ASTM E1951-02(2007)

(Guide)Standard Guide for Calibrating Reticles and Light Microscope Magnifications

Standard Guide for Calibrating Reticles and Light Microscope Magnifications

SIGNIFICANCE AND USE

These methods can be used to determine magnifications as viewed through the eyepieces of light microscopes.

These methods can be used to calibrate microscope magnifications for photography, video systems, and projection stations.

Reticles may be calibrated as independent articles and as components of a microscope system.

SCOPE

1.1 This guide covers methods for calculating and calibrating microscope magnifications, photographic magnifications, video monitor magnifications, grain size comparison reticles, and other measuring reticles. Reflected light microscopes are used to characterize material microstructures. Many materials engineering decisions may be based on qualitative and quantitative analyses of a microstructure. It is essential that microscope magnifications and reticle dimensions be accurate.

1.2 The calibration using these methods is only as precise as the measuring devices used. It is recommended that the stage micrometer or scale used in the calibration should be traceable to the National Institute of Standards and Technology (NIST) or a similar organization.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1951 −02(Reapproved 2007)

Standard Guide for

1

Calibrating Reticles and Light Microscope Magnifications

This standard is issued under the fixed designation E1951; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Reticlesmaybecalibratedasindependentarticlesandas

components of a microscope system.

1.1 This guide covers methods for calculating and calibrat-

ing microscope magnifications, photographic magnifications,

5. Procedures

video monitor magnifications, grain size comparison reticles,

5.1 Nominal Magnification Calculations:

and other measuring reticles. Reflected light microscopes are

5.1.1 A calculated magnification, using the manufacturer’s

used to characterize material microstructures. Many materials

supplied ratings, is only an approximation of the true

engineering decisions may be based on qualitative and quan-

magnification, since individual optical components may vary

titative analyses of a microstructure. It is essential that micro-

from their marked magnification. For a precise determination

scope magnifications and reticle dimensions be accurate.

of the magnification observed through an eyepiece, see the

1.2 Thecalibrationusingthesemethodsisonlyaspreciseas

procedure describe in 5.5.

the measuring devices used. It is recommended that the stage

5.1.2 For a compound microscope, the total magnification

micrometer or scale used in the calibration should be traceable

(M) of an image through the eyepiece is the product of the

t

to the National Institute of Standards and Technology (NIST)

objective lens magnification (M ), the eyepiece magnification

o

or a similar organization.

(M ), and, if present, a zoom system or other intermediate lens

e

1.3 This standard does not purport to address all of the

magnification (M).An expression for the total magnification is

i

safety concerns, if any, associated with its use. It is the

shown in Eq 1.

responsibility of the user of this standard to establish appro-

M 5 M 3M 3M (1)

t o e i

priate safety and health practices and determine the applica-

5.1.3 Example 1—For a microscope configured with a 10X

bility of regulatory limitations prior to use.

objective, a 10X eyepiece, and a 1.25X intermediate lens, the

2. Referenced Documents

total magnification observed through the eyepiece would be

2

2.1 ASTM Standards:

calculated as follows.

E7 Terminology Relating to Metallography

M 5 10 10 1.25 5 125 (2)

~ !~ !~ !

t

E112 Test Methods for Determining Average Grain Size

5.2 Calibration for Photomicrography Magnifications:

3. Terminology

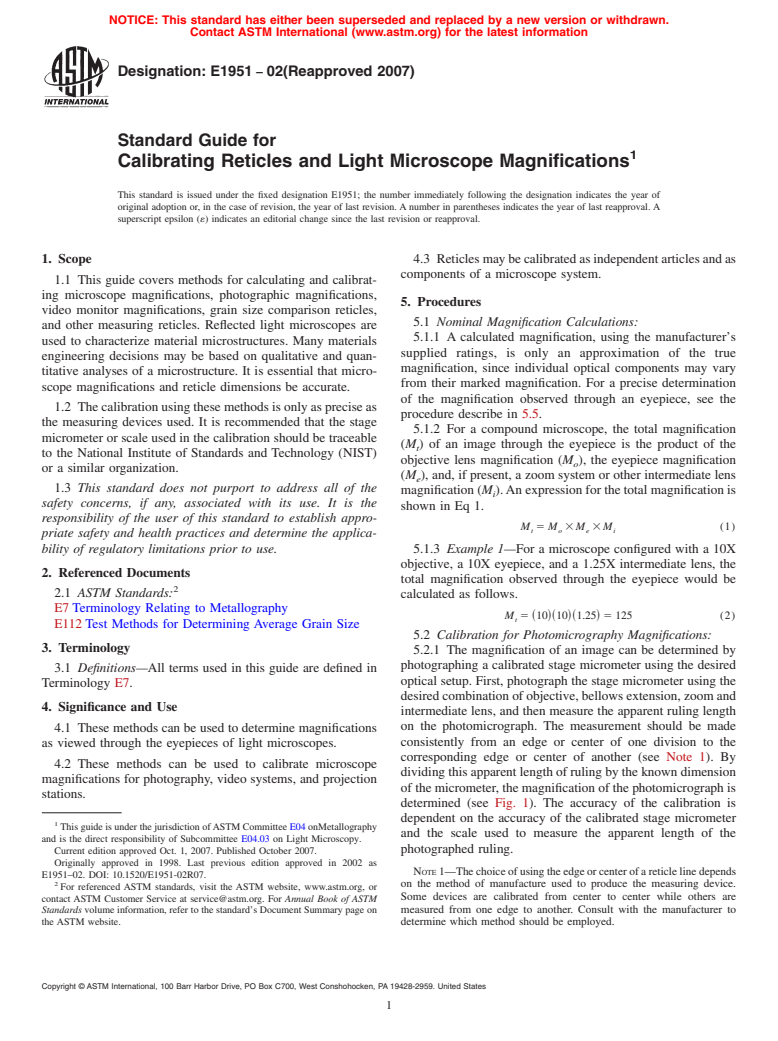

5.2.1 The magnification of an image can be determined by

photographing a calibrated stage micrometer using the desired

3.1 Definitions—All terms used in this guide are defined in

optical setup. First, photograph the stage micrometer using the

Terminology E7.

desired combination of objective, bellows extension, zoom and

4. Significance and Use

intermediate lens, and then measure the apparent ruling length

on the photomicrograph. The measurement should be made

4.1 These methods can be used to determine magnifications

consistently from an edge or center of one division to the

as viewed through the eyepieces of light microscopes.

corresponding edge or center of another (see Note 1). By

4.2 These methods can be used to calibrate microscope

dividing this apparent length of ruling by the known dimension

magnifications for photography, video systems, and projection

of the micrometer, the magnification of the photomicrograph is

stations.

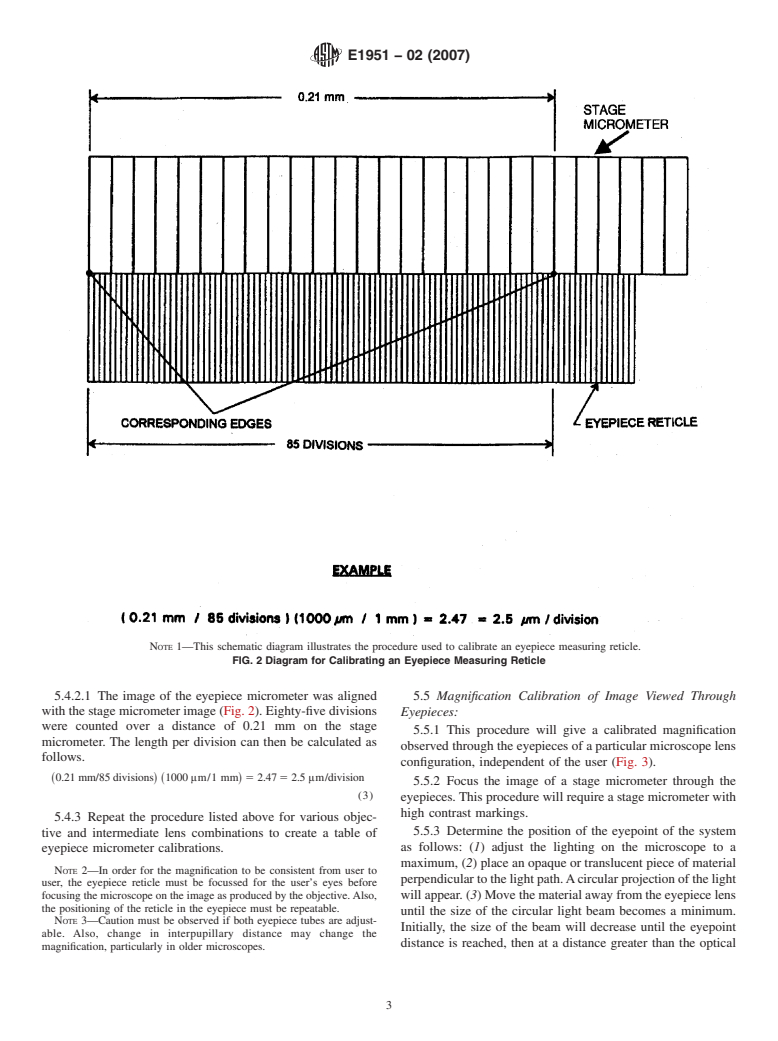

determined (see Fig. 1). The accuracy of the calibration is

dependent on the accuracy of the calibrated stage micrometer

1

This guide is under the jurisdiction ofASTM Committee E04 onMetallography

and the scale used to measure the apparent length of the

and is the direct responsibility of Subcommittee E04.03 on Light Microscopy.

Current edition approved Oct. 1, 2007. Published October 2007. photographed ruling.

Originally approved in 1998. Last previous edition approved in 2002 as

NOTE1—Thechoiceofusingtheedgeorcenterofareticlelinedepends

E1951–02. DOI: 10.1520/E1951-02R07.

2

on the method of manufacture used to produce the measuring device.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Some devices are calibrated from center to center while others are

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on measured from one edge to another. Consult with the manufacturer to

the ASTM website. determine which method should be employed.

Copyright © ASTM International, 100 Barr Harbor Drive,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.