dust-air mixture that will propagate a deflagration in a near-spherical closed vessel of 20 L or greater volume.

Note 1-The minimum explosible concentration (MEC) is also referred to as the lower explosibility limit (LEL) or lean flammability limit (LFL).

1.2 Data obtained from this test method provide a relative measure of the deflagration characteristics of dust clouds.

1.3 This test method should be used to measure and describe the properties of materials in response to heat and flame under controlled laboratory conditions and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1515 – 00

Standard Test Method for

Minimum Explosible Concentration of Combustible Dusts

This standard is issued under the fixed designation E 1515; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method describes procedures for measuring the minimum concentration of a combustible

dust (dispersed in air) that is capable of propagating a deflagration. The tests are made in laboratory

chambers that have volumes of 20 L or larger.

1. Scope D 3175 Test Method for Volatile Matter in the Analysis

Sample of Coal and Coke

1.1 This test method covers the determination of the mini-

E 681 Test Method for Concentration Limits of Flammabil-

mum concentration of a dust-air mixture that will propagate a

ity of Chemicals

deflagration in a near-spherical closed vessel of 20 L or greater

E 1226 Test Method for Pressure and Rate of Pressure Rise

volume.

for Combustible Dusts

NOTE 1—The minimum explosible concentration (MEC) is also re-

ferred to as the lower explosibility limit (LEL) or lean flammability limit

3. Terminology

(LFL).

3.1 Definitions of Terms Specific to This Standard:

1.2 Data obtained from this test method provide a relative

3.1.1 dust concentration, n—the mass of dust divided by the

measure of the deflagration characteristics of dust clouds.

internal volume of the chamber.

1.3 This test method should be used to measure and describe

3.1.2 (dP/dt) , n—the maximum rate of pressure rise dur-

ex

the properties of materials in response to heat and flame under

ing the course of a single deflagration test.

controlled laboratory conditions and should not be used to

3.1.3 minimum explosible concentration (MEC), n—the

describe or appraise the fire hazard or fire risk of materials,

minimum concentration of a combustible dust cloud that is

products, or assemblies under actual fire conditions. However,

capable of propagating a deflagration through a uniform

results of this test may be used as elements of a fire risk

mixture of the dust and air under the specified conditions of

assessment that takes into account all of the factors that are

test.

pertinent to an assessment of the fire hazard of a particular end

3.1.4 P , n—the absolute pressure at the time of

ignition

use.

ignition.

1.4 The values stated in SI units are to be regarded as the

3.1.5 DP , n—the pressure rise in the chamber due to

ignitor

standard.

the ignitor by itself.

1.5 This standard does not purport to address all of the

3.1.6 P , n—the maximum explosion pressure (absolute)

ex,a

safety concerns, if any, associated with its use. It is the

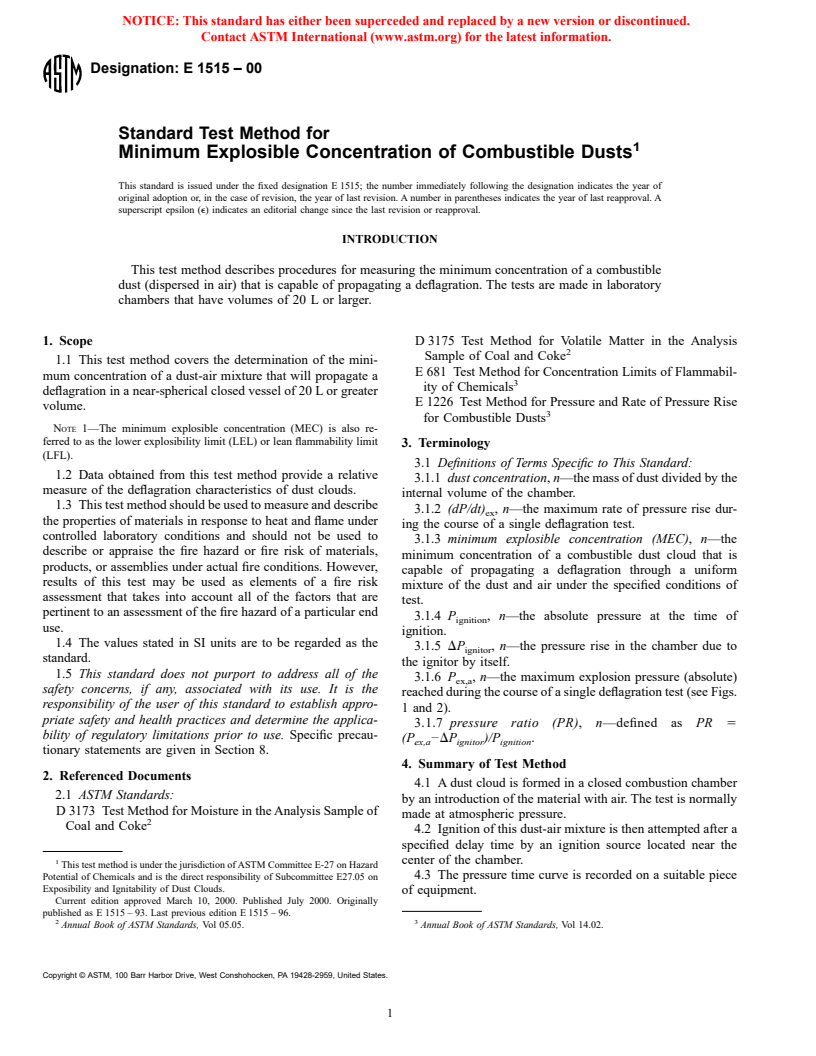

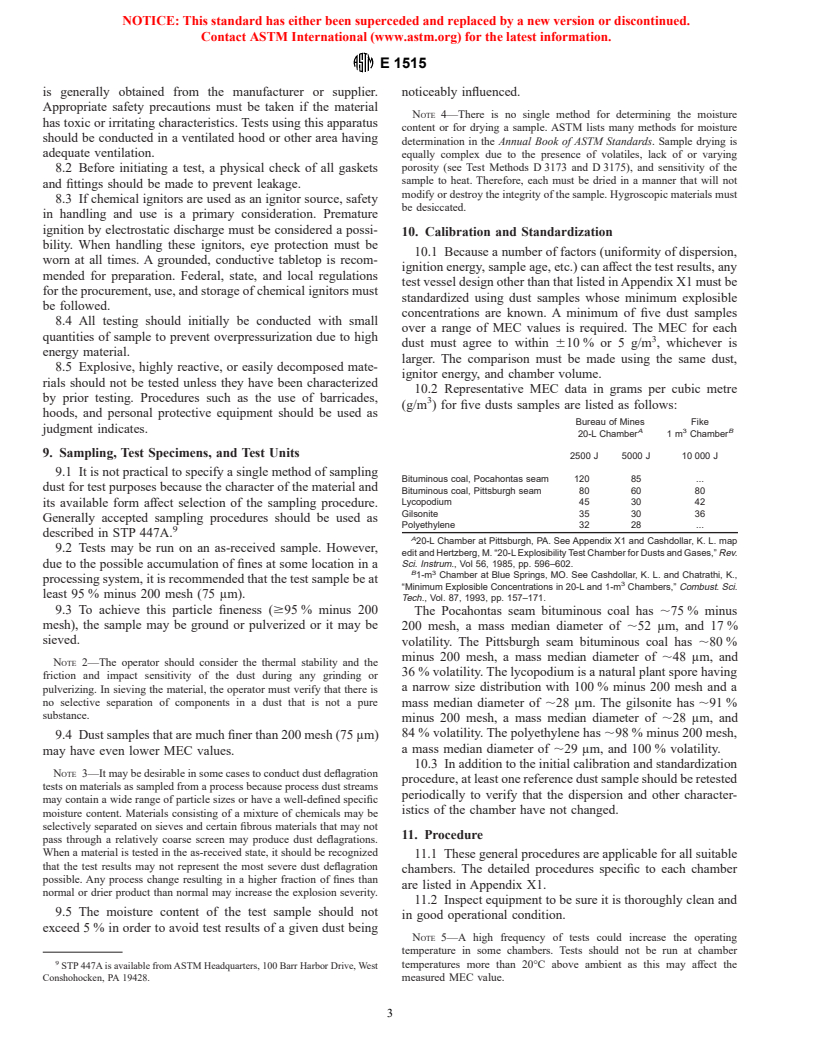

reached during the course of a single deflagration test (see Figs.

responsibility of the user of this standard to establish appro-

1 and 2).

priate safety and health practices and determine the applica-

3.1.7 pressure ratio (PR), n—defined as PR 5

bility of regulatory limitations prior to use. Specific precau-

(P −DP )/P .

ex,a ignitor ignition

tionary statements are given in Section 8.

4. Summary of Test Method

2. Referenced Documents

4.1 A dust cloud is formed in a closed combustion chamber

2.1 ASTM Standards:

by an introduction of the material with air. The test is normally

D 3173 Test Method for Moisture in the Analysis Sample of

made at atmospheric pressure.

Coal and Coke

4.2 Ignition of this dust-air mixture is then attempted after a

specified delay time by an ignition source located near the

center of the chamber.

This test method is under the jurisdiction of ASTM Committee E-27 on Hazard

4.3 The pressure time curve is recorded on a suitable piece

Potential of Chemicals and is the direct responsibility of Subcommittee E27.05 on

Exposibility and Ignitability of Dust Clouds.

of equipment.

Current edition approved March 10, 2000. Published July 2000. Originally

published as E 1515 – 93. Last previous edition E 1515 – 96.

2 3

Annual Book of ASTM Standards, Vol 05.05. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1515

FIG. 1 Typical Recorder Tracings for a Weak Dust Deflagration in

a 20-L Chamber, using a 2500 J Ignitor

a 20-L chamber, comparison tests may also be made in a larger

chamber, such asa1m -chamber.

5.6 If a dust ignites with a 5000 J ignitor but not with a 2500

J ignitor in a 20-L chamber, this may be an overdriven system.

In this case, it is recommended that the dust be tested with a

10 000 J ignitor in a larger chamber, such asa1m -chamber,

to determine if it is actually explosible.

5.7 The values obtained by this test method are specific to

the sample tested (particularly the particle size distribution)

and the method used and are not to be considered intrinsic

FIG. 2 Typical Recorder Tracings for a Moderate Dust

material constants.

Deflagration in a 20-L Chamber, using a 2500 J Ignitor

6. Interferences

5. Significance and Use 6.1 Unburned dust or combustion products remaining in the

chamber or disperser from a previous test may affect results.

5.1 This test method provides a procedure for performing

The chamber and disperser should both be cleaned thoroughly

laboratory tests to evaluate relative deflagration parameters of

before each test is made.

dusts.

5.2 The MEC as measured by this test method provides a

7. Apparatus

relative measure of the concentration of a dust cloud necessary

7.1 The equipment consists of a closed steel combustion

for an explosion.

chamber with an internal volume of at least 20 L, spherical or

5.3 Since the MEC as measured by this test method may

cylindrical (with a length to diameter ratio between 1.3:1 and

vary with the uniformity of the dust dispersion, energy of the

0.7:1) in shape.

ignitor, and propagation criteria, the MEC should be consid-

7.2 The vessel should be designed and fabricated in accor-

ered a relative rather than absolute measurement.

dance with the ASME Boiler and Pressure Vessel Code,

5.4 If too weak an ignition source is used, the measured

Section VIII. A maximum allowable working pressure

MEC would be higher than the “true” value. This is an

(MAWP) of at least 15 bar is recommended.

ignitability limit rather than a flammability limit, and the test

7.3 The apparatus must be capable of dispersing a fairly

could be described as“ underdriven.” Ideally, the ignition

uniform dust cloud of the material.

energy is increased until the measured MEC is independent of

7.4 Optical dust probes, such as those described in Foot-

ignition energy. However, at some point the ignition energy

7,8

notes 7 and 8, may be used to monitor the uniformity of the

may become too strong for the size of the test chamber, and the

dust dispersion.

system becomes “overdriven.” When the ignitor flame be-

7.5 The pressure transducer and recording equipment must

comes too large relative to the chamber volume, a test could

have a combined response rate that is greater than the maxi-

appear to result in an explosion, while it is actually just dust

mum measured rate of pressure rise.

burning in the ignitor flame with no real propagation beyond

7.6 An example of a chamber and specific procedures that

the ignitor.

have been found suitable are shown in Appendix X1.

5.5 The recommended ignition source for measuring the

MEC of dusts in 20-L chambers is a 2500 or 5000 J

8. Safety Precautions

pyrotechnic ignitor. Measuring the MEC at both ignition

8.1 Prior to handling a dust, the toxicity of the sample and

energies will provide information on the possible overdriving

its combustion products must be considered. This information

of the system. To evaluate the effect of possible overdriving in

Available from American Society of Mechanical Engineers, 345 E. 47th St.,

The pyrotechnic ignitors are available commercially from Cesana Corp., PO New York, NY 10017.

Box 182, Verona, NY 13478, or from Fr. Sobbe, GmbH, Beylingstrasse 59, Postfach Cashdollar, K. L., Liebman, I., and Conti, R. S., “Three Bureau of Mines Dust

140128, D-4600 Dortmund-Derne, Germany. Probes,” RI 8542, U.S. Bureau of Mines, 1981.

5 8

Cashdollar, K. L., and Chatrathi, K., “Minimum Explosible Dust Concentra- Conti, R. S., Cashdollar, K. L., and Liebman, I., “Improved Optical Dust Probe

tions Measured in 20-L and 1-m Chambers,” Combustion Science and Technology, for Monitoring Dust Explosions,” Review of Scientific Instruments, Vol 53, 1982, pp.

to be published, 1992. 311–313.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1515

is generally obtained from the manufacturer or supplier. noticeably influenced.

Appropriate safety precautions must be taken if the material

NOTE 4—There is no single method for determining the moisture

has toxic or irritating characteristics. Tests using this apparatus

content or for drying a sample. ASTM lists many methods for moisture

should be conducted in a ventilated hood or other area having

determination in the Annual Book of ASTM Standards. Sample drying is

adequate ventilation.

equally complex due to the presence of volatiles, lack of or varying

porosity (see Test Methods D 3173 and D 3175), and sensitivity of the

8.2 Before initiating a test, a physical check of all gaskets

sample to heat. Therefore, each must be dried in a manner that will not

and fittings should be made to prevent leakage.

modify or destroy the integrity of the sample. Hygroscopic materials must

8.3 If chemical ignitors are used as an ignitor source, safety

be desiccated.

in handling and use is a primary consideration. Premature

ignition by electrostatic discharge must be considered a possi-

10. Calibration and Standardization

bility. When handling these ignitors, eye protection must be

10.1 Because a number of factors (uniformity of dispersion,

worn at all times. A grounded, conductive tabletop is recom-

ignition energy, sample age, etc.) can affect the test results, any

mended for preparation. Federal, state, and local regulations

test vessel design other than that listed in Appendix X1 must be

for the procurement, use, and storage of chemical ignitors must

standardized using dust samples whose minimum explosible

be followed.

concentrations are known. A minimum of five dust samples

8.4 All testing should initially be conducted with small

over a range of MEC values is required. The MEC for each

quantities of sample to prevent overpressurization due to high

dust must agree to within 610 % or 5 g/m , whichever is

energy material.

larger. The comparison must be made using the same dust,

8.5 Explosive, highly reactive, or easily decomposed mate-

ignitor energy, and chamber volume.

rials should not be tested unless they have been characterized

10.2 Representative MEC data in grams per cubic metre

by prior testing. Procedures such as the use of barricades,

(g/m ) for five dusts samples are listed as follows:

hoods, and personal protective equipment should be used as

Bureau of Mines Fike

judgment indicates. A 3 B

20-L Chamber 1m Chamber

9. Sampling, Test Specimens, and Test Units

2500 J 5000 J 10 000 J

9.1 It is not practical to specify a single method of sampling

Bituminous coal, Pocahontas seam 120 85 .

dust for test purposes because the character of the material and

Bituminous coal, Pittsburgh seam 80 60 80

Lycopodium 45 30 42

its available form affect selection of the sampling procedure.

Gilsonite 35 30 36

Generally accepted sampling procedures should be used as

Polyethylene 32 28 .

described in STP 447A.

A

20-L Chamber at Pittsburgh, PA. See Appendix X1 and Cashdollar, K. L. map

9.2 Tests may be run on an as-received sample. However,

edit and Hertzberg, M. “20-L Explosibility Test Chamber for Dusts and Gases,” Rev.

due to the possible accumulation of fines at some location in a Sci. Instrum., Vol 56, 1985, pp. 596–602.

B 3

1-m Chamber at Blue Springs, MO. See Cashdollar, K. L. and Chatrathi, K.,

processing system, it is recommended that the test sample be at

“Minimum Explosible Concentrations in 20-L and 1-m Chambers,” Combust. Sci.

least 95 % minus 200 mesh (75 μm).

Tech., Vol. 87, 1993, pp. 157–171.

9.3 To achieve this particle fineness ($95 % minus 200

The Pocahontas seam bituminous coal has ;75 % minus

mesh), the sample may be ground or pulverized or it may be

200 mesh, a mass median diameter of ;52 μm, and 17 %

sieved.

volatility. The Pittsburgh seam bituminous coal has ;80 %

minus 200 mesh, a mass median diameter of ;48 μm, and

NOTE 2—The operator should consider the thermal stability and the

36 % volatility. The lycopodium is a natural plant spore having

friction and impact sensitivity of the dust during any grinding or

a narrow size distribution with 100 % minus 200 mesh and a

pulverizing. In sieving the material, the operator must verify that there is

no selective separation of components in a dust that is not a pure

mass median diameter of ;28 μm. The gilsonite has ;91 %

substance.

minus 200 mesh, a mass median diameter of ;28 μm, and

84 % volatility. The polyethylene has ;98 % minus 200 mesh,

9.4 Dust samples that are much finer than 200 mesh (75 μm)

a mass median diameter of ;29 μm, and 100 % volatility.

may have even lower MEC values.

10.3 In addition to the initial calibration and standardization

NOTE 3—It may be desirable in some cases to conduct dust deflagration

procedure, at least one reference dust sample should be retested

tests on materials as sampled from a process because process dust streams

periodically to verify that the dispersion and other character-

may contain a wide range of particle sizes or have a well-defined specific

istics of the chamber have not changed.

moisture content. Materials consisting of a mixture of chemicals may be

selectively separated on sieves and certain fibrous materials that may not

11. Procedure

pass through a relatively coarse screen may produce dust deflagrations.

When a material is tested in the as-received state, it should be recognized

11.1 These general procedures are applicable for all suitable

that the test results may not represent the most severe dust deflagration

chambers. The detailed procedures specific to each chamber

possible. Any process change resulting in a higher fraction of fines than

are listed in Appendix X1.

normal or drier product than normal may increase the explosion severity.

11.2 Inspect equipment to be sure it is thorough

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.