ASTM C201-93(2009)

(Test Method)Standard Test Method for Thermal Conductivity of Refractories

Standard Test Method for Thermal Conductivity of Refractories

SIGNIFICANCE AND USE

The thermal conductivity of refractories is a property required for selecting their thermal transmission characteristics. Users select refractories to provide specified conditions of heat loss and cold face temperature, without exceeding the temperature limitation of the refractory. This test method establishes the testing for thermal conductivity of refractories using the calorimeter.

This procedure requires a large thermal gradient and steady state conditions. The results are based upon a mean temperature.

The data from this test method are suitable for specification acceptance, and design of multi-layer refractory construction.

The use of these data requires consideration of the actual application environment and conditions.

SCOPE

1.1 This test method covers the determination of the comparative thermal conductivity of refractories under standardized conditions of testing. This test method is designed for refractories having a conductivity factor of not more than 200 Btu·in./h·ft2·°F (2818 W/m·K), for a thickness of 1 in. (25 mm).

1.2 Detailed ASTM test methods to be used in conjunction with this procedure in testing specific types of refractory materials are as follows: Test Method C 182, Test Method C 202, Test Method C 417, and Test Method C 767.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C201 − 93(Reapproved 2009)

Standard Test Method for

Thermal Conductivity of Refractories

This standard is issued under the fixed designation C201; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E220Test Method for Calibration of Thermocouples By

Comparison Techniques

1.1 This test method covers the determination of the com-

parative thermal conductivity of refractories under standard-

3. Significance and Use

ized conditions of testing. This test method is designed for

3.1 The thermal conductivity of refractories is a property

refractories having a conductivity factor of not more than 200

required for selecting their thermal transmission characteris-

Btu·in./h·ft ·°F(2818W/m·K),forathicknessof1in.(25mm).

tics.Usersselectrefractoriestoprovidespecifiedconditionsof

1.2 Detailed ASTM test methods to be used in conjunction

heat loss and cold face temperature, without exceeding the

with this procedure in testing specific types of refractory

temperature limitation of the refractory. This test method

materials are as follows: Test Method C182, Test Method

establishes the testing for thermal conductivity of refractories

C202, Test Method C417, and Test Method C767.

using the calorimeter.

1.3 The values stated in inch-pound units are to be regarded

3.2 This procedure requires a large thermal gradient and

as standard. The values given in parentheses are mathematical

steady state conditions. The results are based upon a mean

conversions to SI units that are provided for information only

temperature.

and are not considered standard.

3.3 The data from this test method are suitable for specifi-

1.4 This standard does not purport to address all of the

cation acceptance, and design of multi-layer refractory con-

safety concerns, if any, associated with its use. It is the

struction.

responsibility of the user of this standard to establish appro-

3.4 Theuseofthesedatarequiresconsiderationoftheactual

priate safety and health practices and determine the applica-

application environment and conditions.

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

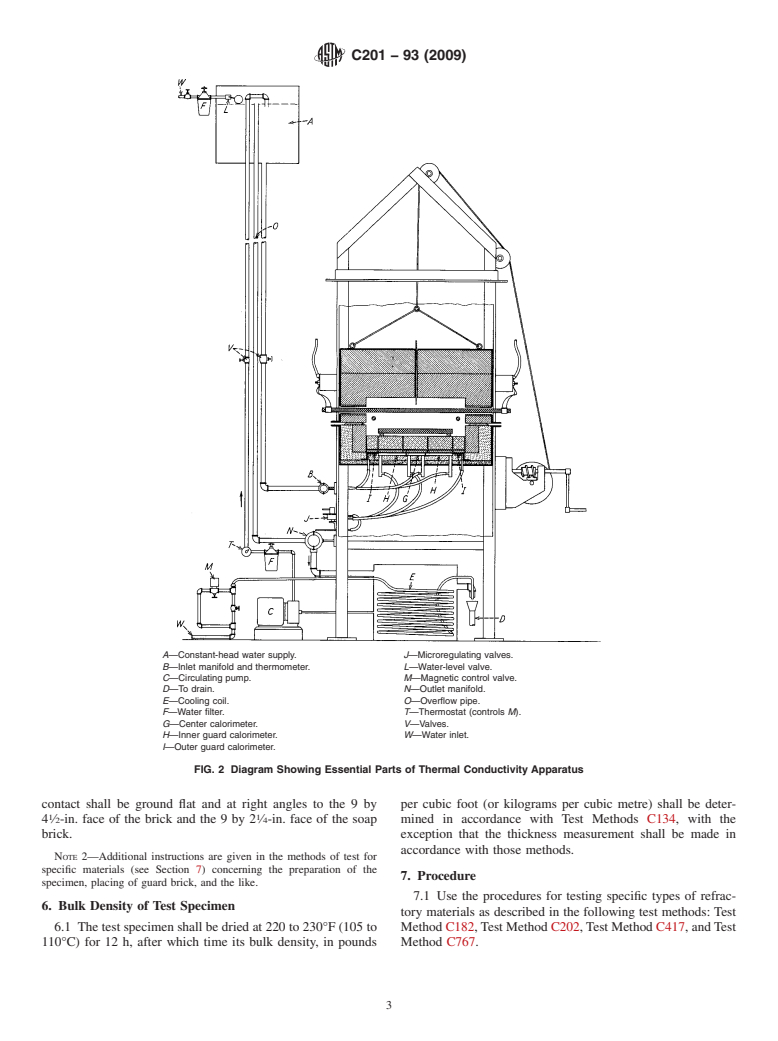

4.1 The apparatus shall conform in close detail with that

2.1 ASTM Standards:

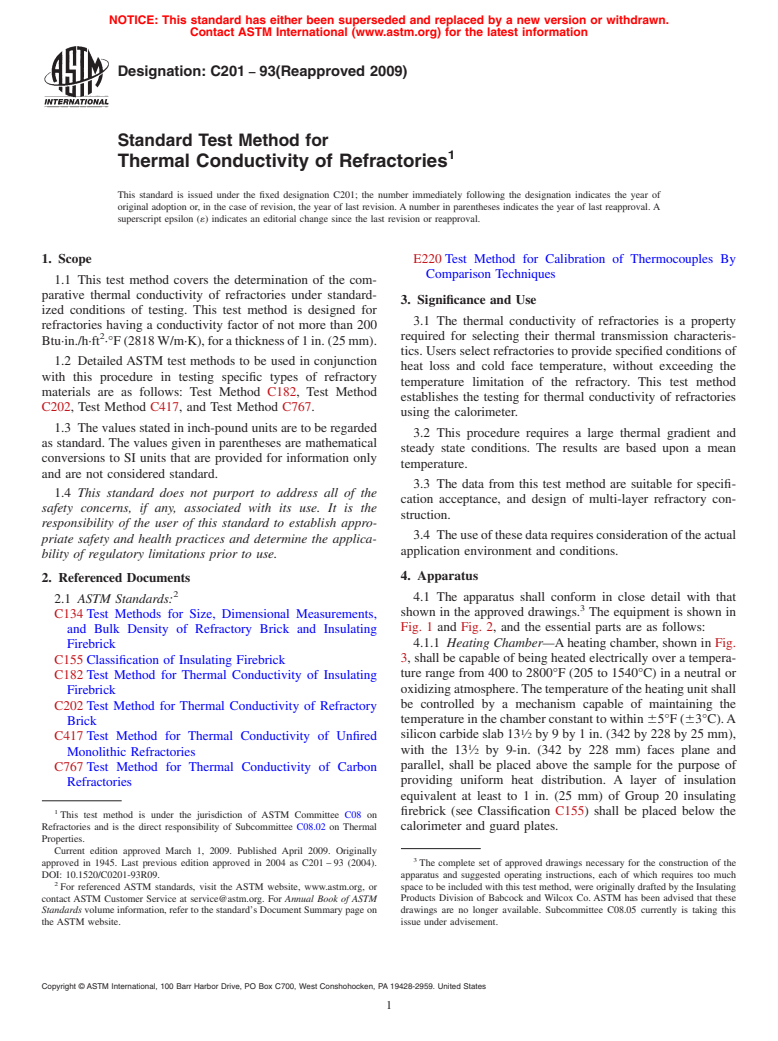

shown in the approved drawings. The equipment is shown in

C134Test Methods for Size, Dimensional Measurements,

Fig. 1 and Fig. 2, and the essential parts are as follows:

and Bulk Density of Refractory Brick and Insulating

4.1.1 Heating Chamber—Aheating chamber, shown in Fig.

Firebrick

3, shall be capable of being heated electrically over a tempera-

C155Classification of Insulating Firebrick

ture range from 400 to 2800°F (205 to 1540°C) in a neutral or

C182Test Method for Thermal Conductivity of Insulating

oxidizingatmosphere.Thetemperatureoftheheatingunitshall

Firebrick

be controlled by a mechanism capable of maintaining the

C202Test Method for Thermal Conductivity of Refractory

temperatureinthechamberconstanttowithin 65°F(63°C).A

Brick

siliconcarbideslab13 ⁄2by9by1in.(342by228by25mm),

C417Test Method for Thermal Conductivity of Unfired

with the 13 ⁄2 by 9-in. (342 by 228 mm) faces plane and

Monolithic Refractories

parallel, shall be placed above the sample for the purpose of

C767Test Method for Thermal Conductivity of Carbon

providing uniform heat distribution. A layer of insulation

Refractories

equivalent at least to 1 in. (25 mm) of Group 20 insulating

1 firebrick (see Classification C155) shall be placed below the

This test method is under the jurisdiction of ASTM Committee C08 on

Refractories and is the direct responsibility of Subcommittee C08.02 on Thermal

calorimeter and guard plates.

Properties.

Current edition approved March 1, 2009. Published April 2009. Originally

approved in 1945. Last previous edition approved in 2004 as C201–93 (2004). The complete set of approved drawings necessary for the construction of the

DOI: 10.1520/C0201-93R09. apparatus and suggested operating instructions, each of which requires too much

For referenced ASTM standards, visit the ASTM website, www.astm.org, or space to be included with this test method, were originally drafted by the Insulating

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Products Division of Babcock and Wilcox Co. ASTM has been advised that these

Standards volume information, refer to the standard’s Document Summary page on drawings are no longer available. Subcommittee C08.05 currently is taking this

the ASTM website. issue under advisement.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C201 − 93 (2009)

4.1.4 Instruments for Measuring Temperature of Specimen

—Calibrated thermocouples shall be embedded in the test

specimen for measuring the temperature. The electromotive

force (emf) for the temperature readings shall be taken with a

potentiometer having an instrument error of not more than

60.05 mV, and the cold junctions of the thermocouples shall

be immersed in a mixture of ice and water.

4.1.5 Instrument for Measuring Temperature Rise in Calo-

rimeter Water—A multiple differential thermocouple shall be

used for measuring within an accuracy of not less than 1% of

the temperature rise of the water flowing through the calorim-

eter. The thermocouple shall be immersed at least 3 ⁄2 in. (89

mm)intheinletandoutletconnections,andthejunctionsshall

be not more than ⁄4 in. (6 mm) distant from the bottom of the

calorimeter. A calibrated differential 10X copper-constantan

thermocouple shall be used, and the millivolt readings shall be

taken with a potentiometer having an instrument error of not

more than 60.01 mV in the range between 0 and 2 mV.

4.1.6 Instruments for Measuring Temperature Difference

BetweenCalorimeterandInnerGuard—Calibrateddifferential

10X copper-constantan thermocouples shall be located in the

calorimeter and inner guard for measuring the temperature

differences between the calorimeter and inner guard. The

temperature difference during a test shall be maintained at a

value less than 60.05°F (60.03°C). The thermocouple junc-

tions shall be placed in the four wells provided for that

purpose, and millivolt readings shall be taken with a potenti-

ometerhavinganinstrumenterrorofnotmorethan 60.01mV

in the range between 0 and 2 mV.

NOTE 1—The upper half of the heating chamber has been raised to

permit introduction of the test samples.

5. Test Sample and Its Preparation

FIG. 1 Photograph of Thermal Conductivity Apparatus

5.1 TestSample—Thetestsampleshallconsistofthree9-in.

1 1

(228-mm)straightbrickandsix9by2 ⁄2by2 ⁄4-in.(228by64

4.1.2 Calorimeter Assembly—A copper calorimeter assem-

by 57-mm) soap brick (Note 2) that are representative of the

bly, of the design shown in Fig. 4, shall be used for measuring

material being tested. These brick shall be selected for unifor-

the quantity of heat flowing through the test specimen. The

mity of structure and bulk density, and they shall be free of

water circulation is such that adjacent passages contain incom-

broken corners or edges. One brick shall be used as the test

ing and outgoing streams of water. The calorimeter shall be 3

specimen, and one each of the other two brick shall be used as

by3in.(76by76mm)squareandshallhaveoneinletandone

guard brick on either side of the specimen. The six soap brick

outlet water connection. The inner guard surrounding the

shallbeplacedaroundtheedgesofthetestspecimenandguard

calorimeter shall be 13 ⁄2 by 9 in. (342 by 228 mm) and shall

bricktopreventsideflowofheat.Thetestspecimenandguard

have two inlet and two outlet water connections. The outer

brick shall cover an area of approximately 18 by 13 ⁄2 in. (456

guardshallextend2in.(51mm)laterallyfromtheinnerguard

by 342 mm).

and shall extend vertically to the member comprising the

NOTE 1—A total of nine 9-in. (228-mm) straight brick may be

bottom of the heating chamber (see Fig. 3). The separation

1 submitted for test, six of which would be cut to obtain the soap brick.

betweenthecalorimeterandtheinnerguardshallbe ⁄32in.(0.8

mm). 5.2 Preparation of Test Sample—The9by4 ⁄2-in. (228 by

4.1.3 Water-Circulating

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.