ASTM E2680-09(2015)e1

(Test Method)Standard Test Method for Appearance of Clear, Transparent Liquids (Visual Inspection Procedure)

Standard Test Method for Appearance of Clear, Transparent Liquids (Visual Inspection Procedure)

SIGNIFICANCE AND USE

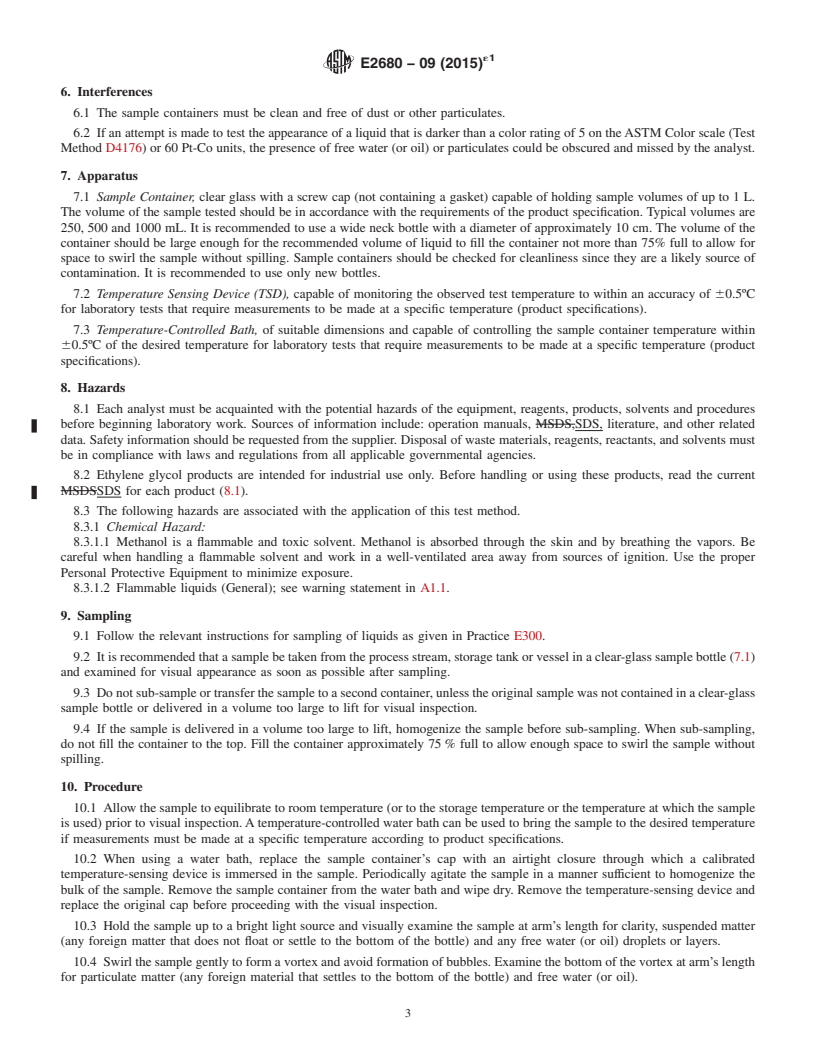

5.1 This method provides a pass/fail test for appearance of clear, transparent liquids. Many liquid organic products have a product specification requiring them to be clear and bright and free of visible particulate matter and of liquid phases other than the main liquid. Producers of these liquid organic products need a test method to confirm the quality of their products meets product specifications for appearance. Appearance is a manufacturing and sales specification test for ethylene glycol products and a loading specification test for methanol wall washes of marine vessels. This test method was originally designed for application to glycols and methanol wall washes of marine vessels, but may be applicable to other clear, transparent liquids. Individuals using this test method for other clear transparent liquids should assure themselves that the method is sufficient for use.

5.2 There are many factors that could affect the appearance during and after sampling of a liquid product. These factors may include transferring of the liquid into a different sample container, contamination by the sample container or contamination by ambient atmosphere. Sampling and evaluation procedures need to be followed to avoid undesirable effects and assure the appearance of the sample is typical for the liquid as manufactured.

SCOPE

1.1 This test method describes the visual assessment of the appearance of clear, transparent liquids for clarity and the presence of undesirable components (contamination) such as suspended matter, free water (or oil) and particulates when examined by transmitted light. Measurements requiring instrumentation are not included in this method. This test method was originally designed for application to glycols and methanol wall washes of marine vessels but may be applicable to other clear transparent liquids.

1.1.1 This method can be used as a field test at storage temperatures or as a laboratory test at room temperatures.

1.1.2 This method provides a rapid pass/fail test for clarity and contamination of clear, transparent liquids. It is a qualitative assessment only.

1.2 Review the current appropriate Safety Data Sheets (SDS) for detailed information concerning toxicity, first aid procedures, and safety precautions.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in the section on Hazards, Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E2680 − 09 (Reapproved 2015)

Standard Test Method for

Appearance of Clear, Transparent Liquids (Visual Inspection

Procedure)

This standard is issued under the fixed designation E2680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial change was made in Subsections 1.2, 8.1, and 8.2 in May 2016.

1. Scope D4176 Test Method for FreeWater and Particulate Contami-

nation in Distillate Fuels (Visual Inspection Procedures)

1.1 This test method describes the visual assessment of the

E300 Practice for Sampling Industrial Chemicals

appearance of clear, transparent liquids for clarity and the

presence of undesirable components (contamination) such as

3. Terminology

suspended matter, free water (or oil) and particulates when

examined by transmitted light. Measurements requiring instru-

3.1 Definitions of Terms Specific to This Standard:

mentation are not included in this method. This test method

3.1.1 appearance, n—the visual perception of a clear, trans-

wasoriginallydesignedforapplicationtoglycolsandmethanol

parent liquid.

wall washes of marine vessels but may be applicable to other

3.1.2 clear and bright (also referred to as clean and bright),

clear transparent liquids.

n—a condition in which the liquid is free of haze, particulates

1.1.1 This method can be used as a field test at storage

or suspended matter particles.

temperatures or as a laboratory test at room temperatures.

1.1.2 This method provides a rapid pass/fail test for clarity

3.1.2.1 bright—aconditioninwhichtheliquidistransparent

and contamination of clear, transparent liquids. It is a qualita-

with no haze or visible fee water (or free oil) in organic (or

tive assessment only.

aqueous) liquids.

1.2 Review the current appropriate Safety Data Sheets

3.1.2.2 clear—a condition in which the liquid contains no

(SDS) for detailed information concerning toxicity, first aid

visible contaminants (not more than the maximum allowed

procedures, and safety precautions.

number of suspended matter particles no greater than 1 mm in

1.3 The values stated in SI units are to be regarded as

diameter or particulates of sufficient size to be easily noted).

standard. No other units of measurement are included in this

3.1.3 free water (or free oil), n—water or oil in excess to

standard.

that soluble in the liquid at ambient temperature which may

1.4 This standard does not purport to address all of the

appearashaze,cloudiness,dropletsorawateroroillayerinan

safety concerns, if any, associated with its use. It is the

organic sample.

responsibility of the user of this standard to establish appro-

3.1.3.1 Discussion—For aqueous samples, the determina-

priate safety and health practices and determine the applica-

tion of free oil is equally important and may have an appear-

bility of regulatory limitations prior to use. Specific hazards

ance similar to that of free water or oil in organic samples.

statements are given in the section on Hazards, Section 8.

3.1.4 haze or cloudiness, n—is a scatter of light from an

2. Referenced Documents

accumulation of tiny suspended particles in the liquid.

2.1 ASTM Standards:

3.1.4.1 Discussion—Cloudiness is considered synonymous

with haze. Quantification of haze requiring instrumentation is

out of the scope of this standard.

This test method is under the jurisdiction of ASTM Committee D16 on

Aromatic Hydrocarbons and Related Chemicals and is the direct responsibility of

3.1.5 particulates, n—any foreign material in the liquid that

Subcommittee D16.16 on Industrial and Specialty Product Standards.

floats or settles to the bottom of the sample bottle.

Current edition approved June 1, 2015. Published June 2015. Originally

ɛ1

3.1.5.1 Discussion—These particulates may be small solid

approved in 2009. Last previous edition approved in 2009 as E2680– 09 . DOI:

10.1520/E2680-09R15E01.

or semi-solid particles, sometimes referred to as silt or sedi-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ment and may be the result of contamination by dust,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

corrosion, protective coating deterioration or product instabil-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E2680 − 09 (2015)

3.1.6 suspended matter particles, n—any foreign material 6. Interferences

that is in suspension in the liquid (does not float or sink) and is

6.1 The sample containers must be clean and free of dust or

insoluble or separated matter.

other particulates.

3.1.6.1 Discussion—This usually refers to things like filter

fibers, droplets, lint from materials used to dry compartments,

6.2 If an attempt is made to test the appearance of a liquid

prior cargo material or fine pieces of tank or vessel coating.

that is darker than a color rating of 5 on theASTM Color scale

(Test Method D4176) or 60 Pt-Co units, the presence of free

3.1.7 transparent, n—liquid is translucent to transmitted

water (or oil) or particulates could be obscured and missed by

light.

the analyst.

4. Summary of Test Method

7. Apparatus

4.1 An amount of liquid sample at storage or room tempera-

ture is visually examined for clarity and presence of contami-

7.1 Sample Container, clear glass with a screw cap (not

nants. The sample is collected in a transparent glass container

containing a gasket) capable of holding sample volumes of up

and held against a bright, transmitted light to examine for

to 1 L. The volume of the sample tested should be in

clarity, suspended matter, haze and the presence of free water

accordance with the requirements of the product specification.

(oroil)andsubsequentlyswirledtocreateavortextodetectthe

Typicalvolumesare250,500and1000mL.Itisrecommended

presence of particulate matter. For different categories of

to use a wide neck bottle with a diameter of approximately 10

glycols, the number of recommended maximum allowed sus-

cm.Thevolumeofthecontainershouldbelargeenoughforthe

pended matter particles to qualify for a pass is defined. (Table

recommended volume of liquid to fill the container not more

1). For other clear, transparent liquids, other numbers may be

than 75% full to allow for space to swirl the sample without

defined (for example, on the relevant product specifications).

spilling. Sample containers should be checked for cleanliness

since they are a likely source of contamination. It is recom-

5. Significance and Use

mended to use only new bottles.

5.1 This method provides a pass/fail test for appearance of

7.2 Temperature Sensing Device (TSD), capable of monitor-

clear, transparent liquids. Many liquid organic products have a

ing the observed test temperature to within an accuracy of

product specification requiring them to be clear and bright and

60.5ºC for laboratory tests that require measurements to be

freeofvisibleparticulatematterandofliquidphasesotherthan

made at a specific temperature (product specifications).

the main liquid. Producers of these liquid organic products

need a test method to confirm the quality of their products

7.3 Temperature-Controlled Bath, of suitable dimensions

meets product specifications for appearance. Appearance is a

and capable of controlling the sample container temperature

manufacturing and sales specification test for ethylene glycol

within 60.5ºC of the desired temperature for laboratory tests

products and a loading specification test

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E2680 − 09 (Reapproved 2015) E2680 − 09 (Reapproved 2015)

Standard Test Method for

Appearance of Clear, Transparent Liquids (Visual Inspection

Procedure)

This standard is issued under the fixed designation E2680; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Editorial change was made in Subsections 1.2, 8.1, and 8.2 in May 2016.

1. Scope

1.1 This test method describes the visual assessment of the appearance of clear, transparent liquids for clarity and the presence

of undesirable components (contamination) such as suspended matter, free water (or oil) and particulates when examined by

transmitted light. Measurements requiring instrumentation are not included in this method. This test method was originally

designed for application to glycols and methanol wall washes of marine vessels but may be applicable to other clear transparent

liquids.

1.1.1 This method can be used as a field test at storage temperatures or as a laboratory test at room temperatures.

1.1.2 This method provides a rapid pass/fail test for clarity and contamination of clear, transparent liquids. It is a qualitative

assessment only.

1.2 Review the current appropriate Material Safety Data Sheets (MSDS)(SDS) for detailed information concerning toxicity, first

aid procedures, and safety precautions.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific hazards statements are given in the section on Hazards, Section 8.

2. Referenced Documents

2.1 ASTM Standards:

D4176 Test Method for Free Water and Particulate Contamination in Distillate Fuels (Visual Inspection Procedures)

E300 Practice for Sampling Industrial Chemicals

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 appearance, n—the visual perception of a clear, transparent liquid.

3.1.2 clear and bright (also referred to as clean and bright), n—a condition in which the liquid is free of haze, particulates or

suspended matter particles.

3.1.2.1 bright—a condition in which the liquid is transparent with no haze or visible fee water (or free oil) in organic (or

aqueous) liquids.

3.1.2.2 clear—a condition in which the liquid contains no visible contaminants (not more than the maximum allowed number

of suspended matter particles no greater than 1 mm in diameter or particulates of sufficient size to be easily noted).

3.1.3 free water (or free oil), n—water or oil in excess to that soluble in the liquid at ambient temperature which may appear

as haze, cloudiness, droplets or a water or oil layer in an organic sample.

This test method is under the jurisdiction of ASTM Committee E15 on Industrial and Specialty Chemicals and is the direct responsibility of Subcommittee E15.02 on

Product Standards.

ϵ1ɛ1

Current edition approved June 1, 2015. Published June 2015. Originally approved in 2009. Last previous edition approved in 2009 as E2680–09 . DOI:

10.1520/E2680-09R15.10.1520/E2680-09R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E2680 − 09 (2015)

3.1.3.1 Discussion—

For aqueous samples, the determination of free oil is equally important and may have an appearance similar to that of free water

or oil in organic samples.

3.1.4 haze or cloudiness, n—is a scatter of light from an accumulation of tiny suspended particles in the liquid.

3.1.4.1 Discussion—

Cloudiness is considered synonymous with haze. Quantification of haze requiring instrumentation is out of the scope of this

standard.

3.1.5 particulates, n—any foreign material in the liquid that floats or settles to the bottom of the sample bottle.

3.1.5.1 Discussion—

These particulates may be small solid or semi-solid particles, sometimes referred to as silt or sediment and may be the result of

contamination by dust, corrosion, protective coating deterioration or product instability.

3.1.6 suspended matter particles, n—any foreign material that is in suspension in the liquid (does not float or sink) and is

insoluble or separated matter.

3.1.6.1 Discussion—

This usually refers to things like filter fibers, droplets, lint from materials used to dry compartments, prior cargo material or fine

pieces of tank or vessel coating.

3.1.7 transparent, n—liquid is translucent to transmitted light.

4. Summary of Test Method

4.1 An amount of liquid sample at storage or room temperature is visually examined for clarity and presence of contaminants.

The sample is collected in a transparent glass container and held against a bright, transmitted light to examine for clarity, suspended

matter, haze and the presence of free water (or oil) and subsequently swirled to create a vortex to detect the presence of particulate

matter. For different categories of glycols, the number of recommended maximum allowed suspended matter particles to qualify

for a pass is defined. (Table 1). For other clear, transparent liquids, other numbers may be defined (for example, on the relevant

product specifications).

5. Significance and Use

5.1 This method provides a pass/fail test for appearance of clear, transparent liquids. Many liquid organic products have a

product specification requiring them to be clear and bright and free of visible particulate matter and of liquid phases other than

the main liquid. Producers of these liquid organic products need a test method to confirm the quality of their products meets product

specifications for appearance. Appearance is a manufacturing and sales specification test for ethylene glycol products and a loading

specification test for methanol wall washes of marine vessels. This test method was originally designed for application to glycols

and methanol wall washes of marine vessels, but may be applicable to other clear, transparent liquids. Individuals using this test

method for other clear transparent liquids should assure themselves that the method is sufficient for use.

5.2 There are many factors that could affect the appearance during and after sampling of a liquid product. These factors may

include transferring of the liquid into a different sample container, contamination by the sample container or contamination by

ambient atmosphere. Sampling and evaluation procedures need to be followed to avoid undesirable effects and assure the

appearance of the sample is typical for the liquid as manufactured.

TABLE 1 Recommended Maximum Number of Suspended

Particles Allowed for a Sample to Pass

Recommended Number Typical Sample

Sample Type

of Particles Allowed Volume (mL)

Ethylene Glycol 0 – 6 500

Diethylene Glycol 0 – 6 500

Triethylene Glycol 0 – 6 500

Tetraethylene 0 – 6 500

Glycol

Methanol Wall 0 – 20 400

Wash

´1

E2680 − 09 (2015)

6. Interferences

6.1 The sample containers must be clean and free of dust or other particulates.

6.2 If an attempt is made to test the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.