ASTM D1867-01

(Specification)Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

Standard Specification for Copper-Clad Thermosetting Laminates for Printed Wiring

SCOPE

1.1 This specification covers twelve grades of thermosetting laminate with copper foil bonded to one or both surfaces. These combination forms are intended primarily for use in fabrication of printed (etched) wiring or circuit boards.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 1867 – 01

Standard Specification for

1

Copper-Clad Thermosetting Laminates for Printed Wiring

This standard is issued under the fixed designation D 1867; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers twelve grades of thermosetting 3.1 For definitions of terms used in this standard, refer to

laminatewithcopperfoilbondedtooneorbothsurfaces.These Terminology D 1711.

combination forms are intended primarily for use in fabrication

4. Classification

of printed (etched) wiring or circuit boards.

1.2 The values stated in inch-pound units are to be regarded 4.1 Base Laminate Grades—Where applicable, the dielec-

tric material forming the base of the copper-clad laminate of

as the standard. The values given in parentheses are for

information only. the types listed in Table 1 and Table 2 shall conform to the

property requirements of that specific grade shown in Specifi-

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the cation D 709.

4.2 Copper Foil Surfaces—The surfaces shall be copper

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- foil, either rolled or electrodeposited, having a minimum purity

of 99.50 % (silver considered as equal to copper). The thick-

bility of regulatory limitations prior to use.

ness tolerances of the copper foil shall conform to the

2. Referenced Documents

requirements of Table 3.

2.1 ASTM Standards: 4.3 Thickness Tolerance Classes—Copper-clad laminates

D 709 Specification for Laminated Thermosetting Materi- are available in two classes of thickness tolerance. Class I

2

als represents those tolerances of standard manufacturing practice.

2

D 1711 Terminology Relating to Electrical Insulation Class II represents a closer tolerance product than Class I.Any

D 3636 Practice for Sampling and Judging Quality of Solid specified class shall conform to the requirements shown in

3

Electrical Insulating Materials Table 4.

D 5109 Test Methods for Copper-Clad Thermosetting 4.3.1 For sheets of laminate equal to or greater than 18 by

3 2

Laminates for Printed Wiring Boards 18 in. (approximately 2.3 ft ) at least 90 % of all thickness test

2.2 Other Standards: measurements made upon any sheet of laminate shall be within

MIL-P-13949 Plastic Sheet, Laminated, Metal Clad (for the limits specified in Table 4. For metric size sheets this 90 %

4

Printed Wiring Boards) requirement shall apply to sheet sizes of 0.5 by 0.5 m or 0.25

5 2

NEMA Publication Number LI-1 m area.

4.3.2 The deviation of any single thickness test measure-

ment value (see Practice D 3636) from the nominal overall

1

thickness listed in Table 4 shall not exceed 125 % of the

This specification is under the jurisdiction of the ASTM Committee D09 on

Electrical and Electronic Insulating Materials and is the direct responsibility of

tolerance listed in Table 4.

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

4.3.3 Any overall laminate thickness not listed in Table 4

Current edition approved Sept. 10, 2001. Published November 2001. Originally

shall meet the tolerance requirements of the next highest

published as D 1867 – 61 T. Last previous edition D 1867 – 96.

2

nominal thickness listed in Table 4.

Annual Book of ASTM Standards, Vol 10.01.

3

Annual Book of ASTM Standards, Vol 10.02.

4.3.4 For cut panels (for example, laminate sheets cut to

4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700 2 2

area less than 2.3 ft or less than 0.25 m ) at least 98 % of all

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

5

thickness test measurements shall be within the specified

Available from National Electrical Manufacturers Association, 2101 L St.,

N.W., Washington, DC 20037. overall laminate thickness tolerance values of Table 4.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 1867

A

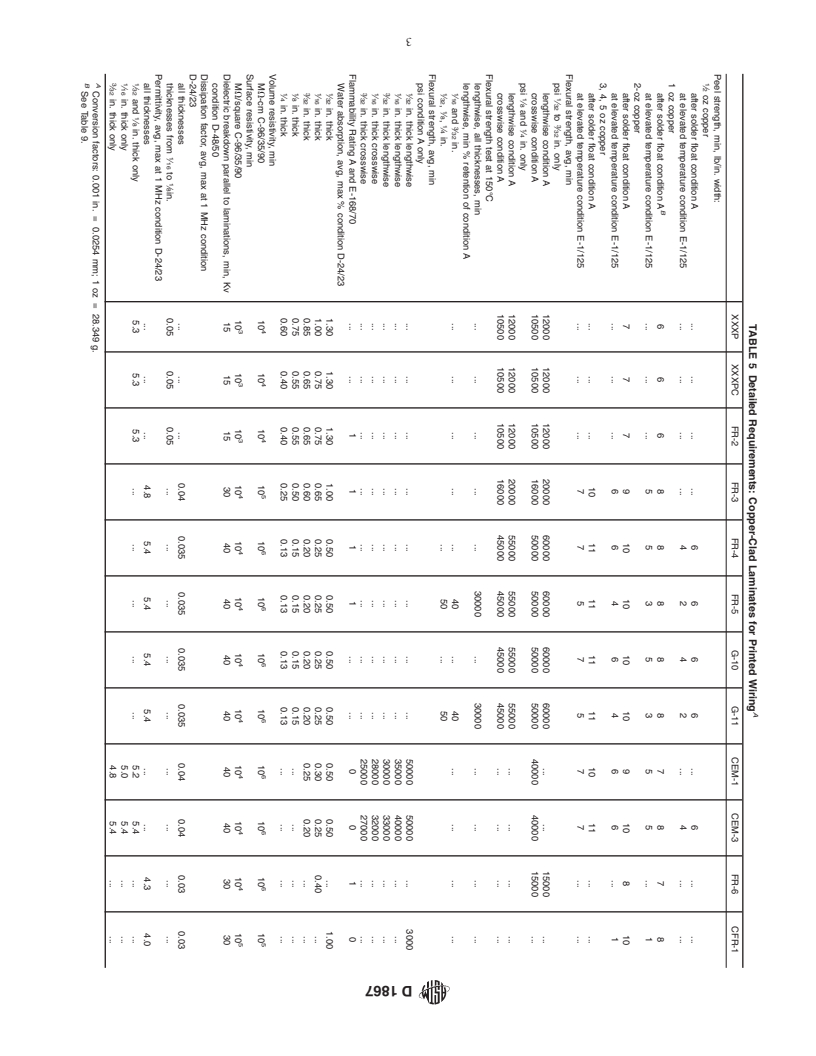

TABLE 1 Base Laminate Grades TABLE 4 Thickness Tolerance of Copper-Clad Sheet, 6 in.

Class I Class II

NOTE 1— A cross reference table of grade designations (see Table 2)

appears here for reference purposes only. The ASTM grades shown are Grades Grades

most closely associated with the NEMA and the military grades listed in

FR-4

Nominal

FR-4, FR-5 XXXP

this table. There is no requirement, stated or implied, in this ASTM

FR-5

Overall

XXXP, XXXPC CEM-1, CEM-3 XXXPC

specification th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.