ASTM G118-96

(Guide)Standard Guide for Recommended Format of Wear Test Data Suitable for Databases

Standard Guide for Recommended Format of Wear Test Data Suitable for Databases

SCOPE

1.1 This guide is intended to assist in the organization of wear test data for the purpose of data storage in computerized databases. It is meant to assist the user in developing databases for the purpose of data comparison and utilization. Data elements (fields) are described covering both materials and wear test issues.

General Information

Relations

Standards Content (Sample)

Designation: G 118 – 96

Standard Guide for

Recommended Format of Wear Test Data Suitable for

1

Databases

This standard is issued under the fixed designation G 118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This guide is intended to assist in the organization of 3.1 Definitions—For definitions of some terms applicable to

wear test data for the purpose of data storage in computerized this guide, see Practice E 1314 and Terminology G 40.

databases. It is meant to assist the user in developing databases 3.2 Definitions of Terms Specific to This Standard:

for the purpose of data comparison and utilization. Data 3.2.1 class—a major material class, for example, metal,

elements (fields) are described covering both materials and ceramic, polymer, etc.

wear test issues. 3.2.2 common name—a name frequently given to a particu-

lar material, for example, nylon.

2. Referenced Documents

3.2.3 contact environment—terms describing the environ-

2.1 ASTM Standards:

ment at the contact, for example, atmosphere, humidity, gases

2

E 527 Practice for Numbering Metals and Alloys (UNS) present, and so forth.

E 1314 Practice for Structuring Terminological Records

3.2.4 form—the material form, for example, rod, sheet, and

Relating to Computerized Test Reporting and Materials cast.

3

Designation Formats

3.2.5 grade—designation given a material by a manufac-

E 1338 Guide for the Identification of Metals and Alloys in turer.

3

Computerized Material Property Databases

3.2.6 hardness—the usual methods for hardness determina-

4

G 40 Terminology Relating to Wear and Erosion tions include Rockwell C, Vickers, etc. Load should be

G 65 Test Method for Measuring Abrasion Using the Dry

specified.

4

Sand/Rubber Wheel Apparatus 3.2.7 processing treatment—a descriptive phrase on the

G 75 Test Method for Determination of Slurry Abrasivity process method, for example, casting, hardening, and condi-

(Miller Number) and Slurry Abrasion Response of Mate-

tions, for example, time, temperature.

4

rials (SAR Number) 3.2.8 specification—a precise statement of a set of require-

G 77 Test Method for Ranking Resistance of Materials to

ments to be satisfied by a material, promulgated by an

4

Sliding Wear Using Block-on-Ring Wear Test organization, for example, ASTM, SAE, etc.

G 83 Test Method for Wear Testing with a Crossed-Cylinder

3.2.9 specimen shape—the shape of the test specimen, for

4

Apparatus example, block, pin.

G 99 Test Method for Wear Testing with a Pin-on-Disk

3.2.10 standard test specification—test designation, that is,

4

Apparatus ASTM, SAE, etc. (Note that the test must conform to the

G 105 Test Method for Conducting Wet Sand/Rubber

standard if so designated.)

4

Wheel Abrasion Tests 3.2.11 subclass—subdivisions of a class, for example, fer-

G 115 Guide for Measuring and Reporting Friction Coeffi-

rous, boride, etc.

4

cients

4

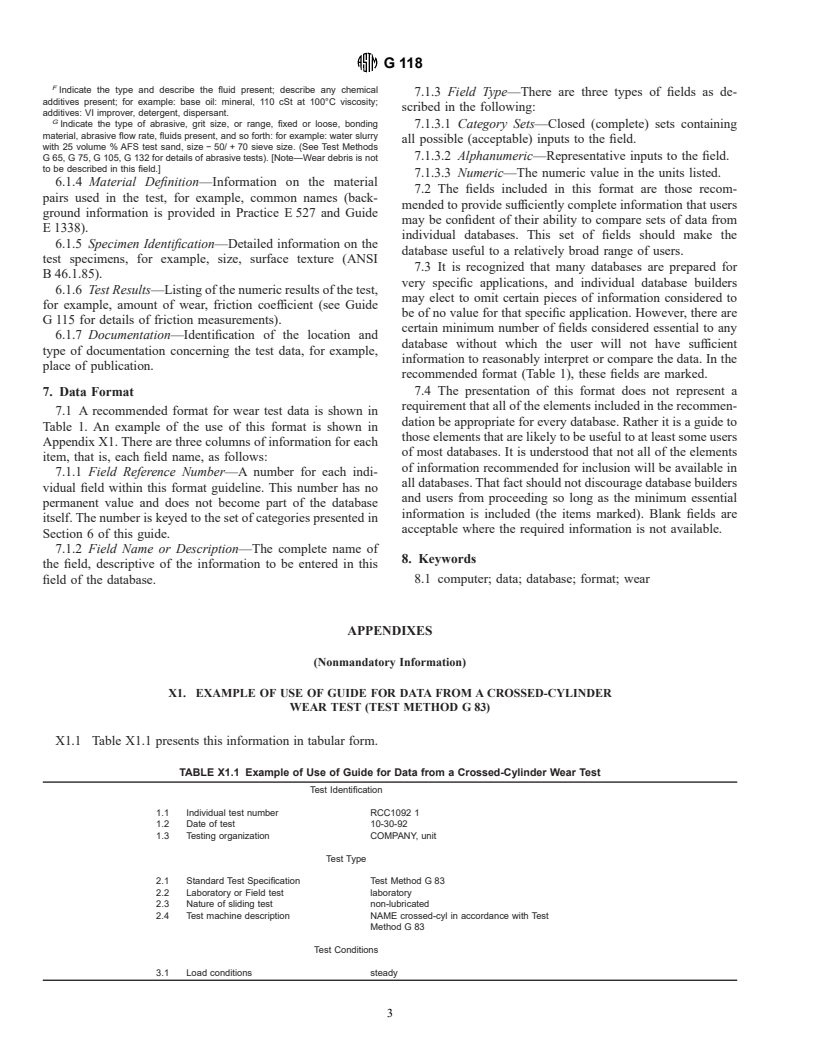

4. Summary of Guide

G 132 Test Method for Pin Abrasion Testing

2.2 ANSI Standard: 4.1 This guide specifies a set of fields that form the basis of

5

B 46.1.85 Surface Texture, Surface Roughness, Waviness a format for organizing wear data for use in computerized

databases. Sufficient information is provided in this guide to

enable the user to construct a database structure suitable for an

1

This guide is under the jurisdiction of ASTM Committee G-2 on Wear and

intended application involving wear. A set of essential fields in

Erosion and is the direct responsibility of Subcommittee G02.20 on Computeriza-

the database are identified. The user may also add or delete

tion in Wear and Erosion.

fields to customize the database format for any particular

Current edition approved Oct. 10, 1996. Published December 1996. Originally

published as G 118 – 93. Last previous edition G 118 – 95.

application.

2

Annual Book of ASTM Standards, Vol 01.01.

3

Annual Book of ASTM Standards, Vol 14.01.

5. Significance and Use

4

Annual Book of ASTM Standards, Vol 03.02.

5

5.1 This guide can be used to facilitate categorizing wear

Available from ANSI, 11 W. 42nd St., 13th Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G118

data for insertion into a computerized database. This guide

Field

identifies a set of essential data fields which should be provided

B

Field Name or Description Field Type or Unit

A

No.

for all records, and also identifies additional optional data

C

3.5 Velocity value or range m/s

fields. This guide does not require the use of any particular

C

3.6 Total sliding distance m

database format, nor does it endorse any particular computer

3.7 Sliding distance per cycle m

C

database software. 3.8 Test temperature °C

C

3.9 Ambient temperature °C

5.2 B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.