ASTM E828-81(2004)

(Test Method)Standard Test Method for Designating the Size of RDF-3 From its Sieve Analysis

Standard Test Method for Designating the Size of RDF-3 From its Sieve Analysis

SCOPE

1.1 This test method of designating the size of refuse-derived fuel from its sieve analysis is applicable to the classified light fraction (RDF-3) of shredded municipal or industrial waste materials less than 0.15 m (6 in.) in size.

1.2 The values stated in acceptable metric units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific precautionary information see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E828–81 (Reapproved 2004)

Standard Test Method for

Designating the Size of RDF-3 From its Sieve Analysis

This standard is issued under the fixed designation E 828; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 lot—a large designated quantity of RDF-3.

3.1.5 representative sample—a sample collected in such a

1.1 This test method of designating the size of refuse-

manner that it has characteristics equivalent to the material

derived fuel from its sieve analysis is applicable to the

being sampled.

classified light fraction (RDF-3) of shredded municipal or

3.1.6 sample division—the process of extracting a smaller

industrial waste materials less than 0.15 m (6 in.) in size.

sample from a gross sample wherein the representative prop-

1.2 The values stated in acceptable metric units are to be

erties of the large sample are retained.

regarded as standard. The values given in parentheses are for

3.2 Definitions of Terms Specific to This Standard:

information only.

3.2.1 refuse-derived fuel (RDF-3)—a shredded fuel derived

1.3 This standard does not purport to address all of the

from municipal solid waste (MSW) that has been processed to

safety concerns, if any, associated with its use. It is the

remove metal, glass, and other inorganics. This material has a

responsibility of the user of this standard to establish appro-

particle size such that 95 weight % passes through a 2-in.

priate safety and health practices and determine the applica-

square-mesh screen.

bility of regulatory limitations prior to use. For more specific

precautionary information see Section 7.

NOTE 1—Other refuse-derived fuel may be classified as follows:

RDF-1—Wastes used as a fuel in as-discarded form.

2. Referenced Documents

RDF-2—Wastes processed to coarse particle size with or without ferrous

metal separation.

2.1 ASTM Standards:

RDF-4—Combustible waste processed into powder form, 95 weight % passing

D 2234 Test Method for Collection of a Gross Sample of

10-mesh screening.

Coal RDF-5—Combustible waste densified (compressed) into the form of pellets,

slugs, cubettes, or briquettes.

E11 Specification for Wire-Cloth Sieves for Testing Pur-

RDF-6—Combustible waste processed into liquid fuel.

poses

RDF-7—Combustible waste processed into gaseous fuel.

E 177 Practice for Use of the Terms Precision and Bias in

4. Summary of Test Method

ASTM Test Methods

4.1 This test method covers the separation of an RDF

3. Terminology

sample into defined size fractions and expressing those frac-

3.1 Definitions:

tions as a weight percent of an air-dried sample.

3.1.1 air drying—a process of partial drying of RDF-3 to

5. Significance and Use

bring its moisture content near to equilibrium with the atmo-

sphere in the room in which the sieving is to take place. 5.1 The purpose of this test method is to provide a means of

3.1.2 gross sample—asamplerepresentingalotofRDFand designating the size classification of RDF-3 for use by con-

composed of a number of increments on which neither reduc- sumers and producers of RDF-3.

tion nor division has been performed.

6. Apparatus

3.1.3 laboratory sample—a representative portion of the

6.1 Sieves:

gross sample delivered to the laboratory for further analysis.

6.1.1 Use sieves conforming to Specification E11. For

recommended sizes see Table 1.

This test method is under the jurisdiction of ASTM Committee D34 on Waste

6.1.1.1 For RDF-3 and larger than 50 mm (2 in.) screens

Management and is the direct responsibility of Subcommittee D34.03.02 on

2 2

having rectangular frames 0.6 to 0.7 m (6 to 8 ft ) sieve area

Municipal Recovery and Reuse.

Current edition approved July 31, 1981. Published February 1982.

are satisfactory.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1.2 For RDF-3 50 mm (2 in.) or smaller, rectangular

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2 2

frames having 2 to 4 ft (0.2 to 0.4 m ) sieve area are

Standards volume information, refer to the standard’s Document Summary page on

satisfactory.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E828–81 (2004)

TABLE 1 Recommended Sieve Sizes (ASTM E11–70)

8.3 Division of the gross sample into the laboratory sample

For screening RDF-3 the following screen may be done by coning and quartering, riffling, or by other

series is recommended:

appropriate method.

Standard (mm) Alternative (in. or mesh)

8.4 The sample shall be approximately 2 kg (4.4 lb) in

100 mm 4 in.

weight.

50 mm 2 in.

8.5 Air-dry the sample in a ventilated drying oven to

25 mm 1 in.

12.5 mm ⁄2 in.

constant weight at 10 to 15°C above the ambient temperature.

6.3 mm ⁄4 in.

(Calculate the loss in weight to percentage of moisture that

3.35 mm No. 6

shall constitute the air-dry loss in the sieve analysis sample.)

1.70 mm No. 12

850 µm No. 20

425 µm No. 40 9. Procedure

The following intermediate screen sizes

9.1 Weigh the air-dried sample.

may be used as needed:

9.2 Hand Sieving:

Standard (mm) Alternative (in. or mesh)

9.2.1 Starting with the sieve having the largest opening,

75 mm 3 in.

sieveaportionoftheRDF-3insuchanincrementaswillallow

37.5 mm 1.5 in.

the individual pieces to be in direct contact with the meshes of

19.0 mm ⁄4 in.

9.5 mm ⁄8 in.

the screen after the completion of shaking of each increment.

4.75 mm No. 4

In shaking, apply a vertical as well as horizontal motion in

2.36 mm No. 8

1.18 mm No. 16 order to allow all small particles to pass through the openings,

600µ m No. 30

until no more material will pass. Hand fitting is not permitted.

9.2.2 Pass the material through successively smaller sieves

in increments small enough to avoid matting of the material to

the extent that the undersized material cannot reach and pass

6.1.1.3 For RDF-3 smaller than 0.01 m (0.5 in.), circular

the screen.

sieves 0.3 m (12 in.) or 0.2 m (8 in.) in diameter are

9.2.3 Continue to shake the sieve after each increment is

satisfactory.

added until no significant amount of material passes through

6.2 Sieving Devices:

the screen.

6.2.1 Hand sieving is permissible.

9.3 Machine Sieving:

6.2.2 Sieving machines that provide the necessary agitation

9.3.1 When sieving machines are used, test their thorough-

and tumbling action may be used. See Annex A1 for recom-

ness of sieving by comparison with hand methods as described

mended screen sizes and machines.

in 9.2.

6.3 Balance (laboratory sample), having sufficient capacity

9.3.2 Stack the sieves progressively starting with the small-

to weigh the sample and container with a sensitivity of 0.5 g in

est aperture size, above the pan, to the largest aperture size at

1000 g.

the top.

9.3.3 Introducetheair-driedsampleabovethelargestscreen

7. Precautions

in small enough increments such that matting of the material

7.1 Due to the origins of RDF-3 in municipal waste,

does not occur to an extent that prevents the undersize material

common sense dictates that some precautions be observed

from reaching and passing the screen. The amount of RDF-3

when conducting tests on the samples. Recommended hygienic

added to the top screen in any increment must not exceed one

practices include use of gloves when handling RDF-3; wearing

thirdofthevolumeofthescreen,inordertopreventmattingor

masks (NIOSH-approved type), especially while shredding

blinding.

RDF-3 samples; conducting tests under a negative pressure

9.3.4 After adding each increment, assemble the pans or

hood when possible; and washing hands before eating or

trays in the machine and turn on agitation for 10 min, or up to

smoking.

15 min if necessary, to complete screening.

9.3.5 Inspect each screen for evidence of matting. If a

8. Sampling

screen is mostly or entirely covered with a mat, decrease the

8.1 Collect increments regularly and systematically so that

size of the initial increments such that no mat forms on any

the entire quantity of RDF sampled will be representative

sieve, and repeat the tests.

proportionately in the gross sample, and with such frequency

9.3.6 Whensievingofeachincrementiscomplete,promptly

that a gross sample of the required amount shall be collected.

determine the weight of material remaining on each screen to

Nosamplingprocedureshallbeusedthatalterstheparticlesize

the nearest 0.5 g. If more than one increment is sieved to pass

distribution.

the entire sample, add the incremental weights remaining on

8.2 Establish the sampling procedures to be used, the

each sieve. If the sum of the weights show a loss of 2 % or

number and size of samples required to obtain a representative

more, reject the analysis and make another test using a second

sample, and the method of division of the gross sample into the

sample.

laboratory sample in accordance with an agreement between

NOTE 3—In order to obtain a complete characterization of the size

purchaser and supplier.

range of an RDF-3 sample, it is necessary that the number of sieves be

NOTE 2—The stati

...

Questions, Comments and Discussion

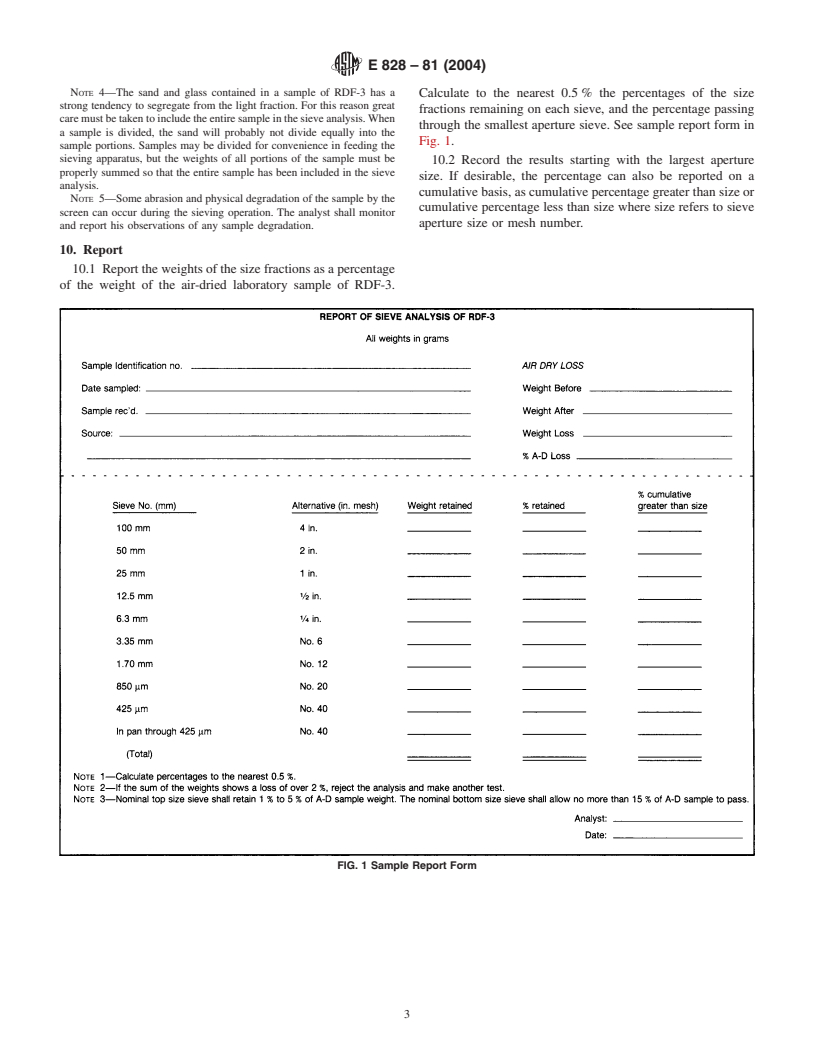

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.