ASTM D3168-85(2005)

(Practice)Standard Practice for Qualitative Identification of Polymers in Emulsion Paints

Standard Practice for Qualitative Identification of Polymers in Emulsion Paints

SIGNIFICANCE AND USE

Identification of specific acrylic polymers in emulsion paints is often difficult or impossible by infrared alone. This is particularly true when the acrylic is present in a small amount as a comonomer with vinyl acetate, or when blended with alkyds or other ester systems. If identification of an acrylic component is required in such a system, it may often be accomplished by gas-liquid chromatographic analysis of the pyrolyzed paint film. The presence of a number of other polymers may often also be confirmed by pyrolysis since they produce characteristic and reproducible pyrograms.

The pyrograms obtained from unknown samples vary in complexity according to the sample composition. It is necessary to establish the presence or absence of as many components as possible from a study of the infrared spectra obtained in the first part of this practice. The gas-liquid chromatography results may then be used to help identify any unknown components present and to confirm identifications made by infrared.

SCOPE

1.1 This practice describes a procedure for the qualitative identification in emulsion paints of most types of polymers present as major components of the paint vehicle. Limitations are discussed in Sections and .

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3168 – 85 (Reapproved 2005)

Standard Practice for

Qualitative Identification of Polymers in Emulsion Paints

This standard is issued under the fixed designation D3168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

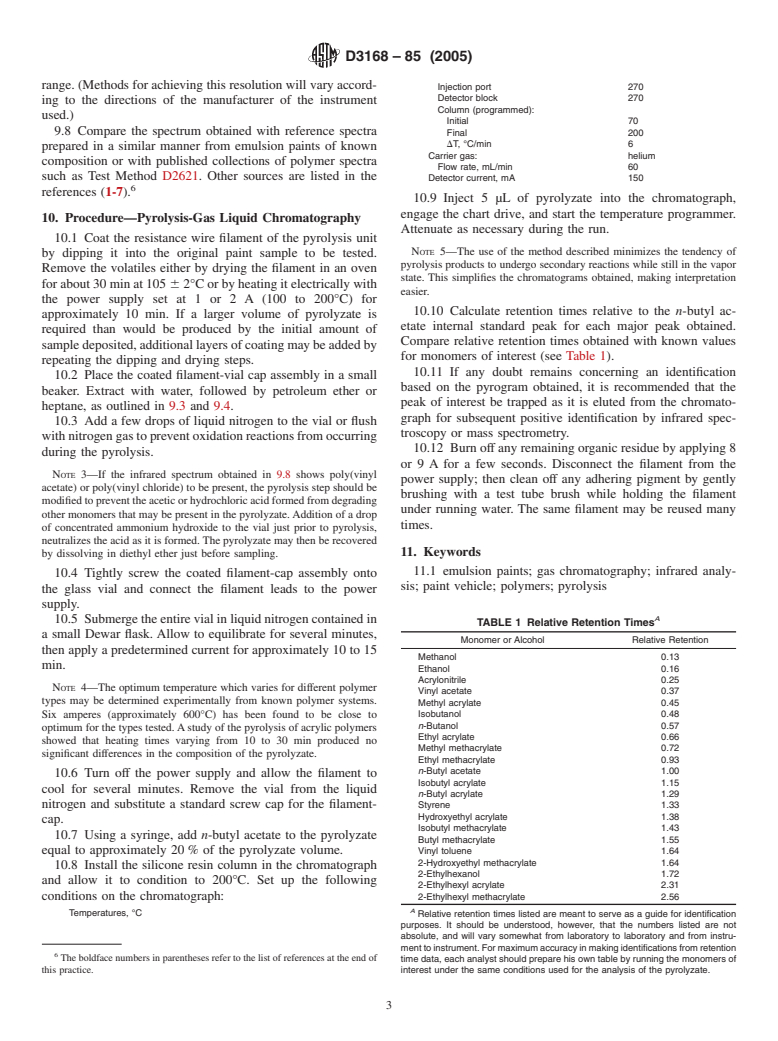

1. Scope 4.2 The paint is applied to a filament and pyrolyzed to

depolymerizethevehicle.Aninternalstandardisaddedandthe

1.1 This practice describes a procedure for the qualitative

pyrolyzate is separated into its components by gas-liquid

identification in emulsion paints of most types of polymers

chromatography. Monomers are identified by comparison of

present as major components of the paint vehicle. Limitations

relative retention times.

are discussed in Sections 5 and 10.

1.2 The values stated in SI units are to be regarded as the

5. Significance and Use

standard. The values given in parentheses are for information

5.1 Identification of specific acrylic polymers in emulsion

only.

paints is often difficult or impossible by infrared alone. This is

1.3 This standard does not purport to address all of the

particularly true when the acrylic is present in a small amount

safety concerns, if any, associated with its use. It is the

as a comonomer with vinyl acetate, or when blended with

responsibility of the user of this standard to establish appro-

alkyds or other ester systems. If identification of an acrylic

priate safety and health practices and determine the applica-

component is required in such a system, it may often be

bility of regulatory limitations prior to use.

accomplished by gas-liquid chromatographic analysis of the

2. Referenced Documents pyrolyzed paint film. The presence of a number of other

polymers may often also be confirmed by pyrolysis since they

2.1 ASTM Standards:

produce characteristic and reproducible pyrograms.

D16 Terminology for Paint, Related Coatings, Materials,

5.2 The pyrograms obtained from unknown samples vary in

and Applications

complexity according to the sample composition. It is neces-

D1193 Specification for Reagent Water

sary to establish the presence or absence of as many compo-

D2621 Test Method for Infrared Identification of Vehicle

nents as possible from a study of the infrared spectra obtained

Solids From Solvent-Reducible Paints

in the first part of this practice. The gas-liquid chromatography

E275 Practice for Describing and Measuring Performance

results may then be used to help identify any unknown

of Ultraviolet and Visible Spectrophotometers

components present and to confirm identifications made by

3. Terminology

infrared.

3.1 Definitions—For definitions of terms, refer to Terminol-

6. Interferences

ogy D16.

6.1 Dibutyl maleate and dibutyl fumarate monomers are not

4. Summary of Practice successfully recovered by this procedure. If their presence is

suspected as comonomer in a vinyl acetate copolymer system,

4.1 The vehicle is extracted from the dried paint and after

n-butyl alcohol should be found in the pyrolyzate. This

filtering is cast on a salt plate. The infrared spectrum is

evidence, together with the absence of butyl acrylate or butyl

obtainedandcomparedwithreferencespectraforidentification

methacrylate monomer peaks, is an indirect indication of the

of major components.

presence of one or both of these monomers.

6.2 The presence of relatively low quantities of copolymer-

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

ized acids may not be successfully established by this proce-

Related Coatings, Materials, and Applications and is the direct responsibility of

dure, due to some unavoidable decomposition of acrylate and

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

methacrylate esters to acrylic or methacrylic acid and the

Current edition approved Jan. 1, 2005. Published February 2005. Originally

approved in 1973. Last previous edition approved in 1999 as D3168 – 85 (1999).

corresponding alcohols during the pyrolysis. The infrared

DOI: 10.1520/D3168-85R05.

spectrum and an acid number determination, both run on the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

polymer solids, may usually be relied upon to establish the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on presence or absence of acid groups in the polymer.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3168 – 85 (2005)

6.3 In the case where the polymer being analyzed is simple 8.2 Purity of Water—Unless otherwise indicated, reference

(such as a vinyl acetate-alkyl ester copolymer, or a single to water shall be understood to mean reagent water conforming

acrylate-methacrylate copolymer), it might be advantageous to to Type II of Specification D1193.

examine the total pyrolyzate directly by infrared (as a solution

8.3 Extraction Solvent Mixture—Equal volumes of o-

in carbon disulfide).

dichlorobenzene, dimethylformamide, and tetrahydrofuran.

8.4 Liquid Nitrogen.

7. Apparatus

8.5 Petroleum Ether (30 to 60°C boiling range) or heptane.

7.1 Spectrophotometer, recording, double-beam, infrared,

with a range from at least 2.5 µm to 15 µm and a spectral 9. Procedure—Infrared Analysis

resolution of at least 0.04 µm over that range. For checking the

9.1 Transfer 1 to 2 g of emulsion paint to a 100-mL

performance of the infrared spectrophotometer, see Practice

borosilicate glass beaker. Add approximately 2 mL of water

E275.

and swirl or use a clean glass rod to spread the paint uniformly

7.2 Cell Mount, demountable.

over the bottom of the beaker.

7.3 Halide Salt Crystals, for use with demountable cell

9.2 Place the beaker in an oven at 105 to 6 2°C for at least

mount.

2 h, breaking up any skins that form so that complete drying is

7.4 Oven, gravity or forced-draft, maintained at 105 6 2°C.

ensured.

7.5 Linear Programmed Temperature Gas Chromatograph,

9.3 Add 50 mLof water, cover with a watchglass, and place

equipped with a thermal conductivity detector.

on a steam bath or low-temperature hotplate for 1 h. This

7.6 Pyrolysis Accessory—Any suitable apparatus for

process removes emulsifiers, protective colloids, and other

achieving pyrolysis external to the chromatograph, that results

water-soluble components that might interfere with interpreta-

in the recovery of sufficient pyrolyzate for identification

tion of the infrared spectrum. Decant off the clear water layer

purposes.TheapparatusdescribedintheAnnexhasbeenfound

and discard. If the addition of the distilled water to the dried

to meet these requirements.

paint film produces a milky dispersion, the drying step in 9.2

7.7 GasChromatographicColumn,3m(10ft)inlength,6.4

was not complete and should be repeated.

mm ( ⁄4 in.) in outside diameter copper tubing packed with

10 %siliconeresin on80to100-meshacid-washed,dimethyl- NOTE 1—If there is an interest in characterization of the emulsifier

system used, the water should be filtered through a fine-texture filter paper

dichlorosilane treated calcined diatomaceous earth.

and taken to dryness. The solids may then be examined by infrared.

7.8 Steam Bath or Low-Temperature Hot Plate.

7.9 Flask, small Dewar.

9.4 Dry for 15 to 20 min in an oven at 105 to 6 2°C. Add

50 mLof petroleum ether or heptane, cover with a watchglass,

8. Reagents

and bring to a slow boil for approximately 5 min. This process

8.1 Purity of Reagents—Reagent grade chemicals shall be removes most emulsified plasticizers, oils, and other water

used in all tests. Unless otherwise indicated, it is intended that insoluble, nonpolymeric organic materials, which might also

all reagents shall conform to the specifications of the Commit-

interfere with the interpretation of the infrared spectrum.

tee onAnalytical Reagents of theAmerican Chemical Society, Decant off the solvent and discard.

where such specifications are available. Other grades may be

NOTE 2—If there is an interest in characterizing the water-insoluble

used, provided it is first ascertained that the reagent is of

petroleum ether-soluble fraction, it should also be filtered through

sufficiently high purity to permit its use without lessening the

fine-texture paper, taken to dryness, and examined by infrared.

accuracy of the determination.

9.5 Add 10 mL of the extraction solvent mixture (8.3) and

place on a steam bath or low-temperature hotplate for approxi-

mately 1 h. Filter, while still hot, through a fine-texture filter

The sole source of supply of silicone resin SE-30, known to the committee at

paper. If the polymer solution is viscous, it may be diluted

this time is General Electric Co. If you are aware of alternative suppliers, please

further with extraction solvent mixture and warmed prior to

provide this information toASTM International Headquarters. Your comments will

receive careful consideration at a meeting of the responsible technical committee, filtration.Alternatively, the pigment may be removed from the

which you may attend.

polymersolutionbycentrifuging.Evaporatethesolutiononthe

The sole source of supply of Chromosorb W, known to the committee at this

steam bath or hotplate to a volume of 1 mL or less.

time is Manville Sales Corp., Filtration and Minerals, P.O. Box 5108, Denver, CO

9.6 Place the concentrated polymer solution on a halide salt

80217-5108. If

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.