ASTM D2029-97(2017)

(Test Method)Standard Test Methods for Water Vapor Content of Electrical Insulating Gases by Measurement of Dew Point

Standard Test Methods for Water Vapor Content of Electrical Insulating Gases by Measurement of Dew Point

SIGNIFICANCE AND USE

5.1 Certain gases have excellent dielectric and electric arc interruption characteristics which make their use in electrical installations very desirable.

5.2 Water content, as the test parameter, is of great importance in determining the dielectric effectiveness of the gas. Under certain conditions, water may condense and become a conducting liquid resulting in a catastrophic dielectric breakdown of the insulation. The water content of these insulating gases as expressed by dew point is listed in Specifications D1933, D2472, and D3283.

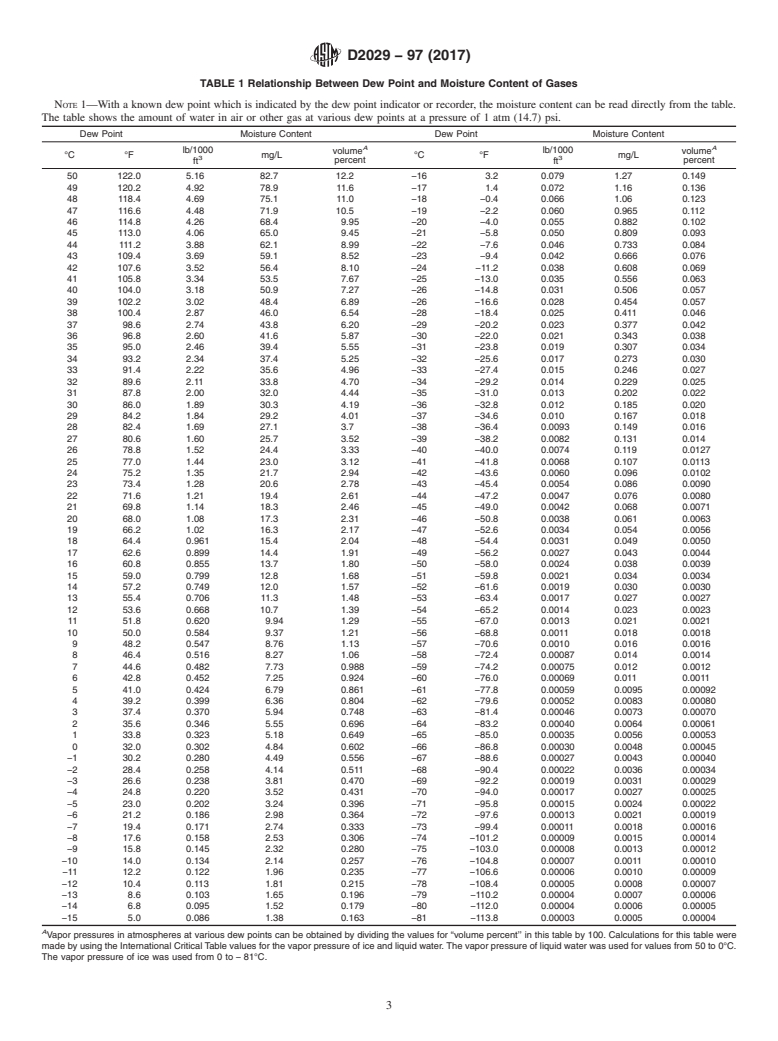

5.3 Once the dew point is determined, a conversion to moisture content may be performed using Table 1. Once moisture content is known, the lowest temperature at which gas insulated equipment can be safely operated can usually be determined by reviewing manufacturers' specifications for the equipment. (A) Vapor pressures in atmospheres at various dew points can be obtained by dividing the values for “volume percent'' in this table by 100. Calculations for this table were made by using the International Critical Table values for the vapor pressure of ice and liquid water. The vapor pressure of liquid water was used for values from 50 to 0°C. The vapor pressure of ice was used from 0 to − 81°C.

5.4 The dew point of the test gas is independent of the gas temperature but does depend on its pressure. Many moisture measurement test instruments are sensitive to pressure, and display moisture values at the instrument inlet pressure and not necessarily at the pressure of the system being sampled. It is therefore important to account for this condition to avoid serious measurement errors.

SCOPE

1.1 These test methods describe the determination of the water vapor content of electrical insulating gases by direct or indirect measurement of the dew point and the calculation of the water vapor content.

1.2 The following four test methods are provided:

1.2.1 Method A describes the automatic chilled mirror method for measurement of dew point as low as − 73°C (−99°F).

1.2.2 Method B describes the manual chilled mirror or dew cup method for measurement of dew point as low as − 73°C (−99°F).

1.2.3 Method C describes the adiabatic expansion method for measurement of dew point as low as − 62°C (−80°F).

1.2.4 Method D describes the capacitance method for measurement of dew point as low as − 110°C (−166°F).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warnings, see 8.1.1, 9.2, 10.1.2 and 10.2.5.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2029 − 97 (Reapproved 2017)

Standard Test Methods for

Water Vapor Content of Electrical Insulating Gases by

1

Measurement of Dew Point

This standard is issued under the fixed designation D2029; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Terminology

1.1 These test methods describe the determination of the 3.1 Definitions:

water vapor content of electrical insulating gases by direct or 3.1.1 dew point, n—the temperature to which a gas must be

indirect measurement of the dew point and the calculation of cooledatconstantpressureandconstantwatervaporcontentin

the water vapor content. order for saturation to occur. Any further cooling usually

results in formation of the first drop of dew.

1.2 The following four test methods are provided:

3.1.2 hygroscopic, adj—readily taking up and retaining

1.2.1 Method A describes the automatic chilled mirror

moisture.

method for measurement of dew point as low as−73°C

(−99°F).

4. Summary of Test Methods

1.2.2 Method B describes the manual chilled mirror or dew

4.1 Method A—The automatic chilled mirror method uses

cup method for measurement of dew point as low as−73°C

the chilled mirror dew point condensation principle to deter-

(−99°F).

mine the water vapor content in gas mixtures. An internal

1.2.3 Method C describes the adiabatic expansion method

mirror, which is in the path of the test gas, is automatically

for measurement of dew point as low as−62°C (−80°F).

cooled. Internal electronics sense the presence of moisture on

1.2.4 Method D describes the capacitance method for mea-

the mirror. The device then automatically brings itself to

surement of dew point as low as−110°C (−166°F).

equilibrium and provides a direct reading of dew point tem-

1.3 This standard does not purport to address all of the

perature.

safety concerns, if any, associated with its use. It is the

4.2 Method B—This method uses the same basic condensa-

responsibility of the user of this standard to establish appro-

tion principle in 4.1; however, the manual chilled mirror

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific method uses a mixture of acetone and ice or other cooling

media to manually chill the dew cup polished surface which

warnings, see 8.1.1, 9.2, 10.1.2 and 10.2.5.

acts as the mirror.

2. Referenced Documents

4.3 MethodC—Adiabaticexpansionusesaprocessinwhich

2

2.1 ASTM Standards: the test gas is cooled rapidly to determine dew point tempera-

ture.Thisrapidexhaustingofthetestgastoatmosphereresults

D1933Specification for Nitrogen Gas as an Electrical Insu-

lating Material in an expansion and cooling of the gas. If the cooling is

sufficient to reduce the temperature of the gas to or below the

D2472Specification for Sulfur Hexafluoride

D3283Specification for Air as an Electrical Insulating Ma- dew point, water vapor will condense out in the form of a fine

mist or fog. Successive trials will determine the minimum

terial

initialpressurethatwillproduceafog.Fromthis,thedewpoint

temperature can be calculated.

4.3.1 The relationship between pressure and temperature

1

These test methods are under the jurisdiction of ASTM Committee D27 on

during adiabatic expansion is as follows:

Electrical Insulating Liquids and Gasesand are the direct responsibility of Subcom-

mittee D27.07 on Physical Test.

K21/K

@ #

T 5 T P /P

F I@ F I#

Current edition approved Jan. 1, 2017. Published February 2017. Originally

approved in 1964. Last previous edition approved in 2008 as D2029-97 (2008).

where:

DOI: 10.1520/D2029-97R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

K = ratio of specific heats for a given gas,

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

T = final temperature,

F

Standards volume information, refer to the standard’s Document Summary page on

T = initial temperature,

I

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2029 − 97 (2017)

6.3.1 For MethodsA, B, and C, the relatively large volume

P = final pressure, and

F

of gas required to deposit sufficient water vapor to create the

P = initial pressure.

I

“dew”.

4.4 Method D—The capacitance method uses a moisture

6.3.2 For Meth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.