ASTM D349-99(2004)

(Test Method)Standard Test Methods for Laminated Round Rods Used for Electrical Insulation

Standard Test Methods for Laminated Round Rods Used for Electrical Insulation

SCOPE

1.1 These test methods cover the procedures for testing rigid round rods used in electrical insulation. These round rods include many types made from fibrous sheets of basic materials, such as cellulose, asbestos, glass, or nylon in the form of paper, woven fabrics, or mats, bonded together by natural or synthetic resins, or by adhesives. Such round rods include vulcanized fiber and thermosetting laminates as well as round rods made from cast, molded, or extruded natural or synthetic resins, with or without fillers or reinforcing materials.

1.2 The procedures appear in the following sections:SectionCompressive strength (axial)DensityDielectric strengthFlexural strengthTensile strengthWater absorption-

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement see .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D349–99 (Reapproved 2004)

Standard Test Methods for

1

Laminated Round Rods Used for Electrical Insulation

This standard is issued under the fixed designation D 349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 668 Test Methods of Measuring Dimensions of Rigid

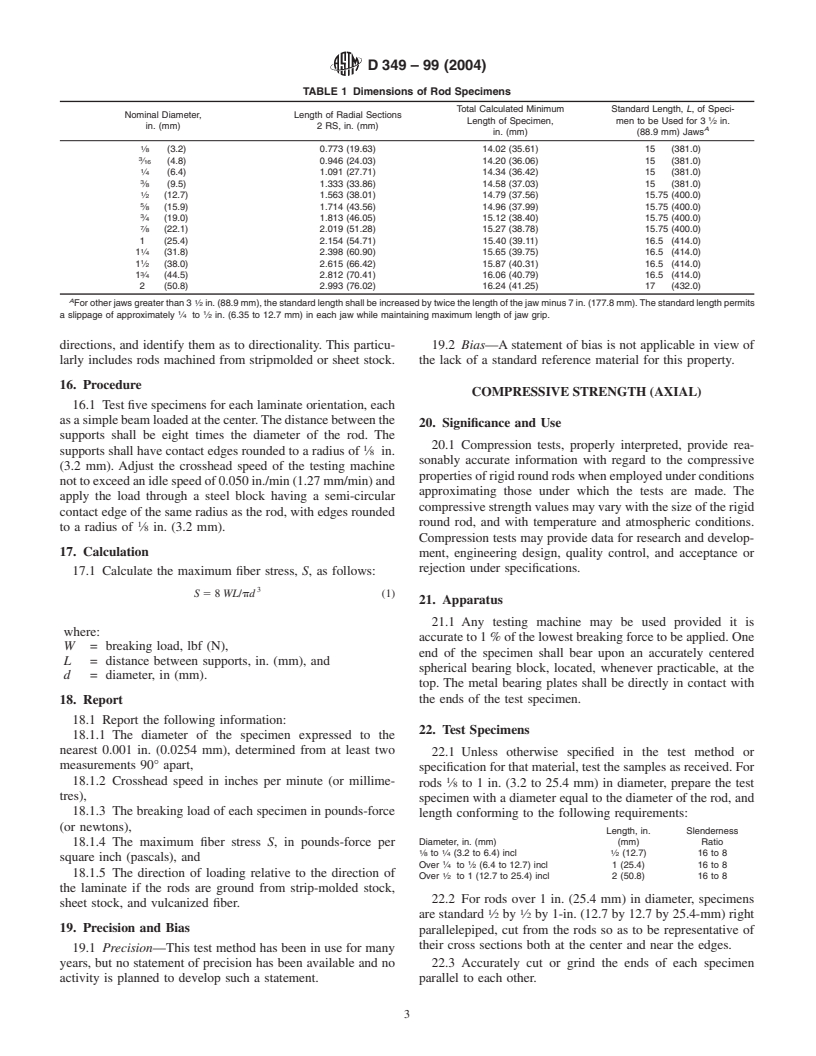

Rods and Tubes Used for Electrical Insulation

1.1 Thesetestmethodscovertheproceduresfortestingrigid

D 792 TestMethodsforDensityandSpecificGravity(Rela-

round rods used in electrical insulation. These round rods

tive Density) of Plastics by Displacement

include many types made from fibrous sheets of basic materi-

D 1711 Terminology Relating to Electrical Insulation

als, such as cellulose, asbestos, glass, or nylon in the form of

D 6054 Practice for Conditioning Electrical Insulating Ma-

paper, woven fabrics, or mats, bonded together by natural or

terials for Testing

synthetic resins, or by adhesives. Such round rods include

vulcanized fiber and thermosetting laminates as well as round

3. Terminology

rods made from cast, molded, or extruded natural or synthetic

3.1 Definitions—Use Terminology D 1711 for definitions of

resins, with or without fillers or reinforcing materials.

terms used in these test methods and associated with electrical

1.2 The procedures appear in the following sections:

or electronic insulation materials.

Section

Compressive strength (axial) 20-25

4. Selection of Test Specimens

Density 28-30

Dielectric strength 31-39

4.1 Specimens for tests shall be selected from portions of

Flexural strength 13-19

material that are free of obvious defects unless the purpose of

Tensile strength 7-12

Water absorption 26-27

the test is to evaluate the effect of these defects.

1.3 The values stated in inch-pound units are to be regarded

5. Conditioning

as the standard.

5.1 In order to eliminate the effects of previous history of

1.4 This standard does not purport to address all of the

humidity exposure and to obtain reproducible results (Note 1),

safety concerns, if any, associated with its use. It is the

in all cases of dispute give the test specimens of laminated rods

responsibility of the user of this standard to establish appro-

a conditioning treatment for physical test as follows:

priate safety and health practices and determine the applica-

5.1.1 Tensile, Flexural, and Compressive Strengths, and

bility of regulatory limitations prior to use. For a specific

Density—Prior to test, condition the machined specimens in

warning statement see 36.2.

accordance with Procedure B of Practice D 6054. All speci-

2. Referenced Documents mens shall be tested at room temperature maintained at 23 6

2 5 °C.

2.1 ASTM Standards:

D 149 Test Method for Dielectric Breakdown Voltage and

NOTE 1—Conditioning of specimens may be undertaken: (a) for the

Dielectric Strength of Solid Electrical Insulating Materials purpose of bringing the material into equilibrium with normal or average

room conditions of 23 °C and 50 % relative humidity; (b) simply to obtain

at Commercial Power Frequencies

reproducible results, irrespective of previous history of exposure; or (c)to

D 570 Test Method for Water Absorption of Plastics

subject the material to abnormal conditions of temperature or humidity in

order to predict its service behavior.

1 The conditions given here to obtain reproducible results may give

These test methods are under the jurisdiction of ASTM Committee D09 on

physical values somewhat higher or somewhat lower than values under

Electrical and Electronic Insulating Materials and are the direct responsibility of

equilibrium at normal conditions, depending upon the particular material

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

Current edition approved April 10, 1999. Published June 1999. Originally and test. To ensure substantial equilibrium under normal conditions of

approved in 1932. Last previous edition approved in 1997 as D 349 – 92 (1997).

humidity and temperature, however, will require from 20 to 100 days or

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

more depending upon thickness and type of material and its previous

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

history. Consequently, conditioning for reproducibility must of necessity

Standards volume information, refer to the standard’s Document Summary page on

be used for general purchase specifications and product control tests.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

----------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.