ASTM F681-82(2018)

(Practice)Standard Practice for Use of Branch Connections

Standard Practice for Use of Branch Connections

ABSTRACT

This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. The branch to run size applications are presented in details. The weld joint designs, fabricated branch connections and threaded fittings shall meet the requirements prescribed.

SCOPE

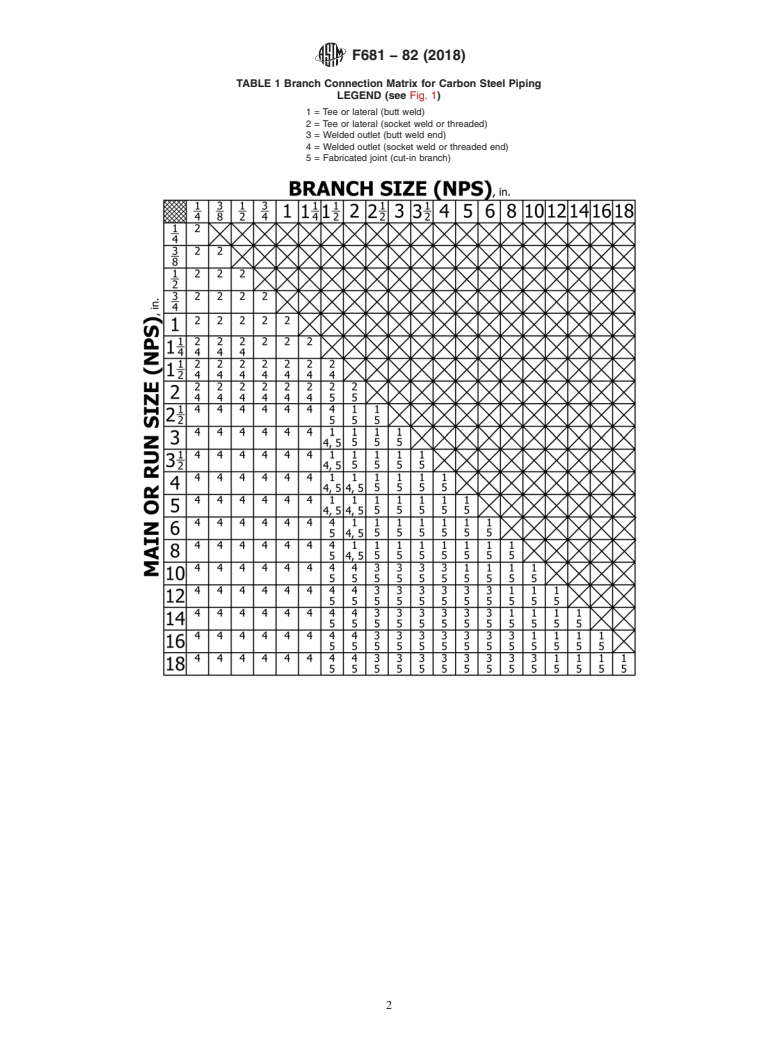

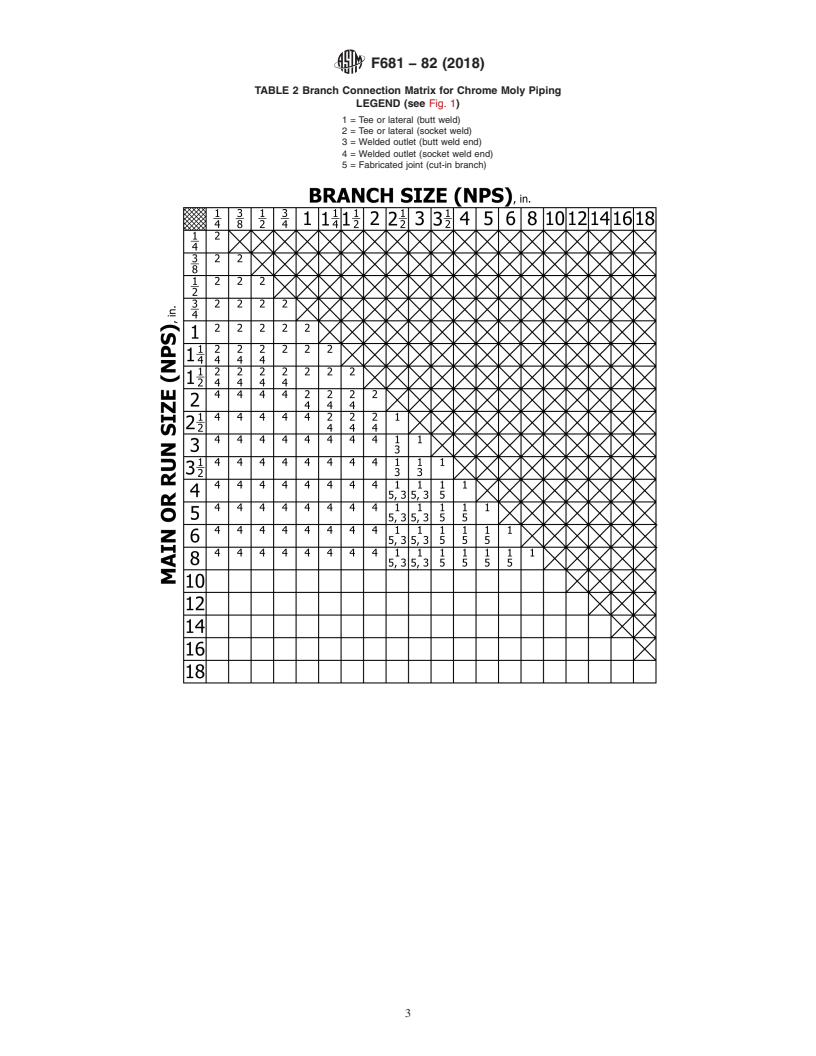

1.1 This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and copper-nickel alloy tubing. Branch to run size applications are given in Table 1, Table 2, and Table 3. Other types of branch connections (Fig. 1) may be used provided they comply with the requirements of Title 46 CFR Subparts 56.07-10(f) and 56.70-15(g) of the USCG Regulations.

FIG. 1 Illustrative Legend for Branch Connections

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F681 − 82 (Reapproved 2018) An American National Standard

Standard Practice for

1

Use of Branch Connections

ThisstandardisissuedunderthefixeddesignationF681;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 This practice lists commonly used types of branch 2.1 ASTM Standards:

connections for carbon steel, chromium-molybdenum steel F722 Specification for Welded Joints for Shipboard Piping

pipe and copper-nickel alloy tubing. Branch to run size Systems

3

applications are given in Table 1, Table 2, and Table 3. Other 2.2 ASME Standard:

typesofbranchconnections(Fig.1)maybeusedprovidedthey B31.1 Power Piping

4

comply with the requirements of Title 46 CFR Subparts 2.3 Other Document:

56.07-10(f) and 56.70-15(g) of the USCG Regulations. Title 46 Code of Federal Regulations (CFR) Shipping, Parts

41 to 69

1.2 The values stated in inch-pound units are to be regarded

as standard. No other units of measurement are included in this

3. General Requirements

standard.

3.1 Weld joint designs shall be in accordance with Specifi-

1.3 This international standard was developed in accor-

cation F722 and the limitations therein.

dance with internationally recognized principles on standard-

3.2 Fabricated branch connections shall meet the reinforce-

ization established in the Decision on Principles for the

ment requirements of Section 104.3 of ASME B31.1 as

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

2

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and the ASTM website.

3

Marine Technology and is the direct responsibility of Subcommittee F25.11 on Available from American Society of Mechanical Engineers (ASME), ASME

Machinery and Piping Systems. International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

Current edition approved Sept. 1, 2018. Published September 2018. Originally www.asme.org.

4

approved in 1980. Last previous edition approved in 2014 as F681 – 82 (2014). Available from DLA Document Services, Building 4/D, 700 Robbins Ave.,

DOI: 10.1520/F0681-82R18. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F681 − 82 (Reapproved 2014) F681 − 82 (Reapproved 2018)An American National Standard

Standard Practice for

1

Use of Branch Connections

This standard is issued under the fixed designation F681; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice lists commonly used types of branch connections for carbon steel, chromium-molybdenum steel pipe and

copper-nickel alloy tubing. Branch to run size applications are given in Table 1, Table 2, and Table 3. Other types of branch

connections (Fig. 1) may be used provided they comply with the requirements of Title 46 CFR Subparts 56.07-10(f) and

56.70-15(g) of the USCG Regulations.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

F722 Specification for Welded Joints for Shipboard Piping Systems

3

2.2 ANSI Standard:

B31.1 Power Piping

4

2.3 Other Document:

Title 46 Code of Federal Regulations (CFR) Shipping, Parts 41 to 69

3. General Requirements

3.1 Weld joint designs shall be in accordance with Specification F722 and the limitations therein.

3.2 Fabricated branch connections shall meet the reinforcement requirements of Section 104.3 of ANSI B31.1 as modified by

Title 46, CFR Subparts 56.07-10(f) and 56.70-15(g) of the USCG regulations.

3.3 Threaded fittings shall be subject to the limitations of Title 46 CFR, Subpart 56.30-20 of the USCG Regulations.

4. Keywords

4.1 branch connnections; carbon steel connections; chromium-molybdenum steel pipe; copper-nickel alloy tubing

1

This practice is under the jurisdiction of ASTM Committee F25 on Ships and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Machinery

and Piping Systems.

Current edition approved Aug. 1, 2014Sept. 1, 2018. Published September 2014September 2018. Originally approved in 1980. Last previous edition approved in 20082014

as F681 – 82 (2008).(2014). DOI: 10.1520/F0681-82R14.10.1520/F0681-82R18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.