ASTM C1795-17

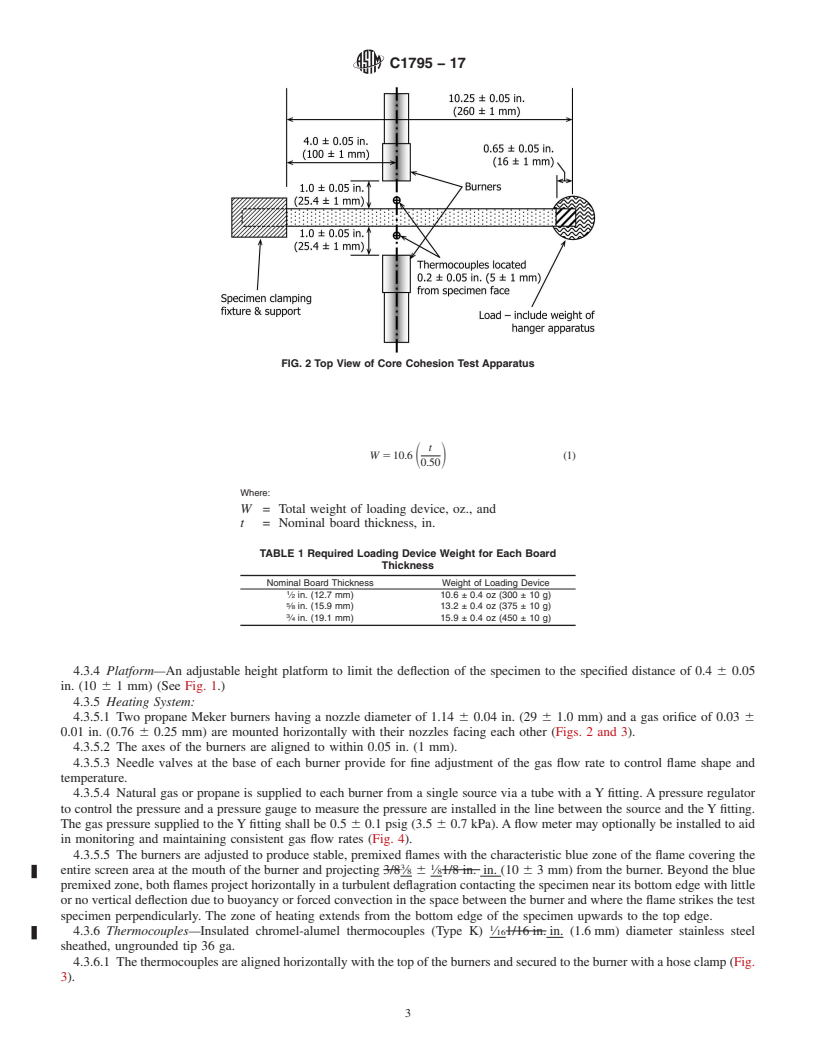

(Test Method)Standard Test Methods for High-Temperature Characterization of Gypsum Boards and Panels

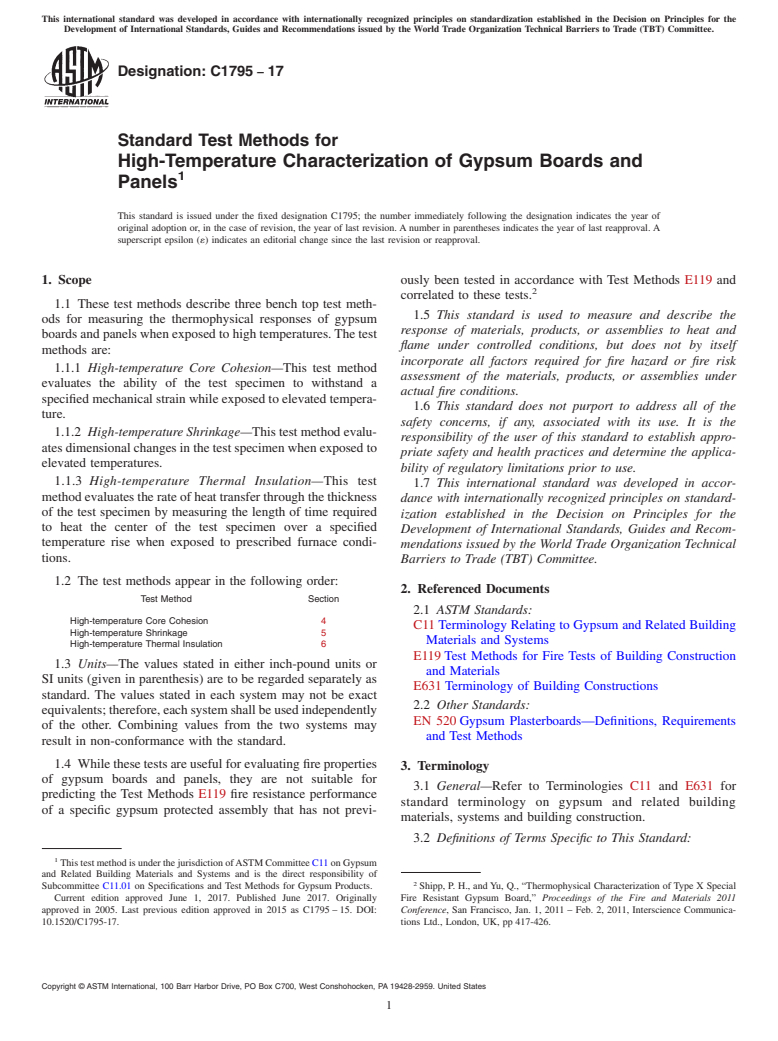

Standard Test Methods for High-Temperature Characterization of Gypsum Boards and Panels

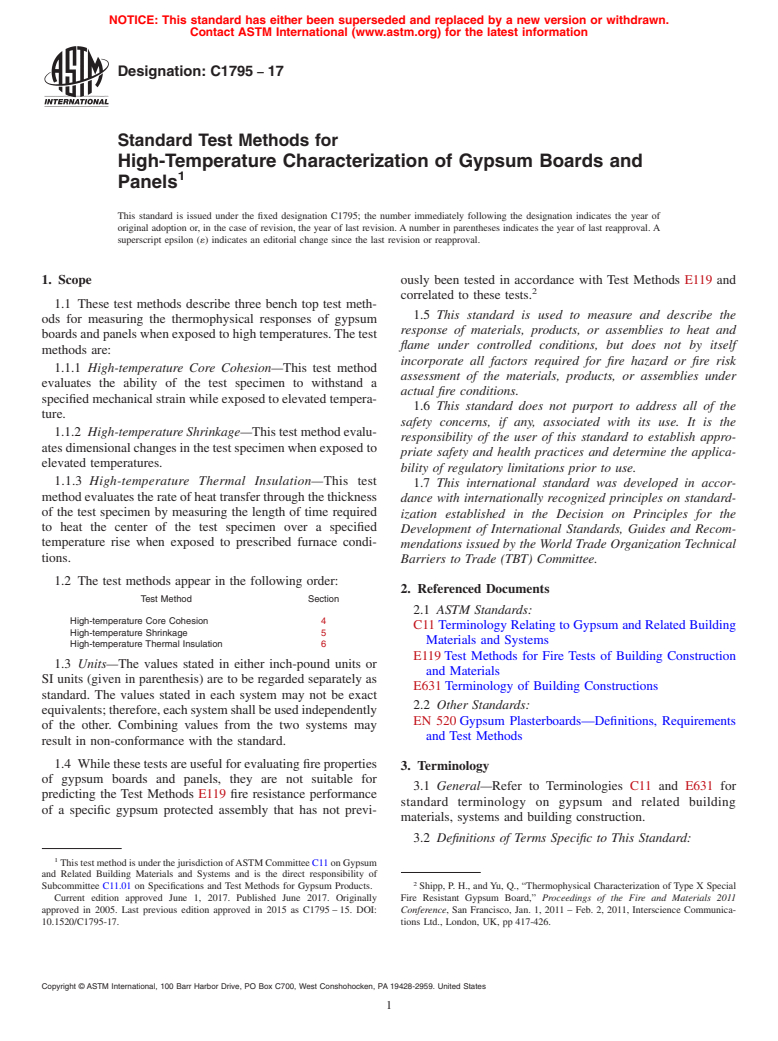

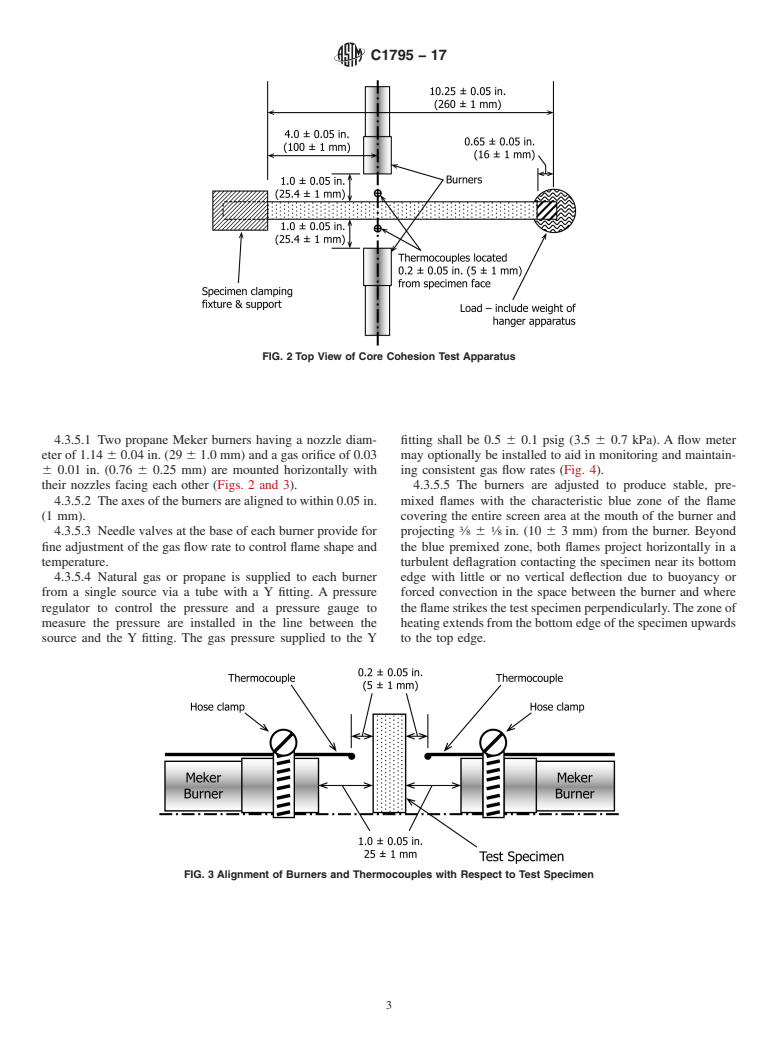

SCOPE

1.1 These test methods describe three bench top test methods for measuring the thermophysical responses of gypsum boards and panels when exposed to high temperatures. The test methods are:

1.1.1 High-temperature Core Cohesion—This test method evaluates the ability of the test specimen to withstand a specified mechanical strain while exposed to elevated temperature.

1.1.2 High-temperature Shrinkage—This test method evaluates dimensional changes in the test specimen when exposed to elevated temperatures.

1.1.3 High-temperature Thermal Insulation—This test method evaluates the rate of heat transfer through the thickness of the test specimen by measuring the length of time required to heat the center of the test specimen over a specified temperature rise when exposed to prescribed furnace conditions.

1.2 The test methods appear in the following order:

Test Method

Section

High-temperature Core Cohesion

4

High-temperature Shrinkage

5

High-temperature Thermal Insulation

6

1.3 Units—The values stated in either inch-pound units or SI units (given in parenthesis) are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 While these tests are useful for evaluating fire properties of gypsum boards and panels, they are not suitable for predicting the Test Methods E119 fire resistance performance of a specific gypsum protected assembly that has not previously been tested in accordance with Test Methods E119 and correlated to these tests.2

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1795 − 17

Standard Test Methods for

High-Temperature Characterization of Gypsum Boards and

1

Panels

This standard is issued under the fixed designation C1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ously been tested in accordance with Test Methods E119 and

2

correlated to these tests.

1.1 These test methods describe three bench top test meth-

1.5 This standard is used to measure and describe the

ods for measuring the thermophysical responses of gypsum

response of materials, products, or assemblies to heat and

boardsandpanelswhenexposedtohightemperatures.Thetest

flame under controlled conditions, but does not by itself

methods are:

incorporate all factors required for fire hazard or fire risk

1.1.1 High-temperature Core Cohesion—This test method

assessment of the materials, products, or assemblies under

evaluates the ability of the test specimen to withstand a

actual fire conditions.

specifiedmechanicalstrainwhileexposedtoelevatedtempera-

1.6 This standard does not purport to address all of the

ture.

safety concerns, if any, associated with its use. It is the

1.1.2 High-temperature Shrinkage—Thistestmethodevalu-

responsibility of the user of this standard to establish appro-

atesdimensionalchangesinthetestspecimenwhenexposedto

priate safety and health practices and determine the applica-

elevated temperatures.

bility of regulatory limitations prior to use.

1.1.3 High-temperature Thermal Insulation—This test

1.7 This international standard was developed in accor-

methodevaluatestherateofheattransferthroughthethickness

dance with internationally recognized principles on standard-

of the test specimen by measuring the length of time required

ization established in the Decision on Principles for the

to heat the center of the test specimen over a specified

Development of International Standards, Guides and Recom-

temperature rise when exposed to prescribed furnace condi-

mendations issued by the World Trade Organization Technical

tions.

Barriers to Trade (TBT) Committee.

1.2 The test methods appear in the following order:

2. Referenced Documents

Test Method Section

2.1 ASTM Standards:

High-temperature Core Cohesion 4

C11Terminology Relating to Gypsum and Related Building

High-temperature Shrinkage 5

Materials and Systems

High-temperature Thermal Insulation 6

E119Test Methods for Fire Tests of Building Construction

1.3 Units—The values stated in either inch-pound units or

and Materials

SI units (given in parenthesis) are to be regarded separately as

E631Terminology of Building Constructions

standard. The values stated in each system may not be exact

2.2 Other Standards:

equivalents;therefore,eachsystemshallbeusedindependently

EN 520Gypsum Plasterboards—Definitions, Requirements

of the other. Combining values from the two systems may

and Test Methods

result in non-conformance with the standard.

1.4 Whilethesetestsareusefulforevaluatingfireproperties

3. Terminology

of gypsum boards and panels, they are not suitable for

3.1 General—Refer to Terminologies C11 and E631 for

predicting the Test Methods E119 fire resistance performance

standard terminology on gypsum and related building

of a specific gypsum protected assembly that has not previ-

materials, systems and building construction.

3.2 Definitions of Terms Specific to This Standard:

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC11onGypsum

and Related Building Materials and Systems and is the direct responsibility of

2

Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products. Shipp, P. H., andYu, Q., “Thermophysical Characterization of Type X Special

Current edition approved June 1, 2017. Published June 2017. Originally Fire Resistant Gypsum Board,” Proceedings of the Fire and Materials 2011

approved in 2005. Last previous edition approved in 2015 as C1795–15. DOI: Conference, San Francisco, Jan. 1, 2011 – Feb. 2, 2011, Interscience Communica-

10.1520/C1795-17. tions Ltd., London, UK, pp417-426.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1795 − 17

3.2.1 Thermal Insulation Index (TI), n—asinglevalueindex a mounting hole drilled in it near the outer extremity and is of

that denotes the rate of heating at the center of the Thermal sufficient length that the hook or wire by which the loading

Insulation Test specimen as determined by

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1795 − 15 C1795 − 17

Standard Test Methods for

High-Temperature Characterization of Gypsum Boards and

1

Panels

This standard is issued under the fixed designation C1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods describe three bench top test methods for measuring the thermophysical responses of gypsum boards

and panels when exposed to high temperatures. The test methods are:

1.1.1 High-temperature Core Cohesion—This test method evaluates the ability of the test specimen to withstand a specified

mechanical strain while exposed to elevated temperature.

1.1.2 High-temperature Shrinkage—This test method evaluates dimensional changes in the test specimen when exposed to

elevated temperatures.

1.1.3 High-temperature Thermal Insulation—This test method evaluates the rate of heat transfer through the thickness of the

test specimen by measuring the length of time required to heat the center of the test specimen over a specified temperature rise

when exposed to prescribed furnace conditions.

1.2 The test methods appear in the following order:

Test Method Section

High-temperature Core Cohesion 4

High-temperature Shrinkage 5

High-temperature Thermal Insulation 6

1.3 Units—The values stated in either inch-pound units or SI units (given in parenthesis) are to be regarded separately as

standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of

the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 While these tests are useful for evaluating fire properties of gypsum boards and panels, they are not suitable for predicting

the Test Methods E119 fire resistance performance of a specific gypsum protected assembly that has not previously been tested

2

in accordance with Test Methods E119 and correlated to these tests.

1.5 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

E119 Test Methods for Fire Tests of Building Construction and Materials

E631 Terminology of Building Constructions

1

This test method is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products.

Current edition approved Dec. 1, 2015June 1, 2017. Published January 2016June 2017. Originally approved in 2005. Last previous edition approved in 2015 as C1795 – 15.

DOI: 10.1520/C1795-1510.1520/C1795-17.

2

Shipp, P. H., and Yu, Q., “Thermophysical Characterization of Type X Special Fire Resistant Gypsum Board,” Proceedings of the Fire and Materials 2011 Conference,

San Francisco, Jan. 1, 2011 – Feb. 2, 2011, Interscience Communications Ltd., London, UK, pp 417-426.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1795 − 17

2.2 Other Standards:

EN 520 Gypsum Plasterboards—Definitions, Requirements and Test Methods

3. Terminology

3.1 General—Refer to Terminologies C11 and E631 for standard terminology on gypsum and related building materials,

systems and building construction.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Thermal Insulation Index (TI), n—a single value index

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1795 − 17

Standard Test Methods for

High-Temperature Characterization of Gypsum Boards and

1

Panels

This standard is issued under the fixed designation C1795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ously been tested in accordance with Test Methods E119 and

2

correlated to these tests.

1.1 These test methods describe three bench top test meth-

1.5 This standard is used to measure and describe the

ods for measuring the thermophysical responses of gypsum

response of materials, products, or assemblies to heat and

boards and panels when exposed to high temperatures. The test

flame under controlled conditions, but does not by itself

methods are:

incorporate all factors required for fire hazard or fire risk

1.1.1 High-temperature Core Cohesion—This test method

assessment of the materials, products, or assemblies under

evaluates the ability of the test specimen to withstand a

actual fire conditions.

specified mechanical strain while exposed to elevated tempera-

1.6 This standard does not purport to address all of the

ture.

safety concerns, if any, associated with its use. It is the

1.1.2 High-temperature Shrinkage—This test method evalu-

responsibility of the user of this standard to establish appro-

ates dimensional changes in the test specimen when exposed to

priate safety and health practices and determine the applica-

elevated temperatures.

bility of regulatory limitations prior to use.

1.1.3 High-temperature Thermal Insulation—This test

1.7 This international standard was developed in accor-

method evaluates the rate of heat transfer through the thickness

dance with internationally recognized principles on standard-

of the test specimen by measuring the length of time required

ization established in the Decision on Principles for the

to heat the center of the test specimen over a specified

Development of International Standards, Guides and Recom-

temperature rise when exposed to prescribed furnace condi-

mendations issued by the World Trade Organization Technical

tions.

Barriers to Trade (TBT) Committee.

1.2 The test methods appear in the following order:

2. Referenced Documents

Test Method Section

2.1 ASTM Standards:

High-temperature Core Cohesion 4

C11 Terminology Relating to Gypsum and Related Building

High-temperature Shrinkage 5

Materials and Systems

High-temperature Thermal Insulation 6

E119 Test Methods for Fire Tests of Building Construction

1.3 Units—The values stated in either inch-pound units or

and Materials

SI units (given in parenthesis) are to be regarded separately as

E631 Terminology of Building Constructions

standard. The values stated in each system may not be exact

2.2 Other Standards:

equivalents; therefore, each system shall be used independently

EN 520 Gypsum Plasterboards—Definitions, Requirements

of the other. Combining values from the two systems may

and Test Methods

result in non-conformance with the standard.

1.4 While these tests are useful for evaluating fire properties

3. Terminology

of gypsum boards and panels, they are not suitable for

3.1 General—Refer to Terminologies C11 and E631 for

predicting the Test Methods E119 fire resistance performance

standard terminology on gypsum and related building

of a specific gypsum protected assembly that has not previ-

materials, systems and building construction.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee C11 on Gypsum

and Related Building Materials and Systems and is the direct responsibility of

2

Subcommittee C11.01 on Specifications and Test Methods for Gypsum Products. Shipp, P. H., and Yu, Q., “Thermophysical Characterization of Type X Special

Current edition approved June 1, 2017. Published June 2017. Originally Fire Resistant Gypsum Board,” Proceedings of the Fire and Materials 2011

approved in 2005. Last previous edition approved in 2015 as C1795 – 15. DOI: Conference, San Francisco, Jan. 1, 2011 – Feb. 2, 2011, Interscience Communica-

10.1520/C1795-17. tions Ltd., London, UK, pp 417-426.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1795 − 17

3.2.1 Thermal Insulation Index (TI), n—a single value index a mounting hole drilled in it near the outer extremity and is of

that denotes the rate of heating at the center of the Thermal sufficient length that the hook or wire by which the loading

Insulation Test specimen as determined by the elapsed time to weight is suspended from the strap does not

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.