ASTM D7279-06

(Test Method)Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer

Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon Viscometer

SIGNIFICANCE AND USE

Many petroleum products and some non-petroleum products are used as lubricants in the equipment, and the correct operation of the equipment depends upon the appropriate viscosity of the lubricant being used. Additionally, the viscosity of many petroleum fuels is important for the estimation of optimum storage, handling, and operational conditions. Thus, the accurate determination of viscosity is essential to many product specifications.

The viscosity of used oils is a commonly determined parameter in the oil industry to assess the effect of engine wear on the lube oils used, as well as the degradation of the engine parts during operation.

The Houillon viscometer tube method offers automated determination of kinematic viscosity. Typically a sample volume of less than 1 mL is required for the analysis.

SCOPE

1.1 This test method covers the measurement of the kinematic viscosity of transparent and opaque liquids such as fresh and used lubricating oils using a Houillon viscometer in automated mode.

1.2 The range of kinematic viscosity covered by this test method is from 0.2 to 1000 mm2/s in the temperature range between 20°C and 150°C; however, the precision has only been determined for the materials, viscosity range, and temperatures as stated in the precision section (viscosity range 25 to 150 mm2/s at 40°C and 5 to 16 mm2/s at 100°C).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7279–06

Standard Test Method for

Kinematic Viscosity of Transparent and Opaque Liquids by

Automated Houillon Viscometer

This standard is issued under the fixed designation D 7279; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6708 Practice for Statistical Assessment and Improve-

ment of Expected Agreement Between Two Test Methods

1.1 This test method covers the measurement of the kine-

that Purport to Measure the Same Property of a Material

matic viscosity of transparent and opaque liquids such as fresh

D 6792 Practice for Quality System in Petroleum Products

and used lubricating oils using a Houillon viscometer in

and Lubricants Testing Laboratories

automated mode.

D 7042 Test Method for Dynamic Viscosity and Density of

1.2 The range of kinematic viscosity covered by this test

Liquids by Stabinger Viscometer (and the Calculation of

method is from 0.2 to 1000 mm /s in the temperature range

Kinematic Viscosity)

between 20°C and 150°C; however, the precision has only

2.2 ISO Standards:

been determined for the materials, viscosity range, and tem-

ISO 5725 Accuracy (Trueness and Precision) of Measure-

peratures as stated in the precision section (viscosity range 25

2 2

ment Methods and Results

to 150 mm /s at 40°C and 5 to 16 mm /s at 100°C).

ISO/EC 17025 General Requirements for the Competence

1.3 The values stated in SI units are to be regarded as

of Testing and Calibration Laboratories

standard. No other units of measurement are included in this

2.3 NIST Standard:

standard.

NIST Technical Note 1297 Guideline for Evaluating and

1.4 This standard does not purport to address all of the

Expressing the Uncertainty of NIST Measurement Re-

safety concerns, if any, associated with its use. It is the

sults

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Summary of Test Method

bility of regulatory limitations prior to use. For specific

3.1 The kinematic viscosity is determined by measuring the

warning statements, see Section 6.

time taken for a sample to fill a calibrated volume at a given

2. Referenced Documents temperature. The specimen is injected into the apparatus and

thenflowsintotheviscometertubewhichisequippedwithtwo

2.1 ASTM Standards:

detection cells. The specimen reaches the test temperature of

D 445 Test Method for Kinematic Viscosity of Transparent

theviscometerbathandwhentheleadingedgeofthespecimen

and Opaque Liquids (and Calculation of Dynamic Viscos-

passes in front of the first detection cell, the automated

ity)

instrument starts the timing sequence. When the leading edge

D 2162 Practice for Basic Calibration of Master Viscom-

of the specimen passes in front of the second detection cell, the

eters and Viscosity Oil Standards

instrument stops timing the flow. The time interval thus

D 4057 Practice for Manual Sampling of Petroleum and

measured allows the calculation of the kinematic viscosity

Petroleum Products

using a viscometer tube constant determined earlier by calibra-

D 4177 Practice for Automatic Sampling of Petroleum and

tion with certified viscosity reference standards.

Petroleum Products

3.2 The kinematic viscosity is calculated using the formula:

D 6299 Practice for Applying Statistical Quality Assurance

Techniques to Evaluate Analytical Measurement System n5 C 3 t (1)

Performance

where:

n = the kinematic viscosity in mm /s,

C = the viscometer tube constant in mm /s, and

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

Current edition approved Oct. 1, 2006. Published October 2006.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7279–06

t = the flow time in s measured during the test.

4. Significance and Use

4.1 Many petroleum products and some non-petroleum

products are used as lubricants in the equipment, and the

correct operation of the equipment depends upon the appropri-

ate viscosity of the lubricant being used. Additionally, the

viscosity of many petroleum fuels is important for the estima-

tion of optimum storage, handling, and operational conditions.

Thus, the accurate determination of viscosity is essential to

many product specifications.

4.2 The viscosity of used oils is a commonly determined

parameter in the oil industry to assess the effect of engine wear

on the lube oils used, as well as the degradation of the engine

parts during operation.

4.3 The Houillon viscometer tube method offers automated

determination of kinematic viscosity. Typically a sample vol-

ume of less than 1 mL is required for the analysis.

5. Apparatus

5.1 Automated Viscometer—The system shall consist of the

following components:

5.1.1 Viscometer Bath:

5.1.1.1 Bath, to ensure optimal thermal equilibration of the

system, the bath is filled with mineral or silicone oil and

equipped with a stirring device.

5.1.2 Temperature Regulation System, to control the bath

temperature to within 0.02°C.

5.1.3 Houillon Viscometer Tubes, made of glass with a

calibratedvolumewhichvariesdependingonthetubesize(see

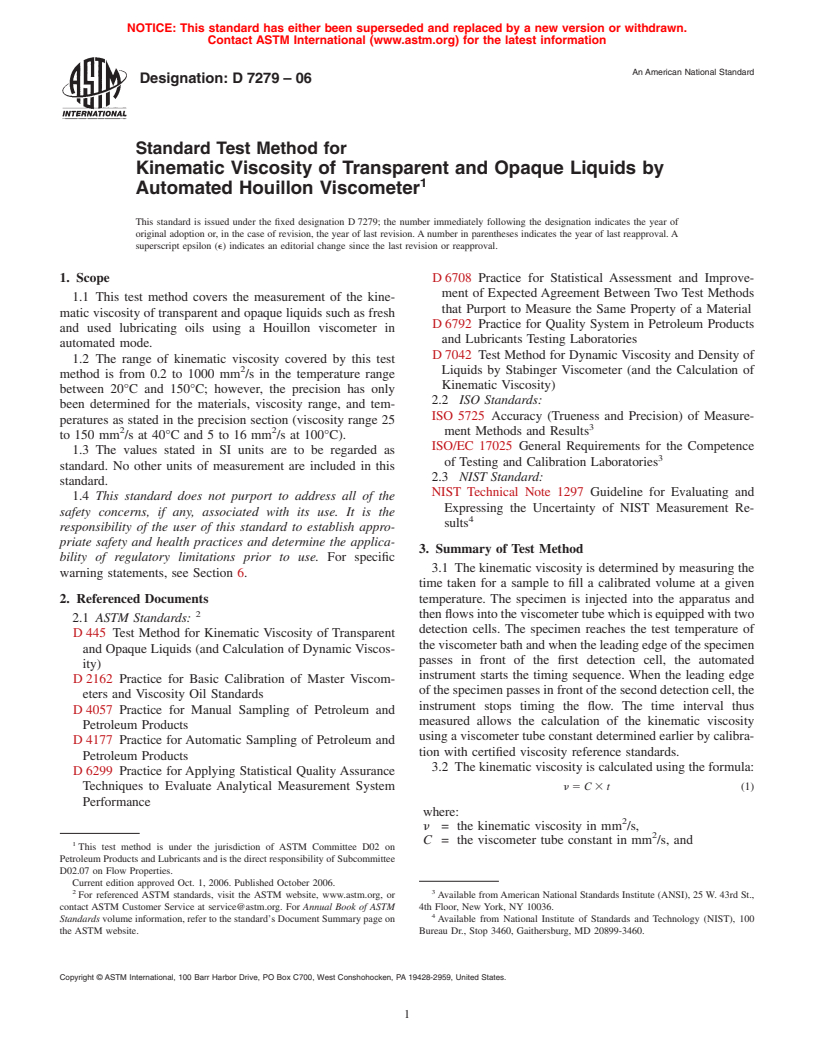

Fig. 1). This technique allows the viscosity to be measured

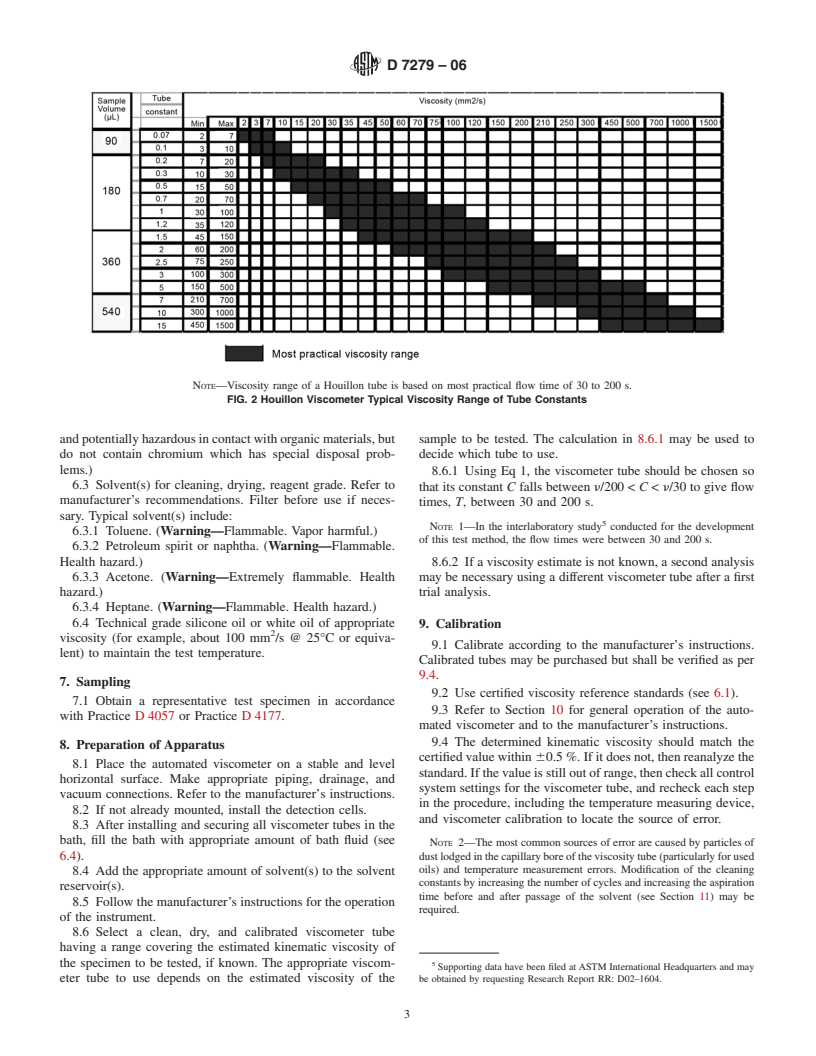

over a wide range of values (see Fig. 2).

5.1.4 Cleaning/Vacuum System, consisting of one or more

solvent reservoirs to transport the solvent(s) to the viscometer

tubes, dry the viscometer tubes after the flushing cycle, to

remove the sample, and for drainage of waste products.

5.1.5 AutomatedViscometerControlSystem—Suitableelec-

tronicprocessorcapableofoperatingtheapparatus,controlling

the operation of the timers, regulating the bath temperature,

cleaning the viscometer tubes, and recording and reporting the

results.

5.1.6 PC-compatible Computer System, may be used for

data acquisition, as per manufacturer’s instructions.

5.1.7 Temperature Measuring Devices—Use either cali-

brated liquid-in-glass thermometers, of an accuracy after cor-

rection of 60.02°C or better, or other thermometric devices of

equal or better accuracy.

FIG. 1 Houillon Tube Schematic Diagram

5.1.8 Timing Devices—Use any timing device that is ca-

pable of taking readings with a discrimination of 0.01 s or

better with an accuracy within 60.07 % of the reading when

of ISO/EC 17025 by independent assessment. The certified

tested over the minimum and maximum intervals of expected

viscosity reference standards shall be traceable to master

flow times.

viscometer procedures described in Test Method D 2162.

5.1.9 Micropipette, of a volume range from 50 to 250 µL

6.1.1 The uncertainty of the certified viscosity reference

with an absolute precision of 62.5 µL.

standard shall be stated for each certified value (k=2@95%

confidence). See ISO 5725 or NIST 1297.

6. Reagents and Materials

6.2 Non-chromium-containing, strongly oxidizing acid

6.1 Certified viscosity reference standards shall be certified cleaning solution. (Warning—Non-chromium-containing,

by a laboratory that has been shown to meet the requirements strongly oxidizing acid cleaning solutions are highly corrosive

D7279–06

NOTE—Viscosity range of a Houillon tube is based on most practical flow time of 30 to 200 s.

FIG. 2 Houillon Viscometer Typical Viscosity Range of Tube Constants

andpotentiallyhazardousincontactwithorganicmaterials,but sample to be tested. The calculation in 8.6.1 may be used to

do not contain chromium which has special disposal prob- decide which tube to use.

lems.)

8.6.1 Using Eq 1, the viscometer tube should be chosen so

6.3 Solvent(s) for cleaning, drying, reagent grade. Refer to

that its constant C falls between n/200 < C < n/30 to give flow

manufacturer’s recommendations. Filter before use if neces-

times, T, between 30 and 200 s.

sary. Typical solvent(s) include:

NOTE 1—In the interlaboratory study conducted for the development

6.3.1 Toluene. (Warning—Flammable. Vapor harmful.)

of this test method, the flow times were between 30 and 200 s.

6.3.2 Petroleum spirit or naphtha. (Warning—Flammable.

Health hazard.) 8.6.2 If a viscosity estimate is not known, a second analysis

6.3.3 Acetone. (Warning—Extremely flammable. Health may be necessary using a different viscometer tube after a first

hazard.) trial analysis.

6.3.4 Heptane. (Warning—Flammable. Health hazard.)

6.4 Technical grade silicone oil or white oil of appropriate 9. Calibration

viscosity (for example, about 100 mm /s @ 25°C or equiva-

9.1 Calibrate according to the manufacturer’s instructions.

lent) to maintain the test temperature.

Calibrated tubes may be purchased but shall be verified as per

9.4.

7. Sampling

9.2 Use certified viscosity reference standards (see 6.1).

7.1 Obtain a representative test specimen in accordance

9.3 Refer to Section 10 for general operation of the auto-

with Practice D 4057 or Practice D 4177.

mated viscometer and to the manufacturer’s instructions.

9.4 The determined kinematic viscosity should match the

8. Preparation of Apparatus

certified value within 60.5 %. If it does not, then reanalyze the

8.1 Place the automated viscometer on a stable and level

standard.Ifthevalueisstilloutofrange,thencheckallcontrol

horizontal surface. Make appropriate piping, drainage, and

system settings for the viscometer tube, and recheck each step

vacuum connections. Refer to the manufacturer’s instructions.

in the procedure, including the temperature measuring device,

8.2 If not already mounted, install the detection cells.

and viscometer calibration to locate the source of error.

8.3 After installin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.