ASTM D2265-19

(Test Method)Standard Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range

Standard Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range

SIGNIFICANCE AND USE

5.1 The dropping point is useful to assist in identifying the grease as to type and for establishing and maintaining bench marks for quality control. The results are to be considered to have only limited significance with respect to service performance because dropping point is a static test.

5.2 Historical cooperative testing3 on conventional soap-thickened greases indicated ( RR:D02-1164) that, in general, dropping points by Test Method D2265 and Test Method D566 were in agreement up to 200 °C. In cases where results differ, there is no known significance. However, agreement between the manufacturer and purchaser as to test method used is advisable.

SCOPE

1.1 This test method covers the determination of the dropping point of lubricating grease.

1.2 This test method uses mercury thermometers. WARNING—Mercury has been designated by many regulatory agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law. The responsible subcommittee, D02.G0.03, continues to explore alternatives to eventually replace the mercury thermometers.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2265 − 19

Standard Test Method for

Dropping Point of Lubricating Grease Over Wide

1

Temperature Range

This standard is issued under the fixed designation D2265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D217Test Methods for Cone Penetration of Lubricating

Grease

1.1 This test method covers the determination of the drop-

D566TestMethodforDroppingPointofLubricatingGrease

ping point of lubricating grease.

D3244Practice for Utilization of Test Data to Determine

1.2 This test method uses mercury thermometers.

Conformance with Specifications

WARNING—Mercury has been designated by many regula-

E1Specification for ASTM Liquid-in-Glass Thermometers

tory agencies as a hazardous material that can cause central

3. Terminology

nervous system, kidney and liver damage. Mercury, or its

vapor, may be hazardous to health and corrosive to materials.

3.1 Definitions:

Caution should be taken when handling mercury and mercury

3.1.1 lubricating grease, n—a semi-fluid to solid product of

containing products. See the applicable product Material

a thickener in a liquid lubricant.

Safety Data Sheet (MSDS) for details and EPA’s website—

3.1.1.1 Discussion—Thedispersionofthethickenerformsa

http://www.epa.gov/mercury/faq.htm—for additional informa-

two-phase system and immobilizes the liquid lubricant by

tion. Users should be aware that selling mercury and/or

surfacetensionandotherphysicalforces.Otheringredientsare

mercury containing products into your state or country may be

commonly included to impart special properties. D217

prohibited by law. The responsible subcommittee, D02.G0.03,

3.1.2 thickener, n—in lubricating grease, a substance com-

continues to explore alternatives to eventually replace the

posed of finely-divided particles dispersed in a liquid to form

mercury thermometers. This standard does not purport to

the product’s structure.

address all of the safety concerns, if any, associated with its

3.1.2.1 Discussion—Thickeners can be fibers (such as vari-

use. It is the responsibility of the user of this standard to

ous metallic soaps) or plates or spheres (such as certain

establish appropriate safety, health, and environmental prac-

non-soapthickeners),whichareinsolubleor,atmost,onlyvery

tices and determine the applicability of regulatory limitations

slightly soluble in the liquid lubricant. The general require-

prior to use.

mentsarethatthesolidparticlesbeextremelysmall,uniformly

1.3 This international standard was developed in accor-

dispersed, and capable of forming a relatively stable, gel-like

dance with internationally recognized principles on standard-

structure with the liquid lubricant. D217

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 dropping point, n—a numerical value assigned to a

mendations issued by the World Trade Organization Technical

grease composition representing the corrected temperature at

Barriers to Trade (TBT) Committee.

which the first drop of material falls from the test cup and

2. Referenced Documents reaches the bottom of the test tube.

2 3.2.1.1 Discussion—In the normal and proper operation of

2.1 ASTM Standards:

this test method, the observed dropping point is corrected by

adding to it a value representing one third of the difference

1

betweentheovenblocktemperatureandtheobserveddropping

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

point temperature. This corrected value is recorded as the

Subcommittee D02.G0.03 on Physical Tests.

droppingpointofthegrease.Thisisnotthesamedefinitionfor

Current edition approved June 1, 2019. Published September 2019. Originally

ɛ1 dropping point that is used in Test Method D566.

approved in 1964. Last previous edition approved in 2015 as D2265–15 . DOI:

10.1520/D2265-19.

3.2.2 observed dropping point, n—the value noted on the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

thermometer monitoring the internal temperature of the grease

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test cup when the first drop of material falls from the test cup

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and reaches the bottom of the test tube.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM Intern

...

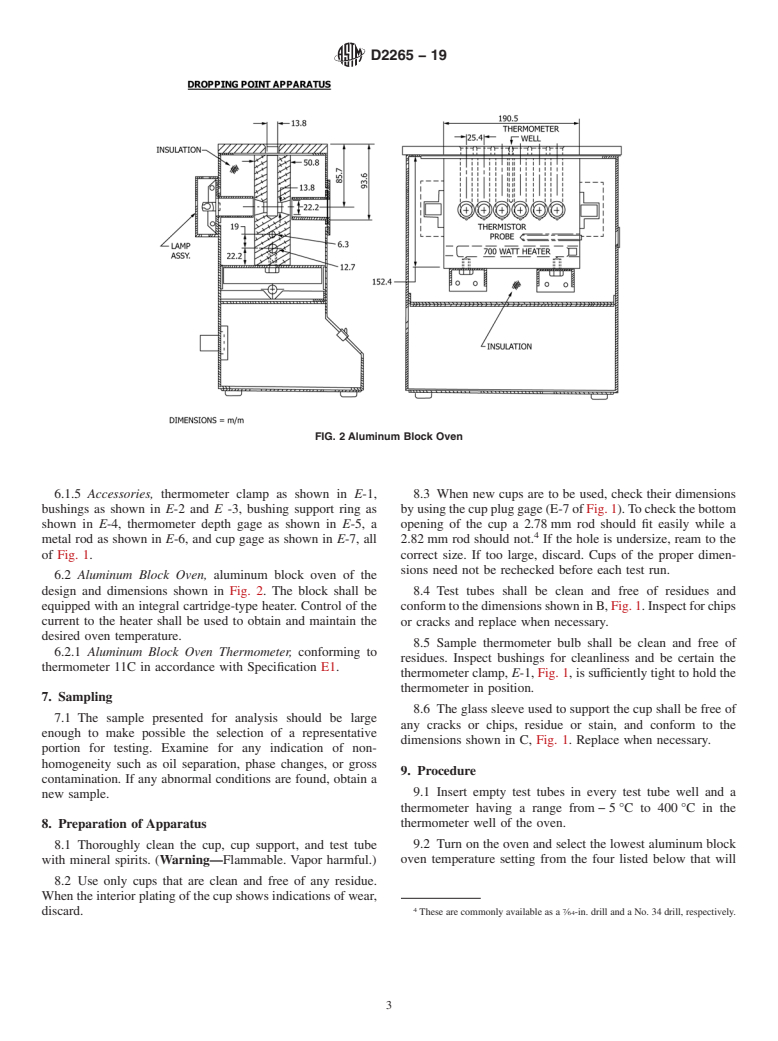

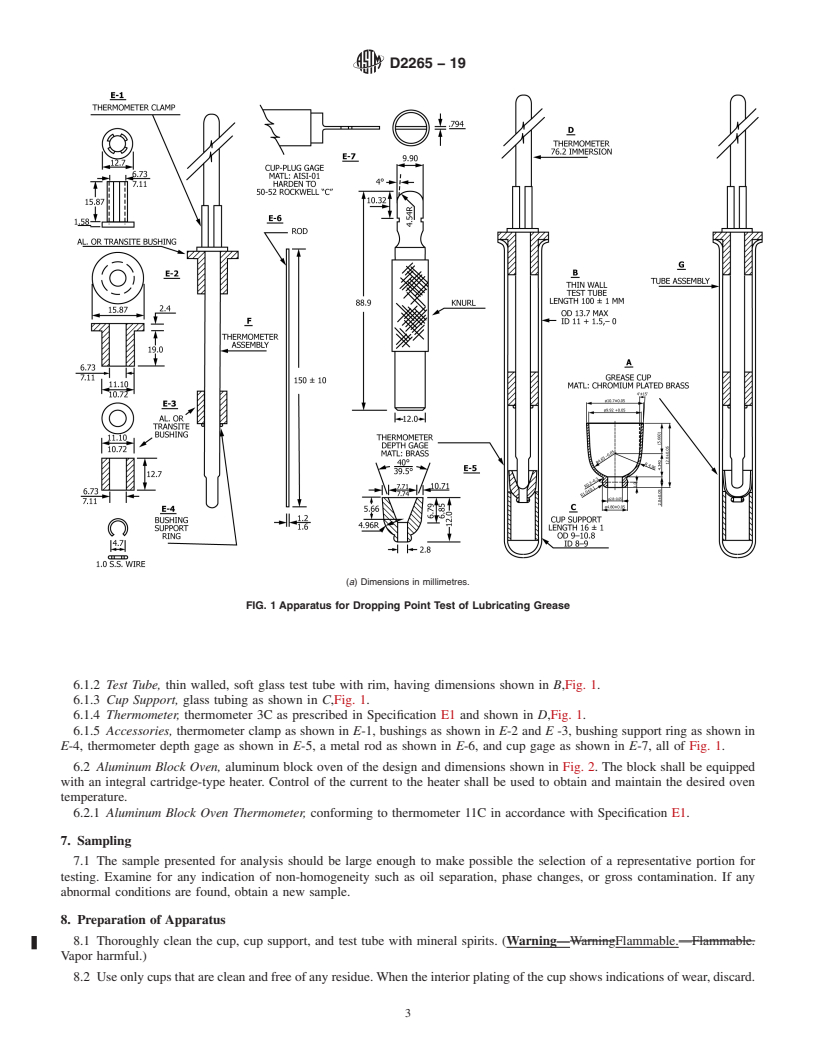

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D2265 − 15 D2265 − 19

Standard Test Method for

Dropping Point of Lubricating Grease Over Wide

1

Temperature Range

This standard is issued under the fixed designation D2265; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—The Summary of Changes section was corrected editorially in February 2018.

1. Scope*

1.1 This test method covers the determination of the dropping point of lubricating grease.

1.2 This test method uses mercury thermometers. WARNING—Mercury has been designated by many regulatory agencies as

a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous

to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the

applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for

additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country

may be prohibited by law. The responsible subcommittee, D02.G0.03, continues to explore alternatives to eventually replace the

mercury thermometers. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is

the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D217 Test Methods for Cone Penetration of Lubricating Grease

D566 Test Method for Dropping Point of Lubricating Grease

D3244 Practice for Utilization of Test Data to Determine Conformance with Specifications

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Terminology

3.1 Definitions:

3.1.1 lubricating grease, n—a semi-fluid to solid product of a thickener in a liquid lubricant.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.03 on Physical Tests.

Current edition approved April 1, 2015June 1, 2019. Published May 2015September 2019. Originally approved in 1964. Last previous edition approved in 20142015 as

ɛ1

D2265 – 06 (2014).D2265 – 15 . DOI: 10.1520/D2265-15E01.10.1520/D2265-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

The dispersion of the thickener forms a two-phase system and immobilizes the liquid lubricant by surface tension and other

physical forces. Other ingredients are commonly included to impart special properties. D217

3.1.2 thickener, n—in lubricating grease, a substance composed of finely-divided particles dispersed in a liquid to form the

product’s structure.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2265 − 19

3.1.2.1 Discussion—

Thickeners can be fibers (such as various metallic soaps) or plates or spheres (such as certain non-soap thickeners), which are

insoluble or, at most, only very slightly soluble in the liquid lubricant. The general requirements are that the solid particles be

extremely small, uniformly dispersed, and capable of forming a relatively stable, gel-like structure with the liquid lubricant. D217

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.2.1 dropping point, n—a numerical value assigned to a grease composition representing the corrected temperature at which

the first drop of material falls from the test cup and reaches the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.