ASTM D7078/D7078M-19

(Test Method)Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method

SIGNIFICANCE AND USE

5.1 This shear test is designed to produce shear property data for material specifications, research and development, quality assurance, and structural design and analysis. Either in-plane or interlaminar shear properties may be evaluated, depending upon the orientation of the material coordinate system relative to the loading axis. Factors that influence the shear response and should therefore be reported include: material, methods of material preparation and lay-up, specimen stacking sequence, specimen preparation, specimen conditioning, environment of testing, specimen alignment and gripping, speed of testing, time at temperature, void content, and volume percent reinforcement.

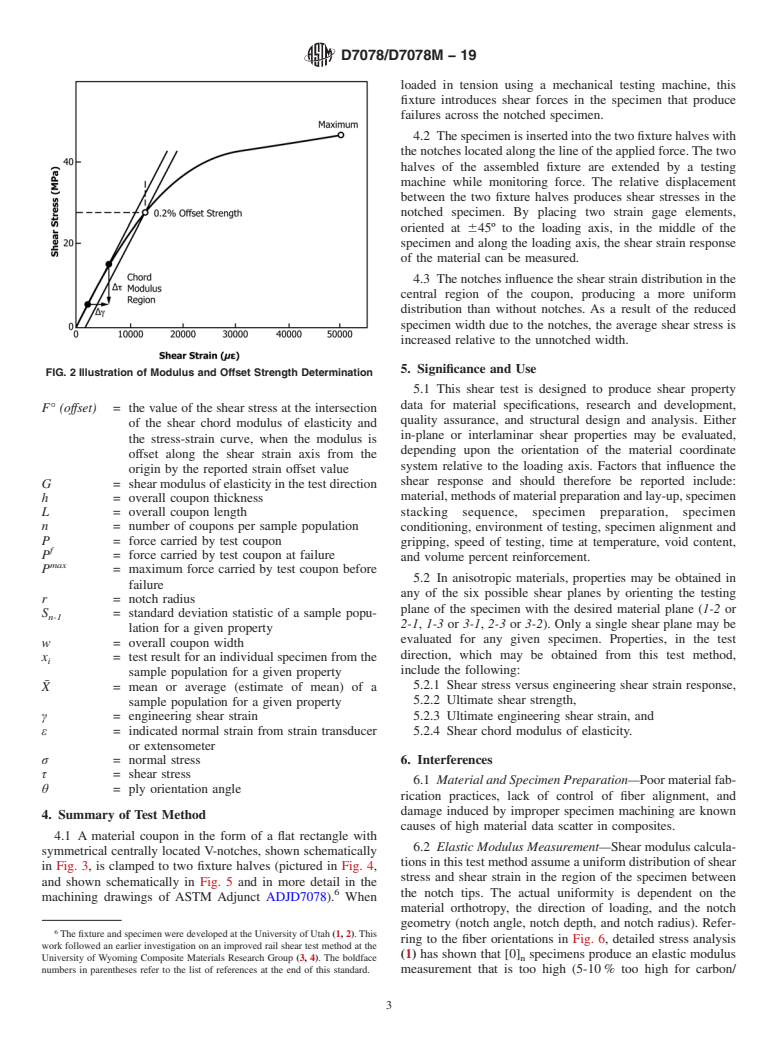

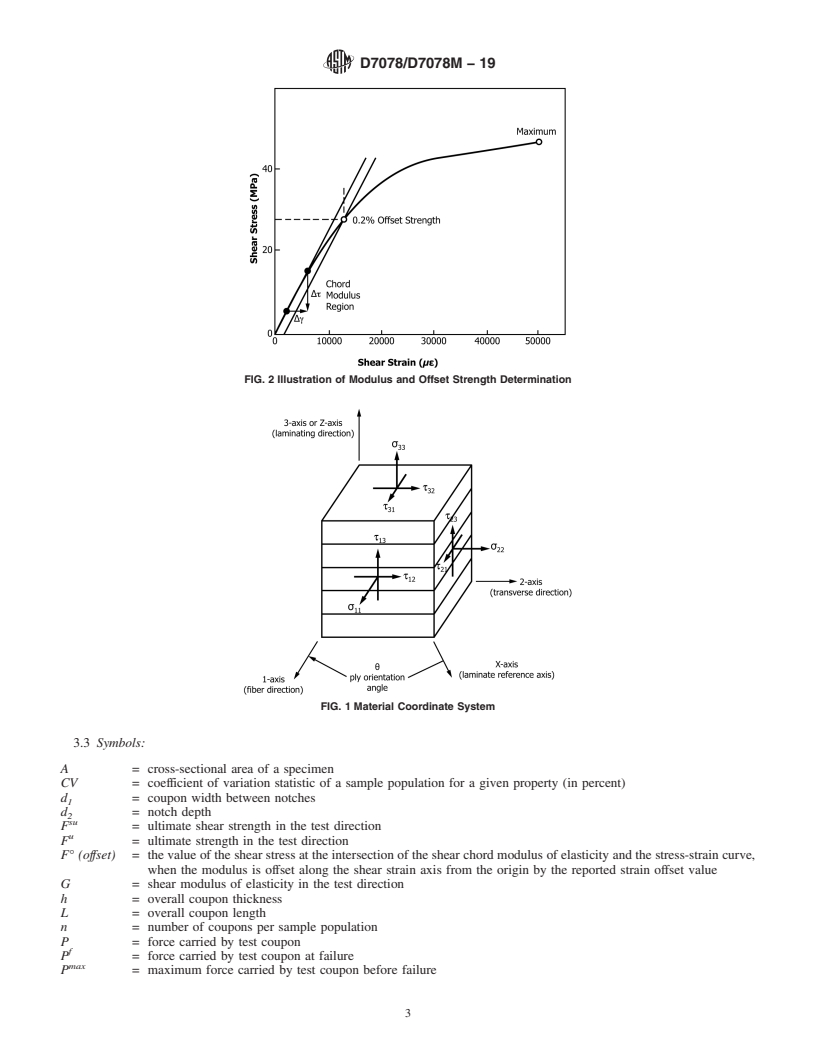

5.2 In anisotropic materials, properties may be obtained in any of the six possible shear planes by orienting the testing plane of the specimen with the desired material plane (1-2 or 2-1, 1-3 or 3-1, 2-3 or 3-2). Only a single shear plane may be evaluated for any given specimen. Properties, in the test direction, which may be obtained from this test method, include the following:

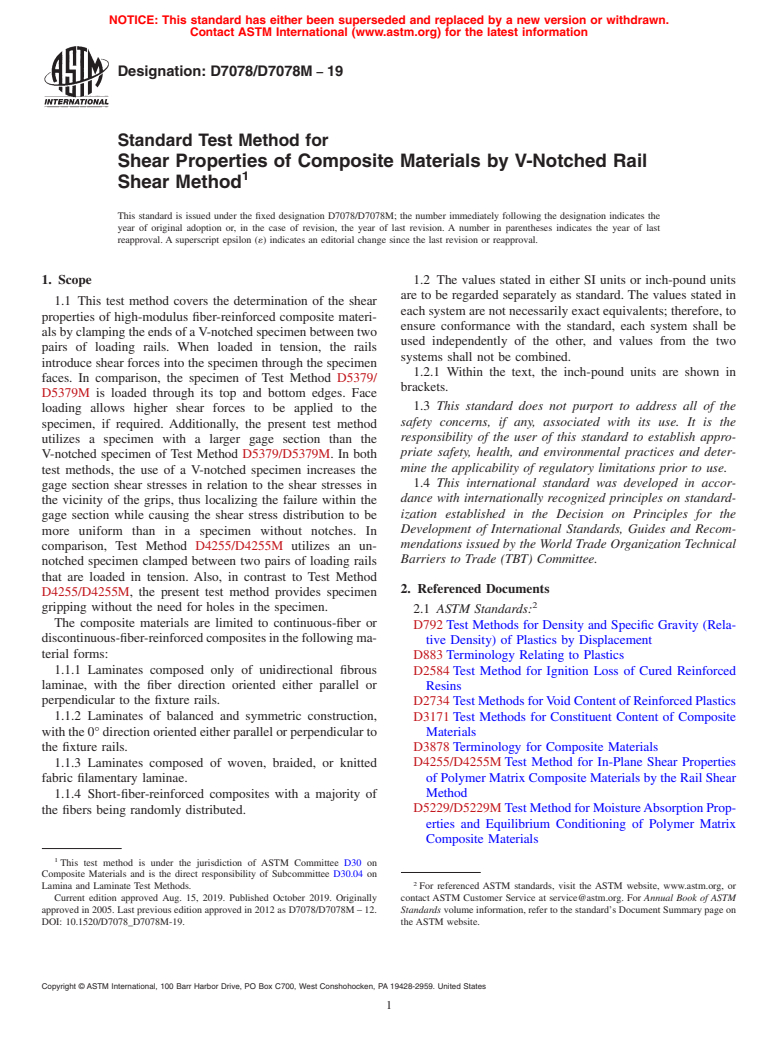

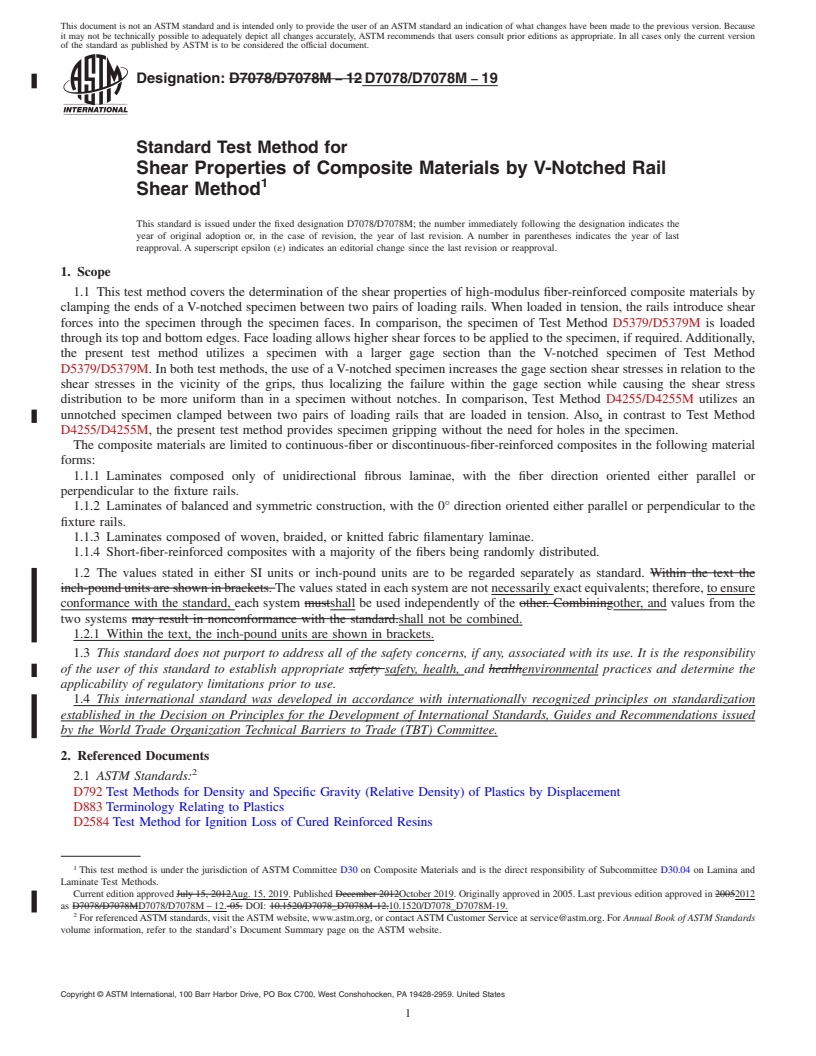

5.2.1 Shear stress versus engineering shear strain response,

5.2.2 Ultimate shear strength,

5.2.3 Ultimate engineering shear strain, and

5.2.4 Shear chord modulus of elasticity.

SCOPE

1.1 This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by clamping the ends of a V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear forces into the specimen through the specimen faces. In comparison, the specimen of Test Method D5379/D5379M is loaded through its top and bottom edges. Face loading allows higher shear forces to be applied to the specimen, if required. Additionally, the present test method utilizes a specimen with a larger gage section than the V-notched specimen of Test Method D5379/D5379M. In both test methods, the use of a V-notched specimen increases the gage section shear stresses in relation to the shear stresses in the vicinity of the grips, thus localizing the failure within the gage section while causing the shear stress distribution to be more uniform than in a specimen without notches. In comparison, Test Method D4255/D4255M utilizes an unnotched specimen clamped between two pairs of loading rails that are loaded in tension. Also, in contrast to Test Method D4255/D4255M, the present test method provides specimen gripping without the need for holes in the specimen.

The composite materials are limited to continuous-fiber or discontinuous-fiber-reinforced composites in the following material forms:

1.1.1 Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or perpendicular to the fixture rails.

1.1.2 Laminates of balanced and symmetric construction, with the 0° direction oriented either parallel or perpendicular to the fixture rails.

1.1.3 Laminates composed of woven, braided, or knitted fabric filamentary laminae.

1.1.4 Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardiza...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7078/D7078M − 19

Standard Test Method for

Shear Properties of Composite Materials by V-Notched Rail

1

Shear Method

This standard is issued under the fixed designation D7078/D7078M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

1.1 This test method covers the determination of the shear

each system are not necessarily exact equivalents; therefore, to

properties of high-modulus fiber-reinforced composite materi-

ensure conformance with the standard, each system shall be

alsbyclampingtheendsofaV-notchedspecimenbetweentwo

used independently of the other, and values from the two

pairs of loading rails. When loaded in tension, the rails

systems shall not be combined.

introduce shear forces into the specimen through the specimen

1.2.1 Within the text, the inch-pound units are shown in

faces. In comparison, the specimen of Test Method D5379/

brackets.

D5379M is loaded through its top and bottom edges. Face

1.3 This standard does not purport to address all of the

loading allows higher shear forces to be applied to the

safety concerns, if any, associated with its use. It is the

specimen, if required. Additionally, the present test method

responsibility of the user of this standard to establish appro-

utilizes a specimen with a larger gage section than the

priate safety, health, and environmental practices and deter-

V-notched specimen of Test Method D5379/D5379M. In both

mine the applicability of regulatory limitations prior to use.

test methods, the use of a V-notched specimen increases the

1.4 This international standard was developed in accor-

gage section shear stresses in relation to the shear stresses in

dance with internationally recognized principles on standard-

the vicinity of the grips, thus localizing the failure within the

ization established in the Decision on Principles for the

gage section while causing the shear stress distribution to be

Development of International Standards, Guides and Recom-

more uniform than in a specimen without notches. In

mendations issued by the World Trade Organization Technical

comparison, Test Method D4255/D4255M utilizes an un-

Barriers to Trade (TBT) Committee.

notched specimen clamped between two pairs of loading rails

that are loaded in tension. Also, in contrast to Test Method

2. Referenced Documents

D4255/D4255M, the present test method provides specimen

2

gripping without the need for holes in the specimen.

2.1 ASTM Standards:

The composite materials are limited to continuous-fiber or

D792Test Methods for Density and Specific Gravity (Rela-

discontinuous-fiber-reinforcedcompositesinthefollowingma-

tive Density) of Plastics by Displacement

terial forms:

D883Terminology Relating to Plastics

1.1.1 Laminates composed only of unidirectional fibrous

D2584Test Method for Ignition Loss of Cured Reinforced

laminae, with the fiber direction oriented either parallel or

Resins

perpendicular to the fixture rails.

D2734TestMethodsforVoidContentofReinforcedPlastics

1.1.2 Laminates of balanced and symmetric construction, D3171Test Methods for Constituent Content of Composite

withthe0°directionorientedeitherparallelorperpendicularto Materials

the fixture rails. D3878Terminology for Composite Materials

1.1.3 Laminates composed of woven, braided, or knitted D4255/D4255MTest Method for In-Plane Shear Properties

of Polymer Matrix Composite Materials by the Rail Shear

fabric filamentary laminae.

Method

1.1.4 Short-fiber-reinforced composites with a majority of

D5229/D5229MTestMethodforMoistureAbsorptionProp-

the fibers being randomly distributed.

erties and Equilibrium Conditioning of Polymer Matrix

Composite Materials

1

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.04 on

2

Lamina and Laminate Test Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 15, 2019. Published October 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2012 as D7078/D7078M–12. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7078_D7078M-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7078/D7078M − 19

D5379/D5379MTest Method for Shear P

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7078/D7078M − 12 D7078/D7078M − 19

Standard Test Method for

Shear Properties of Composite Materials by V-Notched Rail

1

Shear Method

This standard is issued under the fixed designation D7078/D7078M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the shear properties of high-modulus fiber-reinforced composite materials by

clamping the ends of a V-notched specimen between two pairs of loading rails. When loaded in tension, the rails introduce shear

forces into the specimen through the specimen faces. In comparison, the specimen of Test Method D5379/D5379M is loaded

through its top and bottom edges. Face loading allows higher shear forces to be applied to the specimen, if required. Additionally,

the present test method utilizes a specimen with a larger gage section than the V-notched specimen of Test Method

D5379/D5379M. In both test methods, the use of a V-notched specimen increases the gage section shear stresses in relation to the

shear stresses in the vicinity of the grips, thus localizing the failure within the gage section while causing the shear stress

distribution to be more uniform than in a specimen without notches. In comparison, Test Method D4255/D4255M utilizes an

unnotched specimen clamped between two pairs of loading rails that are loaded in tension. Also, in contrast to Test Method

D4255/D4255M, the present test method provides specimen gripping without the need for holes in the specimen.

The composite materials are limited to continuous-fiber or discontinuous-fiber-reinforced composites in the following material

forms:

1.1.1 Laminates composed only of unidirectional fibrous laminae, with the fiber direction oriented either parallel or

perpendicular to the fixture rails.

1.1.2 Laminates of balanced and symmetric construction, with the 0° direction oriented either parallel or perpendicular to the

fixture rails.

1.1.3 Laminates composed of woven, braided, or knitted fabric filamentary laminae.

1.1.4 Short-fiber-reinforced composites with a majority of the fibers being randomly distributed.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text the

inch-pound units are shown in brackets. The values stated in each system are not necessarily exact equivalents; therefore, to ensure

conformance with the standard, each system mustshall be used independently of the other. Combiningother, and values from the

two systems may result in nonconformance with the standard.shall not be combined.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D883 Terminology Relating to Plastics

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.04 on Lamina and

Laminate Test Methods.

Current edition approved July 15, 2012Aug. 15, 2019. Published December 2012October 2019. Originally approved in 2005. Last previous edition approved in 20052012

as D7078/D7078MD7078/D7078M – 12.-05. DOI: 10.1520/D7078_D7078M-12.10.1520/D7078_D7078M-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.