ASTM D6841-21

(Practice)Standard Practice for Calculating Design Value Treatment Adjustment Factors for Fire-Retardant-Treated Lumber

Standard Practice for Calculating Design Value Treatment Adjustment Factors for Fire-Retardant-Treated Lumber

SIGNIFICANCE AND USE

5.1 Fire-retardant-treatments are used to reduce the flame-spread characteristics of wood. Chemicals and redrying conditions employed in treatments are known to modify the strength properties of the wood product being treated. This practice establishes the procedures for determining adjustment factors that account for the isolated effects of fire-retardant treatment on design properties of lumber. These effects are established relative to performance of untreated lumber.

5.2 The effect of fire-retardant treatments on the strength of lumber used in roof framing applications is time related. In this practice, the cumulative effect on strength of annual thermal loads from all temperature bins is increased 50 times to establish treatment adjustment factors for fire-retardant treated lumber roof framing.

5.3 The procedures of Test Method D5664 employ an elevated temperature intended to produce strength losses in a short period of time. Although the exposure is much more severe than that which occurs in an actual roof system, the chemical reactions that occur in the laboratory test are considered to be the same as those occurring over long periods of time in the field.

5.4 Treatment adjustment factors developed under this practice apply to lumber installed in accordance with construction practices recommended by the fire-retardant chemical manufacturer which include avoidance of direct wetting, precipitation or frequent condensation. Application of this practice is limited to roof applications with design consistent with 1.3.

SCOPE

1.1 This practice covers procedures for calculating adjustment factors that account for the effects of fire-retardant treatment on design properties of lumber. The adjustment factors calculated in accordance with this practice are to be applied to design values for untreated lumber in order to determine design values for fire-retardant-treated lumber used at ambient temperatures [service temperatures up to 100 °F (38 °C)] and as framing in roof systems.

Note 1: This analysis focuses on the relative performance of treated and untreated materials tested after equilibrating to ambient conditions following a controlled exposure to specified conditions of high temperature and humidity. Elevated temperature, moisture, load duration, and other factors typically accounted for in the design of untreated lumber must also be considered in the design of fire-retardant-treated lumber, but are outside the scope of the treatment adjustments developed under this practice.

1.2 These adjustment factors for the design properties in bending, tension parallel to grain, compression parallel to grain, horizontal shear, and modulus of elasticity are based on the results of strength tests of matched treated and untreated small clear wood specimens after conditioning at nominal room temperatures [72 °F (22 °C)] and of other similar specimens after exposure at 150 °F (66 °C). The test data are developed in accordance with Test Method D5664. Guidelines are provided for establishing adjustment factors for the property of compression perpendicular to grain and for connection design values.

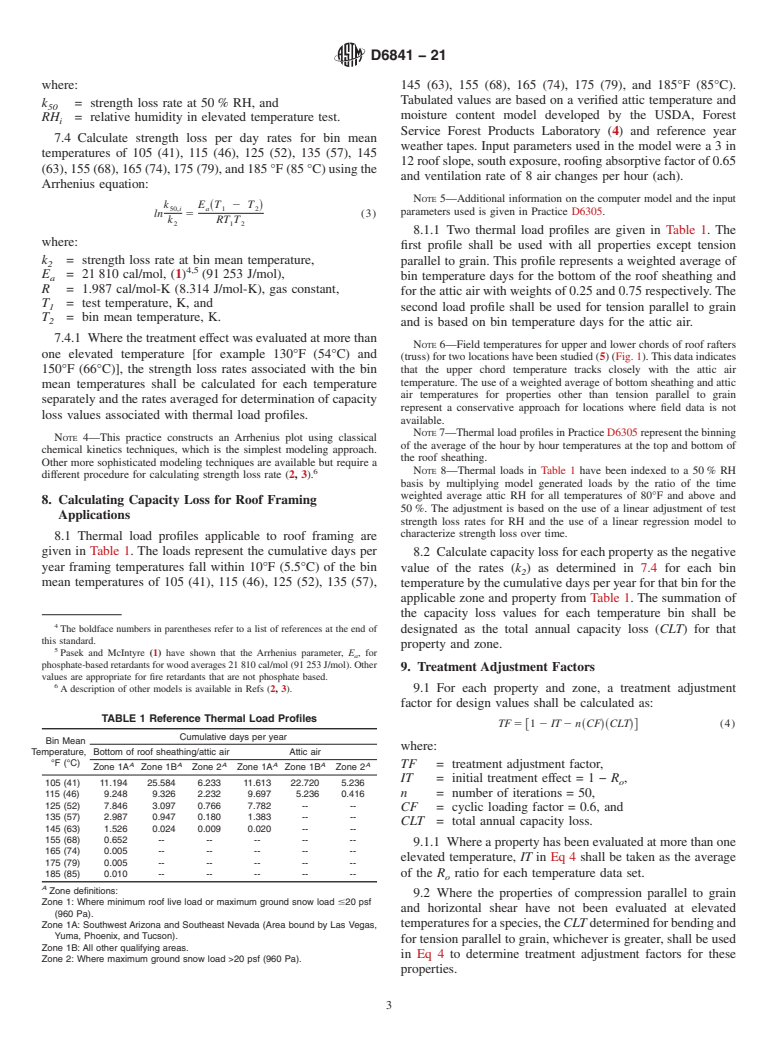

1.3 Treatment adjustment factors for roof framing applications are based on thermal load profiles for normal wood roof construction used in a variety of climates as defined by weather tapes of the American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE).2 The solar loads, moisture conditions, ventilation rates, and other parameters used in the computer model were selected to represent typical sloped roof designs. The thermal loads in this practice are applicable to roof slopes of 3 in 12 or steeper, to roofs designed with vent areas and vent locations conforming to national standards of practice and to designs in which the bottom side of the roof sheathing is exposed to ventilation air. For designs that do not have one or more of these base-line features, the applic...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6841 − 21

Standard Practice for

Calculating Design Value Treatment Adjustment Factors for

1

Fire-Retardant-Treated Lumber

This standard is issued under the fixed designation D6841; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope sloped roof designs. The thermal loads in this practice are

applicabletoroofslopesof3in12orsteeper,toroofsdesigned

1.1 This practice covers procedures for calculating adjust-

with vent areas and vent locations conforming to national

ment factors that account for the effects of fire-retardant

standards of practice and to designs in which the bottom side

treatment on design properties of lumber. The adjustment

of the roof sheathing is exposed to ventilation air. For designs

factors calculated in accordance with this practice are to be

that do not have one or more of these base-line features, the

applied to design values for untreated lumber in order to

applicability of this practice needs to be documented by the

determine design values for fire-retardant-treated lumber used

user.

atambienttemperatures[servicetemperaturesupto100°F(38

°C)] and as framing in roof systems. 1.4 The procedures of this practice parallel those given in

NOTE 1—This analysis focuses on the relative performance of treated

Practice D6305. General references and commentary in Prac-

and untreated materials tested after equilibrating to ambient conditions

tice D6305 are also applicable to this practice.

following a controlled exposure to specified conditions of high tempera-

1.5 Thevaluesstatedininch-poundunitsaretoberegarded

ture and humidity. Elevated temperature, moisture, load duration, and

other factors typically accounted for in the design of untreated lumber

as standard. The SI units listed in parentheses are provided for

must also be considered in the design of fire-retardant-treated lumber, but

information only and are not considered standard.

are outside the scope of the treatment adjustments developed under this

1.6 This standard does not purport to address all of the

practice.

safety concerns, if any, associated with its use. It is the

1.2 These adjustment factors for the design properties in

responsibility of the user of this standard to establish appro-

bending, tension parallel to grain, compression parallel to

priate safety, health, and environmental practices and deter-

grain, horizontal shear, and modulus of elasticity are based on

mine the applicability of regulatory limitations prior to use.

the results of strength tests of matched treated and untreated

1.7 This international standard was developed in accor-

small clear wood specimens after conditioning at nominal

dance with internationally recognized principles on standard-

room temperatures [72 °F (22 °C)] and of other similar

ization established in the Decision on Principles for the

specimens after exposure at 150 °F (66 °C). The test data are

Development of International Standards, Guides and Recom-

developed in accordance with Test Method D5664. Guidelines

mendations issued by the World Trade Organization Technical

are provided for establishing adjustment factors for the prop-

Barriers to Trade (TBT) Committee.

erty of compression perpendicular to grain and for connection

design values.

2. Referenced Documents

1.3 Treatment adjustment factors for roof framing applica-

3

2.1 ASTM Standards:

tions are based on thermal load profiles for normal wood roof

D9Terminology Relating to Wood and Wood-Based Prod-

constructionusedinavarietyofclimatesasdefinedbyweather

ucts

tapes of the American Society of Heating, Refrigerating and

2 D5664Test Method for Evaluating the Effects of Fire-

Air-ConditioningEngineers,Inc.(ASHRAE). Thesolarloads,

Retardant Treatments and Elevated Temperatures on

moisture conditions, ventilation rates, and other parameters

Strength Properties of Fire-Retardant Treated Lumber

used in the computer model were selected to represent typical

D6305Practice for Calculating Bending Strength Design

Adjustment Factors for Fire-Retardant-Treated Plywood

1

Roof Sheathing

This practice is under the jurisdiction ofASTM Committee D07 on Wood and

is the direct responsibility of Subcommittee D07.07 on Fire Performance of Wood.

CurrenteditionapprovedJune1,2021.PublishedJuly2021.Originallyapproved

in 2002. Last previous edition approved in 2016 as D6841–16. DOI: 10.1520/

3

D6841-21. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

2

Available from A

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6841 − 16 D6841 − 21

Standard Practice for

Calculating Design Value Treatment Adjustment Factors for

1

Fire-Retardant-Treated Lumber

This standard is issued under the fixed designation D6841; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for calculating treatment adjustment factors adjustment factors that account for the effects of

fire-retardant treatment on design properties of lumber. The adjustment factors calculated in accordance with this practice are to

be applied to design values for untreated lumber in order to determine design values for fire-retardant-treated lumber used at

ambient temperatures [service temperatures up to 100°F (38°C)] 100 °F (38 °C)] and as framing in roof systems.

NOTE 1—This analysis focuses on the relative performance of treated and untreated materials tested after equilibrating to ambient conditions following

a controlled exposure to specified conditions of high temperature and humidity. Elevated temperature, moisture, load duration, and other factors typically

accounted for in the design of untreated lumber must also be considered in the design of fire-retardant-treated lumber, but are outside the scope of the

treatment adjustments developed under this practice.

1.2 These design value treatment adjustment factors for the properties of extreme fiber design properties in bending, tension

parallel to grain, compression parallel to grain, horizontal shear, and modulus of elasticity are based on the results of strength tests

of matched treated and untreated small clear wood specimens after conditioning at nominal room temperatures [72°F (22°C)] [72

°F (22 °C)] and of other similar specimens after exposure at 150°F (66°C). 150 °F (66 °C). The test data are developed in

accordance with Test Method D5664. Guidelines are provided for establishing adjustment factors for the property of compression

perpendicular to grain and for connection design values.

1.3 Treatment adjustment factors for roof framing applications are based on computer generated thermal load profiles for normal

wood roof construction used in a variety of climates as defined by weather tapes of the American Society of Heating, Refrigerating

2

and Air-Conditioning Engineers, Inc. (ASHRAE). The solar loads, moisture conditions, ventilation rates, and other parameters

used in the computer model were selected to represent typical sloped roof designs. The thermal loads in this practice are applicable

to roof slopes of 3 in 12 or steeper, to roofs designed with vent areas and vent locations conforming to national standards of practice

and to designs in which the bottom side of the roof sheathing is exposed to ventilation air. For designs that do not have one or

more of these base-line features, the applicability of this practice needs to be documented by the user.

1.4 The procedures of this practice parallel those given in Practice D6305. General references and commentary in Practice D6305

are also applicable to this practice.

1.5 The values stated in inch-pound units are to be regarded as standard. The SI units listed in parentheses are provided for

information only and are not considered standard.

1

This practice is under the jurisdiction of ASTM Committee D07 on Wood and is the direct responsibility of Subcommittee D07.07 on Fire Performance of Wood.

Current edition approved March 1, 2016June 1, 2021. Published April 2016July 2021. Originally approved in 2002. Last previous edition approved in 20152016 as

D6841 – 15.D6841 – 16. DOI: 10.1520/D6841-16.10.1520/D6841-21.

2

Available from American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA 30329,

http://www.ashrae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6841 − 21

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accord

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.