ASTM C577-07

(Test Method)Standard Test Method for Permeability of Refractories

Standard Test Method for Permeability of Refractories

SIGNIFICANCE AND USE

This test method is used to measure the rate of flow of air or nitrogen through refractory brick and monoliths and to thus determine the permeability of tested products.

This test method is useful in research and development for establishing the relative permeability of products within comparable classes. It may also be used to identify acceptable products for design purposes and to establish permeability criteria for specification acceptance.

It must be recognized that permeability can vary in different directions and different parts of a refractory due to factors such as forming procedure, grain size and distribution, and heat treatment.

SCOPE

1.1 This test method covers determination of the permeability of refractory brick and monoliths, from which suitable specimens can be cut, at room temperature.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 577–07

Standard Test Method for

1

Permeability of Refractories

This standard is issued under the fixed designation C 577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

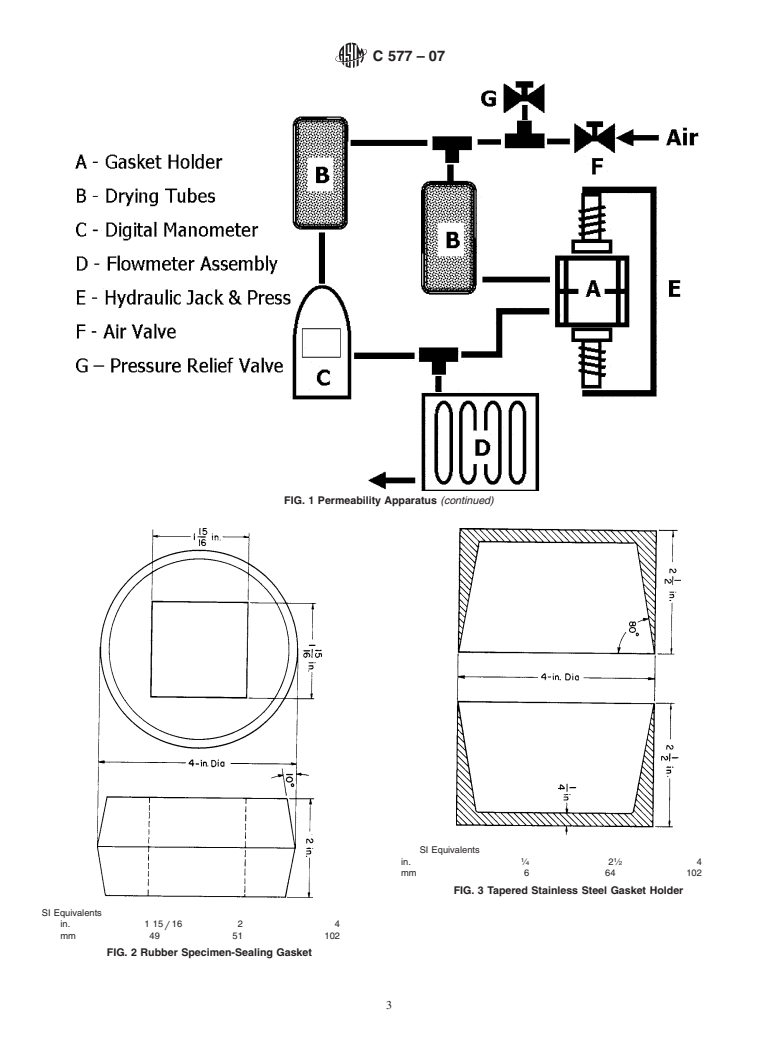

1. Scope with means for controlling gas pressure and measuring gas

4

flow. Figs. 1-3 illustrate a suitable apparatus. The apparatus

1.1 This test method covers determination of the permeabil-

consists of the following components:

ity of refractory brick and monoliths, from which suitable

4.1.1 Permeating Medium, air or nitrogen with regulator-

specimens can be cut, at room temperature.

controlled inlet pressure.

1.2 This standard does not purport to address all of the

4.1.2 Drier Tubes, each filled with a desiccant and strainer;

safety concerns, if any, associated with its use. It is the

used to remove any water or dirt from the gas before entering

responsibility of the user of this standard to establish appro-

the flowmeters.

priate safety and health practices and determine the applica-

4.1.3 Flowmeters—They will measure the flow of permeat-

bility of regulatory limitations prior to use.

3

ing media in the range from 0 to 9000 cm /min. The

2. Referenced Documents

flowmeters may be calibrated to read the flow directly of either

2

air or nitrogen. The range for each flowmeter is shown in Fig.

2.1 ASTM Standards:

1.

C1095 Practice for Calculating Precision Data on Refracto-

3

4.1.4 Manometer—Amultiple scale digital manometer shall

ries (C08) from Interlaboratory Test Results.

be used to measure the differential pressure across the speci-

3. Significance and Use

men.

4.1.5 Rubber Specimen-Sealing Gasket—The gasket (Fig.

3.1 This test method is used to measure the rate of flow of

2) is made to fit tightly arounda2by2by2in.(51by51by

air or nitrogen through refractory brick and monoliths and to

51 mm) test specimen. The two tapered metal-gasket holders

thus determine the permeability of tested products.

(Fig. 3) enclose the rubber gasket, and are compressed with a

3.2 This test method is useful in research and development

hydraulic jack (Fig. 4) to seal the gasket tightly against the test

for establishing the relative permeability of products within

specimen.

comparable classes. It may also be used to identify acceptable

products for design purposes and to establish permeability

5. Specimen Preparation

criteria for specification acceptance.

5.1 One 2 by 2 by 2 in. (51 by 51 by 51 mm) specimen shall

3.3 It must be recognized that permeability can vary in

be cut from each of four pieces constituting the sample of

different directions and different parts of a refractory due to

material to be tested. The specimen should be cut in such a

factors such as forming procedure, grain size and distribution,

manner as to fit snugly into the gasket.

and heat treatment.

5.2 The specimens shall be cut so that three original

4. Apparatus

surfacesareretained.Incaseswhereitisdesirabletodetermine

the permeability of specimens that show directional differences

4.1 The apparatus shall provide a leakproof system for

inpermeability,theoriginalsurfacesshallbeidentified,andthe

testing 2 in. (51 mm) cubes held in a pressurized rubber gasket,

values determined separately for each direction of gas flow.

5.3 The specimens shall be dried for 16 h at 220 to 230°F

1

This test method is under the jurisdiction of ASTM Committee C08 on

(105 to 110°C) and cooled to room temperature before testing.

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

Properties.

After drying, all specimen surfaces shall be blown free of dust

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

with clean dry air and tested within 4 h.

in 1965. Last previous edition approved in 1999 as C 577 – 99.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The apparatus is described in Eusner, G. R., and Shapland, J. T., “Permeability

the ASTM website. of Blast-Furnace Refractories,” Journal, Am. Ceramic Soc., Vol 42, No. 10, 1959,

3

Withdrawn pp. 459–464.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C577–07

3

A—Flowmeter (3 to 80 cm /min) G—Mercury Manometer

3

B—Flowmeter (10 to 180 cm /min) H—Needle Valve

3

C—Flowmeters (100 to 1500 cm /min) J—Pressure-Release Valve

3

D—Flowmeters (500 to 9000 cm /min) K—Gasket Holder

E—Drying Tubes L—Hydraulic Jack

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.