ASTM A439-83(2004)

(Specification)Standard Specification for Austenitic Ductile Iron Castings

Standard Specification for Austenitic Ductile Iron Castings

ABSTRACT

This specification covers austenitic ductile iron castings used for their resistance to heat, corrosion and wear. The castings shall be melt processed using cupolas, air furnaces, electric furnaces or crucible furnaces. The iron castings shall undergo magnetic permeability test. Samples taken from test coupons, broken test specimens, or castings shall conform to the required chemical compositions of carbon, silicon, manganese, phosphorus, nickel and chromium. Mechanical tests shall be performed wherein the iron casting specimens shall conform to the required values of tensile strength, yield strength, elongation and Brinell hardness.

SCOPE

1.1 This specification covers austenitic ductile iron castings, which are used primarily for their resistance to heat, corrosion, and wear, and for other special purposes.

1.2 Austenitic ductile iron, also known as austenitic nodular iron or austenitic spheroidal iron, is characterized by having its graphite substantially in a spheroidal form and substantially free of flake graphite. It contains some carbides and sufficient alloy content to produce an austenitic structure.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 439 – 83 (Reapproved 2004)

Standard Specification for

Austenitic Ductile Iron Castings

This standard is issued under the fixed designation A 439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 Heat treatment required (see 4.2-4.4),

3.1.4 If repair of castings is permitted (see 4.5),

1.1 This specification covers austenitic ductile iron castings,

3.1.5 Size and number of test bars required (see 9.1-9.4 and

which are used primarily for their resistance to heat, corrosion,

10.1),

and wear, and for other special purposes.

3.1.6 Special tests, if required (see 12.1),

1.2 Austenitic ductile iron, also known as austenitic nodular

3.1.7 Certification, if required (see 14.1), and

iron or austenitic spheroidal iron, is characterized by having its

3.1.8 Different preparation for delivery requirements, if

graphite substantially in a spheroidal form and substantially

needed (see 15.1).

free of flake graphite. It contains some carbides and sufficient

alloy content to produce an austenitic structure.

4. Manufacture

1.3 The values stated in inch-pound units are to be regarded

4.1 Melting may be done in any furnaces that produce

as the standard. The values given in parentheses are for

castings meeting the chemical and mechanical requirements

information only.

outlined in this specification. These include cupolas, air fur-

2. Referenced Documents naces, electric furnaces, crucible furnaces, etc.

4.2 By agreement between the manufacturer and the pur-

2.1 ASTM Standards:

chaser, the castings may be stress relieved by heating to 1150

A 370 Test Methods and Definitions for MechanicalTesting

to 1200°F (621 to 650°C) for not less than 1 h nor more than

of Steel Products

2 h per inch of thickness in the thickest section. Heating and

A 732/A 732M Specification for Castings, Investment,

cooling shall be uniform and shall not be more than 400°F

Carbon and Low Alloy Steel for General Application, and

(222°C)/h for castings less than 1 in. (25.4 mm) in maximum

Cobalt Alloy for High Strength at Elevated Temperatures

thickness, nor more than 400°F (222°C) divided by the

E 8 Test Methods for Tension Testing of Metallic Materials

maximum section thickness in inches for thicker castings.

E 30 Test Methods for Chemical Analysis of Steel, Cast

During the cooling cycle, castings may be cooled in still air

Iron, Open-Hearth Iron, and Wrought Iron

after the temperature has dropped to 600°F (315°C).

E 59 PracticeforSamplingSteelandIronforDetermination

4.3 Whenever dimensional changes in high-temperature

of Chemical Composition

service are a problem, by agreement between the manufacturer

E 351 Test Methods for Chemical Analysis of Cast Iron—

and the purchaser, the castings may be stabilized by heating at

All Types

1600°F (870°C) for 1 h per inch of section, with a minimum of

3. Ordering Information

1 h. Otherwise, the austenite, which is super-saturated with

respect to carbon, may reject carbon during service and

3.1 Orders for material to this specification shall include the

produce dimensional changes.

following information:

4.4 By agreement between the manufacturer and the pur-

3.1.1 ASTM designation,

chaser, castings with chilled edges or excessive carbides may

3.1.2 Type of austenitic ductile iron required (see 6.1),

be annealed at 1750 to 1900°F (955 to 1040°C) for ⁄2to5h

followed by uniform cooling, preferably in still air.

This specification is under the jurisdiction of ASTM Committee A04 on Iron

4.5 Repairbywelding,plugging,orotherapprovedmethods

Castings and is the direct responsibility of SubcommitteeA04.02 on Malleable and

may be done only with written permission from the purchaser.

Ductile Iron Castings.

Current edition approved Oct. 1, 2004. Published October 2004. Originally

5. Magnetic Properties

approved in 1960. Last previous edition approved in 1999 as A 439 - 83 (1999).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 In the event that nonmagnetic castings are specified, the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

magnetic permeability test shall be used. The maximum

Standards volume information, refer to the standard’s Document Summary page on

magnetic permeability value shall be agreed upon between the

the ASTM website.

Withdrawn. manufacturer and the purchaser.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 439 – 83 (2004)

NOTE 1—Aconvenient shop test for differentiating the various types of

burnt-on sand and shall be reasonably smooth. Runners, risers,

austenitic ductile iron is based on the fact that a ground face of either the

fins,andotheruselesscast-onpiecesshallberemoved.Inother

testbarorthecastingsofTypesD-2andD-2Cwillnotattractasmallsteel

respects, the castings shall conform to whatever points may be

horseshoe-type magnet which is normally attracted to steel (Alnico

specifically agreed upon between the manufacturer and the

magnet should not be used). Types D-3, D-3A, D-5, and D-5B are

purchaser.

attracted, and types D-2B and D-4 may be slightly attracted. This

nonmagnetic test is a convenient qualitative test only for Types D-2 and

D-2C and shall not be used as a basis for acceptance.

9. Test Bars

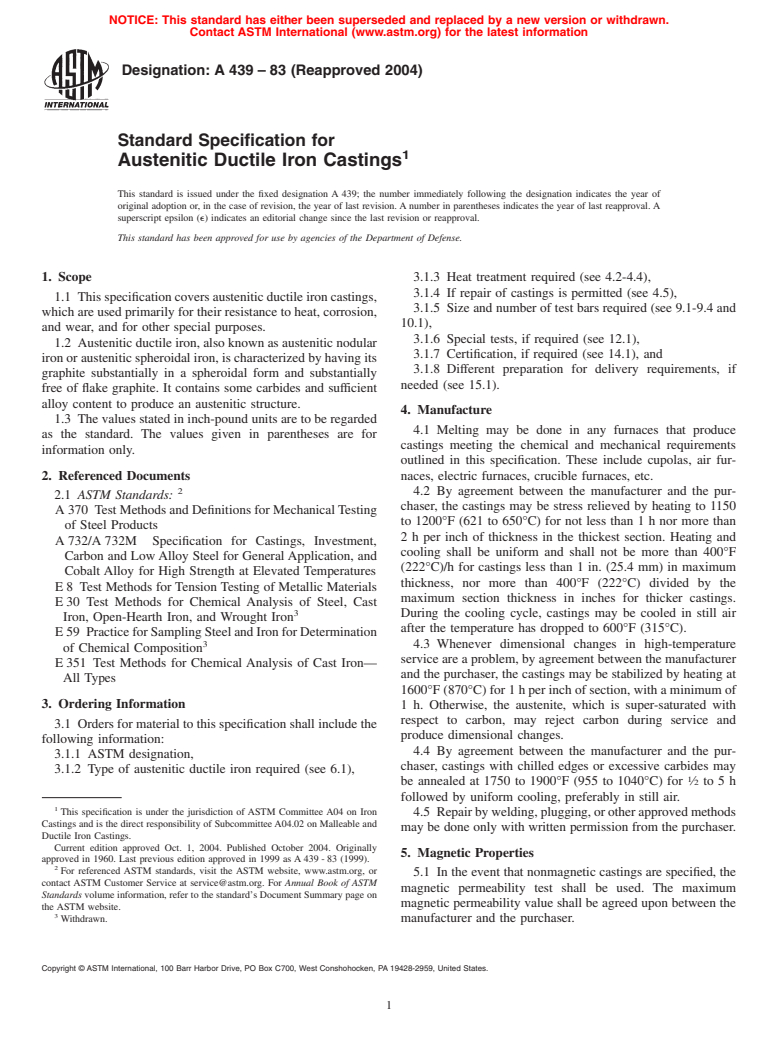

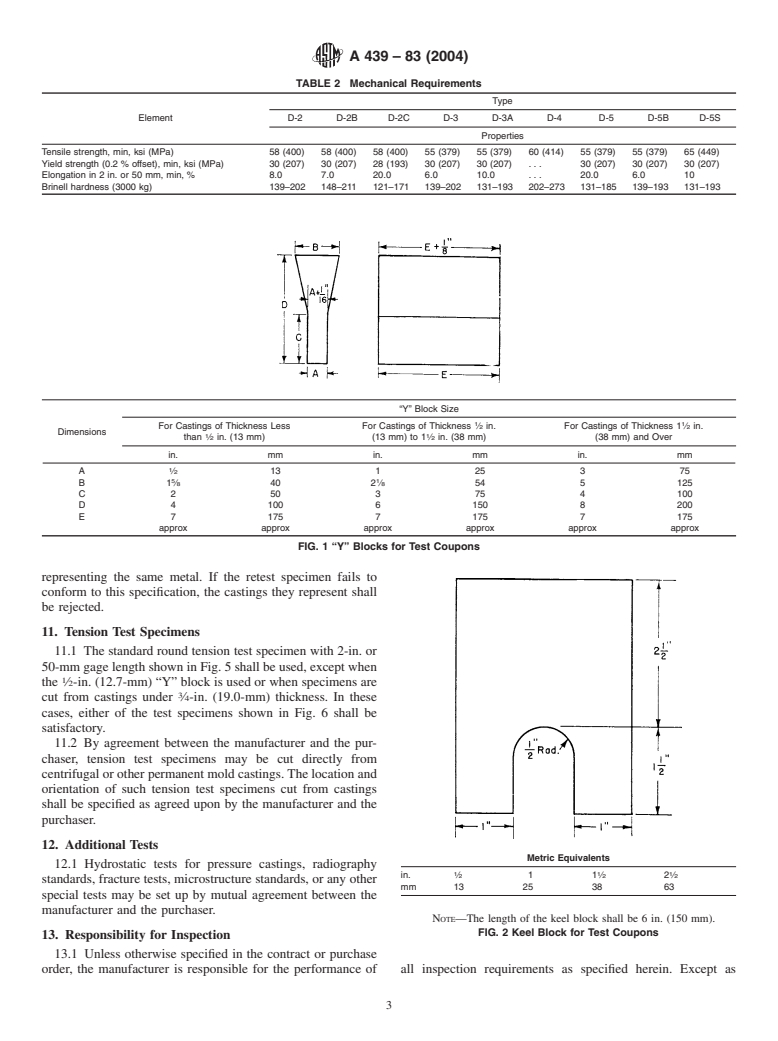

9.1 The standard test bars shall be the 1-in. (25.4-mm) “Y”

6. Chemical Requirements

block and 1-in. (25.4-mm) keel block as shown in Fig. 1 and

6.1 Many combinations of alloys can be used to obtain an

Fig. 2, respectively. A modified keel block cast from the mold

austenitic ductile iron. This specification includes nine general

showninFig.3maybesubstitutedforthe1-in.(25.4-mm)“Y”

types defined by the composition limits in Table 1.

block or the 1-in. keel block.

6.2 Samples taken from test coupons, broken test speci-

9.2 Whenever the section size of the castings is consider-

mens, or castings shall conform to the requirements as to

ably less or greater than 1 in. (25.4 mm) and by agreement

chemical composition prescribed in Table 1. Sampling shall be

between the purchaser and the manufacturer, the ⁄2-in. (12.7-

conducted in accordance with Practice E 59 and chemical

mm) or 3-in. (76.2-mm) “Y” blocks shown in Fig. 1 may be

analysesinaccordancewithTestMethodsE 351andE 30.Test

used.

Methods E 30 should only be used for analyzing those ele-

9.3 The test bars shall be cast in open molds made of a

ments for which specific coverage is not provided for in Test

suitable core sand with a minimum of 1 ⁄2 in. (38.1 mm) of

Methods E 351.

sand on all sides and bottom of the ⁄2 and 1-in. (12.7 and

6.3 Spectrometric techniques may also be used for analysis,

25.4-mm) test bars and 3 in. (76.2 mm) of sand for the 3-in.

but should a dispute arise concerning chemical composition,

(76.2-mm) test bar.

Test Methods E 351 and E 30 shall be used for referee

9.4 Wheninvestmentcastingsaremadetothisspecification,

methods.

the manufacturer may use test specimens cast to size incorpo-

6.4 The chemical analysis for total carbon shall be made on

rated in the mold with the castings, or separately cast to size

either chilled cast pencil-type specimens or thin wafers ap-

using the same type of mold and the same thermal conditions

proximately ⁄32 in. (0.8 mm) thick cut from test coupons.

that are used to produce the castings. These test specimens

Drillings shall not be used because of attendant loss of

shall be made to the dimensions shown in Fig. 1 of Specifica-

graphite.

tion A 732/A 732M or Fig. 4 and Fig. 3 of Test Methods and

Definitions A 370.

7. Mechanical Requirements

9.5 It is recommended that test bars be poured immediately

7.1 Testspecimensofausteniticductileironmadeaccording

after the castings and from the same ladle of metal. Test bars

to this specification shall meet the te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.