ASTM D5664-02

(Test Method)Standard Test Method for Evaluating the Effects of Fire-Retardant Treatments and Elevated Temperatures on Strength Properties of Fire-Retardant Treated Lumber

Standard Test Method for Evaluating the Effects of Fire-Retardant Treatments and Elevated Temperatures on Strength Properties of Fire-Retardant Treated Lumber

SIGNIFICANCE AND USE

The mechanical properties evaluated by this test method provide the following:

5.1.1 Data for use in developing modification factors for the allowable design properties of fire-retardant treated lumber when used at or near room temperatures (see 6.3).

5.1.2 Data for use in developing modification factors for allowable design properties of fire-retardant treated lumber when exposed to elevated temperatures and humidity (see 6.4).

5.1.3 Data (optional) for use in modifying these factors for size effects when fire-retardant treated lumber is used at or near room temperature and when exposed to elevated temperatures and humidity (see 6.5).

Data from the first two procedures in this test method of evaluation are indicative only for that species.

Note 1—The results of the three listed species (Southern pine, Douglas fir, and either white spruce or a Spruce/Fir mixture) may be used together to make inference on untested wood species because the three tested species represent the full spectrum of expected treatability.

Data from the optional third part of this three-part method of evaluation are indicative for all species because it is primarily used to assess size effects.

SCOPE

1.1 This test method covers procedures for obtaining data to assess the initial adjustments to allowable design stresses for lumber treated with candidate commercial fire-retardant (FR) formulations and further procedures for obtaining data to assess the effect of extended exposure to elevated temperature of 66 ± 2°C (150 ± 4°F).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5664 – 02

Standard Test Method for

Evaluating the Effects of Fire-Retardant Treatments and

Elevated Temperatures on Strength Properties of Fire-

1

Retardant Treated Lumber

This standard is issued under the fixed designation D 5664; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope NFPA 703 Standard for Fire Retardant Impregnated Wood

5

and Fire Retardant Coatings for Building Materials

1.1 This test method covers procedures for obtaining data to

U.S. Product Standard PS 20 American Softwood Lumber

assess the initial adjustments to allowable design stresses for

6

Standard

lumber treated with candidate commercial fire-retardant (FR)

formulations and further procedures for obtaining data to

3. Terminology

assess the effect of extended exposure to elevated temperature

3.1 Definitions—Definitions used in this test method are in

of 66 6 2°C (150 6 4°F).

accordance with Terminologies D 9 and E 176 and Nomencla-

1.2 This standard does not purport to address all of the

ture D 1165.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 Thegeneralobjectivesofthistestmethodaretodevelop

bility of regulatory limitations prior to use.

data to adjust allowable design stresses of FR-treated lumber

for the initial effects for the tested FR-formulation(s) and to

2. Referenced Documents

develop data on in-service thermal stability after extended

2.1 ASTM Standards:

2 exposure to environmental conditions up to 66 6 2°C (150 6

D 9 Terminology Relating to Wood

2

4°F) and$50 % relative humidity.

D 143 MethodsofTestingSmallClearSpecimensofWood

4.2 Procedure 1—This procedure uses small clear speci-

D 1165 Nomenclature of Domestic Hardwoods and Soft-

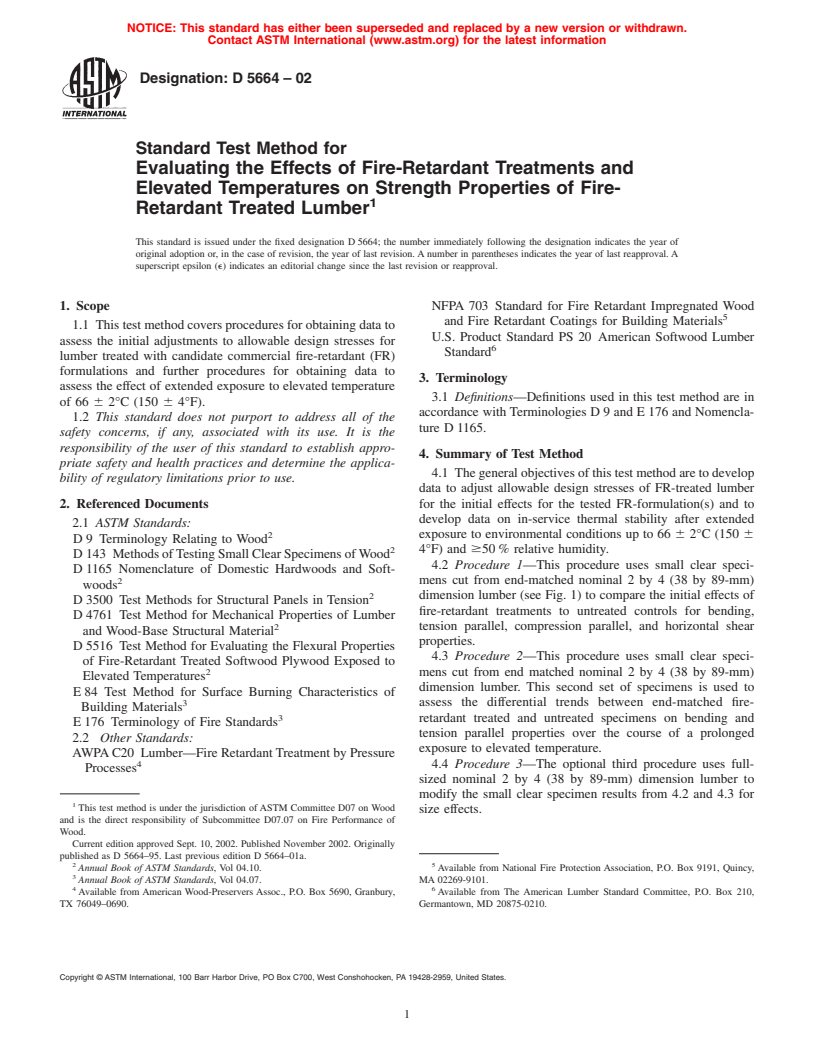

2 mens cut from end-matched nominal 2 by 4 (38 by 89-mm)

woods

2 dimension lumber (see Fig. 1) to compare the initial effects of

D 3500 Test Methods for Structural Panels in Tension

fire-retardant treatments to untreated controls for bending,

D 4761 Test Method for Mechanical Properties of Lumber

2 tension parallel, compression parallel, and horizontal shear

and Wood-Base Structural Material

properties.

D 5516 Test Method for Evaluating the Flexural Properties

4.3 Procedure 2—This procedure uses small clear speci-

of Fire-Retardant Treated Softwood Plywood Exposed to

2 mens cut from end matched nominal 2 by 4 (38 by 89-mm)

Elevated Temperatures

dimension lumber. This second set of specimens is used to

E 84 Test Method for Surface Burning Characteristics of

3 assess the differential trends between end-matched fire-

Building Materials

3 retardant treated and untreated specimens on bending and

E 176 Terminology of Fire Standards

tension parallel properties over the course of a prolonged

2.2 Other Standards:

exposure to elevated temperature.

AWPAC20 Lumber—Fire RetardantTreatment by Pressure

4 4.4 Procedure 3—The optional third procedure uses full-

Processes

sized nominal 2 by 4 (38 by 89-mm) dimension lumber to

modify the small clear specimen results from 4.2 and 4.3 for

1

This test method is under the jurisdiction of ASTM Committee D07 on Wood

size effects.

and is the direct responsibility of Subcommittee D07.07 on Fire Performance of

Wood.

Current edition approved Sept. 10, 2002. Published November 2002. Originally

published as D 5664–95. Last previous edition D 5664–01a.

2 5

Annual Book of ASTM Standards, Vol 04.10. Available from National Fire Protection Association, P.O. Box 9191, Quincy,

3

Annual Book of ASTM Standards, Vol 04.07. MA 02269-9101.

4 6

Available from American Wood-Preservers Assoc., P.O. Box 5690, Granbury, Available from The American Lumber Standard Committee, P.O. Box 210,

TX 76049–0690. Germantown, MD 20875-0210.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5664–02

midpoint of the retention range as specified for the species by

the agency certifying the flame spread index of the treated

lumber. The retention range specified by the certifying agency

shall provide a flame-spread index of 25 or less when tested in

accordance with Test Method E 84 for 10 min, show no

evidenceofsignificantprogressioncombustionwhenthetestis

continued for an additional 20-min period and not allow

progression of the flame front beyond a distance of 3.2 m (10.5

ft) beyond the centerline of the burners anytime during the

30-min extended test.

6.1.1.1 The provisions of 6.1.1 are not int

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.