ASTM D7438-08

(Practice)Standard Practice for Field Calibration and Application of Hand-Held Moisture Meters

Standard Practice for Field Calibration and Application of Hand-Held Moisture Meters

SIGNIFICANCE AND USE

Hand-held meters provide a rapid means of sampling moisture content of wood-based materials during and after processing to maintain quality assurance and compliance with standards. However, these measurements are inferential; that is, electrical parameters are measured and compared against a calibration to obtain an indirect measure of moisture content. The electrical measurements are influenced by actual moisture content, a number of other wood variables, environmental conditions, geometry of the measuring probe circuitry, and design of the meter. The maximum accuracy can only be obtained by an awareness of the effect of each parameter on the meter output and correction of readings as specified by these test methods. Appendix X1 is a commentary that provides explanation of the mandatory sections and discussion of historical practices. Appendix X2 addresses the influence of process and wood variables.

This practice provides for calibration and application of wood products that contain commercial characteristics and that reflect the manufacturing environment.

Most uses of hand-held moisture meters employ correlative (predictive) relationships between the meter reading and wood areas or volumes that exceed that of the direct meter measurement (for example, larger specimens, pieces of lumber, lots). The field calibration section of this practice anticipates the potential need for this type of sampling. These correlative uses are examined in Appendix X3.

SCOPE

1.1 This practice applies to the measurement of moisture content of solid wood, including solid wood products containing additives, that is, chemicals or adhesives, by hand-held moisture meters under conditions of end-use.

1.1.1 This practice includes calibration, use, and interpretation of meters for conditions that relate to wood product characteristics, such as nonuniform grain and growth ring orientation, and to end-use process conditions, such as moisture gradients.

1.1.2 Meters employing differing technologies may not provide equivalent readings under the same conditions. When this practice has been applied, it is assumed that the referenced meter is acceptable unless otherwise specified. Meters shall have been calibrated by Test Methods D 4444.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7438 − 08

StandardPractice for

Field Calibration and Application of Hand-Held Moisture

Meters

This standard is issued under the fixed designation D7438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D6782Test Methods for Standardization and Calibration of

In-Line Dry Lumber Moisture Meters

1.1 This practice applies to the measurement of moisture

2.2 Other ASTM Sources:

content of solid wood, including solid wood products contain-

ASTM Standards on Precision and Bias for Various

ing additives, that is, chemicals or adhesives, by hand-held

Applications, 1992

moisture meters under conditions of end-use.

1.1.1 This practice includes calibration, use, and interpreta-

3. Terminology

tion of meters for conditions that relate to wood product

3.1 Definitions of Terms Specific to This Standard:

characteristics, such as nonuniform grain and growth ring

3.1.1 conductance meters—conductance meters are those

orientation, and to end-use process conditions, such as mois-

that measure predominantly ionic conductance between points

ture gradients.

of applied voltage, usually direct current. Direct-current con-

1.1.2 Meters employing differing technologies may not

ductance meters are commonly referred to as “resistance”

provide equivalent readings under the same conditions. When

meters. Most commercial conductance meters are high-input

thispracticehasbeenapplied,itisassumedthatthereferenced

12 4 12

impedance (about 10 Ω), wide-range (10 to 10 Ω) ohm-

meter is acceptable unless otherwise specified. Meters shall

meters. Their scales are calibrated to read directly in moisture

have been calibrated by Test Methods D4444.

content (oven-dry mass basis) for a particular calibration

1.2 This standard does not purport to address all of the

species and at a specific reference temperature.

safety concerns, if any, associated with its use. It is the

3.1.2 dielectric meters—dielectric meters transmit electro-

responsibility of the user of this standard to establish appro-

magnetic wave energy into the wood to detect the influence of

priate safety and health practices and determine the applica-

moistureinthewoodonthesewavesasanestimateofmoisture

bility of regulatory limitations prior to use.

content. Wave energy is most often in the radio frequency

range; hand-held meters commonly are placed directly on the

2. Referenced Documents

wood surface.

2.1 ASTM Standards:

D2915Practice for Sampling and Data-Analysis for Struc-

4. Significance and Use

tural Wood and Wood-Based Products

4.1 Hand-held meters provide a rapid means of sampling

D4442Test Methods for Direct Moisture Content Measure-

moisture content of wood-based materials during and after

ment of Wood and Wood-Base Materials

processing to maintain quality assurance and compliance with

D4444Test Method for Laboratory Standardization and

standards. However, these measurements are inferential; that

Calibration of Hand-Held Moisture Meters

is, electrical parameters are measured and compared against a

D4933Guide for Moisture Conditioning of Wood and

calibration to obtain an indirect measure of moisture content.

Wood-Based Materials

The electrical measurements are influenced by actual moisture

content, a number of other wood variables, environmental

conditions, geometry of the measuring probe circuitry, and

This practice is under the jurisdiction ofASTM Committee D07 on Wood and

design of the meter. The maximum accuracy can only be

is the direct responsibility of Subcommittee D07.01 on Fundamental Test Methods

obtainedbyanawarenessoftheeffectofeachparameteronthe

and Properties.

meter output and correction of readings as specified by these

Current edition approved April 1, 2008. Published May 2008. DOI: 10.1520/

D7438-08.

test methods. Appendix X1 is a commentary that provides

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

explanation of the mandatory sections and discussion of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

historical practices. Appendix X2 addresses the influence of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. process and wood variables.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7438 − 08

4.1.1 This practice provides for calibration and application mixtures of heartwood and sapwood. Further, these process

of wood products that contain commercial characteristics and variables may change or invalidate some of the calibration

that reflect the manufacturing environment. results obtained under laboratory conditions in Test Methods

D4444.

4.2 Mostusesofhand-heldmoisturemetersemploycorrela-

tive (predictive) relationships between the meter reading and

6.2 Methods—The principles and procedures of calibration

wood areas or volumes that exceed that of the direct meter

in Test Methods D4444 shall be applied to the degree possible

measurement(forexample,largerspecimens,piecesoflumber,

and relevant to develop a meaningful relationship between

lots). The field calibration section of this practice anticipates

meter readings and actual moisture content (MC).

the potential need for this type of sampling. These correlative

6.2.1 All field calibrations shall be referenced to direct MC

uses are examined in Appendix X3.

measurements (Test Methods D4442).

6.2.2 Field calibration shall be carried out with meters that

5. Standardization

have been laboratory standardized and calibrated for appropri-

5.1 General—Standardization shall be performed to estab-

ate wood variables, such as species and temperature usingTest

lish the integrity of the meter and electrode under the field

Methods D4444, and subsequently field standardized.

conditionsofuse.Themetercircuitshallbetestedbyapplying

6.3 Field Variables—The calibration may be based on

the reference material in accordance with manufacturer’s

end-useenvironmentalandproductandprocessconditionsthat

recommendations, noting the corresponding meter response

are more restricted than those evaluated by Test Methods

value, and comparing with the manufacturer’s data. Standard-

D4444. In addition, the process conditions may produce

ization shall be done before calibration. If alternate electrodes

interactions that must be considered in the calibration.

aretobeusedwithameter,standardizationshallbedoneforall

6.3.1 Special care must be taken to minimize errors caused

electrode types and alternate assemblies.

by the influence of unintended wood variables, such as density

5.1.1 Initially, standardization should be performed before

and temperature (uncorrected) on readings. Specimen size for

each period of use. The time interval may be extended if

field testing may be selected to represent the appropriate

experienceshowsthattheparticularmeterisstableforalonger

geometry of the target sample. Field meter readings are

time under equivalent use conditions.

conditional upon both the prior standardization and calibration

5.1.2 Standardizationproceduresinthefieldwillbeaffected

process, the influence of wood variables in the field test, and

by the standardization performance of the meter during evalu-

application information supplied by the meter manufacturer.

ationunderTestMethodsD4444.Thereportofsection5.2.3of

Test Methods D4444 provides this information.

6.4 Calibration Steps—The field calibration shall be con-

ducted on specimens and in conditions that are representative

5.2 The standardization shall be carried out with the instru-

oftheprocessandarecarefullydocumented.SeeAppendixX2

ment, including electrodes, at the temperature of the antici-

for discussion of process variables and wood characteristics.

pated application. This shall include the range of anticipated

6.4.1 Sample Selection—The number of wood specimens

conditions; the reference material shall maintain its essential

usedforthecalibrationshallbeselectedfollowingtheconcepts

characteristics over this range.The sensitivity of this standard-

of Practice D2915, considering the variables to be represented

ization to temperature of the meter shall be part of the

andthedesiredprecisionofthecalibration.Forexample,ifthe

evaluation.

sample is to represent grain patterns, moisture gradients, etc.

5.2.1 If the environmental conditions change during the

found in a lumber grade, these variables shall be considered in

usage period beyond those evaluated in the initial standardiza-

setting sampling criteria. (See also Test Methods D4444.)

tion, the standardization shall be repeated.

6.4.2 Sample Preparation—While the sample may be in-

5.2.2 Ifthemanufacturerrecommendsanarea,amethod,or

tended to include process variables such as moisture gradients,

astandardspecimenforstandardizationthatdoesnotreflectthe

temperature, etc., the measurement and subsequent preserva-

entiredirectmeasurementareaofthemeter,thisshallbenoted

tion of these variables prior to and during meter measurement

as the manufacturer’s recommendation.

shall be considered part of the sampling process. See Test

5.2.3 Field standardization may be difficult to carry out

Methods D4444 for discussion of other relevant issues.

under some ambient field conditions and with the electrodes to

be used. One example is the use in monitoring in-kiln perfor- 6.4.3 Testing—Field calibration shall be based on the rela-

mance.Ifthemeasurementconditionsaredifficulttoreproduce tionshipofthemeterreadingstoTestMethodsD4442moisture

or are transient (for example, in a hot dry kiln), then it shall be measurement values. Because process conditions may be

understood that the validity of the meter readings are depen- transient (for example, temperature and moisture gradients, or

dent upon the laboratory standardization and manufacturer’s both), calibration that reflects these variables requires special

recommendations. treatment of specimens (such as subdividing specimens) or

additional equipment (such as temperature probes). Care shall

6. Calibration

be taken to not distort the original specimen condition with

these additional steps.

6.1 General—Under processing conditions, laboratory cali-

bration procedures maybe impractical, particularly because of 6.4.4 Determination of Corrections—To establish a correc-

moistureandtemperaturegradients,nonstandardtemperatures, tion that reflects the influence of the measured variables, the

unverified species within commercial species groups, non principles of Test Methods D4444, section 6.2.4, shall be

straight-grainwood,andcommonproductionvariablessuchas followed.

D7438 − 08

6.5 Report—Useful application of field test calibration is electrode measurement, in-exact moisture gradients, and other

conditional upon the relevance of the test sample. Conse- specimen variables. Where these non-uniformities and uncer-

quently, accurate reporting of the wood and process variables

tainties cannot be measured or corrected, their presence shall

(see6.3and6.4)iscritical.Thereportshallfollowthepractice

be noted in the report and quantified where possible.

of Test Methods D4444, section 6.2.5.

6.5.1 Field samples often contain uncertainties with respect

toexactspeciesorspeciesmixtures,temperatureatthepointof

APPENDIXES

(Nonmandatory Information)

X1. COMMENTARY

INTRODUCTION

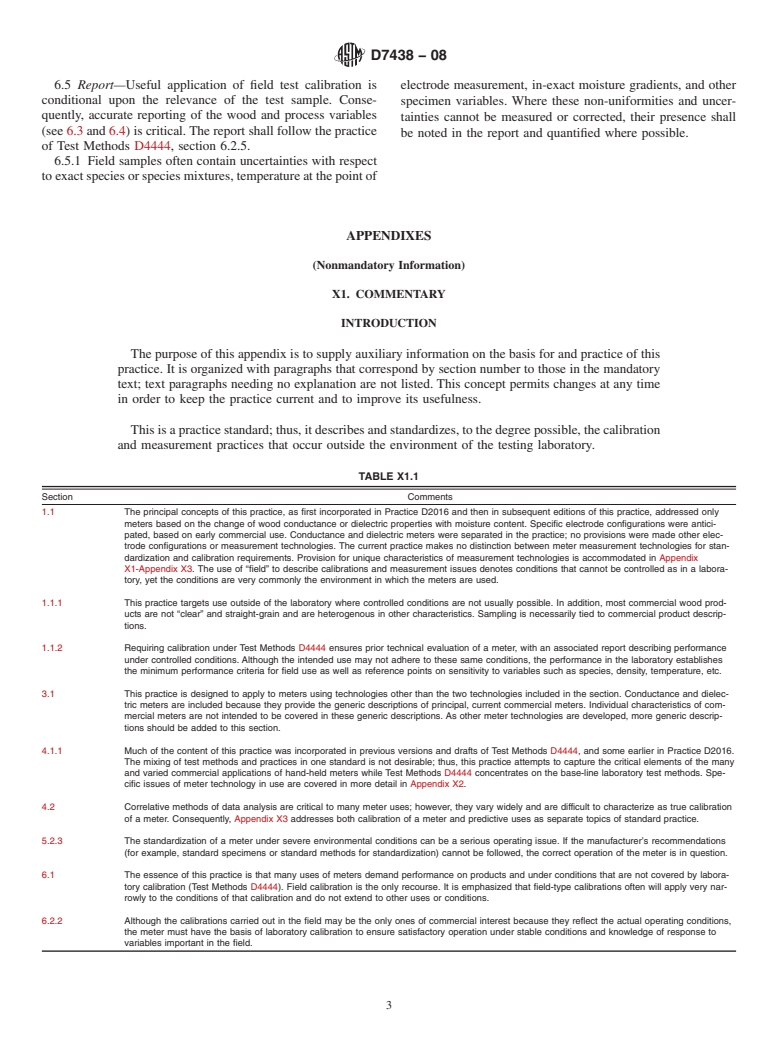

Thepurposeof thisappendixistosupplyauxiliaryinformationonthebasisfor andpracticeof this

practice. It is organized with paragraphs that correspond by section number to those in the mandatory

text; text paragraphs needing no explanation are not listed. This concept permits changes at any time

in order to keep the practice current and to improve its usefulness.

Thisisapracticestandard;thus,itdescribesandstandardizes,tothedegreepossible,thecalibration

and measurement practices that occur outside the environment of the testing laboratory.

TABLE X1.1

Section Comments

1.1 The principal concepts of this practice, as first incorporated in Practice D2016 and then in subsequent editions of this practice, addressed only

meters based on the change of wood conductance or dielectric properties with moisture content. Specific electrode configurations were antici-

pated, based on early commercial use. Conductance and dielectric meters were separated in the practice; no provisions were made other elec-

trode configurations or measurement technologies. The current practice makes no distinction between meter measurement technologies for stan-

dardization and calibration requirements. Provision for unique characteristics of measurement technologies is accommodated in Appendix

X1-Appendix X3. The use of “field” to describe calibrations and measurement issues denotes conditions that cannot be controlled as in a labora-

tory, yet the conditions are very commonly the environment in which the meters are used.

1.1.1 This practice targets use outside of the laboratory where controlled conditions are not usually possible. In addition, most commercial wood prod-

ucts are not “clear” and straight-grain and are heterogenous in other characteristics. Sampling is necessarily tied to commercial product descrip-

tions.

1.1.2 Requiring calibration under Test Methods D4444 ensures prior technical evaluation of a meter, with an associated report describing performance

under controlled conditions. Although the intended use may not adhere to these same conditions, the performance in the laboratory establishes

the minimum performance criteria for field use as well as reference points on sensitivity to variables such as species, density, temperature, etc.

3.1 This practice is designed to apply to meters using technologies other than the two technologies included in the section. Conductance and dielec-

tric meters are included because they provide the generic descriptions of principal, current commercial meters. Individual characteristics of com-

mercial meters are not intended to be covered in these generic descriptions. As other meter technologies are developed, more generic descrip-

tions should be added to this section.

4.1.1 Much of the content of this practice was incorporated in previous versions and drafts of Test Methods D4444, and some earlier in Practice D2016.

The mixing of test methods and practices in one standard is not desirable; thus, this practice attempts to capture the critical elements of the many

and varied commercial applications of hand-held meters while Test Methods D4444 concentrates on the base-line laboratory test methods. Spe-

cific issues o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.