ASTM D6667-14

(Test Method)Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence

Standard Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet Fluorescence

SIGNIFICANCE AND USE

4.1 The sulfur content of LPG, used for fuel purposes, contributes to SOx emissions and can lead to corrosion in engine and exhaust systems. Some process catalysts used in petroleum and chemical refining can be poisoned by sulfur bearing materials in the feed stocks. This test method can be used to determine sulfur in process feeds, to measure sulfur in finished products, and can also be used for compliance determinations when acceptable to a regulatory authority.

SCOPE

1.1 This test method covers the determination of total volatile sulfur in gaseous hydrocarbons and liquefied petroleum (LP) gases. It is applicable to analysis of natural, processed, and final product materials. Precision has been determined for sulfur in gaseous hydrocarbons in the range of 1 mg/kg to 100 mg/kg and for sulfur in LP gases in the range of 1 mg/kg to 196 mg/kg (Note 1).

Note 1: An estimate of pooled limit of quantification (PLOQ), information regarding sample stability and other general information derived from the interlaboratory studies on precision can be referenced in the ASTM research reports.2,3

1.2 This test method may not detect sulfur compounds that do not vaporize under the conditions of the test.

1.3 This test method is applicable for total volatile sulfur determination in LP gases containing less than 0.35 % (mass/mass) halogen(s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 3.1 and Sections 6 and 7 for specific warning statements.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6667 −14

Standard Test Method for

Determination of Total Volatile Sulfur in Gaseous

Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet

1

Fluorescence

This standard is issued under the fixed designation D6667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

4

1.1 This test method covers the determination of total 2.1 ASTM Standards:

volatile sulfur in gaseous hydrocarbons and liquefied petro- D1070 Test Methods for Relative Density of Gaseous Fuels

leum (LP) gases. It is applicable to analysis of natural, D1265 Practice for Sampling Liquefied Petroleum (LP)

processed, and final product materials. Precision has been Gases, Manual Method

determined for sulfur in gaseous hydrocarbons in the range of D3700 Practice for Obtaining LPG Samples Using a Float-

1 mg/kg to 100 mg/kg and for sulfur in LP gases in the range ing Piston Cylinder

of 1 mg/kg to 196 mg/kg (Note 1). D5287 Practice for Automatic Sampling of Gaseous Fuels

D6299 Practice for Applying Statistical Quality Assurance

NOTE 1—An estimate of pooled limit of quantification (PLOQ),

and Control Charting Techniques to Evaluate Analytical

information regarding sample stability and other general information

Measurement System Performance

derived from the interlaboratory studies on precision can be referenced in

2,3

the ASTM research reports.

F307 Practice for Sampling Pressurized Gas for Gas Analy-

sis

1.2 This test method may not detect sulfur compounds that

5

2.2 Gas Processor Association (GPA) Standards:

do not vaporize under the conditions of the test.

GPA 2166 Obtaining Natural Gas Samples for Analysis by

1.3 This test method is applicable for total volatile sulfur

Gas Chromatography

determination in LP gases containing less than 0.35 % (mass/

GPA 2174 Obtaining Liquid Hydrocarbon Samples for

mass) halogen(s).

Analysis by Gas Chromatography

1.4 The values stated in SI units are to be regarded as

3. Summary of Test Method

standard.

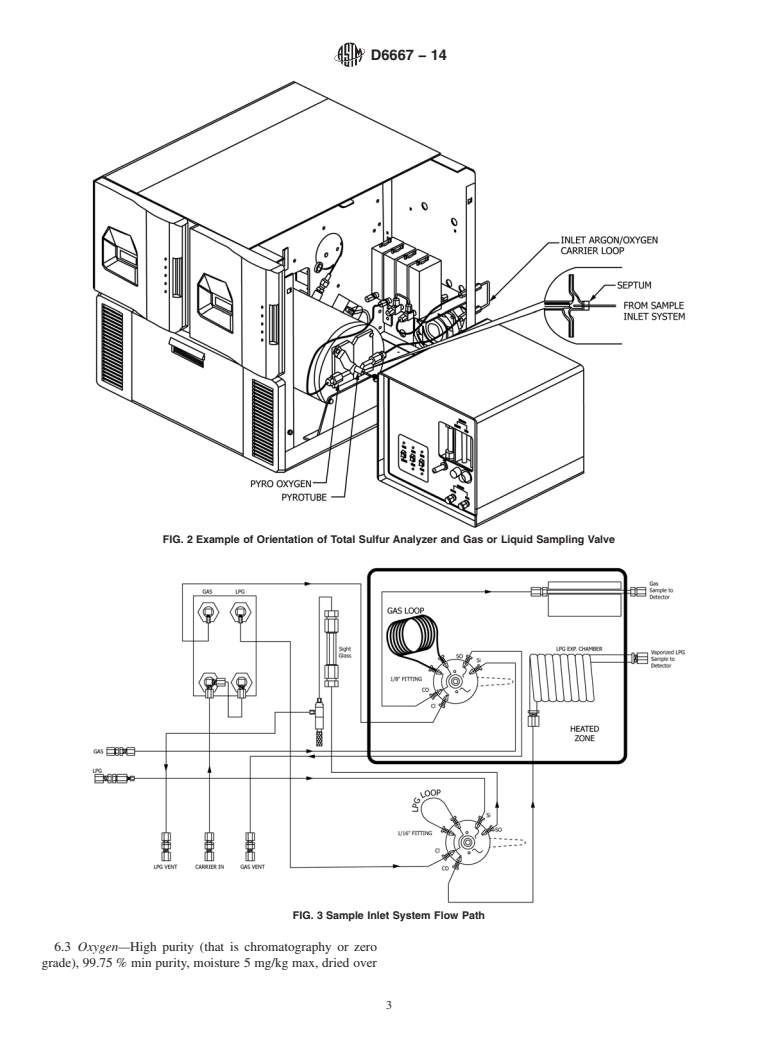

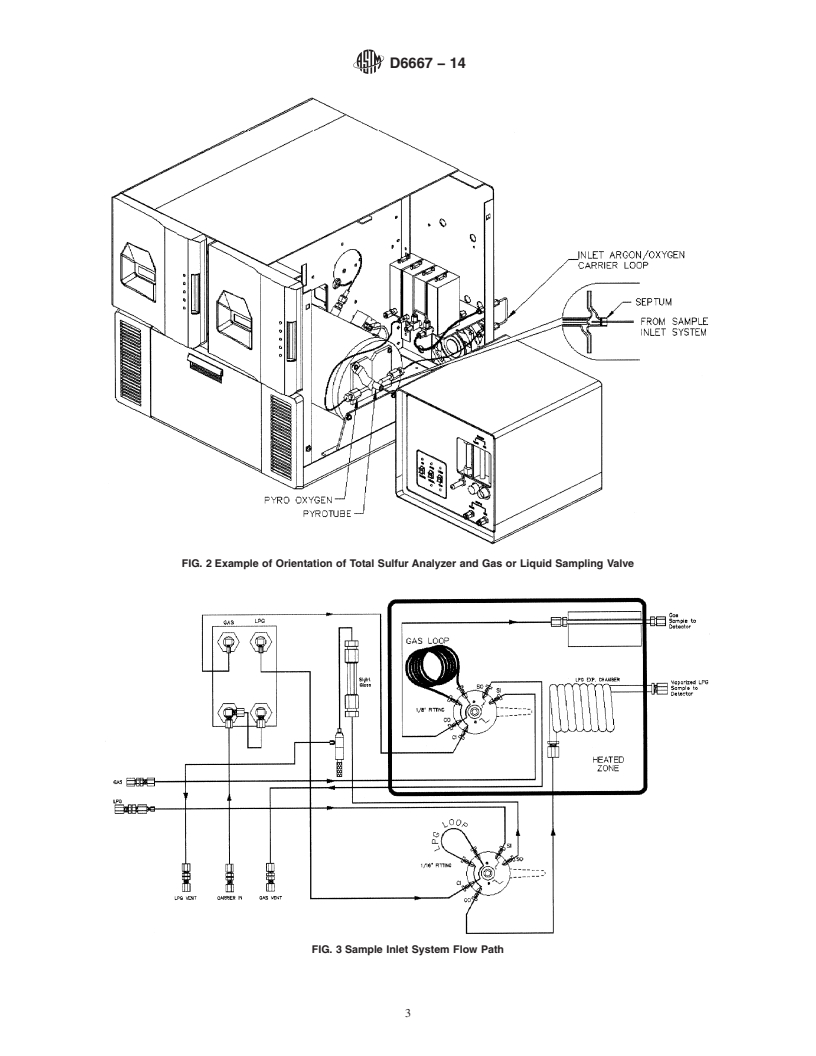

3.1 Aheatedsamplevalveisusedtoinjectgaseoussamples.

1.5 This standard does not purport to address all of the

Liquefied petroleum gas (LPG) samples are injected by a

safety concerns, if any, associated with its use. It is the

sample valve connected to a heated expansion chamber. The

responsibility of the user of this standard to establish appro-

gaseous sample then enters a high temperature combustion

priate safety and health practices and determine the applica-

tube where sulfur is oxidized to sulfur dioxide (SO)inan

bility of regulatory limitations prior to use. See 3.1 and

2

oxygen rich atmosphere. Water produced during the sample

Sections 6 and 7 for specific warning statements.

combustion is removed and the sample combustion gases are

next exposed to ultraviolet (UV) light. The SO absorbs the

2

1

This test method is under the jurisdiction of ASTM Committee D02 on

energy from the UV light and is converted to an excited sulfur

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

*

dioxide (SO ). Fluorescence emitted from the excited SO as

Subcommittee D02.03 on Elemental Analysis.

2 2

*

Current edition approved Oct. 1, 2014. Published October 2014. Originally

it returns to a stable state SO is detected by a photomultiplier

2

approved in 2001. Last previous edition approved in 2010 as D6667 – 10. DOI:

10.1520/D6667-14.

2 4

Supporting data have been filed at ASTM International Headquarters and may For referenced ASTM standards, visit the ASTM website, www.astm.org, or

beobtainedbyrequestingResearchReportRR:D02-1506.ContactASTMCustomer contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Service at service@astm.org. Standards volume information, refer to the standard’s Document Summary page on

3

Supporting data have been filed at ASTM International Headquarters and may the ASTM website.

5

beobtainedbyrequestingResearchReportRR:D02-1784.ContactASTMCustomer Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

Service at service@astm.org. 74145.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6667−14

tube,theresultingsignalisameasureofthesulfurcontainedin brane drying tube, or a permeation dryer that utilizes a

the sample. (Warning—Exposure to excessive quantities of selective capillary action for water removal.

ultraviolet light is injurious to health. The operator shall avoid

5.5 UV Fluorescence Detector—A quan

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6667 − 10 D6667 − 14

Standard Test Method for

Determination of Total Volatile Sulfur in Gaseous

Hydrocarbons and Liquefied Petroleum Gases by Ultraviolet

1

Fluorescence

This standard is issued under the fixed designation D6667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the determination of total volatile sulfur in gaseous hydrocarbons and liquefied petroleum (LP)

gases. It is applicable to analysis of natural, processed, and final product materials containing sulfur in materials. Precision has been

determined for sulfur in gaseous hydrocarbons in the range of 1 mg/kg to 100 mg/kg and for sulfur in LP gases in the range of

1 mg/kg to 196 mg/kg (Note 1).

NOTE 1—An estimate of pooled limit of quantification (PLOQ), information regarding sample stability and other general information derived from the

2,3

inter-laboratory studyinterlaboratory studies on precision can be referenced in the ASTM research report.reports.

1.2 This test method may not detect sulfur compounds that do not vaporize under the conditions of the test.

1.3 This test method is applicable for total volatile sulfur determination in LP gases containing less than 0.35 % (mass/mass)

halogen(s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See 3.1 and Sections 6 and 7 for specific warning statements.

2. Referenced Documents

4

2.1 ASTM Standards:

D1070 Test Methods for Relative Density of Gaseous Fuels

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases, Manual Method

D3700 Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

D5287 Practice for Automatic Sampling of Gaseous Fuels

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

F307 Practice for Sampling Pressurized Gas for Gas Analysis

5

2.2 Gas Processor Association (GPA) Standards:

GPA 2166 Obtaining Natural Gas Samples for Analysis by Gas Chromatography

GPA 2174 Obtaining Liquid Hydrocarbon Samples for Analysis by Gas Chromatography

3. Summary of Test Method

3.1 A heated sample valve is used to inject gaseous samples. Liquefied petroleum gas (LPG) samples are injected by a sample

valve connected to a heated expansion chamber. The gaseous sample then enters a high temperature combustion tube where sulfur

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved Oct. 1, 2010Oct. 1, 2014. Published November 2010October 2014. Originally approved in 2001. Last previous edition approved in 2010 as

D6667–04(2010).D6667 – 10. DOI: 10.1520/D6667-10.10.1520/D6667-14.

2

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1506. Contact ASTM Customer

Service at service@astm.org.

3

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:D02-1784. Contact ASTM Customer

Service at service@astm.org.

4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

5

Available from Gas Processors Association (GPA), 6526 E. 60th St., Tulsa, OK 74145.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6667 − 14

is oxidized to sulfur dioxide (SO ) in an oxygen rich atmosphere. Water produced during the sample combustion is removed and

2

the sample combustion gases are next exposed to ultraviolet (UV) light. The SO absorbs the energy from the UV light and is

2

* *

converted to an excited sulfur dioxi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.