ASTM D1384-05(2012)

(Test Method)Standard Test Method for Corrosion Test for Engine Coolants in Glassware

Standard Test Method for Corrosion Test for Engine Coolants in Glassware

SIGNIFICANCE AND USE

This test method will generally distinguish between coolants that are definitely deleterious from the corrosion standpoint and those that are suitable for further evaluation. However, the results of this test method cannot stand alone as evidence of satisfactory corrosion inhibition. The actual service value of an engine coolant formulation can be determined only by more comprehensive bench, dynamometer, and field tests.

SCOPE

1.1 This test method covers a simple beaker-type procedure for evaluating the effects of engine coolants on metal specimens under controlled laboratory conditions (see Appendix X1).

Note 1—For more information on engine coolants, see (Refs 1-8).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in 10.1.7.2, 10.1.7.3, and 10.1.7.4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1384 − 05 (Reapproved 2012)

Standard Test Method for

1

Corrosion Test for Engine Coolants in Glassware

This standard is issued under the fixed designation D1384; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G31Guide for Laboratory Immersion Corrosion Testing of

Metals

1.1 This test method covers a simple beaker-type procedure

2.2 ASTM Adjuncts:

for evaluating the effects of engine coolants on metal speci-

4

All-glass apparatus for corrosion test (2 drawings)

mens under controlled laboratory conditions (see Appendix

X1).

3. Summary of Test Method

2

NOTE 1—For more information on engine coolants, see (Refs 1-8).

3.1 Inthistestmethod,specimensofmetalstypicalofthose

1.2 The values stated in SI units are to be regarded as the

present in engine cooling systems are totally immersed in

standard. The values given in parentheses are for information

aeratedenginecoolantsolutionsfor336hat88°C(190°F).The

only.

corrosion-inhibitivepropertiesofthetestsolutionareevaluated

on the basis of the weight changes incurred by the specimens.

1.3 This standard does not purport to address all of the

Each test is run in triplicate, and the average weight change is

safety concerns, if any, associated with its use. It is the

determined for each metal. A single test may occasionally be

responsibility of the user of this standard to establish appro-

completely out of line (see 11.2).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific hazards

4. Significance and Use

statements are given in 10.1.7.2, 10.1.7.3, and 10.1.7.4.

4.1 This test method will generally distinguish between

2. Referenced Documents

coolants that are definitely deleterious from the corrosion

3

2.1 ASTM Standards: standpoint and those that are suitable for further evaluation.

B32Specification for Solder Metal However, the results of this test method cannot stand alone as

B36/B36MSpecification for Brass Plate, Sheet, Strip, And

evidence of satisfactory corrosion inhibition. The actual ser-

Rolled Bar vice value of an engine coolant formulation can be determined

D1176Practice for Sampling and Preparing Aqueous Solu-

only by more comprehensive bench, dynamometer, and field

tionsofEngineCoolantsorAntirustsforTestingPurposes tests.

E1Specification for ASTM Liquid-in-Glass Thermometers

5. Apparatus

E178Practice for Dealing With Outlying Observations

E230Specification and Temperature-Electromotive Force

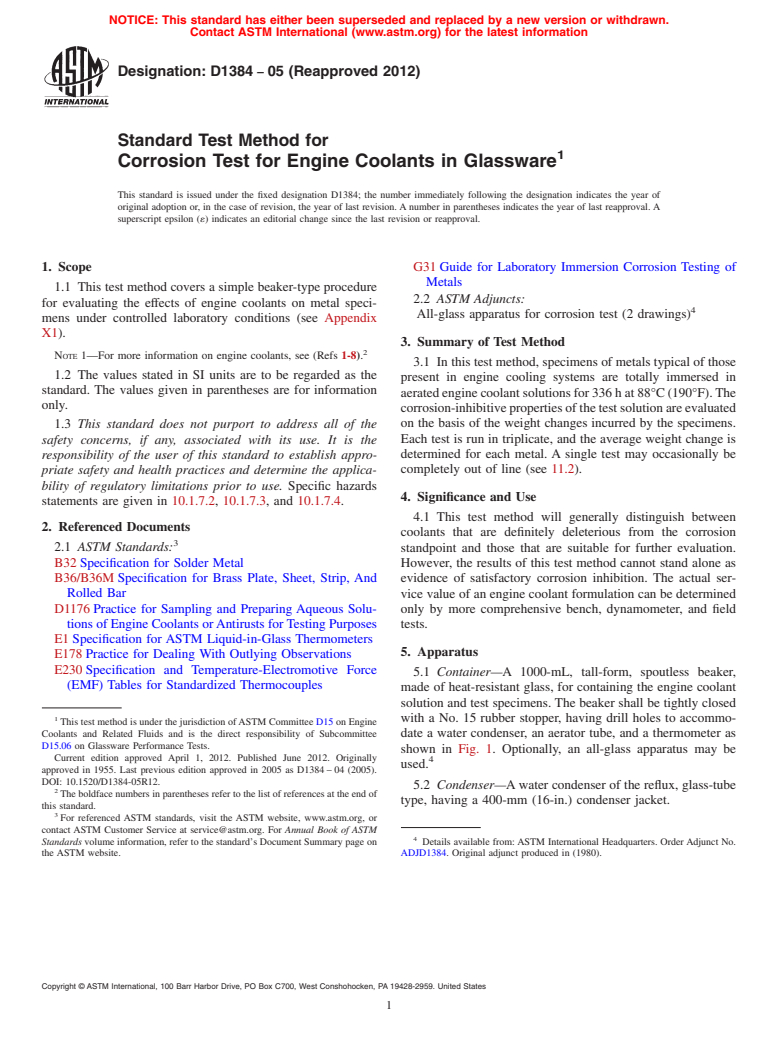

5.1 Container—A 1000-mL, tall-form, spoutless beaker,

(EMF) Tables for Standardized Thermocouples

made of heat-resistant glass, for containing the engine coolant

solution and test specimens. The beaker shall be tightly closed

1

with a No. 15 rubber stopper, having drill holes to accommo-

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Coolants and Related Fluids and is the direct responsibility of Subcommittee date a water condenser, an aerator tube, and a thermometer as

D15.06 on Glassware Performance Tests.

shown in Fig. 1. Optionally, an all-glass apparatus may be

Current edition approved April 1, 2012. Published June 2012. Originally

4

used.

approved in 1955. Last previous edition approved in 2005 as D1384–04 (2005).

DOI: 10.1520/D1384-05R12.

5.2 Condenser—Awater condenser of the reflux, glass-tube

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

type, having a 400-mm (16-in.) condenser jacket.

this standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Details available from:ASTM International Headquarters. OrderAdjunct No.

the ASTM website. ADJD1384. Original adjunct produced in (1980).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1384 − 05 (2012)

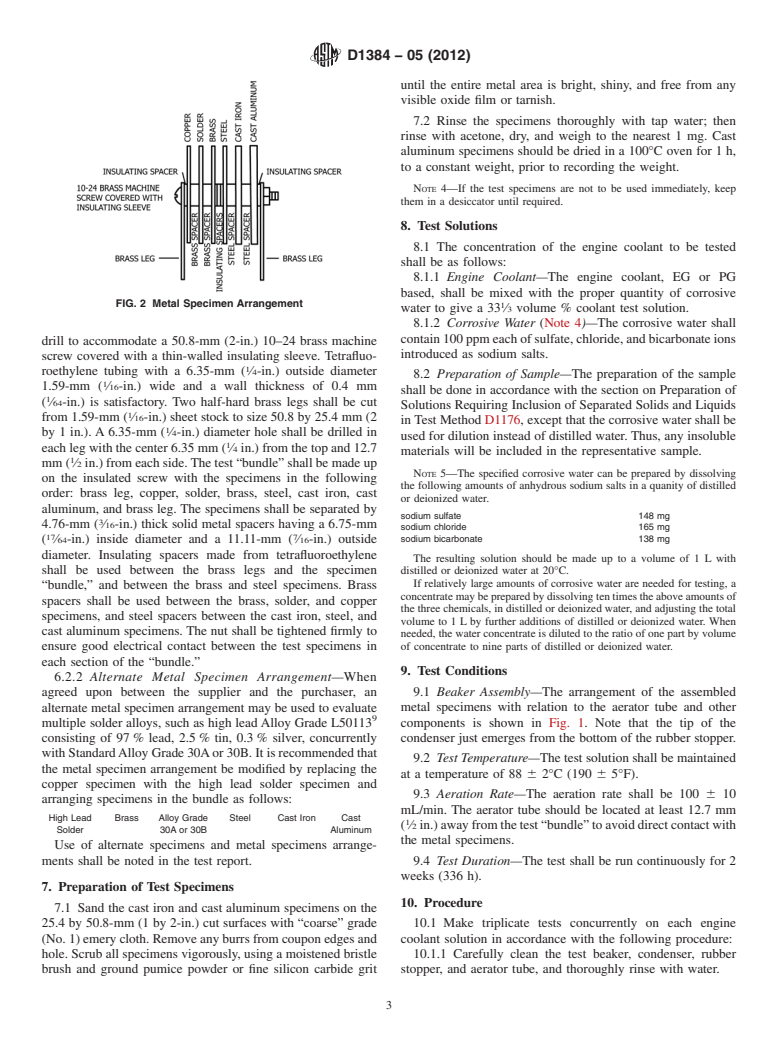

6. Metal Test Specimens

NOTE 2—The specimens prescribed in this test method have been

accepted by automobile manufacturers, but their composition may not be

the same as that of alloys currently used for engine cooling system

components.Therefore, specimens other than those designated in this test

method may be used by mutual agreement of the parties involved.

7

6.1 Type—The following metal test specimens, representa-

tive of cooling system metals, shall be used:

8

6.1.1 Steel, UNS G10200 (SAE 1020), cut from 1.59-mm

1

( ⁄16-in.) cold-rolled sheet stock to size 50.8 by 25.4 mm (2 by

1 i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.