ASTM E688-94(1999)

(Test Method)Standard Test Methods for Waste Glass as a Raw Material for Glass Manufacturing

Standard Test Methods for Waste Glass as a Raw Material for Glass Manufacturing

SCOPE

1.1 These test methods give the various tests for assessing the compliance of glass recovered from wastes for use as a raw material for glass manufacturing.

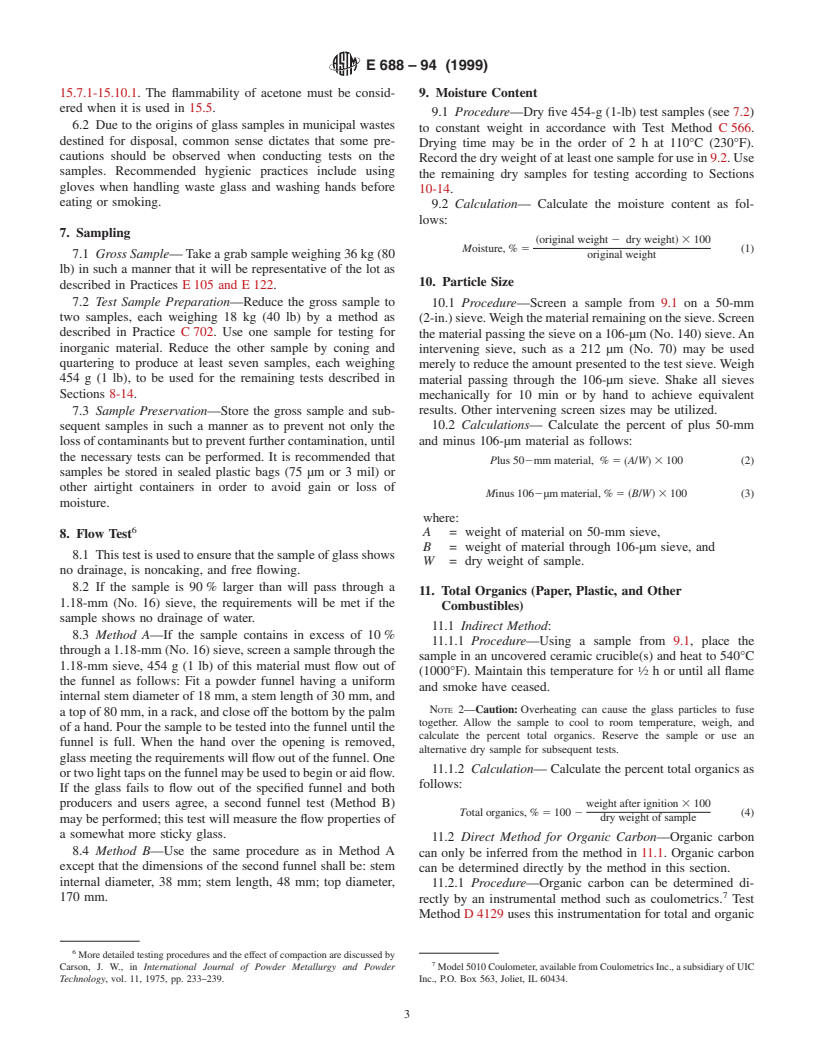

1.2 The test methods combine visual examinations with both chemical and physical tests. A flow chart of the testing sequence is included in this test method (see Fig. 1).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For hazard statements, see 5.3, and Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 688 – 94 (Reapproved 1999)

Standard Test Methods for

Waste Glass as a Raw Material for Glass Manufacturing

This standard is issued under the fixed designation E688; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E11 Specification for Wire-Cloth Sieves for Testing Pur-

poses

1.1 These test methods give the various tests for assessing

E105 Practice for Probability Sampling of Materials

thecomplianceofglassrecoveredfromwastesforuseasaraw

E122 Practice for Choice of Sample Size to Estimate a

material for glass manufacturing.

Measure of Quality for a Lot or Process

1.2 The test methods combine visual examinations with

both chemical and physical tests. A flow chart of the testing

3. Significance and Use

sequence is included in this test method (see Fig. 1).

3.1 These test methods provide a means for determining

1.3 The values stated in SI units are to be regarded as the

whether waste glass is suitable for use as a raw material for

standard. The values given in parentheses are for information

glass manufacturing.

only.

1.4 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 The following various items of equipment required may

responsibility of the user of this standard to establish appro-

be purchased from most laboratory supply houses:

priate safety and health practices and determine the applica-

4.1.1 Aspirator.

bility of regulatory limitations prior to use. For hazard state-

4.1.2 Balance.

ments, see 5.3, and Section 6.

4.1.3 Burner, Fisher (Meker) type.

4.1.4 Crucible, porcelain or other ceramic.

2. Referenced Documents

4.1.5 Crucible, platinum.

2.1 ASTM Standards:

4.1.6 Flask, filtering, with side tube, 2000-ml.

C169 Test Methods for Chemical Analysis of Soda-Lime

4.1.7 Funnel, Büchner, approximately 171 mm in diameter.

and Borosilicate Glass

4.1.8 Funnel, approximately 150 mm in diameter, filtering.

C566 TestMethodforTotalMoistureContentofAggregate

4.1.9 Furnace, 540°C or 1000°F.

by Drying

4.1.10 Clamps, tubing, screw compressor.

C702 Practice for Reducing Samples of Aggregate to

4.1.11 Magnet, C-shaped, Alnico.

Testing Size

4.1.12 Magnifier,53,103.

C729 Test Method for Density of Glass by the Sink-Float

4.1.13 Oven, 110°C or 230°F.

Comparator

4.1.14 Scales, triple-beam.

D1068 Test Methods for Iron in Water

4.1.15 Sieves, U.S. Standard Series—50mm(2in.),6.3mm

D1193 Specification for Reagent Water

( ⁄4in.),1.18mm(No.16),850µm(No.20),425µm(No.40),

D2576 Test Method for Metals in Water and Waste Water

3 250 µm (No. 60), 106 µm (No. 140), conforming to Specifi-

by Atomic Absorption Spectrophotometry

cationE11.

D4129 TestMethodforTotalandOrganicCarboninWater

4.1.16 Sink-Float Standard, sp gr 2.65.

by High Temperature Oxidation and by Coulometric De-

4.1.17 Triangle, platinum.

tection

4.1.18 Tubing, vinyl.

4.1.19 Other ancillary laboratory equipment.

1 5. Reagents and Materials

These test methods are under the jurisdiction of ASTM Committee D34 on

WasteManagementandarethedirectresponsibilityofSubcommitteeD34.03.03on

5.1 Purity of Reagents—Reagent grade chemicals shall be

Industrial Recovery and Reuse.

used in all tests. Unless otherwise indicated, it is intended that

Current edition approved Nov. 15, 1994. Published January 1995. Originally

e1

published as E688–79. Last previous edition E688–79(1988)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Tygon plastic tubing, available from Norton Co., Plastics and Synthetics Div.,

the ASTM website. Dept TR2, 12 East Ave., Tallmadge, OH 44278, or equivalent, has been found

Discontinued—See 1980 Annual Book of ASTM Standards, Part 31. suitable for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 688 – 94 (1999)

FIG. 1 Simplified Testing Flow Chart

all reagents shall conform to the specifications of the Commit- 5.5 Hydrochloric Acid (3 N and 6 N) (see 12.3.2/15.11)—

tee onAnalytical Reagents of theAmerican Chemical Society, Prepare 3 N acid by diluting 1 part of concentrated hydrochlo-

where such specifications are available. Other grades may be ric acid (HCl, sp gr 1.19) with 3 parts of water. Prepare 6 N

used, provided it is first ascertained that the reagent is of acidbydiluting1partofconcentratedHClwith1partofwater.

sufficiently high purity to permit its use without lessening the

NOTE 1—Caution:These materials are corrosive and injurious to the

accuracy of the determination.

skin as well as irritating to the eyes and mucous membranes.

5.2 Purity of Water— Unless otherwise indicated, refer-

5.6 Potassium Hydroxide, Saturated Solution—Add 100 g

encestowatershallbeunderstoodtomeanreagentwater,Type

of potassium hydroxide (KOH) slowly, while stirring, to 100

II, as defined in Specification D1193.

ml water. Store this solution in a polyethylene bottle. This

5.3 Warning: Acetone (see 15.5)—This substance is highly

solution is corrosive and injurious to the skin.

flammable (Class B) and must not be used in the vicinity of

5.7 Sodium Carbonate (Na CO ).

2 3

open flames or other ignition sources. Vapors should not be

5.8 sym-Tetrabromoethane (Acetylene Tetrabromide) (sp gr

inhaled, since they can cause skin and membrane irritation.

2.964)—This substance has a threshold limit value (8 h

5.4 Ethyl Alcohol, denatured.

time-weighted average exposure) of 1 ppm and a short time

exposurelimit(15min)of1.25ppm.Itmustbeusedinahood

or under conditions of ensured ventilation.

Reagent Chemicals, American Chemical Society Specifications, American

6. Hazards

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

6.1 The analyst should be aware of good laboratory prac-

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

tices. Adequate ventilation is necessary, particularly for han-

and National Formulary, U.S.PharmaceuticalConvention,Inc.(USPC),Rockville,

MD. dling sym-tetrabromoethane and the density liquids used in

E 688 – 94 (1999)

15.7.1-15.10.1. The flammability of acetone must be consid- 9. Moisture Content

ered when it is used in 15.5.

9.1 Procedure—Dry five 454-g (1-lb) test samples (see 7.2)

6.2 Due to the origins of glass samples in municipal wastes

to constant weight in accordance with Test Method C566.

destined for disposal, common sense dictates that some pre-

Drying time may be in the order of2hat110°C (230°F).

cautions should be observed when conducting tests on the

Recordthedryweightofatleastonesampleforusein9.2.Use

samples. Recommended hygienic practices include using

the remaining dry samples for testing according to Sections

gloves when handling waste glass and washing hands before

10-14.

eating or smoking.

9.2 Calculation— Calculate the moisture content as fol-

lows:

7. Sampling

~originalweight 2 dryweight! 3100

Moisture,% 5 (1)

7.1 Gross Sample—Takeagrabsampleweighing36kg(80 originalweight

lb) in such a manner that it will be representative of the lot as

10. Particle Size

described in Practices E105 and E122.

7.2 Test Sample Preparation—Reduce the gross sample to

10.1 Procedure—Screen a sample from 9.1 on a 50-mm

two samples, each weighing 18 kg (40 lb) by a method as

(2-in.)sieve.Weighthematerialremainingonthesieve.Screen

described in Practice C702. Use one sample for testing for

thematerialpassingthesieveona106-µm(No.140)sieve.An

inorganic material. Reduce the other sample by coning and

intervening sieve, such as a 212 µm (No. 70) may be used

quartering to produce at least seven samples, each weighing

merely to reduce the amount presented to the test sieve.Weigh

454 g (1 lb), to be used for the remaining tests described in

material passing through the 106-µm sieve. Shake all sieves

Sections 8-14.

mechanically for 10 min or by hand to achieve equivalent

results. Other intervening screen sizes may be utilized.

7.3 Sample Preservation—Store the gross sample and sub-

sequent samples in such a manner as to prevent not only the 10.2 Calculations— Calculate the percent of plus 50-mm

and minus 106-µm material as follows:

lossofcontaminantsbuttopreventfurthercontamination,until

the necessary tests can be performed. It is recommended that

Plus502mmmaterial, % 5 ~A/W! 3100 (2)

samples be stored in sealed plastic bags (75 µm or 3 mil) or

other airtight containers in order to avoid gain or loss of

Minus1062µmmaterial,% 5 ~B/W! 3100 (3)

moisture.

where:

A = weight of material on 50-mm sieve,

8. Flow Test

B = weight of material through 106-µm sieve, and

8.1 Thistestisusedtoensurethatthesampleofglassshows

W = dry weight of sample.

no drainage, is noncaking, and free flowing.

8.2 If the sample is 90% larger than will pass through a

11. Total Organics (Paper, Plastic, and Other

1.18-mm (No. 16) sieve, the requirements will be met if the

Combustibles)

sample shows no drainage of water.

11.1 Indirect Method:

8.3 Method A—If the sample contains in excess of 10%

11.1.1 Procedure—Using a sample from 9.1, place the

througha1.18-mm(No.16)sieve,screenasamplethroughthe

sample in an uncovered ceramic crucible(s) and heat to 540°C

1.18-mm sieve, 454 g (1 lb) of this material must flow out of

(1000°F). Maintain this temperature for ⁄2 h or until all flame

the funnel as follows: Fit a powder funnel having a uniform

and smoke have ceased.

internal stem diameter of 18 mm, a stem length of 30 mm, and

NOTE 2—Caution:Overheating can cause the glass particles to fuse

atopof80mm,inarack,andcloseoffthebottombythepalm

together. Allow the sample to cool to room temperature, weigh, and

ofahand.Pourthesampletobetestedintothefunneluntilthe

calculate the percent total organics. Reserve the sample or use an

funnel is full. When the hand over the opening is removed,

alternative dry sample for subsequent tests.

glassmeetingtherequirementswillflowoutofthefunnel.One

11.1.2 Calculation— Calculate the percent total organics as

ortwolighttapsonthefunnelmaybeusedtobeginoraidflow.

follows:

If the glass fails to flow out of the specified funnel and both

producers and users agree, a second funnel test (Method B) weightafterignition 3100

Totalorganics,% 5100 2 (4)

dryweightofsample

maybeperformed;thistestwillmeasuretheflowpropertiesof

a somewhat more sticky glass.

11.2 Direct Method for Organic Carbon—Organic carbon

8.4 Method B—Use the same procedure as in Method A

can only be inferred from the method in 11.1. Organic carbon

except that the dimensions of the second funnel shall be: stem

can be determined directly by the method in this section.

internal diameter, 38 mm; stem length, 48 mm; top diameter,

11.2.1 Procedure—Organic carbon can be determined di-

170 mm.

rectly by an instrumental method such as coulometrics. Test

Method D4129 uses this instrumentation for total and organic

More detailed testing procedures and the effect of compaction are discussed by

Carson, J. W., in International Journal of Powder Metallurgy and Powder Model5010Coulometer,availablefromCoulometricsInc.,asubsidiaryofUIC

Technology, vol. 11, 1975, pp. 233–239. Inc., P.O. Box 563, Joliet, IL 60434.

E 688 – 94 (1999)

carboninwater.Theinstrumentcanbereadilyadaptedtosolid fc).Visuallypickouttheoff-colorglassparticles.Theoff-color

materials such as waste glass. particles should be segregated into amber, green (emerald

greenandGeorgiagreenshouldbesegregatedwhenexamining

12. Magnetic Material (Iron Contamination)

aflintglassbecauseemeraldgreenhasachromiumcontentten

12.1 The method of testing for iron contamination will

times that of Georgia green), flint, and other glass fractions.

depend on the particle size of the sample.

Georgia green can be visually distinguished from emerald

12.2 Determination of Iron Contamination in Coarse Glass

green,sinceGeorgiagreenislighterincolor.Otherglasscolors

(Larger Than 6 mm in Size):

are those other than the colors listed. Save the fractions.

12.2.1 Procedure—Using the sample from 9.1 or from a

13.2.2 Calculation— Calculate the percent off-color glass

replicate dry sample, spread a portion of the sample over a

as follows:

clean, dry surface in such a manner as not to have any piles

weightofoff2colorglass 3100

overthreeparticlesdeep.CoverthepolesofaC-shapedAlnico

Off2colorglass,% 5 (7)

dryweightofsample

magnet or its equivalent with a piece of paper or plastic film.

Draw the magnet slowly through the glass particles so as to

13.3 Examples—The following examples are used to dem-

collect any magnetic material present. Transfer the magnetic

onstrate the method of calculating the off-color fraction:

material to an appropriate container by removing the cover

13.3.1 Example 1:

from the magnet, while holding it over the container. Continue

this process until all of the sample has been exposed to the

Given: A flint glass analytical sample with a dry weight of

magnet. Screen at 6.3 mm ( ⁄4 in.); then combine the magnetic

447.8 g.

material from all portions of the sample, weigh, and calculate

Off-Color Fractions:

the percent magnetic material. Reserve all portions of the

Amber 513.4g

sample, or from a replicate sample for subsequent tests.

12.2.2 Calculation— Calculate the percent magnetic mate-

Georgiagreen 521.9g

rial as follows:

Emeraldgreen 52.2g

weightoftrampiron 3100

Other 52.2g

Magneticmaterial,% 5 (5)

dryweightofsample

Then:

12.3 Determination of Iron Contamination in Fine Glass

(Smaller than 6 mm Size):

13.4 3100

Amber,% 5 53.0

12.3.1 Weigh 100 g from the sample from 11.1 or from a 447.8

replicate.

12.3.2 Add 250 ml of 6 N hydrochloric acid (HCl) and

21.9 3100

Georgiagreen,% 5 54.9

slowly heat to a vigorous boil. Stir while boiling.

447.8

NOTE 3—Caution:Rapid heating may cause “bumping.”

2.2 3100

12.3.3 Cool the sample and filter through a medium filter Emeraldgreen,% 5 50.5

447.8

paper. Catch the filtrate in a 500-ml volumetric flask and wash

the insolvable sample at least five times with warm distilled

4.9

water. Wash water should not exceed 500 ml. Allow the flask

Equivalentemeraldgreen,% 50.5 1 51.0

and its contents to cool to room temperature and dilute to

volume with distilled water.

2.2 3100

12.3.4 Transfer an appropriate sized aliquot to a 200-ml

Other,% 5 50.5

447.8

volumetric flask and analyze for iron, by either Test Methods

D1068 or Test Method D2576.

Flin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.