ASTM C1058-03(2008)

(Practice)Standard Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

Standard Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

SIGNIFICANCE AND USE

The various methods for measuring and calculating thermal properties provide data and information for manufacturer's published information, for comparison of related products, and for designers and users to evaluate insulation products for particular applications. For these purposes it is advisable to provide basic data and information produced under standard temperature conditions.

Thermal properties of a specimen may change with mean temperature, with temperature difference across the specimens, and with high temperature exposure. Data and information at standard temperatures are necessary for valid comparison of thermal properties.

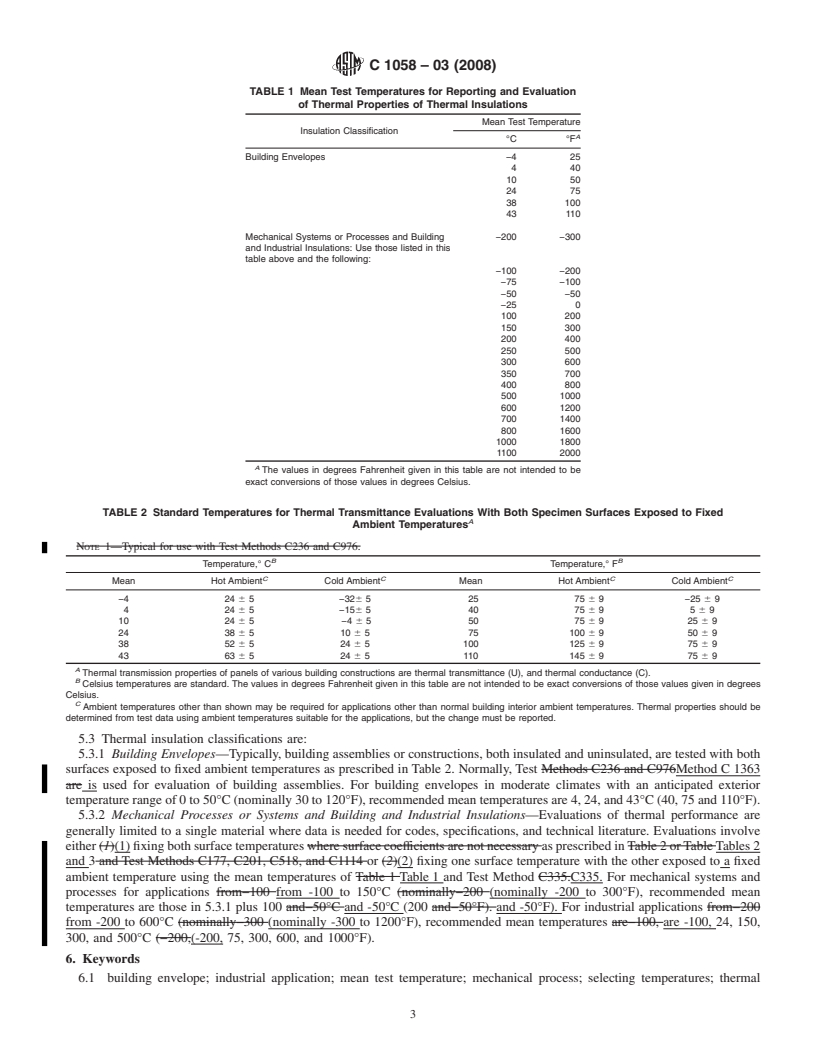

The mean test temperatures to measure thermal properties shall be selected from those listed in Table 1. It is recommended that thermal properties of insulation materials be evaluated over a mean temperature range that represents the intended end use. For this situation, the lowest and greatest mean temperatures should be within 10°C of the maximum and minimum mean temperature of interest. The temperature differences for any chosen mean temperature will depend upon both the thermal insulation application (see appropriate materials specification), the method of evaluation, and the limitations of the apparatus. Temperature differences or relevant temperatue conditions required by ASTM material specifications shall take precedence over those recommended in this practice.

Standard conditions are presented where both surfaces are exposed to fixed ambient temperatures that are typical for testing building constructions, both insulated and uninsulated (Table 2).

Standard conditions are presented where the temperatures of the two surfaces are fixed and surface coefficients are not considered (Table 3).

For conditions where the temperature of only one surface is fixed with the other exposed to fixed ambient temperature, use the mean temperatures of Table 1.

These conditions must be stated to describe accurately thermal properties su...

SCOPE

1.1 This practice covers standard mean temperatures for reporting thermal properties of thermal insulations, products, and materials, and of related systems and components, both insulated and uninsulated.

1.2 Thermal properties shall be determined as a function of temperature by standard test methods. (Test Methods C 177, C 201, C 236, C 335, C 518, C 745, C 976, C 1114, Guide C 653, and Practice C 687, all in combination with Practice C 1045.)

Note 1—Standard referenced materials are needed to span the temperature range of the tests.

1.3 This practice recommends standard conditions for use in testing and evaluating thermal properties as a function of temperature by standard test methods.

1.4 General applications of thermal insulations include:

1.4.1 Building envelopes,

1.4.2 Mechanical systems or processes, and

1.4.3 Building and industrial insulations.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. Approximate inch-pound units are provided in the tables.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1058–03 (Reapproved 2008)

Standard Practice for

Selecting Temperatures for Evaluating and Reporting

Thermal Properties of Thermal Insulation

This standard is issued under the fixed designation C1058; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C201 Test Method for Thermal Conductivity of Refracto-

ries

1.1 This practice covers standard mean temperatures for

C335 Test Method for Steady-State Heat Transfer Proper-

reporting thermal properties of thermal insulations, products,

ties of Pipe Insulation

and materials, and of related systems and components, both

C518 Test Method for Steady-State Thermal Transmission

insulated and uninsulated.

Properties by Means of the Heat Flow Meter Apparatus

1.2 Thermal properties shall be determined as a function of

C653 GuideforDeterminationoftheThermalResistanceof

temperature by standard test methods. (Test Methods C177,

Low-Density Blanket-Type Mineral Fiber Insulation

C201, C236, C335, C518, C745, C976, C1114, Guide C653,

C687 Practice for Determination of Thermal Resistance of

and Practice C687, all in combination with Practice C1045.)

Loose-Fill Building Insulation

NOTE 1—Standard referenced materials are needed to span the tem-

C745 Test Method for Heat Flux Through Evacuated Insu-

perature range of the tests.

lations Using a Guarded Flat Plate Boiloff Calorimeter

1.3 Thispracticerecommendsstandardconditionsforusein

C1045 PracticeforCalculatingThermalTransmissionProp-

testing and evaluating thermal properties as a function of

erties Under Steady-State Conditions

temperature by standard test methods.

C1114 Test Method for Steady-State Thermal Transmission

1.4 General applications of thermal insulations include:

Properties by Means of the Thin-Heater Apparatus

1.4.1 Building envelopes,

C1363 Test Method for Thermal Performance of Building

1.4.2 Mechanical systems or processes, and

Materials and Envelope Assemblies by Means of a Hot

1.4.3 Building and industrial insulations.

Box Apparatus

1.5 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

only.Approximate inch-pound units are provided in the tables.

3.1 Definitions— For definitions of terms and symbols used

1.6 This standard does not purport to address all of the

in this practice, refer to Terminology C168.

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 The various methods for measuring and calculating

bility of regulatory limitations prior to use. thermal properties provide data and information for manufac-

turer’s published information, for comparison of related prod-

2. Referenced Documents

ucts, and for designers and users to evaluate insulation prod-

2.1 ASTM Standards:

ucts for particular applications. For these purposes it is

C168 Terminology Relating to Thermal Insulation

advisable to provide basic data and information produced

C177 Test Method for Steady-State Heat Flux Measure-

under standard temperature conditions.

ments and Thermal Transmission Properties by Means of

4.2 Thermal properties of a specimen may change with

the Guarded-Hot-Plate Apparatus

mean temperature, with temperature difference across the

specimens, and with high temperature exposure. Data and

information at standard temperatures are necessary for valid

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

comparison of thermal properties.

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

4.3 The mean test temperatures to measure thermal proper-

Measurement.

Current edition approved Aug. 1, 2008. Published August 2008. Originally ties shall be selected from those listed in Table 1.Itis

approved in 1986. Last previous edition approved 2003 as C1058 – 03. DOI:

recommendedthatthermalpropertiesofinsulationmaterialsbe

10.1520/C1058-03R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1058–03 (2008)

TABLE 1 Mean Test Temperatures for Reporting and Evaluation

4.3.3 For conditions where the temperature of only one

of Thermal Properties of Thermal Insulations

surface is fixed with the other exposed to fixed ambient

Mean Test Temperature

temperature, use the mean temperatures of Table 1.

Insulation Classification

A

°C °F

4.4 These conditions must be stated to describe accurately

Building Envelopes −4 25 thermal properties such as thermal conductivity versus mean

temperature for thermal insulating materials. Thermal insula-

10 50

tions exhibiting inflection points due to the change of state of

24 75

38 100 insulating gases (see Note 2), must be tested at sufficiently

43 110

small temperature differences between (1) the hot and cold

sides and (2) between mean temperatures.The test temperature

Mechanical Systems or Processes and Building −200 −300

and Industrial Insulations: Use those listed in this differences used depend on the vapor pressure versus tempera-

table above and the following:

turerelationshipofthegasesinvolvedandtheabilityofthetest

−100 −200

apparatus to provide accurate measurements of low tempera-

−75 −100

−50 −50 ture differences.

−25 0

100 200

NOTE 2—Certain closed-cell cellular plastic insulations are of this type.

150 300

200 400

5. Procedure

250 500

300 600

5.1 Since there are distinctly different needs or uses for

350 700

thermal performance information, the test conditions selected

400 800

500 1000 must be appropriate to the need or use.

600 1200

5.2 Determine the use classification described in 5.3 and

700 1400

choose the appropriate temperature conditions from the tables.

800 1600

1000 1800

5.2.1 Ifthetablesdonotcontaintheappropriatetemperature

1100 2000

conditions, specifically report exceptions.

A

The values in degrees Fahrenheit given in this table are not intended to be

5.3 Thermal insulation classifications are:

exact conversions of those values in degrees Celsius.

5.3.1 Building Envelopes—Typically, building assemblies

orconstructions,bothinsulatedanduninsulated,aretestedwith

evaluated over a

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1058–97 Designation:C1058–03 (Reapproved 2008)

Standard Practice for

Selecting Temperatures for Evaluating and Reporting

Thermal Properties of Thermal Insulation

This standard is issued under the fixed designation C1058; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers standard mean temperatures for reporting thermal properties of thermal insulations, products, and

materials, and of related systems and components, both insulated and uninsulated.

1.2 Thermal properties mayshall be determined as a function of temperature by standard test methods. (Test Methods C177,

C201, C236, C335, C518, C745, C976, C1114, Guide C653, and Practice C687, all in combination with Practice C1045.)

NOTE 1—Standard referenced materials are needed to span the temperature range of the tests.

1.3 This practice recommends standard conditions for use in testing and evaluating thermal properties as a function of

temperature by standard test methods.

1.4 General applications of thermal insulations include:

1.4.1 Building envelopes,

1.4.2 Mechanical systems or processes, and

1.4.3 Building and industrial insulations.

1.5The mean test temperatures to measure thermal properties shall be selected from those listed in Table 1. It is recommended

that thermal properties of insulation materials be evaluated over a mean temperature range that represents the intended end use.

For this situation, the lowest and greatest mean temperatures should be within 10°C of the maximum and minimum mean

temperatureofinterest.Thetemperaturedifferencesforanychosenmeantemperaturewilldependuponboththethermalinsulation

application (see appropriate materials specification), the method of evaluation, and the limitations of the apparatus. Temperature

differences or relevant temperatue conditions required by ASTM material specifications shall take precedence over those

recommended in this practice.

1.5.1Standardconditionsarepresentedwherebothsurfacesareexposedtofixedambienttemperaturesthataretypicalfortesting

building constructions, both insulated and uninsulated (Table 2).

1.5.2Standard conditions are presented where the temperatures of the two surfaces are fixed and surface coefficients are not

considered (Table 2 or Table 3).

1.5.3For conditions where the temperature of only one surface is fixed with the other exposed to fixed ambient temperature, use

the mean temperatures of Table 1.

1.6The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

Approximate inch-pound units are provided in the tables.

1.7

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

Approximate inch-pound units are provided in the tables.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C168Terminology Relating to Thermal Insulating Mate- rials Terminology Relating to Thermal Insulation

This practice is under the jurisdiction of ASTM Committee C-16C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurements.

Current edition approved May 10, 1997.Aug. 1, 2008. Published August 1997.2008. Originally published as C1058–86.approved in 1986. Last previous edition

C1058–92.approved 2003 as C1058–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.06.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1058–03 (2008)

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C201 Test Method for Thermal Conductivity of Refractories C236Test Method for Steady-State Thermal Performance of

Building Assemblies by Means of a Guarded Hot Box

C335 Test Method for Steady-State Heat Transfer Properties of Horizontal Pipe Insulation

C518 TestMethodforSteady-StateHeatFluxMeasurementsandThermalTransmissionPropertiesbyMeansoftheHeatFlow

Meter Apparatus

C653 Guide for Determination of the Thermal Resistance of Low-Density Blanket-Type Mineral Fiber Insulation

C687 Practice for Determination of the Thermal Resistance of Loose-Fill Building Insulation

C745Test Method for Heat Flux Through Evacuated Insulations Using a Guarded Flat Plate Boiloff Calorimeter

C976Test Method forThermal Performance of BuildingAssemblies by Means of a Calibrated Hot Box Test Method for Heat

Flux Through Evacuated Insulations Using a Guarded Flat Plate Boiloff Calorimeter

C1045Practice for Calculating Thermal Transmission Properties from Steady-State Heat Flux Measurements Practice for

Calculating Thermal Transmission Properties Under Steady-State Conditions

C1114Test Method for Steady State Thermal Transmission Properties by Means of the Thin-HeaterApparatus Test Method

for Steady-State Thermal Transmission Properties by Means of the Thin-Heater Apparatus

C1363 Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box

Apparatus

3. Terminology

3.1 Definitions— For definitions of terms and symbols used in this practice, refer to Terminology C168.

4. Significance and Use

4.1 The various methods for measuring and calculating thermal properties provide data and information for manufacturer’s

publishedinformation,forcomparisonofrelatedproducts,andfordesignersanduserstoevaluateinsulationproductsforparticular

applications. For these purposes it is advisable to provide basic data and information produced under standard temperature

conditions.

4.2 Thermal properties of a specimen may change with mean temperature, with temperature difference across the specimens,

and with high temperature exposure. Data and information at standard temperatures are necessary for valid comparison of thermal

properties.

4.3These conditions must be stated to describe accurately thermal properties such as thermal conductivity versus mean

temperature for thermal insulating materials. Thermal insulations exhibiting inflection points due to the change of state of

insulating gases (see

4.3 The mean test temperatures to measure thermal properties shall be selected from those listed inTable 1. It is recommended

that thermal properties of insulation materials be evaluated over a mean temperature range that represents the intended end use.

For this situation, the lowest and greatest mean temperatures should be within 10°C of the maximum and minimum mean

temperatureofinterest.Thetemperaturedifferencesforanychosenmeantemperaturewilldependuponboththethermalinsulation

application (see appropriate materials specification), the method of evaluation, and the limitations of the apparatus. Temperature

differences or relevant temperatue conditions required by ASTM material specifications shall take precedence over those

recommended in this practice.

4.3.1 Standard conditions are presented where both surfaces are exposed to fixed ambient temperatures that are typical for

testing building constructions, both insulated and uninsulated (Table 2).

4.3.2 Standard conditions are presented where the temperatures of the two surfaces are fixed and surface coefficients are not

consi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.