ASTM D1867-96

(Specification)Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

SCOPE

1.1 This specification covers twelve grades of thermosetting laminate with copper foil bonded to one or both surfaces. These combination forms are intended primarily for use in fabrication of printed (etched) wiring or circuit boards.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1867 – 96 An American National Standard

Standard Specification for

Copper-Clad Thermosetting Laminates for Printed Wiring

This standard is issued under the fixed designation D 1867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

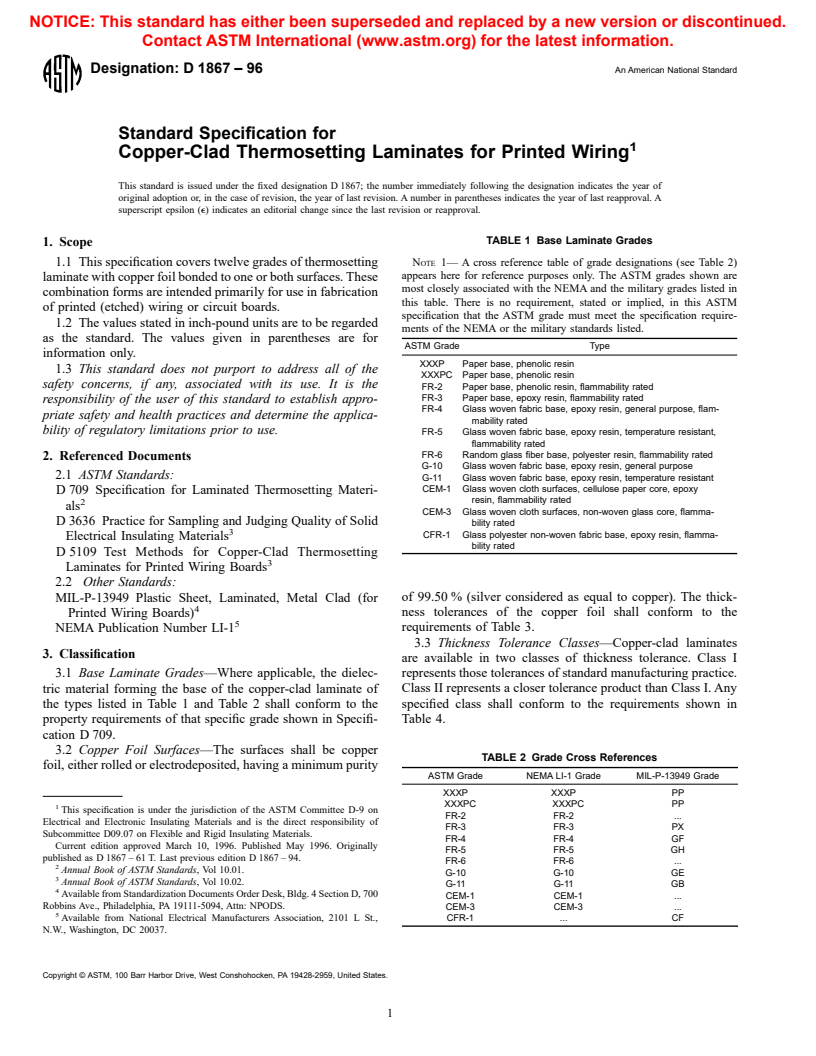

TABLE 1 Base Laminate Grades

1. Scope

1.1 This specification covers twelve grades of thermosetting NOTE 1— A cross reference table of grade designations (see Table 2)

appears here for reference purposes only. The ASTM grades shown are

laminate with copper foil bonded to one or both surfaces. These

most closely associated with the NEMA and the military grades listed in

combination forms are intended primarily for use in fabrication

this table. There is no requirement, stated or implied, in this ASTM

of printed (etched) wiring or circuit boards.

specification that the ASTM grade must meet the specification require-

1.2 The values stated in inch-pound units are to be regarded

ments of the NEMA or the military standards listed.

as the standard. The values given in parentheses are for

ASTM Grade Type

information only.

XXXP Paper base, phenolic resin

1.3 This standard does not purport to address all of the

XXXPC Paper base, phenolic resin

safety concerns, if any, associated with its use. It is the

FR-2 Paper base, phenolic resin, flammability rated

FR-3 Paper base, epoxy resin, flammability rated

responsibility of the user of this standard to establish appro-

FR-4 Glass woven fabric base, epoxy resin, general purpose, flam-

priate safety and health practices and determine the applica-

mability rated

bility of regulatory limitations prior to use.

FR-5 Glass woven fabric base, epoxy resin, temperature resistant,

flammability rated

FR-6 Random glass fiber base, polyester resin, flammability rated

2. Referenced Documents

G-10 Glass woven fabric base, epoxy resin, general purpose

2.1 ASTM Standards:

G-11 Glass woven fabric base, epoxy resin, temperature resistant

CEM-1 Glass woven cloth surfaces, cellulose paper core, epoxy

D 709 Specification for Laminated Thermosetting Materi-

resin, flammability rated

als

CEM-3 Glass woven cloth surfaces, non-woven glass core, flamma-

D 3636 Practice for Sampling and Judging Quality of Solid

bility rated

CFR-1 Glass polyester non-woven fabric base, epoxy resin, flamma-

Electrical Insulating Materials

bility rated

D 5109 Test Methods for Copper-Clad Thermosetting

Laminates for Printed Wiring Boards

2.2 Other Standards:

of 99.50 % (silver considered as equal to copper). The thick-

MIL-P-13949 Plastic Sheet, Laminated, Metal Clad (for

ness tolerances of the copper foil shall conform to the

Printed Wiring Boards)

requirements of Table 3.

NEMA Publication Number LI-1

3.3 Thickness Tolerance Classes—Copper-clad laminates

3. Classification

are available in two classes of thickness tolerance. Class I

represents those tolerances of standard manufacturing practice.

3.1 Base Laminate Grades—Where applicable, the dielec-

tric material forming the base of the copper-clad laminate of Class II represents a closer tolerance product than Class I. Any

the types listed in Table 1 and Table 2 shall conform to the specified class shall conform to the requirements shown in

property requirements of that specific grade shown in Specifi- Table 4.

cation D 709.

3.2 Copper Foil Surfaces—The surfaces shall be copper

TABLE 2 Grade Cross References

foil, either rolled or electrodeposited, having a minimum purity

ASTM Grade NEMA LI-1 Grade MIL-P-13949 Grade

XXXP XXXP PP

XXXPC XXXPC PP

This specification is under the jurisdiction of the ASTM Committee D-9 on

FR-2 FR-2 .

Electrical and Electronic Insulating Materials and is the direct responsibility of

FR-3 FR-3 PX

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

FR-4 FR-4 GF

Current edition approved March 10, 1996. Published May 1996. Originally

FR-5 FR-5 GH

published as D 1867 – 61 T. Last previous edition D 1867 – 94.

FR-6 FR-6 .

Annual Book of ASTM Standards, Vol 10.01.

G-10 G-10 GE

Annual Book of ASTM Standards, Vol 10.02.

G-11 G-11 GB

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

CEM-1 CEM-1 .

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

CEM-3 CEM-3 .

Available from National Electrical Manufacturers Association, 2101 L St.,

CFR-1 . CF

N.W., Washington, DC 20037.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1867

A

TABLE 3 Copper Foil Thickness

thickness; and the thickness tolerance class (see 3.3).

Nominal

Thickness Tolerance, in.

Nominal Weight,

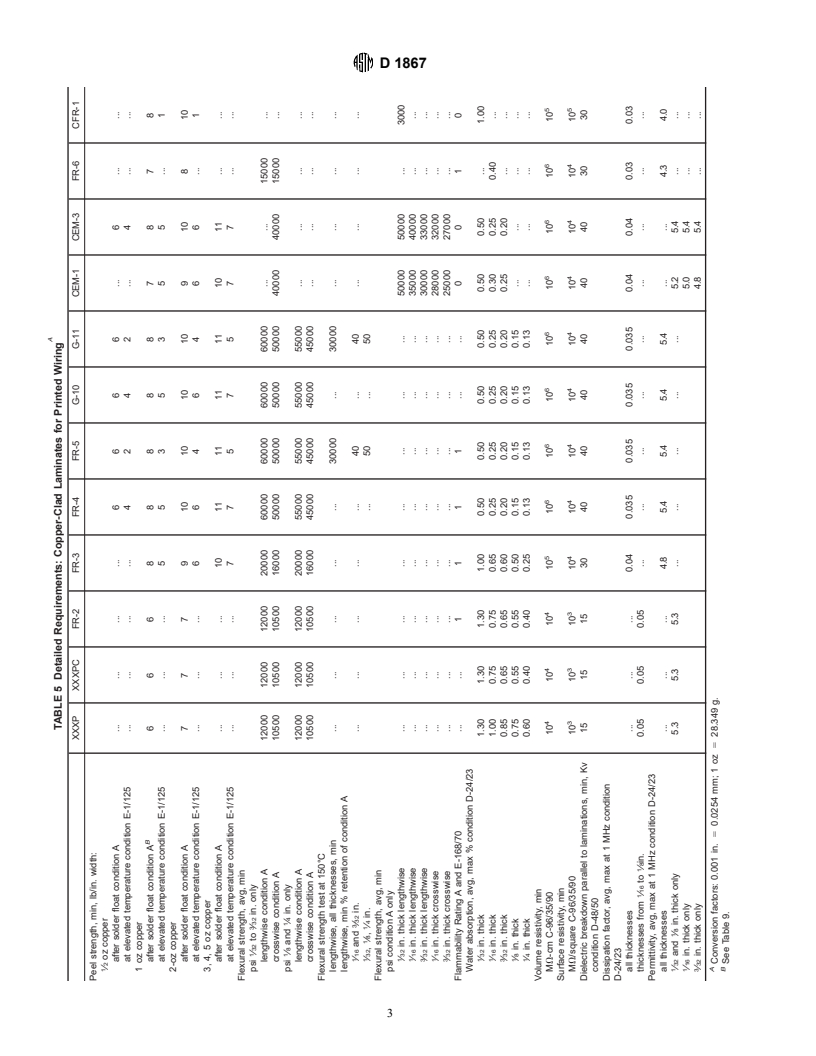

Thickness, 5. Detailed Requirements

oz/ft

Plus Minus

in.

5.1 The laminate shall meet the requirements shown in

⁄2 0.0007 0.00007 0.00007

Table 5.

1 0.0014 0.0004 0.0002

2 0.0028 0.0007 0.0003

6. Warp or Twist

3 0.0042 0.0004 0.0004

4 0.0056 0.0006 0.0006

6.1 The warp or twist of copper-clad laminate shall meet the

5 0.0070 0.0007 0.0007

requirements of Table 6. The maximum values shown in Table

A 2 2

Conversion factor: 0.001 in. 5 0.0254 mm; 1 oz/ft 5 0.305 kg/m .

6 are percentage values applicable only to sheet sizes as

manufactured and to sheets cut such that neither length nor

A

TABLE 4 Thickness Tolerance of Copper-Clad Sheet, 6 in.

width is less than 18 in. (457 mm). The values shown are

Class I Class II

percentages based upon 36-in. (914-mm) dimension sheets.

Grades Grades

7. Blistering

FR-4

Nominal

FR-4, FR-5 XXXP

FR-5

Overall

7.1 No blistering shall occur due to exposure of specimens

XXXP, XXXPC CEM-1, CEM-3 XXXPC

G-10

Laminate

FR-2, FR-3 FR-6, G-10, FR-2

of the material to air at the temperatures and times shown in

G-11

Thickness,

G-11 FR-3

B

CFR-1 Table 7. This requirement applies to copper-clad specimens

in.

and to laminate from which all of the copper has been etched.

1 oz, 2 Sides 2, All Weights All All

1 oz,

3, 4,5oz1or2 1or2 Weights 1 Weights 1

1 Side

Sides Sides or 2 Sides or 2 Sides

8. Workmanship and Surface Requirements

⁄32 0.004 0.0045 0.0065 0.003 0.004

8.1 Grades XXXP, XXXPC, FR-2 and FR-6 Only:

⁄64 0.005 0.0055 0.0075 0.0035 0.005

8.1.1 Copper surfaces shall be free from defects which may

⁄16 0.0055 0.006 0.0075 0.004 0.005

⁄32 0.007 0.0075 0.009 0.005 0.007

affect serviceability of the laminate. Such defects in copper

⁄8 0.0085 0.009 0.012 0.006 0.009

surfaces include blisters, wrinkles, cracks, dents, and scratches.

⁄32 0.0095 0.010 0.015 0.007 0.010

3 8.1.2 The copper shall not contain any pin holes having

⁄16 0.010 0.011 0.019 0.008 0.012

⁄32 0.011 0.012 0.021 0.009 0.012 average diameter greater than 0.015 in. (0.381 mm).

⁄4 0.012 0.012 0.022 0.009 0.012

8.1.3 Pin holes in the copper exceeding average diameter

CFR-1

0.005 in. (0.127 mm) shall not be present in concentration

C

0.0085 NA NA NA NA 0.0015 2

exceeding one per ft .

0.015 NA NA NA NA 0.002

8.1.4 The number of inclusions in copper which are larger

0.020 NA NA NA NA 0.002

0.030 NA NA NA NA 0.003

than 0.020 in. (0.508 mm) in length shall be limited in a single

2 2

A

Conversion factor: 0.001 in. 5 0.0254 mm; 1 oz 5 28.349 g.

ft of laminate and in any single sheet of approximately 0.5 m

B

CFR-1 laminate thickness as listed is without copper foil in accordance with

size. The limits are:

MIL-P-13949. Tolerance values for CFR-1 apply to the dielectric layer only.

C

8.1.4.1 5 in any one ft , and

Not applicable.

8.1.4.2 10 in any one 0.5 m size sheet.

8.1.5 The unclad laminate surface shall have a semi-gloss or

3.3.1 For sheets of laminate equal to or greater than 18 by

dull finish.

18 in. (approximately 2.3 ft ) at least 90 % of all thickness test

8.2 Grades FR-3, FR-4, FR-5, CEM-1, CEM-3, G-10, G-11,

measurements made upon any sheet of laminate shall be within

and CFR-1:

the limits specified in Table 4. For metric size sheets this 90 %

8.2.1 Copper surfaces shall be free from defects which may

requirement shall apply to sheet sizes of 0.5 by 0.5 m or 0.25

affect serviceability. Such defects include blisters, wrinkles,

m area.

and cracks. The copper surfaces shall be free from other defects

3.3.2 The deviation of any single thickness test measure-

as required in 8.2.2.

ment value (see Practice D 3636) from the nominal overall

8.2.2 Pits are small holes occurring as imperfections that do

thickness listed in Table 4 shall not exceed 125 % of the

not penetrate entirely through the copper foil. Dents are

tolerance listed in Table 4.

depressions in the copper foil that do not significantly decrease

3.3.3 Any overall laminate thickness not listed in Table 4

the thickness of the copper foil. Pits and dents are limited by a

shall meet the tolerance requirements of the next highest

point count system in which the maximum total allowable

nominal thickness listed in Table 4.

2 2

point count for pits and dents is 35 per ft (377/m ). Pits and

3.3.4 For cut panels (for example, laminate sheets cut to

2 2

dents carry various point counts depending upon the longest

area less than 2.3 ft or less than 0.25 m ) at least 98 % of all

dimension of the pit or dent.Table 8 and Table 9 provides point

thickness test measurements shall be within the specified

count values for various dimensions.

overall laminate thickness tolerance values of Table 4.

8.2.3 Pinholes are small holes occurring as imperfections

4. Ordering Information

that penetrate entirely through the copper foil. A pinhole

4.1 Orders for copper-clad laminates shall specify the grade having an area equivalent to a 0.005-in. (0.127-mm) diameter

of laminate base (see 3.1); the type of copper foil (either rolled circle is a defect. A maximum of one such pinhole is allowable

2 2

or electrodeposited); the nominal weight of the copper foil (see in a 5-ft (0.46-m ) area of laminate. Pinholes of smaller area

3.2); one- or two-side cladding; nominal overall laminate are also defects and the aggregate sum of the areas of all

D 1867

A

TABLE 5 Detailed Requirements: Copper-Clad Laminates for Printed Wiring

XXXP XXXPC FR-2 FR-3 FR-4 FR

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.