ASTM A125-96(2018)

(Specification)Standard Specification for Steel Springs, Helical, Heat-Treated

Standard Specification for Steel Springs, Helical, Heat-Treated

ABSTRACT

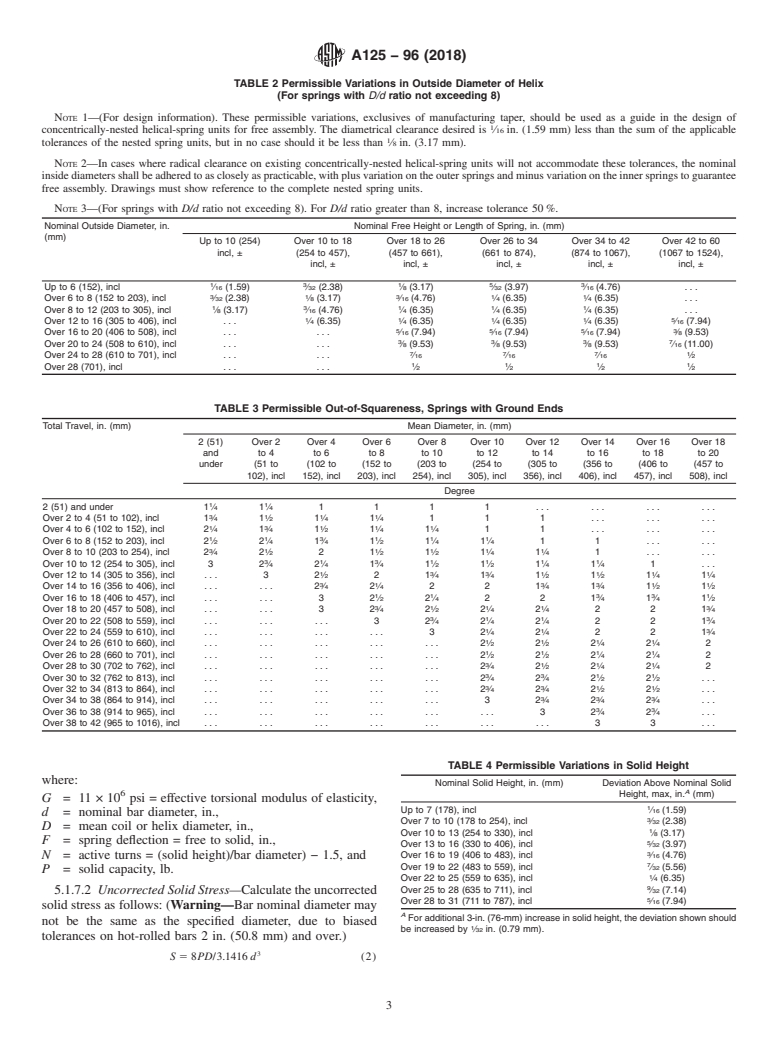

This specification covers the standard for hot-coiled, heat-treated helical compression springs with tapered, closed, squared and ground ends made of hot-wrought round steel bars. Cross sections for hot-wrought round, square, and round-cornered square bars of steel of the bar diameter shall be taken into consideration when designing and calculating the solid height, spring rate, solid stress, and solid capacity. The spring shall undergo quenching and tempering to have sufficiently high hardness and withstand the stresses developed in testing. Springs with specific indentation diameter shall not exceed the specified Brinell hardness numbers. The spring shall meet the metallurgical requirement, end construction, physical requirements such as measurements, solid height, free height, loaded height, permanent set, uniformity of pitch, outside diameter and calculations of solid capacity and uncorrected solid stress.

SCOPE

1.1 This specification covers hot-coiled, heat-treated helical compression springs with tapered, closed, squared and ground ends made of hot-wrought round steel bars 3/8 in. (9.5 mm) and larger in diameter.

1.2 This specification also serves to inform the user of practical manufacturing limits, mechanical tests, and inspection requirements applicable to the type of spring described in 1.1.

1.3 Supplementary Requirements S1 to S8 inclusive of an optional nature are provided. They shall apply only when specified by the purchaser. Details of these supplementary requirements shall be agreed upon by the manufacturer and purchaser.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A125 −96 (Reapproved 2018)

Standard Specification for

1

Steel Springs, Helical, Heat-Treated

This standard is issued under the fixed designation A125; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E10Test Method for Brinell Hardness of Metallic Materials

E112Test Methods for Determining Average Grain Size

1.1 This specification covers hot-coiled, heat-treated helical

E709Guide for Magnetic Particle Testing

compression springs with tapered, closed, squared and ground

3

endsmadeofhot-wroughtroundsteelbars ⁄8in.(9.5mm)and

3. Ordering Information

larger in diameter.

3.1 Orders for springs under this specification shall include

1.2 This specification also serves to inform the user of

the following information:

practical manufacturing limits, mechanical tests, and inspec-

3.1.1 Quantity,

tion requirements applicable to the type of spring described in

3.1.2 Name of material,

1.1.

3.1.3 A drawing or list showing required dimensions and

1.3 Supplementary Requirements S1 to S8 inclusive of an

loads, and part number,

optional nature are provided. They shall apply only when

3.1.4 Packaging, marking and loading, and

specified by the purchaser. Details of these supplementary

3.1.5 End use.

requirements shall be agreed upon by the manufacturer and

NOTE 1—A typical ordering description is: 500 springs Drawing 3303

purchaser.

Rev. A. to ASTM A125, 1095 steel, for cyclical machine operation.

1.4 Thevaluesstatedininch-poundunitsaretoberegarded Palletize, maximum weight 4000 lb.

as standard. The values given in parentheses are mathematical

4. Materials and Manufacture

conversions to SI units that are provided for information only

and are not considered standard.

4.1 Material:

1.5 This international standard was developed in accor- 4.1.1 Unless otherwise specified, the springs shall be made

dance with internationally recognized principles on standard- of carbon steel bars conforming to the requirements of Speci-

ization established in the Decision on Principles for the

fication A689. Due to hardenability limitations of carbon steel,

5

Development of International Standards, Guides and Recom- it is suggested that the bar diameter be limited to 1 ⁄8 in. (41.8

mendations issued by the World Trade Organization Technical

mm) max in order to withstand the maximum test stress

Barriers to Trade (TBT) Committee. requirements of this specification.

4.1.2 If alloy steel is specified, the springs shall be made

2. Referenced Documents

fromalloysteelbarsconformingtoSpecificationA689.Anyof

2

the alloy steel grades referred to may be used at the option of

2.1 ASTM Standards:

the spring manufacturer, providing that a minimum as-

A29/A29MSpecificationforGeneralRequirementsforSteel

quenched hardness of Rockwell HRC-50 will be achieved at

Bars, Carbon and Alloy, Hot-Wrought

the center of the bar section representing the spring when

A689Specification for Carbon and Alloy Steel Bars for

quenched in the same media and manner as the spring.

Springs

4.1.3 Springs Made from Bars Over 2 in. (50.8 mm)—Note

that the bias tolerance (reference Specification A29/A29M,

TableA1.1 on Permissible Variations in Cross Section for

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Hot-Wrought Round, Square, and Round-Cornered Square

Stainless Steel and RelatedAlloysand is the direct responsibility of Subcommittee

A01.15 on Bars.

Bars of Steel) of the bar diameter shall be taken into consid-

Current edition approved Sept. 1, 2018. Published September 2018. Originally

eration when designing and calculating the solid height, spring

ɛ1

approved in 1929. Last previous edition approved in 2013 as A125–96 (2013) .

rate, solid stress, and solid capacity.

DOI: 10.1520/A0125-96R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Hardness:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2.1 The springs must be quenched and tempered to a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sufficiently high hardness (strength) to withstand the stresses

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A125−96 (2018)

developed in testing the finished spring. The maximum hard

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.